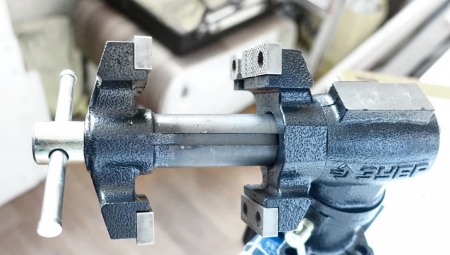

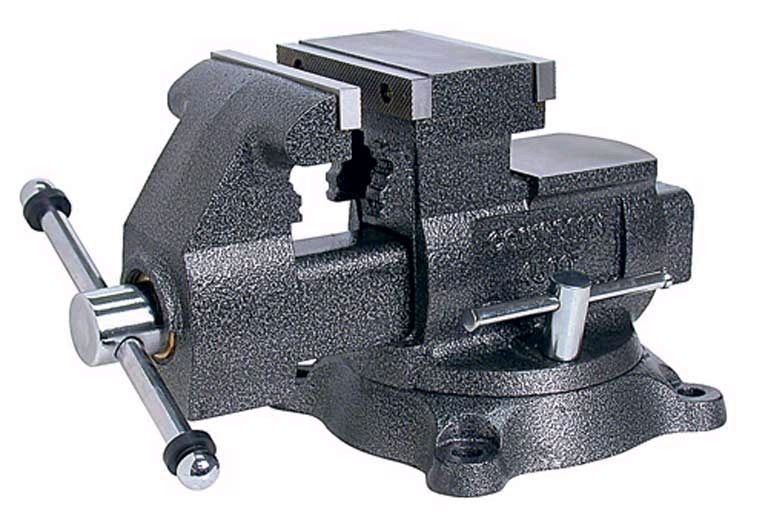

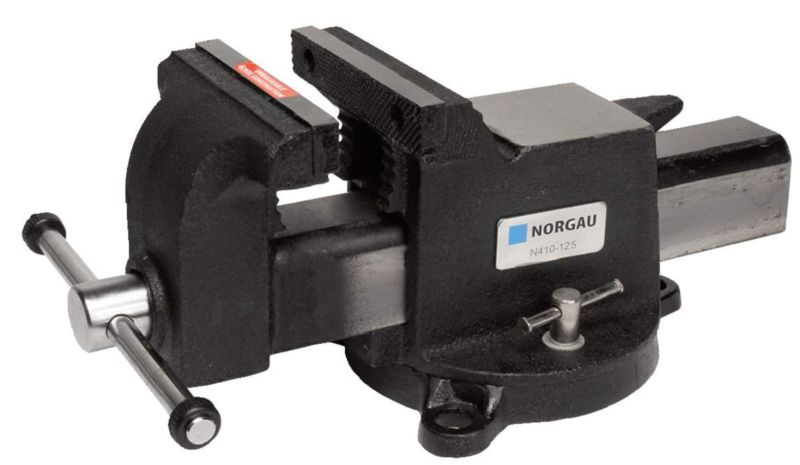

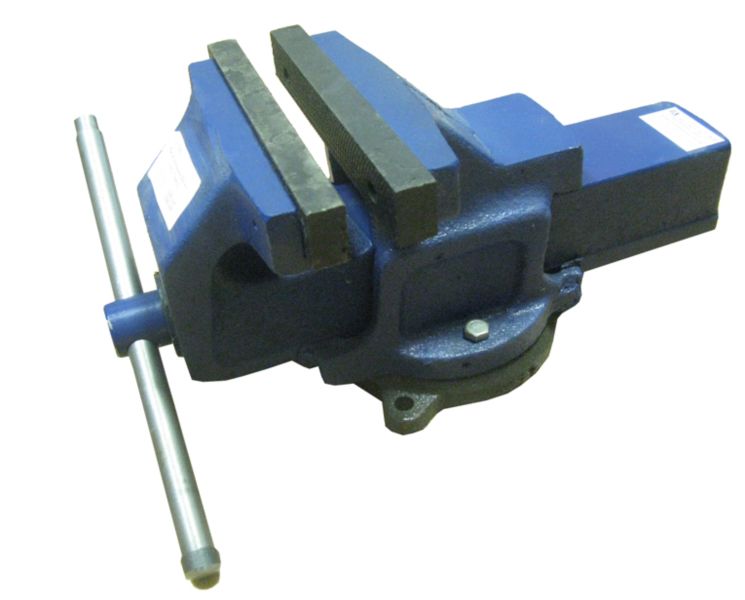

Swivel Parallel Locksmith Vise - Design Features

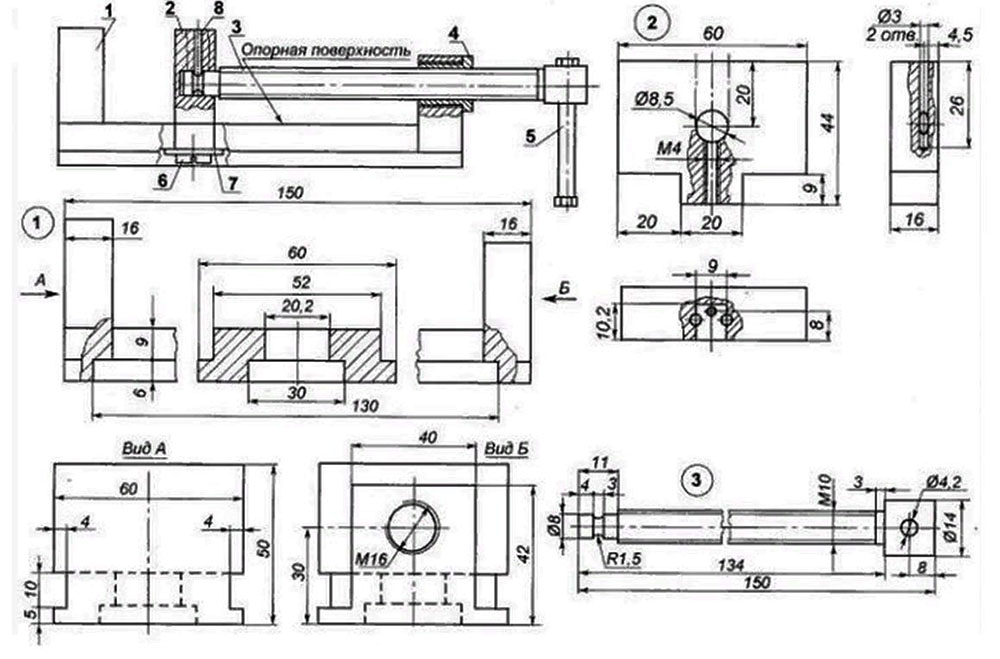

The massive base of the device has three holes with holes. Their purpose is to secure the device to the workbench with bolts. The base can be steel or cast iron, as it does not carry shock loads. The workbench, table or log to which the device will be mounted must be heavy, stable and difficult to turn. It is necessary to install the device on a horizontal surface with a rotary handle to the edge. The most comfortable position is when the rotary handle rotates freely without being thrown over and does not touch the edge of the workbench.

The fixed jaw has two screws at its base, which are designed to fix its position relative to the base. After loosening both screws, the vise mechanism can be turned clockwise and counterclockwise at an arbitrary angle (up to 120 °) relative to the base. After setting the required working position, the fixing screws must be tightened.

In the upper part, the stationary jaw passes into a plane that has the purpose of an anvil. It is the use of locksmith vices made in accordance with GOST 4045-75, as an anvil, that determines the use of steel components.

The part of the upper jaw at the workpiece clamping point is equipped with a replaceable jaw. It is secured with two countersunk screws. Fully tightening the screws does not immobilize the pad. This is to ensure that the workpiece is not damaged when the clamping screw is tightly tightened. The jaws are always steel, even if other parts are made of cast iron. Replaceable linings are hardened and can have two types of notches: cruciform or dotted. When fixing soft materials, their surface can be damaged by the notch. If this is critical, then soft pads (made of wood, aluminum) can be used on the cheeks. In addition, when fixing parts that have a shape close to spherical or cylindrical, it is recommended to install cheeks of a special geometric shape instead of the usual flat ones, which are also provided for by GOST.

The movable jaw is also equipped with a similar notched steel jaw. It provides its rectilinear movement by the presence of a guiding hollow rectangular parallelepiped (trunk), which moves through a rectangular hole in a fixed jaw (the guiding trunk and hole can be of another shape - semicircular, trapezoidal).

