Maintenance and repair

Before starting work, the equipment is installed on a flat area with dense ground to adjust the working elements. Wooden or metal bars with a height of 20-30 mm less than the estimated depth of processing are laid under the wheels. The difference simulates the immersion of the rollers in the soil while driving. It is not allowed to use spacer elements of different heights under the wheels of the left and right sides. A 350 mm thick timber is placed under the stand with the addition of the depth of tillage and subtraction of the value of the wheels' sinking into the ground.

Then the position of the frame is adjusted with screw mechanisms. It is considered correct to evenly place the tips of the supports of long beams on the liners, while the support platforms of the paws are placed on the main plate. Then the position of the shortened and one-sided beads is corrected, the working axis is repositioned to change the position.

Maintenance consists in regular cleaning of the unit from adhering dirt that corrodes steel elements. Rusty parts of the frame are brushed to metal, primed and painted. The bent working bodies are straightened; if it is impossible to return to the original configuration, it is recommended to replace the units. The hydraulic lines are visually inspected; if a leak occurs, the hoses or O-rings must be replaced. Contamination of the cylinder rods is not allowed, leading to damage to the oil seals.

If bends or tears in the welded seams are detected on the frame, the cultivator operation is terminated. It is recommended to carry out refurbishment in a specialized center equipped with measuring equipment. In case of unqualified restoration, distortions of parts and poor quality welding are possible, which will be destroyed when a standard force is applied.

Device and functioning features

- The KPS 4 cultivator is actively used to care for soil of different composition in order to prepare it for sowing winter crops. In this case, the summer resident will not be able to carry out deep cultivation of the soil. It is worth noting that the KPS cultivator can be installed on tractors of traction class 1.4. If we talk about the technical characteristics of the KPS 4, it is worth noting that it is equipped with mechanisms for installing 4 medium tooth harrows or with one spring. The operating instructions for this KPS model are simple and will be understandable even to an inexperienced summer resident. According to reviews, this model is highly functional. The product of this model is an indispensable tool for a summer resident who seeks to ensure the safety of soil moisture reserves. The structure consists of the following units:

welded frame;

- snitch, which is assembled from 3 bars;

- support pneumatic wheels;

- walked with paws;

- a mechanism for mounting harrows with a leash, which is made in the form of a structure of 4 rods with rods, leads and 4 stretch marks;

- hydraulic cylinder 10, which is designed to transfer mechanisms from one position to another;

- According to the manufacturer's instructions, the KPS 5 cultivator is intended for continuous pre-sowing and steam cultivation of soils with simultaneous harrowing. The design of the device is simple and convenient, which is confirmed by the reviews of summer residents. It can be installed on tractors of drawbar category 2.0. The model is equipped with:

- a mechanism for mounting tooth harrows;

- with a reinforced type, which reduces the likelihood of breaking the hitch to almost zero;

- wheels with pneumatic tires, which guarantees a smooth running of the device and completely eliminates the adhesion of soil.

