What are they?

The main division of band saws includes:

- toothed;

- toothless;

- electrospark formats.

The toothed product is equipped with a closed sawing contour. It allows you to saw and cut through a wide variety of materials. The other two types differ only in the type of teeth. A hand-held (aka portable) band saw can:

- cut down trees in the garden;

- prepare firewood;

- cut wooden blanks to exact dimensions;

- sand wood furniture.

Devices complemented by bimetallic blades can be used to process not only wood, but also metal. The main part of such a canvas is formed by a special spring steel. The working area itself is formed from thoroughly sharpened tool steel. But there is another division of canvases:

- for quenched throughout the volume;

- on those that have not been hardened;

- on flexible blades with strong teeth.

Products with the same hardness as the width are very well compatible with medium diameter pulleys. The harder the teeth, the less blunt they will be. In addition, the permissible speed of rotation of the saw depends on this property. Bench belt system, regardless of the strength of the teeth and other parts, has excellent power, it works as reliably as possible

Its important characteristic is the slope of the working surface, which determines the cutting angle of the material.

The orientation of the canvas is another important differentiation criterion. Horizontal and vertical band saws are very different from each other. The vertical format of the fixture can be called with almost every reason a large industrial jigsaw. Despite its small dimensions, such a device is capable of working with thick material. Slicing can be done along the most complex path.

Double-sided saws are usually characterized by increased cutting accuracy

But besides the performance features, other technical parameters must also be taken into account, including the cutting depth. It can reach from 8 to 50 cm

A thin blade can easily break when working with wood that is difficult to process. If you use a very powerful saw, thin bars are often damaged.

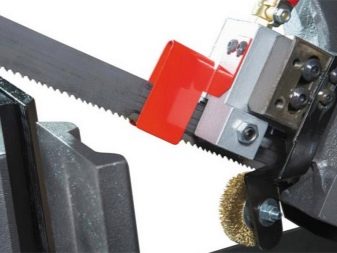

Description of band saws

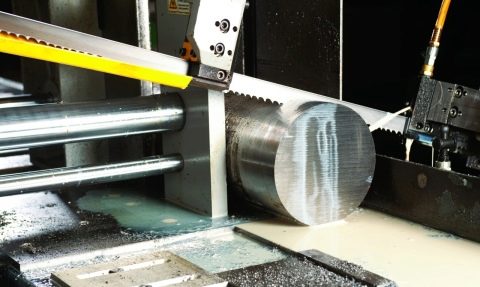

Two rotating wheels supporting the belt are placed on the bed. They are driven by an electric motor drive. The cutting band is fixed by two rollers and a stop next to the work table, and its adjustment is provided. The size of the teeth on the saw blade is determined by the size of the unit and the type of operation, as in hand saws. The teeth are sharpened to the shape of the universal profile.

Two rotating wheels supporting the belt are placed on the bed. They are driven by an electric motor drive. The cutting band is fixed by two rollers and a stop next to the work table, and its adjustment is provided. The size of the teeth on the saw blade is determined by the size of the unit and the type of operation, as in hand saws. The teeth are sharpened to the shape of the universal profile.

To close the strip of the cutting blade into a ring, use soldering with copper solder, so the ends are attached to each other and the break point is connected during repair. At the factory, soldering is carried out by electric welding, small workshops use a torch or special pliers.

Varieties of aggregates

They are available in three types:

- units with a toothed blade;

- toothless friction machines;

- saws working on the principle of electric spark action.

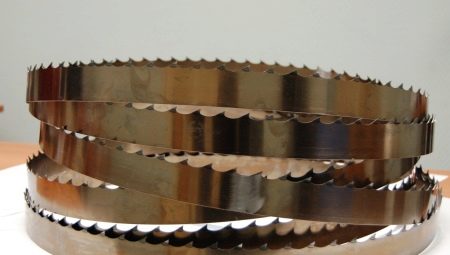

From a hacksaw blade, the strip of a toothed saw differs in size in length and is made in the form of a ring, but in appearance in the open state they do not differ. Serrated strips are used for installation in tape machines for metal or wood, are used in meat and fish production for butchering carcasses, in industry they cut foam concrete, mineral insulation, foam and other building materials with their help.