Fixation of the workpiece and movement of the movable jaw is carried out thanks to the screw, which is rotated by means of a rotary handle. The screw can have different thread pitches. The smaller it is, the more accurately you can clamp the workpiece.

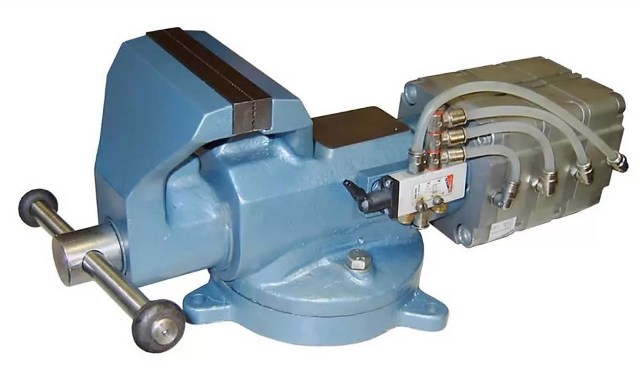

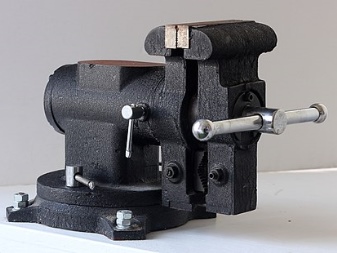

Pneumatic Parallel Locksmith Vise

The release of such devices is regulated by GOST 12.2.029-77. Structurally, this device differs from the usual clamping locksmith mechanism (made according to GOST 4045-75) only by the presence of a pneumatic drive, which provides a high operating speed (2-3 s for one clamping), the same clamping force and excludes the use of great physical force. Control is carried out using a lever or pedal.