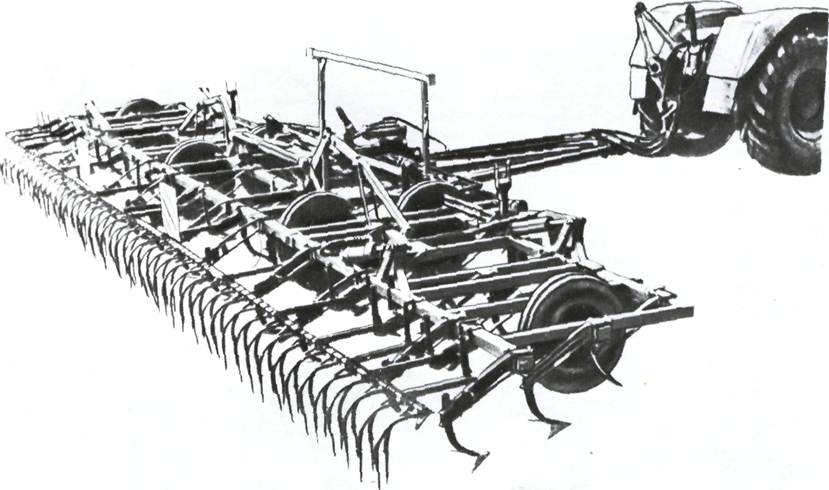

- The KPS 8 cultivator is shown in the following photo. It can be used for general pre-sowing cultivation of soil and steam care with simultaneous harrowing, which is confirmed by the instructions for use from the manufacturer. The model is equipped with a structure for a harrow canopy of tooth and spring type. Reviews of experienced summer residents indicate that thanks to the use of such a cultivator, it is possible to perform high-quality loosening of the soil to the required depth (within 5 - 12 cm). Such a KPS cultivator helps to cope with the phenomenon hated by every summer resident - weeds. It can be installed on a tractor that belongs to traction class 3.

Popular manufacturer models

The manufactured KPS cultivators have technical characteristics that allow the use of wheeled tractors such as MTZ-80/82 or K-150, as well as tracked vehicles DT-75 or T-150, as tractors.

Depending on the modification, the width of the working area changes (the value in meters is indicated in the model index).

KPS-4

The KPS-4 installation provides processing of a strip 3.9 m wide, adjustable teeth crush the soil to a depth of 120 mm. For towing the unit, it is recommended to use a wheeled traction class tractor 1.4-2.0 t. The frame design allows the connection of 2 machines into a single unit with an increased working area. The rigidity of the structure allows you to work in the field at a speed of up to 12 km / h. The set of the KPS-4G cultivator includes tooth harrows of the BZSS-1 type and devices for hinging working elements, as well as loosening or lancet paws.

KPS-5

The KPS-5 cultivator is distinguished by the use of wheels located closer to the axis of symmetry. For the manufacture of the frame, a rectangular pipe was used, reinforcements made of sheet steel are provided. Additionally, the hinges of the beam attachment are reinforced and metal strips with an increased profile cross-section are used. For towing, a tractor with a pulling force of 2 t is used, equipped with a hydraulic system with an outlet to the rear of the body and a spool valve.

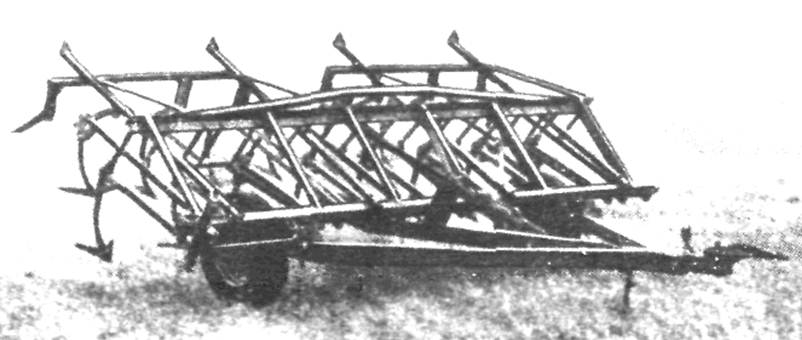

KPS-6

The KPS-6 cultivator is built on the basis of a metal frame with side wheels equipped with a position adjustment mechanism. The soil is cultivated with a harrow and an additional pipe leveling the soil layer. Additionally, a device is installed for peeling the remains of the stems of cereal plants after harvesting. A modification with a reinforced structure is available on request, allowing the processing of solid or virgin soils (version U).

Hydraulic cylinders are installed on the frame, hoses with quick-release couplings are brought to the towing device. The working area is 6 m; to tow the unit, a wheeled or tracked tractor equipped with a diesel engine with a power of at least 120 hp is required. The design of the agricultural machine allows a working speed in the range of 8-14 km / h, during transportation it is possible to accelerate the coupling up to 20-25 km / h.

