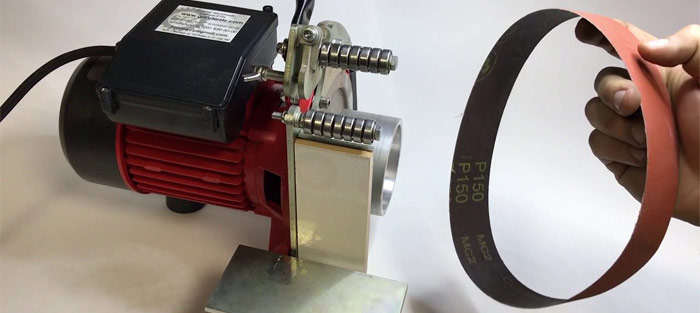

Abrasive Belt For Grinder

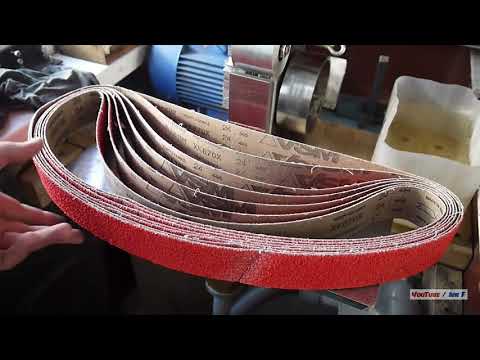

An abrasive belt is a consumable material for belt sander. And each such material has its own characteristics, performance properties, features, which allows you to cope with a specific task. Shliflenta is the widest segment in the group of consumable abrasives. It is efficient to work with and easy to use.

Abrasive skins or abrasives are the working equipment of many machine tools and machines. Such a power tool reaches high speeds during operation, which allows you to process soft wood, hard stones, and concrete. The belt sander is used for processing workpieces made of soft materials.

Hand grinders, that is, small machines, are also equipped with abrasive belts. The rotation frequency of such a device is low, however, due to the small area of the tooling, you can carefully grind or adjust the edges, edges of small products. It should be borne in mind that grinding belts for a grinder are a separate segment on the market, which is why they should be selected for a specific type of tool.

With regard to the question of the variety of thin-cut belts, they are distinguished of two types:

That is, the landing socket should be either narrow or wide, however, universal tools are also sold that allow you to change the width of the abrasive grip. Also, tapes differ in the type of material used in the base. The most popular are fabric and paper, although professionals recommend using combination and polyester tapes (in some cases).

The rough coating, that is, the abrasive itself applied to the belt, has a high value. The abrasive in this case can be silicon carbide or electrocorundum. The first type is reliable, wear-resistant, but there is also a minus - silicon can destroy the metal surface. Electrocorundum has the best performance, but such a tape is not ideal in work.

Tips for choosing equipment

The basis of the working filling of a straight grinder is an electric motor, a gearbox and a spindle. Most models are equipped with electronics that control the operation of the units.

Pay attention to the quality of the material of the die grinder body. It should be remembered that operation takes place in harsh conditions, and therefore hard plastic, resistant to mechanical damage, will fully meet the necessary requirements

Cleaning up traces of corrosion, especially in an uncomfortable position, is an unpleasant process that you always want to deal with as quickly as possible. Excessive surface pressure will result in exceeding the maximum permissible load, which will be signaled by an increased noise level of the tool. If the signals are ignored, the internal mechanism will break or simply jam. In the second case, a reliable housing will protect the operator from damage from fragments of parts.

The next detail that requires attention is the ergonomics of the model. Long-term operation of the straight grinder should not cause inconvenience due to design flaws. Before purchasing, be sure to check the following points:

- Convenience of grip. If the case does not fit your hands, you should refuse to purchase.

- Balance. The degree of fatigue in the process of working with a straight grinder depends on this quality.

- Dimensions and weight. Remember that holding the model in your hands will not take two minutes, but much longer.

- Location of buttons and switches. They should be within reach without changing your grip.

- Handle material. We recommend giving preference to rubber coated parts.

- Security.The operation of a straight grinder is accompanied by the formation of a large amount of dust. We recommend choosing a model with dust collection function.

The apparatus should be an extension of the hand, not just a tool. Only if this condition is met, the work will please with a positive result.

The power of the electric motor of a straight grinder is an important indicator. The performance of the device directly depends on it.

Manual grinding rules

Do-it-yourself sanding should be started with the coarse-grained sandpaper available in order to eliminate obvious defects from the wood surface. But here it is still necessary to take into account the nature of the damage that needs to be eliminated.

