Continuous cultivator KSO-8

Check out these articles as well

-

Tractor T-40

-

Inter-row cultivator

-

Grain grinder Piggy 350

-

Tractor T-16

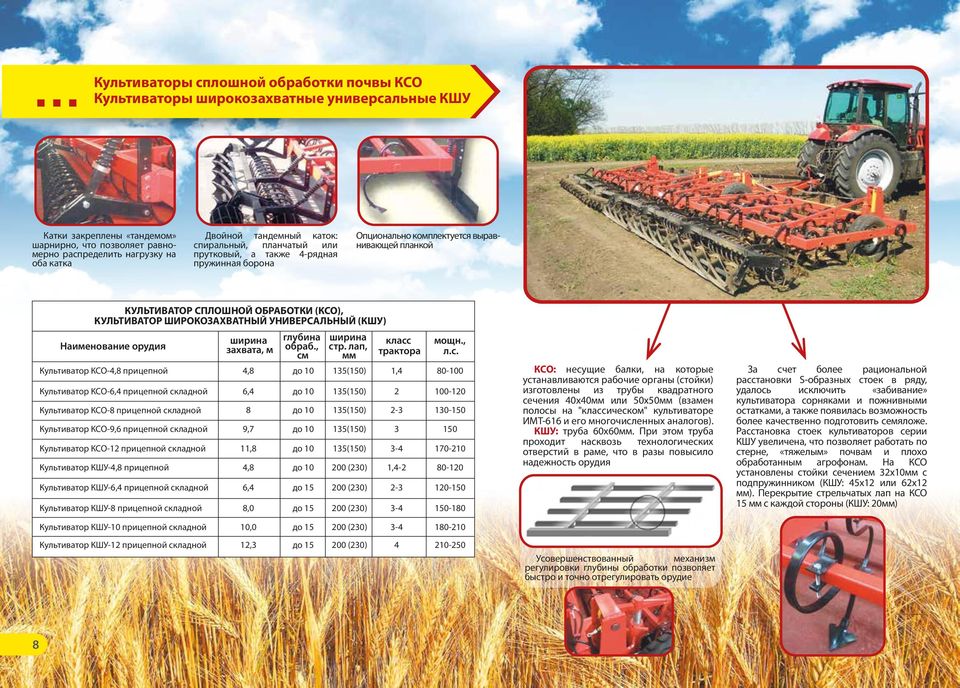

Cultivator solid for processing Soil KSO-8 is used for steam and pre-sowing soil cultivation. At the customer's choice, it can be completed with a roller with a leveler, a spring-loaded two-row harrow, or a device for mounting tooth harrows. Due to the four-row arrangement of the working bodies (the minimum distance between adjacent beads is 800mm), this design prevents the cultivator from clogging up with plant residues.

The frame KSO-8 is made of thick-walled shaped pipes, which gives a large margin of safety to the unit. The beams are designed with replaceable polyurethane bushings designed for 1000-1500 hectares of operation. The detachable fastening of the beams' brackets to the frame on stepladders reduces unnecessary welding stresses and allows you to adjust the width of the overlap. Cultivators are painted with high quality acrylic enamels with preliminary priming.

For other purposes, a hiller cultivator is used.

Photo of the cultivator KSO-8

The KSO-8 cultivator is aggregated with tractors with an engine power of 130-150 hp.

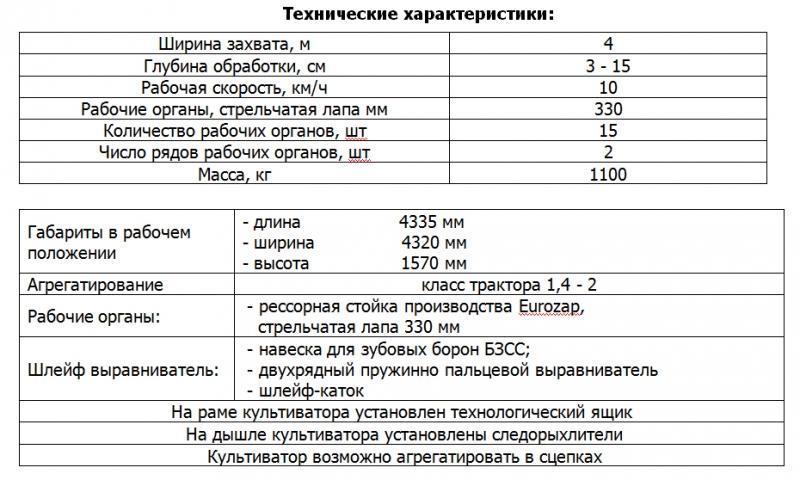

Technical characteristics of KSO cultivator models

| Name | Capture width, m | Number of working bodies, pcs | Depth of processing, cm | Width of paws, cm | Tractor power, h.p. |