KPS-8

The equipment is equipped with a frame assembled from longitudinal and transverse ties. For the manufacture of the structure, a steel pipe was used, the parts are connected by arc welding with additional kerchiefs (to increase rigidity). An adjustable harrow with a spring suspension is used for soil cultivation; the wheels are placed on the side edges of the unit. For leveling the soil surface, a roller made of steel pipe is provided.

The trailed cultivator KPS-8 has a working width of 8 m, the working depth is varied by a screw mechanism in the range of 20-100 mm. To improve the quality of processing, the working bodies are overlapped by 50 mm. The unit has a curb weight of 2800 kg; towing requires a wheeled tractor equipped with a 160 hp power unit. and higher.

KPS-9

The KPS-9 cultivator is designed for soil cultivation before sowing crops. The design of the equipment includes a central section and folding side elements that expand the working area. On the central part there are 2 wheels with pneumatic tires, the side elements are equipped with additional wheels. The design uses racks with overlapping working areas, which provides improved soil cultivation and excludes clogging of working elements with plant material.

The equipment is equipped with blocks of teeth mounted on a spring platform with the ability to change the angle of installation. The use of springs allows the rig to follow the terrain as it moves. To adjust the working depth, a worm gear with a control dial is used. The installation provides processing of a strip with a width of 9 m; towing requires a tractor with a pulling force of 3 tons.

Models

The KPS-4 cultivator is used before sowing. With the help of the device, a multilayer loosening of the soil is carried out, weeds are destroyed, fertilizers are applied and harrowing is carried out at a speed of up to 12 kilometers per hour. This cultivator can be both mounted and trailed. It is worth mentioning that KPS-4 can be equipped with additional harrows.

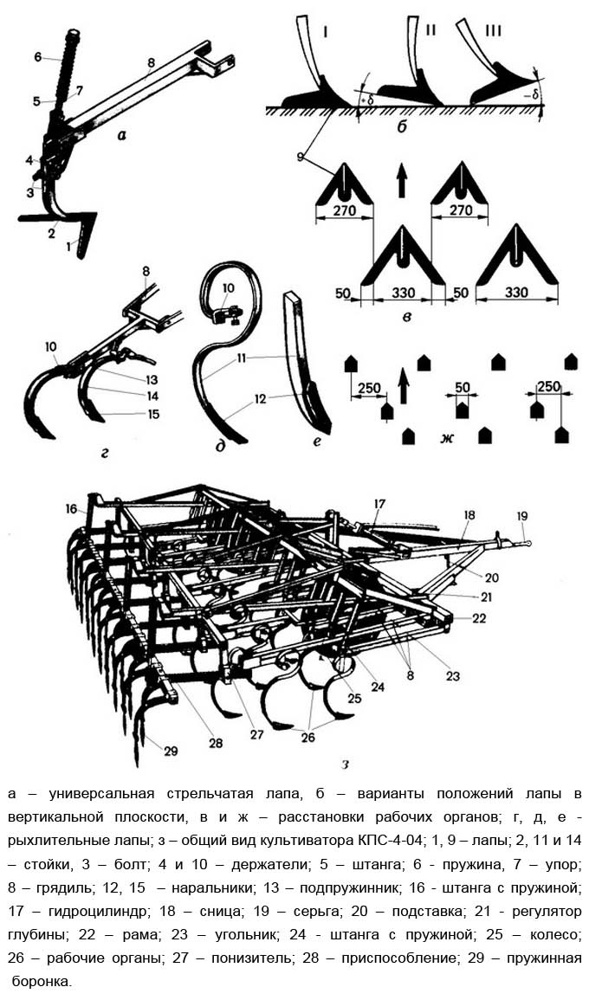

The soil is cultivated with the help of lancet-type tines, loosening tines and spring tines for loosening. The former are able to cover the width of the site, equal to either 27 or 33 centimeters. Rigid shank loosening tines handle widths from 35 to 65 millimeters. Finally, the spring arms have a grip width of 5 millimeters. For the paws, special beams are equipped, connected by hinges to the cultivator frame.

