Top 10 popular models

The tool is distinguished by the material from which it is made, dimensions, weight.

Feona 126-0500

- Purpose: sawing wood.

- Manufacturing material - metal, plastic.

- Lightweight and inexpensive tool for small workpieces.

- One canvas included.

STANLEY Raker Tooth 1-15-379 530

- Wood.

- Made of metal and plastic (handle).

- Blade length - 530 mm.

- An inexpensive tool for sawing small to medium sized workpieces.

BAHCO Ergo 10-30-51 759

- For working with wood and plywood parts.

- Blade length - 759 mm. Weight - 866 g.

- A professional tool made from reliable materials.

- You can work with wide workpieces - up to 780-800 mm.

- Convenient fastening and adjustment of the blade tension.

STANLEY 1-20-447 300

- A universal tool for working with wood, plywood, metals.

- Installation of a curtain up to 300 mm long is allowed.

- The set includes two canvases: for wood and for metal.

- Comfortable grip.

- For sawing wood.

- Cloth - 530 mm.

- Weight - 740 g.

- Convenient bow saw for home and summer cottages.

BAHCO Ergo 10-21-51 530

- Professional bow saw for working with wooden blanks.

- Blade length - 530 mm.

- Light weight - 680 g.

- Ergonomic handle, comfortable and reliable blade tensioning mechanism.

- One is attached to the bow saw.

SW 30 1001621

- Created for sawing off branches, twigs, thin workpieces - no thicker than 20 cm.

- The kit includes a plastic case for storage and carrying with blade protection.

- Sawing in tight spots thanks to the arched front.

- Light weight - 500 g.

RACO 4216-53 / 355

- Designed to work with various wood blanks.

- The blade is 533 mm long.

- Comfortable ergonomic handle.

- Reliable construction, high quality performance.

Heyco HE-50816100000

- Designed for sawing metal and wood parts.

- Installation of canvases up to 300 mm is allowed.

- Strong construction, durable materials.

- Comfortable handle with rubberized pad, lightweight - 525 g.

- The set includes two canvases: for wood and for metal.

Unlike hacksaws, circulars and gasoline-powered cutting tools, the bow saw allows you to make neat cuts along or against the grain. The manufacturing technology of the canvases makes it possible for the blade to work both when moving towards itself and against. The tool does not require fuel, electricity, and also practically does not make noise. All this makes it indispensable in the country and in the home workshop.

Reciprocating saw battery: how to choose the right one, what characteristics to pay attention to when selecting, rating of the best models, their pros and cons

Hand-held circular saw for wood: how to choose, their types, an overview of models and tips for selection and maintenance

Miter saw: what it is, design and application features, how to choose the best option, an overview of popular models, their pros and cons

Hand saws for wood: how to choose a suitable model by purpose and characteristics, popularity rating, pros and cons