| KSO-4.8 trailed | 4,8 | 40 | to 10 | 135 (150) | 80-100 |

| KSO-6.4 prits. folding | 6,4 | 54 | 100-120 | ||

| KSO-8 prits. folding | 8,0 | 67 | 130-150 | ||

| KSO-9.6 prits. folding | 9,7 | 81 | 150-170 | ||

| KSO-12 prits. folding | 12,3 | 98 | 170-210 |

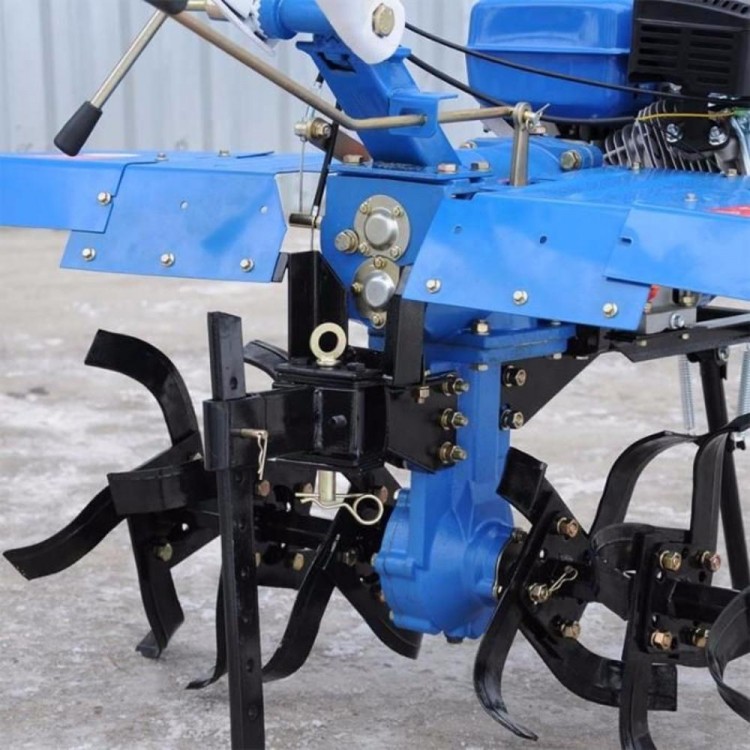

Petrol cultivator

If you look at the photo of cultivators for a summer residence, you can see certain outlines that are characteristic of all such devices. The main stationary part is the frame on which the entire structure is supported. On the top of it there are handles and controls. On the reverse side, the unit itself is located directly.

The gasoline cultivator for summer cottages has its own unique features. Firstly, the device of the unit itself. Thanks to their power, they are great for large plots of land.

In addition to power, among the advantages I would like to note the autonomy, thanks to which you can process even the most remote areas from home. Autonomy is manifested in the fact that, working on fuel, it does not need other sources of energy.

The engine of such a cultivator may differ. The two-stroke engine runs on a mixture of oil and gasoline. At the same time, the four-stroke will only run on pure gasoline. The second option is considered more innovative and modern, since the cultivator runs much quieter with such an engine.

The lineup

Today the market is represented by a huge selection of pre-sowing equipment, while Russian-made cultivators are very popular among farmers. They are of high quality, reasonable price and long service life.

Reliable modifications include the KBM-7.2P cultivator. The type of this device is trailed, the maximum operating speed is up to 10 km / h, the transport speed is 20 km / h. It is designed for fallow treatment, weed cutting and is ideal for all types of land, regardless of the climatic zone where the plots are located.

In addition, the manufacturer has provided in such a cultivator the possibility of changing the depth of soil cultivation and changing the angle of inclination of the screen, which greatly simplifies the work.

The main element in the design is the roller, it is used for crumbling the dry layer and consists of two parts: a front with a diameter of 27 cm and a rear with a diameter of 21 cm.The parts are interconnected by spring levers, due to the fact that the elements have different diameters, they rotate at different speeds and crumbles the topsoil well.

The hydraulic system of the device is represented by four couplings, hydraulic cylinders and high pressure hoses.

On sale you can also find pre-sowing cultivators KBM-6, they are analogues of the previous model and differ little from it in terms of technical characteristics. Such devices are most often used for soil cultivation, the moisture content of which does not exceed 28%. Their ground clearance is 30 cm and the maximum transport speed does not exceed 20 km / h.

Kompaktomat K1250 PS is characterized by a more compact design, in addition, the design has been improved. It provides both heavy and medium rollers of slatted, tubular and gear type. Due to the fact that the leveling bar is controlled by the hydraulic system from the tractor cab, it is possible to level even large irregularities, including chill.

The cultivator tines are spring-loaded, they are placed in four rows and can be mounted on paws up to 17 cm wide.