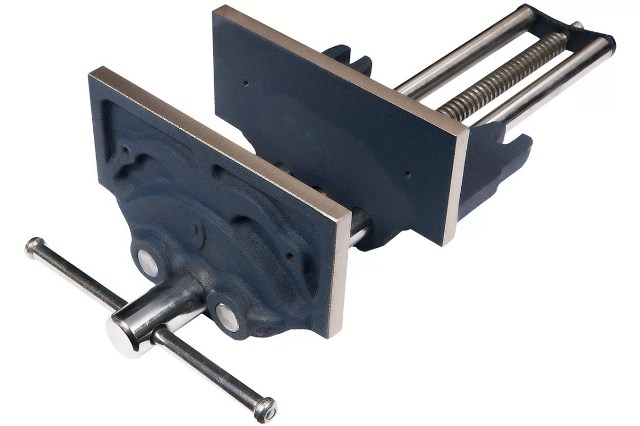

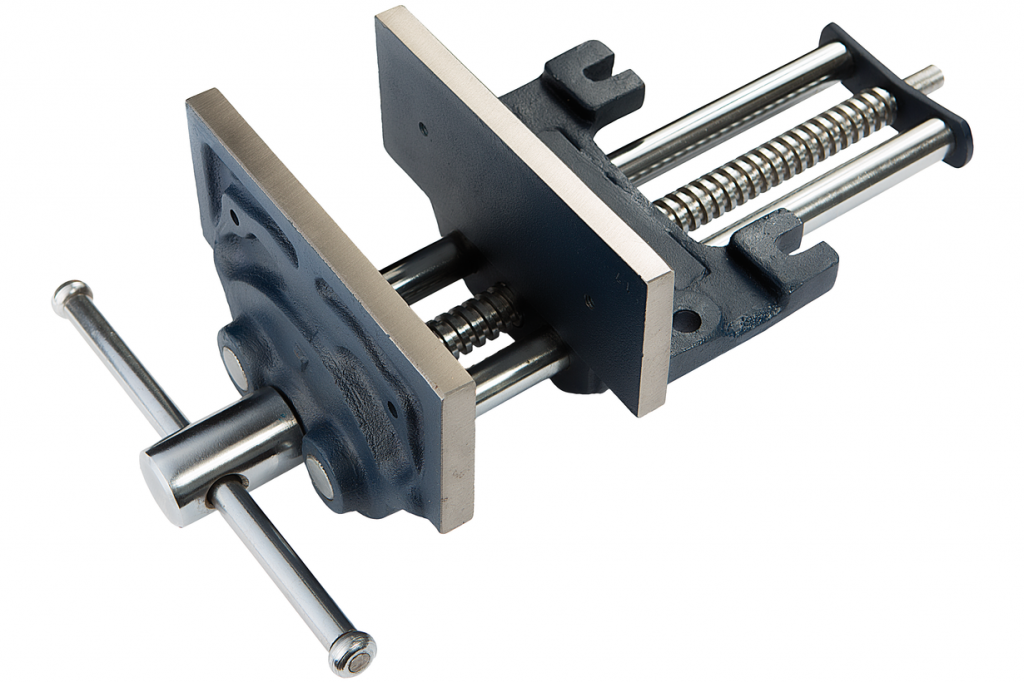

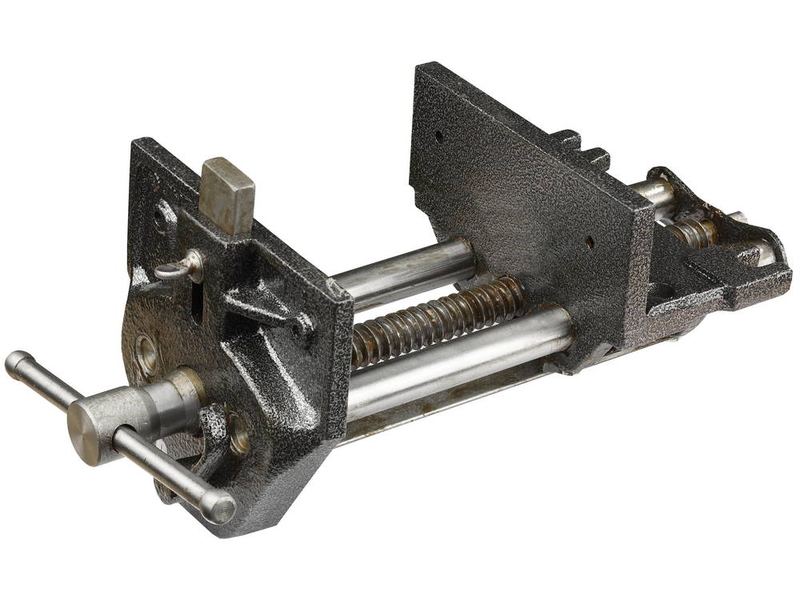

Best joinery vice

The joinery vise has one specific feature. They must not only securely, but also carefully hold the wooden products. For this, manufacturers complete the devices with smooth sponges, as well as special soft pads.

Buyers should pay attention to the travel and height of the jaws.Here are some interesting models

WILTON WWV / 175 65017EU

The low price and compact dimensions make the WILTON WWV / 175 65017EU a desirable tool in the carpentry shop. By spreading high jaws (70 mm) to a distance of 210 mm, it is possible to cut and cut impressively large blocks. At the same time, the wood does not deform, since the sponges have a perfectly smooth surface. The frame structure is attached to the table with hardware, for this the manufacturer has provided special holes. The undercarriage is quite reliable due to two rails and a clamping screw. The model deservedly takes first place in our rating.

Users are satisfied with the quality of the cast iron, the size of the vice, the smooth running, the protection against corrosion. Of the minuses, the lack of a rotation function is noted.

- reliable frame construction;

- anti-corrosion treatment;

- large sponges with a smooth surface;

- smooth running.

there is no swivel mechanism.

Triton SJA100E

Triton SJA100E stand vise is a multifunctional tool. This mobile equipment is capable of fixing large-sized workpieces. The working stroke is 955 mm, which is enough for fixing the door leaf. The device is light enough (14.5 kg) and mobile. The clamping mechanism has a foot drive for squeezing. And the sponges are provided for manually. This design allows you to do without a workbench, table or additional stands. The experts put the vise-stand in second place in the rating for the high price.

Users have appreciated the convenience of the equipment, durability, mobility and the presence of a swivel mechanism. The large working stroke allows clamping of large-sized joinery.

- reliable folding legs;

- wide jaws (178 mm);

- large working stroke;

- swivel mechanism.

high price.

BISON EXPERT 32731-175

The BISON EXPERT 32731-175 joiner's vice perfectly combines an affordable price and workmanship. The equipment allows you to quickly and reliably fix wood blanks. A distinctive feature of the model is the trapezoidal threaded clamping screw. This design ensures effective fastening and durability of the working mechanism. Two guides are responsible for smooth rectilinear movement. The manufacturer has provided for the possibility of attaching the base to the workbench using hardware. Special holes are made in the jaws for mounting the linings.