In this case, the lancet paws are distributed in two rows in a checkerboard pattern - 27 cm in the first row, and 33 cm in the second row, on a long auxiliary beam. In the case when the soil is cultivated at a depth of up to 25 centimeters, loosening paws are used, and at a depth of 16 centimeters - spring loosening paws. In this case, short beams are equipped with one loosening paw, and long ones - with two.

The cultivator "KPS-8" is used for cultivating the soil before sowing, and for caring for pairs, accompanied by harrowing. The design allows the use of both tooth and spring harrows. The depth to which the soil can be cultivated varies from 5 to 12 centimeters. "KPS-8" also allows you to get rid of weeds.

The "KPS-6" cultivator is used to cultivate any soil. In this case, harrowing can occur only with stony debris not exceeding 60 millimeters. This device is quite simple to operate. It has a reinforced snare that prevents breakage, as well as the ability to hang tine harrows. The cultivator's wheels are equipped with pneumatic tires, thanks to which the attachment moves smoothly, which means that the soil is processed evenly. "KPS-6" is often used for early spring treatments.

Presowing stubble "KPS-12" allows you to cultivate seams of land up to 9 meters wide to a depth of 15 centimeters

It is important to mention that the impact on the soil also occurs on the stubble. The cultivator has four rows of tines on which the paws are located with a width corresponding to 280 millimeters

Thanks to this design, plant fragments will not clog parts, and therefore disrupt the work of the cultivator. By the way, there is also a screw roller, the diameter of which corresponds to 350 millimeters. However, this function is optional, and "KPS-12" functions perfectly well without it. The depth of tillage is regulated by means of a special handle, which is equipped with a special scale.

For information on how to prepare a high-speed steam cultivator (KPS) for work, see the next video.

Compliance of "KPS-4" with agrotechnical requirements

Presowing soil cultivation is carried out to the depth of seeding. If the work is carried out on a cultivated field, not littered, with a sufficient degree of cultivation, this depth is quite enough. It is undesirable to exceed the depth of soil cultivation. Since the working bodies of the cultivator should not throw the lower, wet layer of soil onto the surface of the earth.

But in those cases when it is necessary to cultivate highly compacted land, clogged with the remnants of foreign vegetation, the depth of soil cultivation increases - rippers with spring tines are used. In full compliance with agrotechnical requirements, the "KPS-4" cultivator provides an even cultivation of the surface layer of the soil, with an uneven cultivation depth not exceeding one centimeter. After the work, the upper layers of the soil acquire a fine-lumpy structure, all weeds and their roots in the cultivator's area of operation are completely cut and crushed.

After cultivation, the bottom of the furrows of the field turns out to be even, with the height of the ridges of the loosened layer not exceeding 3-4 centimeters. Therefore, cultivation is often carried out with simultaneous harrowing.

An important point: continuous cultivation on "KPS-4" should be carried out across the previous direction of cultivation, or, in any case, at an angle to it. It is also necessary to observe the optimal speed to ensure leveling of the surface: 9-12 km / h. An even surface of the field is the key to the best conditions for the future operation of the seeding units.

The actual parameters of the quality of pre-sowing cultivation can be determined, first of all, by a normal visual inspection. After a tractor with a "KPS-4" cultivator passes the field, the soil surface should become uniform, especially in places where there were fall ridges and split furrows.

It is also important to take into account the timeliness of the land cultivation carried out, which is assessed by comparing the actual period of work with the period established in the agrotechnical plan (adjusted for current weather conditions). Other indicators of the quality of pre-sowing cultivation are also processing depth, ridging, completeness of cutting weeds, absence of blemishes.

The depth of processing is determined in 10-15 places along the diagonal of the site,across the entire working width cultivator, by measuring the depth of cultivation with a ruler with graduations. The ruler is inserted into the treated layer up to the sole. The ridge index can be measured with a profiler, also in 10-15 places along the diagonal of the area processed by the cultivator.