The principle of toothless band friction is applied according to the same principle as the friction hole saws. There are also teeth on the working blade, but their shape contributes not to cutting, but to heating the treated layer. The release of heat in this case increases the performance of the unit. The cutting blade in friction saws is made with a thickness of 0.6-1.7 mm, with a width of 6 to 26 mm.

The electric spark action of a saw is used when cutting workpieces with a thickness of 150-400 mm, which cannot be processed with circular saws due to a sore pitch and diameter, which causes strong beating.

Types of material for canvases

For cutting wood, strips of steels with a high carbon content, blades with brazed teeth made of carbide material and bimetallic strips are most often used. The bimetallic version provides for a flexible blade and hard teeth, for which two types of metal are used. The base of the strip is made of a springy material, a tool high-speed wire is welded to it using an electron-beam type of welding, from which a toothed profile is subsequently milled.

They produce blades that are universal in use and special saws used for specific steels. The area of use is selected taking into account the parameters of the teeth:

- size;

- hardness;

- geometry;

- wiring.

For cutting large workpieces, strips with large teeth are used, in particular, for processing sheet metal of significant dimensions, blades with enlarged elements are used. To avoid beating of the blade and resonance phenomena, teeth of different sizes are attached to the same strip (variable pitch).

The hardness of the cutting elements depends on this index of the steel. Most often, in the manufacture of teeth, metal is used with the designation M42 (this means the edge hardness according to the Vickers category - 950 units). To machine tool steel, such an indicator is not enough, therefore, the hardness of the teeth is M71 (100 units according to Vickers), work of medium complexity requires the hardness of M51.

The hardness of the cutting elements depends on this index of the steel. Most often, in the manufacture of teeth, metal is used with the designation M42 (this means the edge hardness according to the Vickers category - 950 units). To machine tool steel, such an indicator is not enough, therefore, the hardness of the teeth is M71 (100 units according to Vickers), work of medium complexity requires the hardness of M51.

The geometric shape is determined by the sharpening angle and the profile of the cutting element. To cut a profile (channel, corner, T-bar, I-beam, pipes) to size, it is required to form teeth with reinforced backs. This is dictated by the special shape of the profile, during cutting of which shock and vibration occur, leading to the occurrence of chips and cracks. To process viscous stainless steel or other materials with similar characteristics, the teeth are made sharp, leaving a significant gap between them.

The layout of the cutting elements is done depending on the size and massiveness of the material being processed. For example, to prevent pinching when cutting solid massive material, strips are used on the saw with alternating narrow and wide setups.

Types of saws depending on the work with the material

The following division into categories is made according to the processing material:

The following division into categories is made according to the processing material:

- for stone;

- for metal;

- for wood;

- for synthetics.

Working with hard materials (metal, stone) is carried out with a tool in which the working saw blade is reinforced with heavy-duty teeth from the corresponding alloys. The wrong choice of the saw blade leads to its breakage and deterioration of the edges on the workpiece being cut. Before buying a saw, determine the front for further work.

Peculiarities

The band saw is the main tool for working with a wide variety of materials. The band saw consists of a flexible looped band with teeth on one side. The tape is put on the pulleys that are attached to the engine.

Saws can be made in a wide variety of configurations, which makes it possible to use such a tool in a wide variety of areas: from furniture production to the manufacture of building materials. Varieties of band saws:

- toothed;

- toothless;

- electric spark principle of action.

This tool differs from simple hacksaws in that it has a closed principle of operation.Almost any material can be cut with such devices.

Aggregates operating on friction and electric spark action are somewhat different from classic band saws.

When choosing a device, you should know how such a unit functions. For example, a metal band saw is cutting all kinds of workpieces. The presence of rotary mechanisms makes it possible to cut at any angle. Band saw selection criteria:

- engine power;

- how much the unit weighs;

- what are the dimensions of the pulleys.