The vise occupies the third place in our rating due to the large amount of grease that strives to get on the wooden part. But users consider the versatility of the tool to be a positive feature of the model.

Problems

Cast iron specimens are less durable than steel products. The rest of the inconvenience is associated with the individual characteristics of each type.

Cons of locksmith vice

- Most often they have a backlash.

- Alignment of the jaws is required, which is not always possible without the use of a professional tool.

- Rapid wear of the lock washers requires regular replacement.

- Long parts are difficult to pinch across the jaws.

Cons of a chair vise

- Looseness of fastening of the tool on the workbench and of the grip.

- Gripping narrow objects during clamping is possible only with the upper parts of the jaws, and wide ones - with the lower ones. This is because their working surfaces are not parallel to each other in all positions.

- The clamps cut into the part, leaving dents on it.

- An open thread screw becomes dirty and prone to rapid wear.

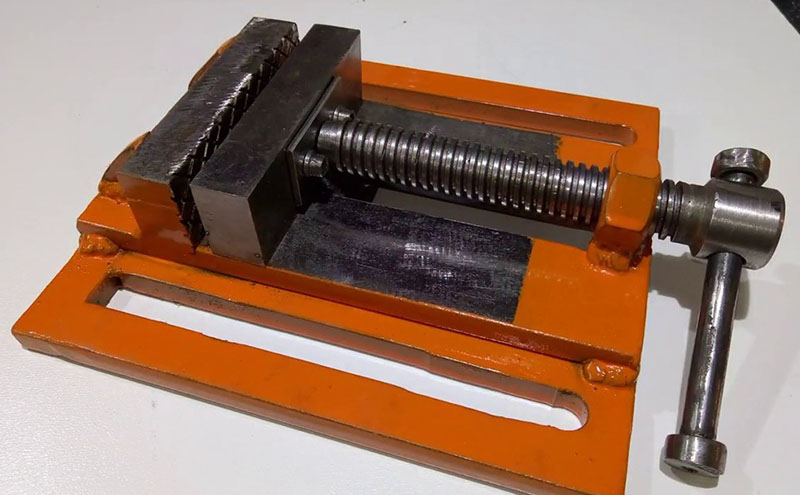

Cons of machine vice

- They are focused on lifting parts due to the vertical distortion of the jaw, therefore, if the laying is uneven, traces of a vice remain on the workpiece.

- To level the skew under the base of the movable jaw, you have to slip a foil or use a vice, gripping the parts only with the upper edge.

Cons of hand vices

- The small width and run of the jaws do not allow processing large elements.

- The correct clamp is only provided for soft metals, but the prongs found on most handheld models will dent it.

- Not suitable for working at an angle without accessories.

- It is not possible to clamp the dimensional part in the desired position.

Cons of carpentry vice

- Not suitable for machining parts with increased rigidity.

- More often they are applicable only as a household improvised tool.

- Models without workbenches are unpopular due to their reduced grip stiffness.

- Variations with workbenches often come in an extended configuration, demanding space and lighting.

User manual

The service life of any equipment depends to a large extent on correct operation. Therefore, first of all, you should carefully study the instructions that come with the vice. It contains all the technical parameters of the instrument, its functional features, installation and maintenance method.

The preparation of the tool and the rules of work consist in the following steps:

- install and fix the vice on the workbench, strictly adhering to the instructions of the instructions;

- adjust the moving parts;

- the weight and dimensions of the workpieces to be processed must exactly correspond to the parameters specified in the instructions for which the vice is designed, and not exceed them;

- fix the part firmly by moving the movable jaw;

- after work, it is necessary to clean the tool from shavings, dirt, dust, and then lubricate the running gear and other rubbing parts.

When working, you must follow the safety rules:

- control the fastening of the vice for strength and reliability and exclude the possibility of spontaneous loosening of the clamping part;

- it is strictly forbidden to apply impact force to the tool handle, as well as lengthen it with a pipe or pin;

- heated metal workpieces must not be processed in a vice, since after cooling, the dimensions of the part change, which can lead to a weakening of its clamping in the jaws and injure the worker;

- the level of force provided by the instructions must not be exceeded.