Specifications

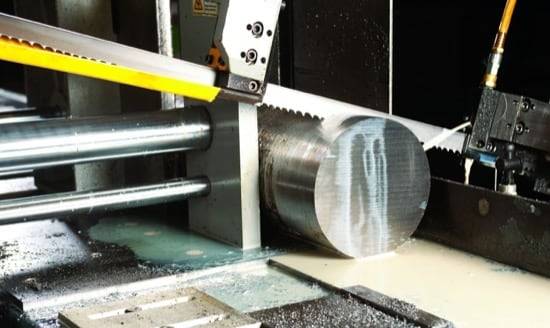

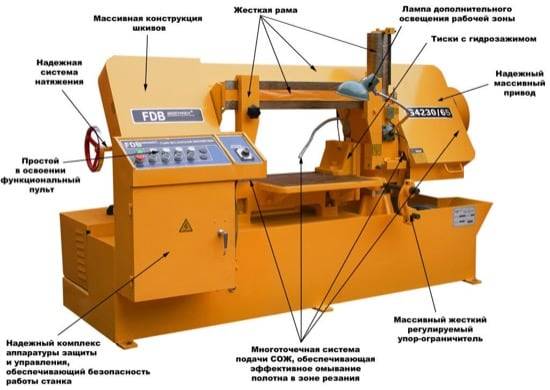

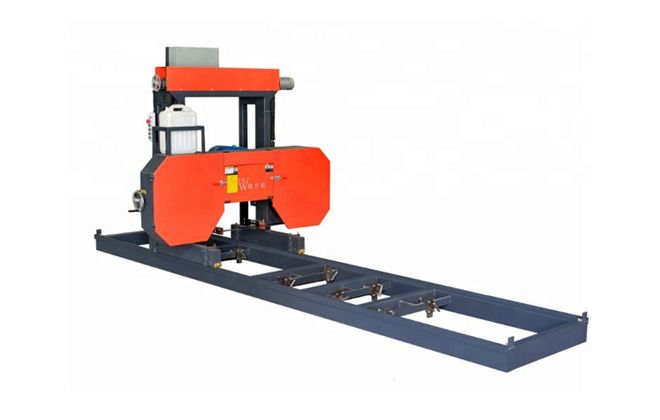

Vertical and horizontal band saws have very good performance, which is ensured by their universal configuration. The design determines the convenience in performing functions, as well as functionality. The devices are launched at a speed of 700 to 900 meters per minute. This allows the correct cutting of wood to be carried out as quickly as possible.

The vertical unit, like the horizontal one, operates from an uninterruptible power supply network, the voltage of which is 230 volts. In order to carry out the correct woodworking processes, it is necessary that the equipment consume power from 800 watts. The drum diameter of the installation is from 250 millimeters, which allows processing wood of various thicknesses. The most convenient operation is ensured by the optimal size of the machine table.

The table can be installed at an angle of 45 or 90 degrees. The latter method is used if the vertical type is installed.

The units can have a variety of cutting speeds, which allows them to be used not only in households, but also in production. Due to the relatively low weight of the machine, its installation can be carried out without the involvement of special equipment. The units are characterized by relatively small dimensions and therefore take up little space in the room, which provides convenience during the performance of their functions.

Due to the versatility of the units, it is possible to adjust the position of the plate at the required angle, which fixes the workpiece. This allows the cut to be carried out with the highest quality. In order to organize the exhaust system, the equipment can be equipped with a branch pipe. A rod is used to guide the workpiece during woodworking.

Bandsaws have excellent technical characteristics, which allows you to guarantee high accuracy of the result when performing woodwork.

How to choose a band saw

Before purchasing such equipment, you should familiarize yourself with the technical characteristics of the various models. After analyzing the data obtained, you will be able to choose the machine that will be most effective in your particular production.

The main operational parameters are:

- performance, which is expressed in power (kW) of the unit;

- sawing speed (m / min);

- distance from the stop to the saw blade (kerf width in mm);

- cutting depth (in mm);

- size and angles of inclination of the working surface of the table.

When purchasing such a technique, you need to know that only a wide belt can be re-sharpened, a narrow belt is operated until it is completely worn out. Depending on the characteristics of the production process, manual models, semi-automatic or automatic machines are used.

You can get more detailed information about the modifications of the machines, the features of their operation, in the companies for the production, sale and maintenance of such equipment.

Advantages and disadvantages

Some people think that buying a band saw is a waste of money, just having a circular saw is enough. In fact, a band saw saves you working time and improves the quality of your workpieces. In factories and furniture factories, a band saw pays for itself in a short time and increases productivity.

Saw Band Advantages:

- Quiet, fast and safe operation.

- The tabletop model is lightweight and does not take up much space.

- Energy saving.

- Cope even with logs and beams.

- Will quickly make a figured cut.

- Reduces the amount of chips.

- The sections do not need to be sanded.

The disadvantages include the low durability of the tooth, which must be ground every time, as well as the need to prepare the machine.

Usage Tips

It is important to consider that you will have to be careful when working with the band saw. Regular maintenance includes wiring and careful sharpening. These manipulations are quite complicated, and in the absence of work experience, it is advisable to use the help of service centers.

You can sharpen saws with a working band with special wheels. The selection of sharpening devices is made in accordance with the strength of the teeth of the instrument

These manipulations are quite complicated, and in the absence of work experience, it is advisable to use the help of service centers. You can sharpen saws with a working band with special wheels. The selection of sharpening devices is made in accordance with the strength of the teeth of the instrument.