Specifications

A steam cultivator, as a rule, is trailed, for example, the KPS-10 and KPS-8 models, by the example of which you can consider the main technical characteristics. The working depth in all cases varies from two to 10 centimeters, and the working speed ranges from 8 to 14 kilometers per hour. The same parameters are such as the step of the footprint - 15 centimeters, the overlap of the working bodies equal to 50 millimeters, the height of the rack, reaching 650 millimeters, as well as the cross-section of the rack corresponding to 60 by 12 millimeters. The weight of the KPS-10 is 3600 kilograms, and the weight of the KPS-8 corresponds to 2800 kilograms.

The KPS-10 capture width reaches 10 meters, and the KPS-8 capture width corresponds to 8 meters. The productivity of the first unit ranges from 8 to 14 hectares per hour, and the productivity of the second - from 6.4 to 11 hectares per hour. The number of KPS-10 paws is 68, and the number of KPS-8 paws corresponds to 54 pieces. The power of the tractor working with the first cultivator should be equal to 147.1 kilowatts, and with the second cultivator a little less - 117.7 kilowatts. The frame, by the way, is foldable for both models, and the number of rows of paws is four.

Mounted cultivator KMN 8.4

Check out these articles as well

-

Mini tractor Scout T-15

-

Motor-cultivator Tarpan-03

-

Harvester Don 1500

-

Fungicide Topaz

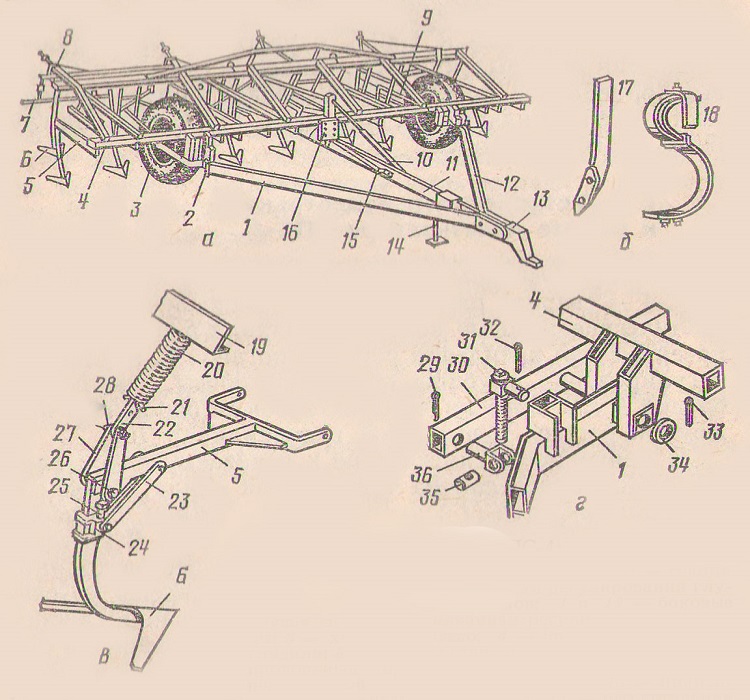

Cultivators are designed for complete soil preparation for sowing in one pass, combining cultivation, harrowing and pre-sowing packing after plowing. Modular mounted cultivators KMN-8-3, KMN-8-4 meet the requirements of technical conditions and a set of documentation in accordance with GOST 1114-84 (cultivators row-crop)

Photo of the cultivator KMN 8.4

The advantages of these cultivators are in lowering energy costs by 2-2.5 times, compared to the existing system of soil preparation for sowing, the possibility of cultivation to a depth of 3 to 10 cm, 100% leveling of the soil, maximum moisture retention in the subsurface rolled soil, combing weeds.

Technical features of the modular KMN-8-4

-

- Reduction of energy consumption by 2 - 2.5 times in comparison with the existing technology of soil preparation for sowing (due to the complete preparation of the soil for sowing in one pass and a large working width).