You need to influence the surface correctly: it is best to move the block or just sandpaper in a straight line along the fibers in the back and forth direction. And grinding, for example, in a circular motion can lead to unnecessary scratches.

Having reached the edge of the surface to be treated, be sure to grind off sharp corners. Soon, dust piles will begin to appear on the wood as a result of exposure to a coarse abrasive. They should be carefully vacuum cleaned. Then you can proceed to processing the next sandpaper, which has medium grit.

This processing is carried out according to the same principles as described above. The final stage is grinding with the finest grit. After that, the wooden product should become completely flat, no flaws should remain on it.

Types of sandpaper grit

As already mentioned, the grit size of the sandpaper is the size of the abrasive fragments. They are measured in micrometers. The smallest grain that is found in sandpaper is only 3-5 microns, the largest is 1000 microns (this is 1 mm). According to the grain size, fine-grained and coarse-grained abrasives are distinguished.

Usually we are only interested in the grain size or grit size of the sandpaper.

Russian standards

In order to be able to understand what specific material is in front of you, the size of the abrasive grain is indicated in the marking. But with her, not everything is so simple. During the Soviet era, GOST (3647-80) was introduced, the designation according to which still exists, although in 2005 a new standard was introduced (GOST R 52381-2005), which was developed on the basis of common European norms. The difference between the old and new GOST is significant.

This method of marking is used in some countries of the post-Soviet space.

-

Old standard

For coarse-grained emery, the grain size of the sandpaper is indicated in microns, and after it write the letter H with a hyphen in front of it - "H". For example, 63-H. This means that the minimum grain size on emery will be 63 microns or 630 micrometers (μm). But there will also be larger particles. How much larger? Slightly smaller than the previous brand. In this case, only 80-H is larger than 63-H, that is, the grain will be slightly less than 800 microns. The second example is 6-H. The grain size is no more than 6 microns or 60 microns, and the largest will be no more than 80 microns (since the previous grade 80-N).

the minimum grain size is prescribed. That is, the larger the number, the larger the grain. But one must bear in mind that some of the grains are smaller. In addition, the marking (letter designation) is different for coarse and fine grain. This is worth remembering.

| Grain marking of sandpaper according to GOST 3647 | ISO 6344 marking (GOST 52381-2005 Russia) | Grain size in micrometers (μm) | Scope and types of work |

|---|---|---|---|

| 80-R | P22 | 800-1000 | Rough machining of steel, other metal, wood, removal of rust, burrs |

| 63-N | P24 | 630-800 | |

| 50-N | P36 | 500-630 | |

| 40-N | P40 | 400-500 | Rough woodwork, initial sanding of wood |

| 32-H | P46 | 315-400 | |

| 25-N | P60 | 250-315 | |

| 20-N | P80 | 200-250 | Smoothing, Primary grinding. Plaster, wood, metal |

| 16-H | P90 | 160-200 | |

| 12-H | P100 | 125-160 | |

| 10-H | P120 | 100-125 | |

| 8-H | P150 | 80-100 | Removing paint, sanding metal and soft wood, preparing for sanding hard wood |

| 6-H | P180 | 63-80 |

- According to the new standard (GOST R 52381-2005), the grain size of the emery paper is indicated by the number of sieve fibers through which the abrasive is sieved. It turns out that the lower the number, the larger the grain. The letter "P" is placed before the number.

| Sandpaper marking according to GOST 3647-80 | Sanding paper marking ISO 4344 (GOST 52381-2005 Russia) | The grain size of the abrasive paper in micrometers (μm) | What works to use |

|---|---|---|---|

| 5-N or M 63 | P240 | 50-63 | Leveling before painting and starting sanding hard rocks |

| 4-H or M 50 | P280 | 40-50 | |

| H-3 or M 40 | P400 | 28-40 | Final leveling for painting, wood sanding |

| H-3 or M28 | P600 | 20-28 | |

| N-1 or M20 | P1000 | 14-20 | Grinding metal, plastic, ceramics, wet lapping to the smoothness of wood |

| M14 | P1200 | 10-14 | |

| H-0 or M10 | R1500 | 7-10 | Ultrafine polishing of metal, finishing to the gloss of plastic, wood |

| H-01 or M7 | P2000 | 5-7 | |

| H-00 or M5 | P2500 | 3-5 |

As you can see, it's already pretty confusing. It is also worth mentioning that, according to the old standard, fine-grained emery can have a double designation - with the letters M and H - as in the table. Moreover, more often it was the options in microns that were in use. Therefore, the smallest grain - 5M or 00-N - is often called zero. This is because it is 3-5 micrometers in size. According to the rounding rules, this can be considered zero. This is where the name comes from.