But the geometry of the sharpening parts is also determined by the technological parameters of the saw. Before sharpening, make sure that the teeth of the tool can cut surfaces as evenly as possible. Taking on such work, you cannot make jerks. The sufficient level of coolant in the grinding mechanism must be checked. The accuracy of the adjustment of the teeth depends on this.When the sharpening is complete, you need to inspect the band saw. Any burrs, debris and particles must be removed. Sharpening the tool is required strictly in protective goggles, while wearing a respirator. It is recommended to give preference to professional grade grinding machines.

Setting the teeth is just as important as sharpening them. The task of such manipulation is to reduce the friction force. Complex types of wiring are done only by trained professionals. It is also imperative to adjust the band saw. This procedure is required for each newly assembled machine and after changing the blade. Cleaning of the pulleys is a must. It is needed even with stable dust protection. The setting also includes the required tension of the canvases. It is weakened if they plan not to work for 2-3 days.

See the next video for more details.

What are they?

The main division of band saws includes:

- toothed;

- toothless;

- electrospark formats.

The toothed product is equipped with a closed sawing contour. It allows you to saw and cut through a wide variety of materials. The other two types differ only in the type of teeth. A hand-held (aka portable) band saw can:

- cut down trees in the garden;

- prepare firewood;

- cut wooden blanks to exact dimensions;

- sand wood furniture.

Devices complemented by bimetallic blades can be used to process not only wood, but also metal. The main part of such a canvas is formed by a special spring steel. The working area itself is formed from thoroughly sharpened tool steel. But there is another division of canvases:

- for quenched throughout the volume;

- on those that have not been hardened;

- on flexible blades with strong teeth.

Products with the same hardness as the width are very well compatible with medium diameter pulleys. The harder the teeth, the less blunt they will be. In addition, the permissible speed of rotation of the saw depends on this property. Bench belt system, regardless of the strength of the teeth and other parts, has excellent power, it works as reliably as possible

Its important characteristic is the slope of the working surface, which determines the cutting angle of the material.

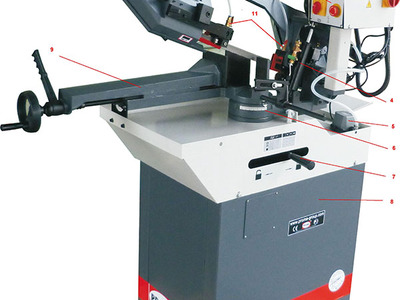

The orientation of the canvas is another important differentiation criterion. Horizontal and vertical band saws are very different from each other. The vertical format of the fixture can be called with almost every reason a large industrial jigsaw. Despite its small dimensions, such a device is capable of working with thick material. Slicing can be done along the most complex path.

Double-sided saws are usually characterized by increased cutting accuracy

But besides the performance features, other technical parameters must also be taken into account, including the cutting depth. It can reach from 8 to 50 cm

A thin blade can easily break when working with wood that is difficult to process. If you use a very powerful saw, thin bars are often damaged.

Machine tool manufacturers

The manufacturer manufactures the equipment in several stages. Initially, sketches are made, which include nodes and details. According to them, the production of units is carried out in the future. For the manufacture of the frame, closed profiles are used. They can have various sizes, which are directly influenced by the dimensions of assemblies and parts. Most often for the production of a machine for woodworking is made from U-shaped profiles.

The manufacturer initially manufactures the base of the machine. For this purpose, sheet steel is most often used, the thickness of which is 4 millimeters. The frame is necessarily attached to the base. Next, the desktop is processed. For this, a bushing is welded, which is intended for the axes of the support bracket. Ball bearings are characterized by an axle to which the lower disc is screwed. The upper disc is mounted on ball bearings.The axle is fastened with a special bracket, with the help of which the angle of inclination is changed.

The manufacturer fixes the supporting frame with bolts or nuts, the guides are placed on it. A cover is attached to the front of the machine. For this purpose, screws are most commonly used. For the highest quality movement of the workpiece on the table, it is made of PCB. The pulley is secured with screws or a pin. The lower and upper discs are installed in a divorced manner.

The production of bandsaw machines is carried out according to a strictly established scheme. This ensures a long service life for the saw band.

The body of the unit is characterized by the presence of a paint-and-varnish coating, which protects it from corrosion. For the production of the machine, high-quality materials are used, which guarantees it not only excellent performance, but also a long service life.