- Possibility of cultivation to a depth of 12 centimeters (the depth of soil cultivation is adjustable).

- Achieved 100% leveling of the soil.

- Maximum moisture retention occurs in the subsurface compacted soil layer.

- Achieved by combing out weeds due to the constant vibration of the working bodies.

- Cultivators are designed for complete soil preparation for sowing in 1 pass, combining cultivation, harrowing and pre-sowing packing.

Technical characteristics of KMN-8-4

| Productivity, ha / h |

8 |

| Capture width, m |

8 |

| Weight, kg |

1900 |

| Tractor, traction class |

3 |

| Depth of processing, cm |

from 3 to 10 |

| Working speed, km / h |

up to 12 |

| Transport speed, km / h |

up to 15 |

|

Overall dimensions, mm |

8020x2220x1440 |

Working principle and service

Before using the cultivator, it must be set up and adjusted. If this is not its primary operation, then you will have to clean the device from dirt and organic fragments. Next, the presence of mandatory parts and their condition is checked, as well as the fact whether something needs to be strengthened or tightened, for example, the oil seals on the hub. If necessary, defective parts are replaced with new ones, for which it is always worth having spare parts in stock. The flat wheels are inflated and the bearings are additionally lubricated.

The cultivator must be adjusted on a leveled area. During this process, a lining should be placed under the wheels, which will be less than the immersion depth by 2 or 3 centimeters, which disappeared due to the lowering of the wheels

It is important to maintain the same height of both wheels for accurate adjustment and further operation. A pad is also placed under the stand, the thickness of which corresponds to 350 millimeters, to which is added the parameter used for the pad under the wheels

At the next stage, the working units are adjusted to the required stroke depth. At this time, the moving device is prepared, after which both components are combined.

The very process of operation of the KPS steam cultivator is as follows: a moving device with an attached cultivator drives into the treated area. The frame is lowered in such a way that the tines penetrate into the soil to the required depth. During this process, the stalks and roots of the weeds are trimmed with the sharp parts of the paws.

The lumps that were on the surface move up the legs, and then break up into small fragments at the moment they fall down. Thus, a uniform layer of earth is formed on the surface. Sometimes, in order to crush the soil more intensively, the general scheme is supplemented by the action of tooth harrows placed on the cultivator. By the way, the size of how deeply the legs sink can be changed using the support wheels. When the latter rise, the impact increases inward, and when they fall, it decreases. Whether or not the processing takes place uniformly can be determined by interacting with the spring on the rod.Squeezing it increases the depth of the stroke, and relaxation, accordingly, decreases it.

It is important to mention that the cultivation itself is first performed across the main cultivation and then perpendicular to the previous run. The device usually moves in a shuttle motion

After finishing the processing of the main passes, it is necessary to pay attention and process the turning zones of the site

Basic adjustments of the KPS-4 cultivator

⇐ Previous123

The KPS-4 cultivator is designed for pre-sowing soil cultivation and fallow processing with simultaneous harrowing. When completing the cultivator, tooth harrows BZSS-1.0 are used.

When processing lightly clogged fields, set on the front row of winged paws with a grip of 270 mm, on the back - 330 mm (Figure 4.1). For the processing of heavily clogged fields, lancet paws with a grip of 330 mm are used. To comb out the roots of the scion weeds, single holders of spring struts are installed on the beams of the front row, and double holders on the beams of the rear row.

The cultivator is adjusted on a level surface. A lining is installed under the wheels of the cultivator 2-3 cm less than the depth of processing (immersion of the wheels in the soil). Both wheels are set in the same height in height, otherwise the working depth will be different across the cultivator width. A 350 mm thick lining plus the working depth reduced by the immersion depth of the wheels in the soil is also installed under the trailer stand. After that, with the screw of the adjustment mechanism, set such a position of the frame so that the heads of the rods of the long beams rest on the liners, and the soles of the paws lie on the base plate. After the installation of long beams, short and one-sided ones are exposed. This is achieved by shifting the axis along the adjusting holes of the rod.