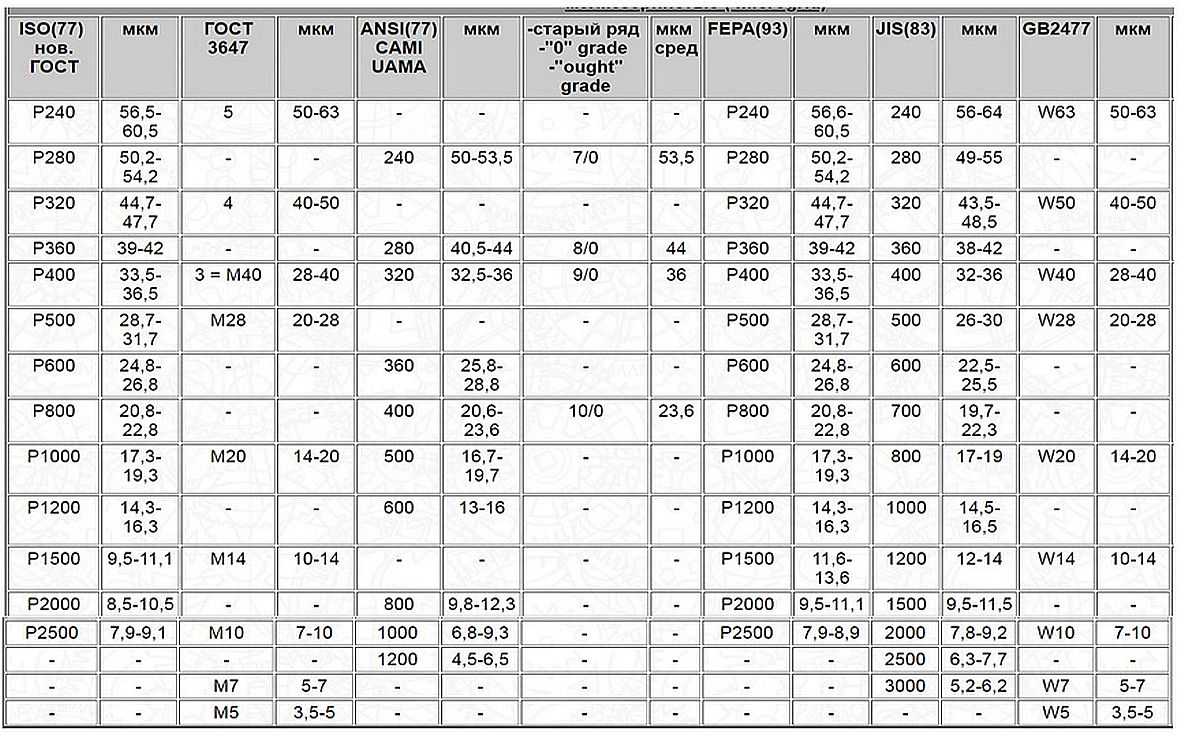

Compliance tables for other countries

As you can see, the situation is not easy. And there is also American ANCI (USA and Canada), European FEPA or its other name ISO 6344, Japanese JIS and Chinese GB2478. Moreover, on the market you can find material from almost all these countries / parts of the world. So it is desirable to have at least some data. The most common ones are shown in the tables.

Grit designation table for different standards: coarse grit

Country Sandpaper Grit: Fine

Note that the grain sizes in micrometers (μm) are written next to each column. Dimensions differ

It can be important for work.

Cleaning and sanding

After assembling a wooden product, its surface needs to be leveled and sanded. End cuts, places where grooves were taken with a plane, traces of carpentry glue, places where small chips broke off, protruding fibers in places of longitudinal sawing or cutting at an angle are subject to processing.

When preparing the surface for treatment with stains or varnishes for sanding, the use of the finest sandpaper will be required. It is also recommended to grind plywood products with fine-grained grades, despite the apparent evenness of their surface. The smallest irregularities, invisible to the eye, after varnishing will acquire a relief and excellent visibility.