The main brands found in the market today are Jet, Proma, Altesa, Makita, Metabo, Holzstar and others.

Wood processing equipment is unique not only in its components, but also in technical parameters. This allows the material to be processed at the proper level. A large number of types of units allows you to solve any problems with their help.

If you find an error, please select a piece of text and press Ctrl + Enter.

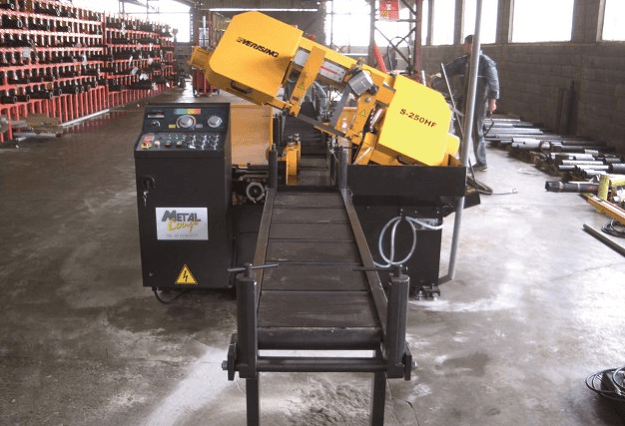

The best mobile band saws

Despite its compact size, this type of equipment is not cheap. Its main advantages are high mobility. Leading manufacturers produce cordless and cordless hand-held band saws.

Bosch GCB 18 V-LI 06012A0300

This mobile band saw is used for cutting all hard materials, including non-ferrous metals and steel. It is equipped with an 18 volt brushed motor and a powerful lithium-ion battery. Protection against overheating and overload, blocking from accidental start is provided. The model has a balanced design and comfortable handling. There is an illumination of the working area.

Main characteristics:

- weight 3.8 kg;

- belt speed 162 m / min;

- saw blade length 733 mm;

- saw blade width up to 12.7 mm;

- maximum cutting depth 63.5 mm.

Pros of Bosch GCB 18 V-LI

- Lightness and compactness.

- Possibility of autonomous work.

- High reliability.

- Infinitely variable speed control.

- Comfortable rubberized handles.

- Easy replacement of blade and electric motor brushes.

Cons Bosch GCB 18 V-LI

- High price.

Output. This saw is intended for professional use. It can be recommended to installers and repair workers who regularly have to work in the field.

Makita 2107 FK

The hand-held bandsaw of this brand operates on a standard 220-volt AC power supply. It is designed for cutting metal parts with a cross section up to 120x120 mm. She has two speed modes with the possibility of electronic speed control. There is a local backlight.

Main characteristics:

- weight 6.3 kg;

- power consumption of the electric motor 710 W;

- belt speed 60/80 m / min;

- saw blade length 1140 mm;

- saw blade width up to 13 mm;

- maximum cutting depth 120 mm.

Pros of Makita 2107 FK

- The ability to cut parts of a large profile.

- High power.

- Balanced design.

- Comfortable handles.

- Fast belt replacement.

- Backlight.

Cons of Makita 2107 FK

- Large mass for a manual model.

- High price.

- Mobility is limited by cable length.

Output. This professional saw is suitable for the repair shop or small production of piece metal products.

Metabo MBS 18 LTX 2.5

This model is equipped with an 18 volt DC brush motor, Li-ion or LiHD battery. It is designed for cutting metal products. The battery is protected against overload and deep discharge.There is a lock against accidental activation and illumination of the cutting area. Comfortable handles are equipped with soft inserts. The saw blade can be changed without the use of keys or other accessories.

Main characteristics:

- weight 4.1 kg;

- belt speed 174 m / min;

- saw blade length 835 mm;

- saw blade width up to 13 mm;

- maximum cutting depth 63.5 mm.

Pros of Metabo MBS 18 LTX 2.5

- Low weight.

- Ergonomic design.

- Autonomy.

- Low vibration.

- Easy adjustment.

- Backlight.

- Battery charge level indication.

Cons of Metabo MBS 18 LTX 2.5

- High price.

- Battery and charger sold separately.

Output. A convenient and powerful tool for autonomous work with metal, suitable for repair and emergency recovery services.