When working on light soils or loosening to a depth of 6-8 cm, the paws of the cultivators are set so that they adjoin the entire cutting edge to the surface of a flat platform. For work on heavy soils, the tines should be inclined with the toes forward by 2-3 °.

Drawing. 4.1 - Arrangement of beams and lancet paws KPS-4.Completing and adjusting the unit when working with a KPE-3.8 cultivator

The KPE-3,8 cultivator is designed for pre-sowing and main soil cultivation, leaving stubble on its surface in order to combat wind erosion. The unit of 1 cultivator is completed with the MTZ-80 and MTZ-82 tractors, out of 2 with the T-150 and T-150K, out of 4 with the K-701. With wide-cut aggregates (KPE-3.8 and K-701), use the hydraulic coupler SP-16 or SP-20.

After completing the unit, technical control of the cultivator is carried out; the technical condition of units, parts and working bodies is checked in the same way as for KPS-4.

Adjustment and adjustment of KPI-3.8 is carried out on a level surface. The cultivator working depth is regulated by moving the adjusting stop on the remote hydraulic cylinder rod. The hydraulic distributor lever is set to the floating position.

Setting up the KPS-4 cultivator

To set up the KPS-4.2 cultivator, as well as the KPS-4 cultivator, it is installed on a flat, preferably firm ground. The tractor and the structure are raised above the ground by 2-4 cm less than the required depth of penetration of the paws.

- the universal paws touched the platform with the entire surface of the cutting edges;

- loosening elements rested on the ground with a tip.

At the same time, the steam distributor of the traction equipment is set to neutral. In this case, it is necessary to ensure that the stand of the KPS-4 cultivator, the push rods rest their heads against the liners.

In cases where this does not happen, it is necessary, by rearranging the rods closer to the leashes of the working elements and removing the adjusting pads, to achieve the specified position. After that, the angle of inclination of the cutting edges is determined. If the soil is soft, no adjustment is required. For the processing of heavy soils, the paws are tilted by adjusting screws 2-3o forward.

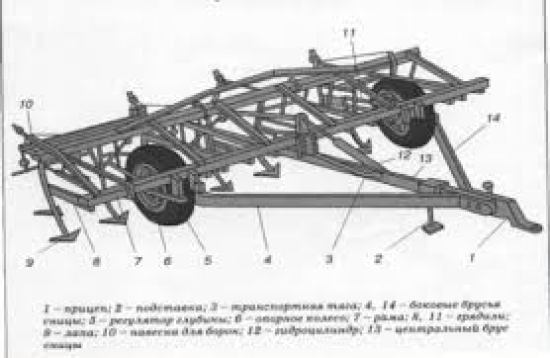

Diagram and device of the cultivator KPS-4

Below we provide a diagram of the KPS-4 cultivator

The steam high-speed cultivator KPS-4 is used for multilayer loosening of the soil before the start of sowing work and the destruction of various types of weeds, while harrowing occurs at a speed of up to 12 km / h. This model is available in two versions, trailed and mounted, additionally there is a device for attaching additional harrows. The working bodies of the cultivator are universal lancet-type paws, they have a working width of 27 cm or 33 cm, the second element is loosening shares based on a rigid stand, the working width is from 35 to 65 mm, the last element is spring loosening shares with a working width of 5 cm.

The tines of the paws are mounted on special beetles, which are hinged to the cultivator frame. Universal lancet paws are located in two rows of a checkerboard pattern. Paws 27 cm wide are attached in the front row of the bed, and in the secondary row 33 cm wide paws are attached to a long bed.

With the T-150 and T-150K tractors, two or three cultivators are aggregated with the SP-11 hitch or the central section of the SP-16 hitch, and with the K-701 - four with the SP-16 hitch. Cultivators in row units are connected to each other by hinges, which creates stability of the course and good copying of the relief in the vertical-transverse plane.