The foundation

Abrasive paper can be made on different materials:

- The bulk of products with abrasives are produced on a paper basis. To increase the strength of the paper web to tear, abrasion, bending, it is impregnated with polymers and resins. Thanks to these compositions, the product also acquires moisture-resistant properties. But all the same, paper is a fragile object and is not suitable for intensive long-term work. Fine grain is applied to it.

- Cloth-based abrasive paper is more resistant to abrasion and wear. The grain holds just as well, the canvas additionally has elasticity and resistance to moisture, intensive work with different materials, even a grinder, for which Velcro attachments are produced.

- The combined fabric and paper fabric (two-layer) combines the best properties of the previous materials. The product has elasticity, resistance to abrasion, bending, moisture. On a combined basis, coarse sandpaper is produced.

On sale you can find paper with a spongy base. This is good for dust permeability, is not afraid of moisture, suitable for manual and mechanical work for a long time.

Grit types by material

The abrasive is made on different bases:

- Silicon carbide (carborundum) is suitable for working with hard surfaces made of metal, plastic.

- Pomegranate grains are hard and soft at the same time: such abrasive paper is able to remove irregularities from the surface of the wood and seal the fibers, due to which the coating with paint or varnish lays down evenly.

- Ceramics are used to make coarse sandpaper used for smoothing wood.

- Aluminum oxide is a material of considerable price, but its service life is impressive for its "fellow tribesmen": soft crystals break during grinding, smoothing the surface, but in their place are formed smaller particles with the same sharp edges.

- Diamond sandpaper is the most durable and expensive. Almost does not wear out, it is mainly used for machine processing of products in industry.

Dry and wet sanding

For sanding wood before and after finishing coatings, two relevant techniques are used - dry and wet.

Dry grinding increases the efficiency of the abrasive and makes it possible to use it more accurately. At the stages of intermediate sanding of delicate finishing materials, this is what you need. The disadvantage of this technique is that the skin is quickly clogged with debris. To eliminate this problem, experts advise using an emery cloth with anti-clogging properties.

Wet sanding involves applying liquid to the gritty surface of the sandpaper. An ordinary soap solution, white spirit and mineral oil can act as such a working fluid.

Abrasives during wet grinding clog up much more slowly and, accordingly, its service life increases. But the wet method also involves the formation of an unpleasant mess of chips and foam. In this case, the home craftsman will have to periodically wipe the wooden product.

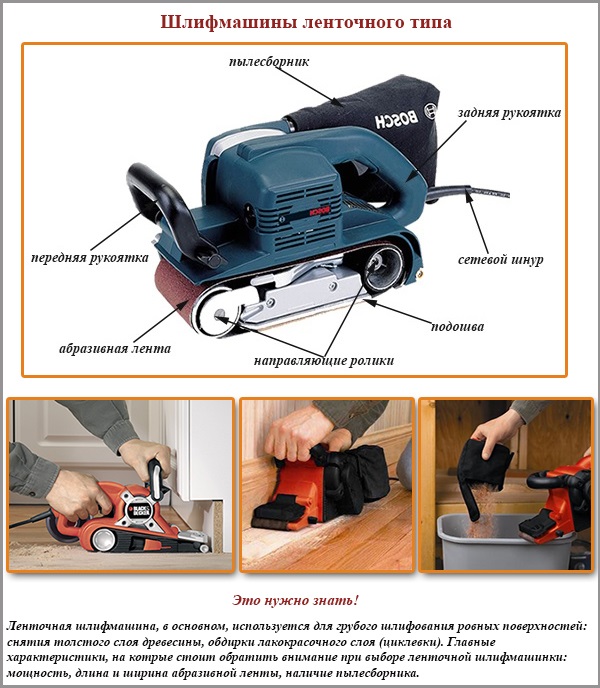

Makita 9403

Main characteristics:

- Power - 1200 W;

- Belt speed - 500 m / min;

- Tape - 610 × 100 mm;

- Weight - 5.9 kg.

Body and ergonomics. With its small dimensions, this grinder, due to the manufacturer's reasonable preferences for the use of metal parts, has an impressive weight of 5.9 kg. This causes some difficulties when working on weight, but does not require additional pressure when processing horizontal surfaces. The product is equipped with two handles that are equally comfortable to grip on both the right and left sides.

Design features. In this model, the steel platform has cork and graphite lining, which facilitates the sliding of the skin, dampens vibration and sound waves.

Makita 9403 platform.

A labyrinth-type shaft seal reliably protects the bearings from contamination. The branch pipe for connecting a vacuum cleaner or fixing a dust collector can be easily deployed in any direction. The cable length of 5 meters is enough for free movement inside the workshop.