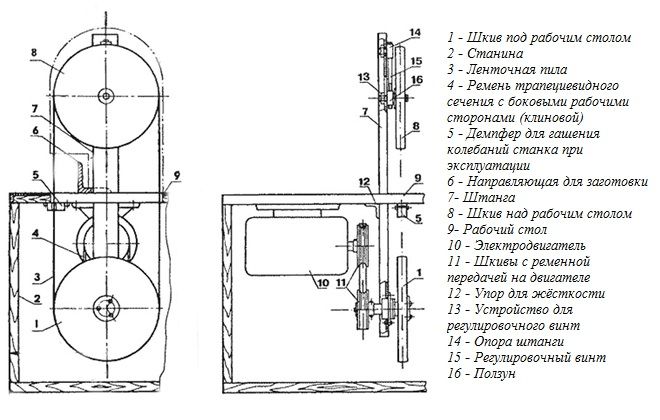

Band saw device

At first glance, the design of a band saw is simple, but the quality of sawing wood directly depends on it. The vertical type is characterized by the arrangement of the saw in a vertical position, and the horizontal type in a horizontal position. On some models, the position of the saw may be tilted. The vertical type allows movement only for a console that has a work item.

With the help of horizontal band saws, wood can be cut into frozen material. This is because they have a versatile design. In the modern world, automatic models are most often used. They are easy to operate and require virtually no operator assistance. The material is fed into the mechanism by a motor and a feeding vice in automatic mode. The most commonly used unit for mass wood processing enterprises.

The cutting tool of band saws for wood is the blade. The width of the canvas can be in the range of 2.5-5 centimeters, and the length is 0.9-1.1 millimeters. To carry out standard operations, it is necessary to use any standard size of the saw that fits into these parameters. The manufacturer uses carbon steel most often to make the saw. This is due to the fact that this material is the most durable and is able to produce the highest quality sawing of wood. The saw type can be varied. It has a hardened or flexible back, or even hardened. The saw rests on several large pulleys to ensure proper positioning and movement.

An integral part of any wood band saw is the engine. The functionality of the installation directly depends on its power. That is why the most powerful motors are installed in the vertical machine, which allows them to perform the most complex tasks.

The design of the units is simple. This simplifies management. Large amounts of woodworking can be done with a band saw.

Which miter saw is better to buy

For occasional woodwork, it doesn't make much sense to buy professional models, which are more relevant for a significant amount of work. The main indicator of device performance is power, the minimum recommended value here is 1000 W, and the higher it is, the less parts will heat up.

Here's which miter saw to choose, depending on your goals:

- For working with aluminum surfaces, Hammer STL1400 / 210, Metabo KGS 315 Plus or Zubr ZPT-210-1400 hp will be relevant.

- The model "Caliber PTE-1750/255-Am" or Metabo KS 216 M Lasercut will perfectly cope with plastic.

- The Hammer STL1200 / 210C is ideal for longitudinal dissolution.

- Long workpieces are best handled with the Makita LS1040F.

- Bosch PCM 8 S or Zubr ZPT-190-1200 PL will help to make high-quality grooves.

- Those looking for a cheaper alternative to a machine tool should look at the Makita LS1216.

- For corner cuts, the Bosch GCM 8 SJL is the best option.

- DeWALT DW717XPS will cope with complex work with dignity.

Before choosing the appropriate option from the rating of miter saws, first of all, you should decide on the budget, because the capabilities of the devices depend on this.

Quality

The company's catalog contains a large selection of reliable tools that are suitable for active use in the construction and carpentry industries.

KAMI offers the following tool:

Wide ones are used for ripping logs of hard and soft varieties. They are made of high-carbon steel from 80 mm wide and equipped with a crimped or stellited tooth.

Narrow saws are made from rolled products with a hardness of 44-46 hrc, while the strength of the teeth varies in the range of 60-64 units. Thanks to this, the blade keeps sharpening and setting, allowing you to save on consumables, as well as reduce the energy consumption required for frequent sharpening on machines.

Designed for straight and curved sawing of soft and hard wood, panel products. These tools are characterized by a resilient hardened back and hardened precision-machined teeth for a clean cut.

Equipping equipment with such devices as band saws will allow you to:

- to reduce the costs associated with the instrumental support of the enterprise;

- to increase the quality and quantity of the processed material;

- improve production efficiency.