When preparing the unit for operation, the tractor's hitch mechanism is set to the uppermost position, and the towing bracket is set to the rear yoke forks. A harness is put on it.

To work with three or four cultivators, it is necessary to unfold the side wings of the special SP-16 hitch and mark the joints on the cultivator bar. The nominal distance between two points of the cultivator's trailer is 4 m. In this case, the cultivators must be positioned so that their trailers are located on the same line, and the distance between the ends of the front beams of their frames is 80 ... 100 mm. The bars of the cultivator frames are connected to each other by hinges.

Cultivator trailers are connected to the hitch, remote hydraulic cylinders are installed on the cultivators and connected to the tractor hydraulic system.

Technical characteristics of the cultivator

Below is a table with the technical characteristics of KPS-4 cultivators of various modifications

| Indicators | KPS-4 | KPS-4-01 | KPS-4-02 | KPS-4-03 | KPS-4-04 | KPS-4-05 |

| Type of | Trailed | Hinged | Trailed | Hinged | ||

| Capture width, cm | 400 | 390 | 400 | 390 | 390 | |

| Tillage depth, | from 5 to 12 cm. | |||||

| Working speed, km / h | up to 12 | to 10 | up to 12 | to 10 | up to 12 | up to 12 |

| Productivity per hour of main time: | ||||||

| unit from one machine | 2.9-3.5 ha | 3.36 ha | 4.45 ha | |||

| unit of two machines | 6.33-6.54 ha | — | — | — | — | |

| Cultivator weight of this model, kg | 820 | 890 | 690 | 760 | 927 | 785 |

| Support wheel tire dimensions, inches | 6,00-16 | |||||

| Excessive air pressure in tires, MPa | 0,19-0,24 | |||||

| Axial clearance in bearings of support wheels, mm | 0,10-0,35 |

How to prepare the attachment for work?

Before starting sowing, it is necessary to prepare the cultivator for work in the summer cottage. To do this, the summer resident needs to check him for malfunctions of a various nature. Experts claim, and practice confirms that the timely elimination of minor breakdowns will prevent the need for overhaul of the models. And this significantly increases the service life of equipment of this nature.

Next, you should perform the following sequence of actions:

- install the working units of the KPS unit to the required stroke depth;

- prepare the tractor;

- connect the tractor with the purchased cultivator for the cultivation of a summer cottage. Now a walk-behind tractor with attachments can be used for cultivating a summer cottage.

Let's sum up

Cultivators KPS 2, 4 and other models, with the help of which it is possible to carry out continuous cultivation of the soil, greatly simplify the process of cultivating the land before the start of sowing.Due to the availability of KPS models that are different in their characteristics and purpose, each summer resident will be able to choose the best option for such equipment. The video in this article will tell you about the features of using KPS cultivators at a summer cottage for the purpose of cultivating the land.

Scope and main functions of "KPS-4"

"KPS-4" loosens and swells the surface layers of the soil; effectively destroys weeds and their roots. With the installation of the appropriate additional equipment, the cultivator can also work not only as a steam unit, but also as a tilled unit, that is, it can perform inter-row cultivation of fields, without harming the cultivated plants. And it is also capable of working the soil while feeding it, applying fertilizers.

Continuous cultivation of "KPS-4" loosens the surface layers of the soil to a depth of 5 to 12 centimeters, bringing them to the state of small clods, destroys the shoots and roots of weeds; evens out the overall surface of the field. Loosening improves air and moisture permeability of the soil, promotes high-quality nutrition of cultivated plants with water and oxygen, and prevents rapid evaporation of water.

With continuous cultivation, weeds are eliminated and, for a sufficiently significant period, their new appearance is prevented. The surface layer of the soil after cultivating with a cultivator receives a structure most favorable for the accumulation and preservation of moisture and nutrients in forms available for assimilation by cultivated plants.