Functionality and capabilities. The machine has a high power of 1200 W and develops an optimal linear speed of the skin movement of 500 m / min. It uses a tape 100 mm wide and 610 mm long. Speed control is not provided, so this model is more suited for grinding homogeneous surfaces of a large area.

Equipment. The product is delivered in a cardboard box with sanding tape installed in a completely ready-to-use state.

Pros of Makita 9403

- High power.

- Ergonomic handles.

- Start latching button for continuous operation.

- Low vibration and noise levels.

- Double insulation of current-carrying elements.

- Reliability.

Cons of Makita 9403

- One speed without soft start and speed stabilization system.

- Great weight.

- High price.

Types of sandpaper basics

Sanding belt for a grinder is the most demanded abrasive. It is popularly called a skin, since earlier shark skins were used for grinding. It, like the tape, has its own basis.It is worth taking a closer look at the most common skin bases.

- Paper. This is the most common and economical type of foundation. Such paper is impregnated with polymers to impart strength and resistance to abrasion or tearing. But it is not recommended for intensive use.

- Textile. It is an elastic base that easily conforms to the shape of the product. It is more stable, it has a long service life, but the abrasive can crumble when pulled. The fabric base of the skin is durable and resistant to moisture. It is used for intensive work with various types of wood.

- Fiber. It is used for processing hard materials.

- Combined. It is a combination of cloth and paper that has been coated with abrasive. This base combines the beneficial properties of paper and fabric. It is resistant to bending, abrasion and moisture. Such a base has a high cost.

Grain

The quality of processing of any surfaces will depend on this property. If the grit size of the abrasive material is higher, then the treatment is softer. The grain size is usually denoted by the English letter P. It corresponds to a numerical range from 12 to 2500. The larger the number, the finer the abrasive. There are several types of coarse belts.

- Very large. Such tapes have especially coarse grains (P22 – P36). They are necessary for rough grinding of surfaces and their leveling.

- Large. Tapes with P40 – P60 index. They are required for the initial processing of the material, they are not clogged with dust due to the coarse grain size.

- For initial processing. Tapes marked P70 – P120 are recommended for removing paint and varnish bases or rust.

- For final processing. Tapes with P150 – P220 index. With their help, they clean the surface before polishing.

Fine-grained belts also come in several types.

- For finishing. They are recommended for the final sanding of hardwoods. Their grain size is P240 – P280.

- For polishing. These tapes make painted surfaces smooth but can become clogged with dust and paint. Their grain size is P400 – P600.

- For fine sanding. P1000 belts are ideal for finishing metal, ceramic or varnished wood.

For information on how to choose a sanding belt for a grinder, see the next video.

What and how can you grind

The purpose of wood polishing is to remove defects as quickly and efficiently as possible without leaving noticeable deep scratches. To do this, you can use special tools - now their price is not too high.

On the free sale you can find several types of grinders:

- tape;

- oscillatory;

- grinders (angle grinders);

- surface grinding;

- orbital.

You can install not only abrasive wheels on the grinder, but also brushes. So, nylon brushes are actively used for grinding wood. They allow you to make the surface not only smooth, but also to highlight the texture of the wood, choosing softer fibers. This process is called brushing.

For large surfaces made of wood and materials based on it (veneer, chipboard, fiberboard, plywood), belt and surface grinders are best suited.

Many people still prefer to grind decorative items, furniture, toys, frames by hand, and this is not such a bad way - it allows you to achieve a perfectly smooth surface efficiently and cost-effectively. At least, when working with your own hands, you will not need to think about where to get a sander (ask a neighbor, buy in a store, rent, leaving a deposit).