The above information can help the average consumer decide on the choice of model.

For an overview of popular models of locksmith vices, see the following video.

Specifications

Having the same design, a vice can have some distinctive characteristics: a different shape and a different ratio of parameters such as length, width, height, weight and material of manufacture.

Materials (edit)

The strength of the material used to make the vice is an important characteristic. The material for making metal locksmith vices is usually carbon steel and gray cast iron.

The advantages of cast iron are its high hardness and strength, corrosion resistance. It is resistant to rust and effectively absorbs impact forces.

Models made from selected cast iron alloys, such as ferritic cast iron, have a high strength, almost 10 times that of gray cast iron. However, cast iron is brittle when subjected to intense impact and is heavy.

Steel products are more versatile because they can be used to process workpieces of different materials and perform delicate work, therefore they have a higher price.

Dimensions (edit)

The working dimensions of the vice are also of great importance: the width of the jaws and the depth of their opening (the course of the jaws). These parameters determine how deep and wide they cover the workpiece, as well as the dimensions of the parts to be machined - the larger the working dimensions of the jaws, the larger the workpieces can be processed.

The size of the jaws for different models can vary from 80 to 250 mm, and they can be maximally opened by 200-250 mm, the clamping force is 15-55 (F), the length of the entire structure is 290-668 mm, and the height is 140-310 mm.

The following types of vise for the house are distinguished by size (length, height, jaw stroke, weight):

- small vice - 290 mm, 140 mm, 80 mm, 8 kg;

- medium - 372 mm, 180 mm, 125 mm, 14 kg;

- large - 458 mm, 220 mm, 160 mm, 27 kg.

The weight

Weight is an equally important parameter, since the clamping force of the vice also depends on it. It is believed that weight affects the strength of the entire structure - the greater the mass, the stronger the vice.

What kind of care does the vise require?

Like most tools, the vise requires special care. For them to work well, all parts must be clean. The tool must be cleaned with a cloth dampened in solvent. This procedure must be repeated after each use of the vise.

Tool parts must be lubricated. Engine oil can be used. Such care will help keep the sponges in working order, as a result, they will open smoothly. After processing, the risk of corrosion is reduced.

If rust appears, then it must be removed from the tool mechanically. If this method does not help and the plaque has already firmly settled in the vice, then you need to use special compounds to combat metal corrosion. You can apply a cleaning compound and leave it overnight. In the morning you need to wash it off with water and dry the instrument.

How to choose a locksmith vice?

So, it was decided to buy a locksmith's vice, which one is better to choose? To begin with, you need to understand how they will be used: with small parts or with large ones, for serious blacksmithing work or purely for domestic needs. Having identified your goals and reading the information above, you can easily determine which type of locksmith vice is best suited.

When choosing a specific model, it is important to pay attention to the absence of backlash, the possibility of changing lips and key parameters: size and material of manufacture

Bench vices - dimensions

The two main dimensional characteristics of the device are the parameters of the width of the jaws and the distance of their maximum dilution. These and other parameters are clearly spelled out in GOST 4045-75 "Hand-operated locksmith's vice":

- The smallest values of these indicators are for hand-held vices for small jobs: their jaws are 6.10 or 16 mm wide and are divorced by 5.5 or 6.5 mm.

- The standard hand tool is slightly larger: with a width of 36, 40, 50 or 56 mm and an opening range of 28, 30, 40, 50 or 55 mm.

- Ordinary locksmith parallel vices have the following parameters: jaws of 80, 100, 120 or 140 mm, divorced by 65, 100, 140 or 180 mm. Moreover, the non-swivel ones, in contrast to the swivel ones, have an even smaller configuration with a width of 60 mm and an opening of 45 mm.

- Locksmith large chair vices generally have jaws of 100, 130, 150 or 180 mm, spreading 90, 130, 150 or 180 mm.

What material is a locksmith vise made of?

Due to the severe stress on the tool, it is best to choose a steel locksmith vise. The strongest - chair, forged from carbon structural steel completely, except for the surface in contact with the product. Tool steel equipped with special notches is used for it. The parallel vise is lightened by casting their body in cast iron, although the jaws remain steel. Brass or aluminum jaw pads will help prevent dents on the workpiece. Structural and tool carbon steel also serves as a material for hand vices.