The presowing cultivator KBM-8PS has a wide-coverage roller (8 m), capable of deepening into the ground by 8 cm, the stand of the structure is low (40 cm), it is placed in three rows. The width of the paws is 15 cm, the working speed of the device reaches 12 km / h, its productivity is 9 ha / h. This model was developed by the engineers of the Russian Academy and has successfully proven itself for its reliability and long service life.

The cultivator qualitatively prepares the soil for sowing crops such as mine, rapeseed, beets, corn and sunflowers, providing good loosening.

Description

Designed for pre-sowing treatment of all types of soils on the background of cultivation and plowing, with the filling of breakup furrows. The KSO cultivator performs high-quality weed control in one pass, surface (up to 8 cm) loosening, leveling, mulching and packing of the soil (adjustable compaction of the upper soil layer) with the creation of a compacted bed for seeds in the sowing layer, provides resource-saving complex soil cultivation.

In the system of basic tillage according to traditional technology, it is intended for leveling plow-fields, pre-sowing cultivation, and care for fallows. In the system of minimum basic tillage, it is intended for pre-sowing cultivation, as well as for leveling the field micro-relief.

The KSO series cultivator is used in various agro-climatic zones, on all types of soils, including those prone to wind and water erosion, except for stony ones:

KSO cultivators are equipped as standard with a double tandem roller (spiral, slatted, or bar). A single roller, a leveling bar and a 4-row spring harrow are optionally available.

Slatted and slatted spiral rollers are designed so that the bar enters the ground close to the vertical, and comes out almost flat. As a result, it digs well, cuts ridges and levels the surface of the field after the passage of the implement.

In the case of work on loose soil, for example, cutting plowing, when the rollers fail and become clogged with earth. Then the rollers must be turned 180 °. Then the bar will lie flat on the ground and come out vertically. This increases the contact surface of the roller, and the roller itself will grip less soil and become less clogged.

The main advantages of the KSO series cultivators:

- The bearing beams, on which the working bodies (racks) are installed, of the KSO series cultivators are made of a square tube 40x40 mm or 50x50 mm (instead of the strip on the “classic” IMT-616 cultivator and its numerous analogues).At the same time, the pipe passes through the technological holes in the frame, which significantly increased the reliability of the tool.

- Due to a more rational arrangement of S-shaped racks in a row, it was possible to exclude "clogging" of the cultivator with weeds and crop residues, as well as an opportunity to better prepare the seedbed.

- Weed control is flawless. On the cultivators of the KSO series, an S-shaped rack with a section of 32x10 mm (with a spring) or 32x12 mm (without a spring) is installed. The overlap of the duckfoots is 15 mm on each side.

- The rollers are not rigidly fixed in tandem, but hinged, which allows to evenly distribute the load on both rollers.

- The advanced depth adjustment mechanism allows quick and accurate tool adjustments.

- Intermediate metal tubes are excluded from the hydraulic system, the number of connections and hydraulic cylinders is reduced.

- The width and height of KSO-9.6 in the transport position are, respectively, 3350 mm and 4370 mm, which allows it to be transported on public roads without additional permits.

Device and characteristics

Modern products are made up of several important parts. First, the power unit (an electric motor or an internal combustion engine running on gasoline or diesel fuel). Secondly, each of them has a transmission and chassis.

In addition, each model has handles located at the back. They contain buttons and levers that are controlled.

All types are usually divided by power into light, medium and heavy. Since it is this criterion that plays a key role in the choice, let us dwell in more detail on the characteristics of each species.

Light technique

Light types can be called a budget option. The weight of such a unit rarely exceeds 30 kg, and the power is about 1.5-3.5 horsepower. They are great for processing small areas (no more than 15 acres), but their capacity will not be enough to work on large areas (Figure 2).

Lightweight technology has several important advantages:

- Low price: such units are notable for their low power, and their cost, respectively, is the lowest among the available range.

- Mobility: it is easy to transport such an aggregate, as it is light and compact. If necessary, it can be easily placed in the trunk of a regular passenger car.

- Ease of use: in addition to reduced weight, such equipment allows for soil cultivation in hard-to-reach places that simply cannot be captured by more powerful and large units.

Figure 2. Light models

Figure 2. Light models

When choosing light equipment, be sure to take into account the type of soil on the site. Products with the lowest power are ways to loosen the soil to a depth of no more than 10 cm, so they can only be used in areas where the soil has already been cultivated. For the processing of virgin lands or garden work, you can pick up light models, with a capacity of about 3-4 horsepower. Their weight is usually up to 30 kg, but they offer the same advantages as the less powerful models.