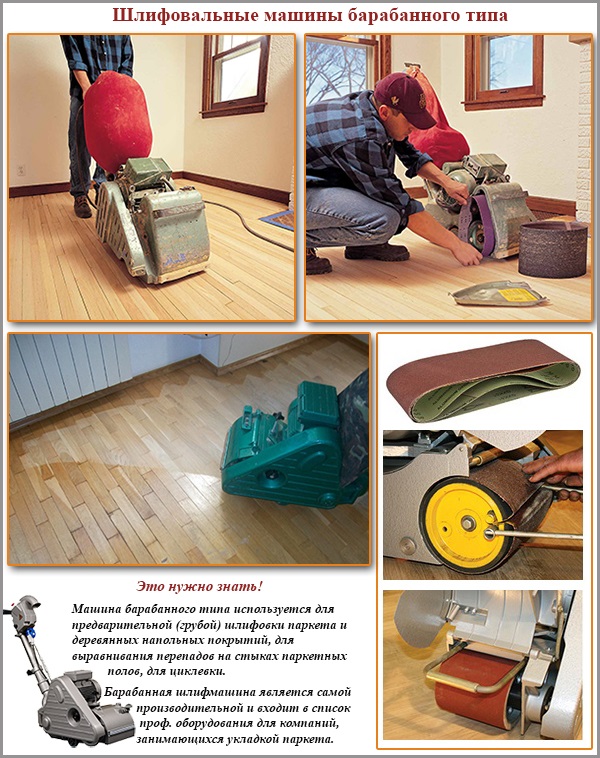

3> Belt type machine

Tape machines are so named because the sandpaper here is made in the format of a tape and it moves continuously thanks to the rollers. This machine is designed for intermediate and rough sanding.But in order to achieve perfect smoothness and perfect finishing (this is especially true for those who are engaged in the manufacture of furniture), you will have to additionally use other grinding equipment.

The belt sander can be fitted with different types of sandpaper. And, for example, when inserting sandpaper with a fine grain, it is quite possible to achieve a result normal for joinery products going under dyeing. And, say, to eliminate long scratches, you will have to carry out stepwise grinding, changing the grain size several times.

The belt sander has excellent performance. However, it should be recognized that the tape is placed on it in such a way that not all points and grooves on the surface of the board can be properly processed.

Even with a large belt width, it grinds mainly with its center. The parts of the tape at the back and front are not used for this. They are in a slightly raised position and their main function is to feed the driving roller mechanisms.

Another obvious drawback of tape equipment is a solid mass, it is rather difficult to perform any actions with such machines on weight, processing vertical products.

> Wood sanding machines also have such a disadvantage as high noise - working without earplugs or headphones will not be very comfortable. And one more important point: if you leave the machine in one place for a long time during work, a fairly noticeable hole will appear.

Surface Grinder

Even sanding large pieces of wood with a surface grinder is quite fast. The key organ of the apparatus is a flat, rather large plate (sole), to which the required abrasive is attached. This design is famous for the almost complete absence of dead zones (that is, zones that cannot be reached with a machine and tolerably processed) - any corners are relatively easy to grind.

The demand for flat grinders among wood craftsmen is due to their moderate price and availability of equipment

When choosing such a machine, you should pay attention to such parameters as motor power (usually we are talking about indicators in the range from 150 to 300 watts), weight, amplitude and frequency of the sole stroke.

3> Manually

Sanding wood by hand, of course, requires a lot of labor and physical effort. But this method of grinding is a priori less aggressive and allows you to fully control the process. Even in hard-to-reach places - in corners and on difficult curved bends - you can get decent quality grinding when choosing a manual method.

With the so-called interlayer sanding of finishing coatings, manual work has no alternatives at all - only it allows you to eliminate the risk of damage to the already applied finish. Manual processing (when compared with grinders) allows you to get the smoothest and smoothest surface, although it takes several times longer.

2> Marking sandpaper

For different types of work, they produce grades of abrasive paper that are very different in their properties and cost. In order to choose a suitable brand and not overpay, it is worth understanding its labeling.

There are two main systems for marking sandpaper - European and GOST. The GOST used the principle of decreasing values as the grain size decreases, and the smallest skin was called "zero".

In the European system, on the contrary, the smallest grain corresponds to large values - from P2500 to P1200, and the coarse-grained skin will have the indices P36 or P22.

Marking table

In addition, backfill labeling is important. Solid backfill is used in domestic, manual use, and backfill with a density of about 50% of the surface is more suitable for industrial applications and use in grinding machines.

Conclusion

When choosing grinding equipment, one should proceed from two main factors - the requirements of the machine and the parameters of cleaning the material with a specific set of characteristics. Obviously, the choice of skin for concrete and wood will be different. So is the choice between hand grinder and industrial machine belts. The only thing that unites different types of sanding belts, regardless of purpose, is the characteristics of wear resistance, reliability and durability. A high-quality sanding belt, even in harsh operating conditions, shows the proper processing effect, removing the millimeters and microns it needs. However, it is hardly possible to check the quality of the tape without practical use. Experts recommend immediately after purchasing a grinder to contact its manufacturer to test the working equipment of this brand. At a minimum, the products of one brand will be compatible in basic performance parameters.