Differentiation of equipment is usually like this:

- pulley diameter 355 mm - considered a light machine;

- pulley diameter 435-535 mm - average;

- if the diameter exceeds 535 mm, that such machine is considered heavy.

The first type of machines is equipped with a 1.9 kW engine, if the unit is more massive, then its power can reach 4.2 kW.

Special standards are required for the canvas. When cutting metal, bimetallic blades are also used; they are made of several types of materials. Most often it is:

- durable plastic steel;

- wire made of special high-strength steel.

Canvases based on carbon steel are very popular. Tape blades also vary:

- with congruent density Constant hardness;

- with flexible base and durable Flex back - Hard Edge teeth;

- hardened Hard Back canvases.

The first blades for which the hardness coefficient is identical can operate on pulleys with minimum diameters; at the same time, their strength can reach 49 units (HRc scale).

Saws of the second type, which are made of ductile steel, have a hard tooth and have a rather complex structure. Only the upper edge of the cutting tooth is hardened (hardness 64–66 on the HRc scale).

And finally, the third type is the most durable (hardness up to 68 on the HRc scale).

The hardness of the teeth provides the level of productivity of the tool, its durability.

Choice

Before choosing the right tool, you should know the main criteria by which band saws differ:

- the size of the cut;

- which canvas is involved;

- Energy consumption;

- engine power;

- compactness of parameters;

- the weight;

- the ability to customize;

- type of material supply.

The equipment can be different, in accordance with this, the prices for it vary.

The belt itself can also change the speed of movement from 12 to 98 meters per second.

Also, the units differ in the parameters of the belt tension. The tape has a power of 2100 W and can reach 3000 W and even more.

Visually, it is easy to determine when buying: if the tape has large teeth, this means that it cuts to a greater depth. There is one more indicator - this is the setting of the teeth, it directly affects the efficiency of the saw. For small jobs, a wave profile is sufficient. The most effective option is the arrangement of the teeth in pairs.

What is a circular saw for wood?

In order not to make mistakes when choosing a circular saw for wood, the buyer should know what kind of device he is going to purchase. A circular saw is more correctly viewed as a compromise option for a technique that occupies an intermediate place between a conventional electronic jigsaw and a chainsaw that is capable of sawing thick tree trunks.

This is a fairly versatile device with which you can perform both professional tasks and household operations. With the correct use of this device, you can get fairly accurate and fast cuts. Thanks to this technique, straight lines can be obtained, while it can be used for processing wood of various thicknesses.

Circular saws are quite functional devices that can cut any tree shape. With the help of this equipment, you can cut any decorative elements from wood, while such equipment will serve much longer than a low-power jigsaw.

If you try to evaluate the quality of the technology in question and compare it with a conventional chainsaw, then it is the circular saw that provides higher processing accuracy. Gasoline saws are powerful enough to create rough cuts. Another thing is when a circular saw is used, which is capable of making neat cuts.

Device

Continuing our acquaintance with a circular saw for wood, it is necessary to dwell on what constituent elements this device consists of.

The main component in this equipment is the electric motor. It has a shaft on which the saw blade is located. Most models use synchronous brushed motors. They are equipped with special brushes, which gradually wear out during operation. They must be constantly monitored, otherwise, if these parts are not changed in time, the engine may fail. For this reason, it is recommended to buy a circular saw with the ability to automatically turn off the motor.

Engine power directly affects how efficiently the tool will perform the operation. More powerful models can easily cut thicker boards. Also, the power affects what diameter the knives used in this tool have. Accordingly, the price for them will differ depending on this indicator.

In addition to the above, circular saws are more bulky equipment if a sufficiently powerful device is purchased. For this reason, before making a final decision in favor of a particular model, the buyer should already know for what amount of work he is going to use this equipment. If you need a tool to perform a large number of operations, then there is no point in spending a large sum of money to buy a very powerful circular saw.