Medium-weight models

This group is considered the most optimal for gardening and horticultural work. The weight of such units is about 40-65 kg, and the power can reach 5.5 horsepower. Moreover, such a technique has several gears (2 forward and 1 reverse), while in the lungs there is only one forward gear. The grip width in the lungs reaches 85 cm, and the soil can be loosened to a depth of 35 cm (Figure 3).

Figure 3. Weight average models

Figure 3. Weight average models

Such characteristics make it possible to use them for various soils and rather large areas. In addition, they have sufficient weight and power to install additional equipment.

Heavy duty garden cultivators

Models of this type are often compared with walk-behind tractors, although certain differences still exist. The power of such equipment exceeds 5.5 horsepower, and the weight is more than 70 kg. They are suitable for processing large areas, including virgin lands. At the same time, the soil is loosened to a depth of more than 20 cm, and the working width, depending on the cutter used, is more than 60 cm (Figure 4).

Figure 4. Heavy agricultural machinery

Figure 4. Heavy agricultural machinery

In addition, these models are great for installing additional attachments. The only drawback is the high cost, but if you need to regularly process large areas, you should not save on the purchase, since such a unit can greatly facilitate work in the garden.

Classification

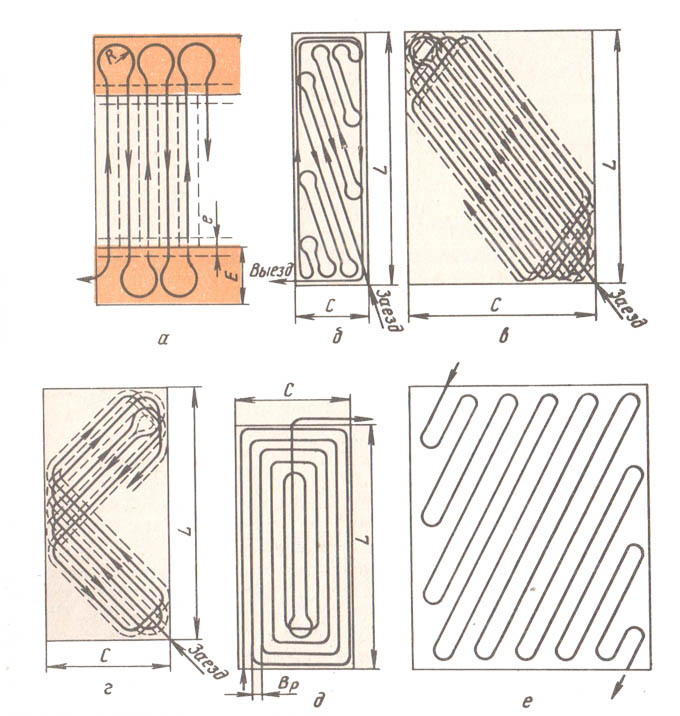

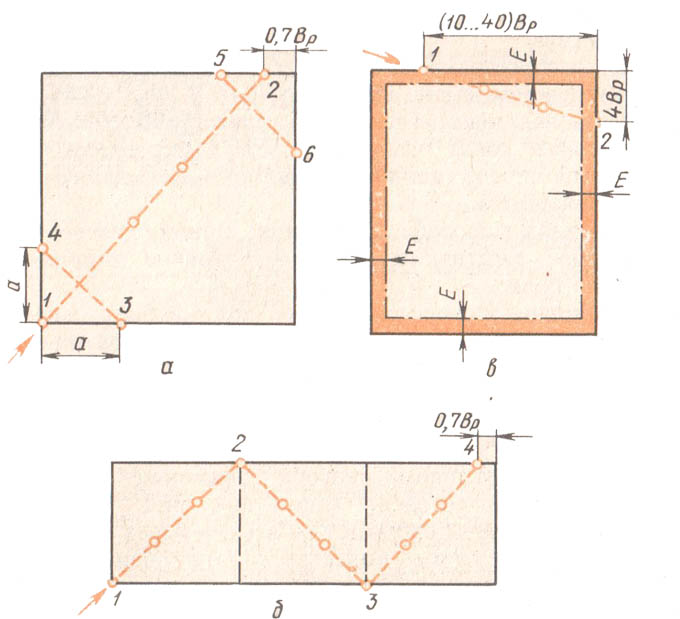

If we classify such a technique according to the type of traction, cultivators for continuous processing can be:

- trailed;

- hinged.

The immersion depth can be adjusted, the main task of such units is to destroy weeds before sowing, so the cutters do not sink deeply. Trailed cultivators are easy to use and maintain. The levers are quickly switched by the operator, during operation the equipment is easily aligned longitudinally and transversely. Thanks to the presence of a rigid hitch, the attachment is lifted together with the control system. The working bodies are practically not clogged with plant residues. Mounted cultivators are used when incomplete crushing of solid soil fragments is required. After processing with them, moisture remains in the ground for a long time.