Equipment parameters

When choosing a hand-held circular saw for wood of an electric type, the buyer has to take into account many different parameters, among which the number of revolutions is quite important. The best option is a circular saw model that has the ability to adjust this parameter. As a result, it is possible to achieve a better quality cut with an optimal level of load on the equipment.

Another requirement that must be met is the electronic protection of the selected saw blade. Then the owner can be sure that in the event of an emergency, he and the tool used by him will be reliably protected. Even at the stage of choosing this technique in the store, you need to find out if this tool has an accidental launch lock.

You also need to pay attention to how the purchased equipment looks like. It is convenient if this equipment has an additional handle provided in the package.

Much attention must be paid to the material from which the product is made - it must be strong and able to cope with stress and mechanical stress.

The cost of a circular saw is influenced not only by the power indicator, but also by the frequency of disassembly. It is best to choose those models that provide the ability to comfortably balance the tool during operation, and the handles do not slip. Then the user can firmly hold the tool in his hands without fear of injury.

The best circular saws with a cutting depth of 70-85 mm

For domestic use, a cutting depth of 70 mm is almost never needed. Therefore, almost all tools of this class are professional devices and which circular saw is better, one must choose based on the set production tasks.

| Makita 5008MG | Bosch GKS 190 | |

| Power, W | 1800 | 1400 |

| Number of revolutions, rpm | 5200 | 5500 |

| Speed control | ||

| Disc diameter, mm | 210 | 190 |

| Rim diameter, mm | 30 | 30 |

| Max depth of cut at an angle of 90 °, mm | 75,5 | 70 |

| Max depth of cut at an angle of 45 °, mm | 57 | 50 |

| Smooth start | ||

| Possibility to work with a guide rail | ||

| Maintaining constant speed under load | ||

| Weight, kg | 5,1 | 4,2 |

Circular saw Makita 5008MG

The working disc 210x30 mm is the cuts of 75.5 mm and 57 mm with a tilt of 57 °. Confident operation of the tool is provided by a 1800 watt motor, which accelerates the saw blade up to 5200 rpm.

+ Pros of Makita 5008MG

- 4.8 kg is not the highest weight for a saw with these characteristics.

- When working, high power is immediately felt - the saw "runs" smoothly and without jerks.

- Good weight distribution and overall ergonomics - if necessary, allows the saw to be guided with one hand.

- Smooth clean cut on all materials of suitable thickness.

- Rubber pads on the handles - confident holding of the tool during work.

- Cons of Makita 5008MG

- A small network cable - 2.5 meters is not always enough for comfortable work.

- The parallel stop is springy - not always confidently "keeps the trajectory".

- There is no groove in the outsole for travel on the guide rail.

- When you start the saw, the backlight automatically turns on - even when not needed.

- Difficulty viewing the work area - due to the design features of the tool.

Circular saw Bosch GKS 190

Professional circular saw with a 1.4 kW motor that rotates the blade at 5500 rpm. The saw gives out a cutting depth of 70 mm, and when the blade is tilted by 45 ° - 50 mm.

+ Pros of Bosch GKS 190

- Long power cable - 4 meters is enough to move the instrument around a large room.

- The weight of 4.2 kg is very small, as for a professional-grade device - if necessary, the tool can be held with one hand or operated on a vertical plane.

- High blade revolutions give a clean, even cut - in most cases, it does not even need to be processed further.

- The angle of inclination of the sole relative to the disc can be set within 55 °.

- The cutting depth is sufficient for all situations where you need to cut boards with a hand circular. If you really need a little more, then by removing the lower cover you can put a 200 mm disc and the cutting depth will increase to 75 mm.

- Cons Bosch GKS 190

- The disc clamp hexagon may fall out of the mount on the case unnoticed - it is best to store it separately.

- The sawdust collection system does not always perform its functions correctly - when the vacuum cleaner is running, chips often fly out from under the knife.

- Lack of smooth start - when starting, you must firmly hold the saw in your hands.

- It may be difficult to find a disc with an outer diameter of 190 and an inner diameter of 30 mm.