Advantages and disadvantages of Tarpan cultivators

Since Tarpan motor-cultivators are assembled at an enterprise related to the defense industry, the plant's products are distinguished by high quality and assembly reliability. The first models began to be assembled in the early 90s, when a production crisis forced the company to look for alternative directions of development. Lack of experience left its mark on the first cultivators - they could not compete with the products of foreign manufacturers. However, after the introduction of new technologies and the conclusion of contracts with leading manufacturers of engines for agricultural machinery, Tulamashzavod managed to arrange the assembly of equipment that meets the most stringent technical requirements and standards.

The competitive advantages of modern Tarpan motor-cultivators include:

- Reliable, durable motors from leading manufacturers in the industry;

- High build quality, technical performance;

- Adaptation to domestic operating conditions;

- Unpretentious maintenance, high maintainability;

- A wide selection of attachments allows you to expand the range of work performed.

The disadvantages of the devices include a rather small number of service centers and representative offices of the company, which creates certain difficulties in the process of servicing and repairing equipment. However, this disadvantage is compensated for by the simplicity of the design - if necessary, following the instructions of the user manual, the owner of the cultivator will be able to eliminate most of the faults on his own.

Fuel pump repair

The cultivator motor plays the most important role in the design of the machine. Often it will not start due to a malfunctioning fuel pump.

The pump serves to supply the fuel mixture to the carburetor at a certain point in the cycle. If no fuel is supplied, then the engine will not start. The pump is defective in such cases:

- If the fuel supply to the engine injectors is interrupted;

- In case of fuel leakage as a result of mechanical wear;

- The appearance of strange noises during operation.

To fix the damage, the pump should be disassembled and inspected. It is possible that the engine will not start on the cultivator due to dirt inside the pump. In this case, the device will need to be cleaned and reinstalled.

This cultivator model is designed for cultivating a plot of land that has an area of no more than fifteen acres. The Tarpan cultivator was developed over 25 years ago. At the same time, work on improving the design by the plant during all this time did not stop.

About changing the oil

After the first five hours of operation, most customers change the oil. This information is easy to find in reviews. Otherwise, the engine may jam due to debris trapped inside the engine. It is best to leave it hot while work is in progress.

The waste is drained into a separate container when the motor has been warmed up to a suitable temperature. The equipment is left in one position until the liquid is completely drained. After the plug is tightened, new oil is poured.

The best option is formulations that were originally intended for four-stroke engines. Quality materials reduce friction between individual parts. The resource of the engine is increased, it receives protection from corrosion.

Don't forget about changing the oil

Don't forget about changing the oil

Repair and maintenance of the Tarpan walk-behind tractor

When operating a walk-behind tractor, the farmer must perform periodic maintenance of the unit.

It is as follows:

- After the first start of the machine, it is necessary to change the oil in the gearbox.

- Every day is held:

- cleaning and wiping the walk-behind tractor;

- check for leaks of oil and fuel fluid in all connections;

- control of fasteners, tightening of bolts, nuts;

- checking the oil level in the gearbox;

- check of work, cleaning, repair of the clutch.

- Every 100 hours or once a year:

- oil change in the gearbox;

- lubrication of traction and controls.

In the event of malfunctions of one of the nodes or connections, it is necessary to repair or completely replace it. On Tarpan, spare parts and parts can be bought from dealers of the brand or on free sale in domestic markets.

Various parts and materials can be subject to rapid wear and consumption, including:

- drive belts;

- oil seals;

- rings;

- bushings;

- filters.

During the warranty period, do-it-yourself repairs are prohibited, only the manufacturer should carry out it.

Instructions for using the Tarpan unit provides all the necessary knowledge for working on a motor cultivator.

If additional attachments are attached to the machine, certain skills are required for the operator. For this, the manufacturer has developed special rules and operating instructions for mounted mechanisms. These technical documents are supplied complete with the walk-behind tractor.

Which engines do you prefer: Japanese or American?

User manual

The purchased cultivator must be assembled in accordance with the recommendations set out in the documentation. It is recommended to check the tightening of threaded connections and the oil level in the gearbox and engine crankcases.

The deepening of the soil milling cutters is carried out by applying force to the handles. The installed plowing depth regulator also goes into the ground and creates additional resistance to movement, correcting the speed of movement. If the cutters began to dig into the ground, and the speed dropped to zero, then it is necessary to reduce the deepening of the tool into the soil. For turning, the cultivator tilts to the left or right using the handles.

The documentation contains a list of routine maintenance, the intervals depend on the type of motor installed. For example, the initial oil change in the engine is performed after the unit has been run-in, the duration of which depends on the engine modification. During operation, it is recommended to check the oil level; some engines are equipped with an emergency ignition switch, which is triggered when the volume of liquid decreases.

Malfunctions and their elimination

If it is difficult to start the gasoline engine or interruptions in operation, you should check the operation of the carburetor and the standard speed governor. To carry out DIY repairs, you need to adjust the regulator in accordance with the manufacturer's recommendations and check for the presence of fuel in the tank. Additionally, the condition of the connecting line and the crane is monitored, and then the gap between the spark plug contacts is checked.

Overheating of the power unit indicates an overload on the cultivator or clogged air filter and fins with dirt. To restore performance, you should reduce the depth of loosening or change the filter. If the problem persists, then inspection and cleaning of the outside of the engine from accumulated dirt is required. A common defect, according to the owners, is oil leakage through the joint line of the gearbox housing halves. The defect occurs due to cracks or wear of the gasket or oil seals. Repair consists in purchasing and installing new parts.

Vibration during operation indicates that stones are trapped between the cutter teeth or that the tool is damaged. Stop the engine, inspect the cultivator and replace worn parts. Additionally, it is recommended to check the tightness of the motor fixing bolts.

Maintenance features and operating instructions

Let's take as a basis the operating rules from the instructions for "TMZ-MK 03".

Change the oil in the gearbox

Draining the oil immediately after use makes the procedure easier.

We use oil TAD-17I GOST 23652-79. Replacement with gear oils of class SAE 90, SAE 75W / 90, categories API GL-4, GL-5 with a volume of 0.35 liters is acceptable.

Motor-cultivator ≪Tarpan MK-03-02 WM168FB≫

- Change the oil in the gearbox after the first 5 hours of operation of the cultivator.

- Every 5 hours or daily we check the tightness of the engine parts connection for oil and fuel leaks.

- Change the gearbox oil every 100 hours or annually.

- To check the oil level in the gearbox, it must be drained into a measuring container and added to a volume of 0.35 liters.

- The oil is drained and filled into the gearbox through the same hole, which is closed with a plug.

Replacement of oil seals

During the warranty period, contact the service center or the manufacturer to eliminate the damage.

After the warranty period, the oil seal will be replaced without problems at the service center. But you can do it yourself.

Replacing the oil seal is necessary in case of oil leakage from the gearbox.

The cultivator runs in in the first 12 hours

For self-replacement of the oil seal:

- clean the gearbox and drain the oil;

- turn the gearbox upside down and open the housing;

- mark the position of the shaft with gears in relation to the housing with a marker so that after repair the shaft will fit correctly;

- remove the oil seal with the cover from the shaft;

- carefully remove the gland that is tight in the lid with a blunt screwdriver or similar tool, without damaging the lid;

- put the new oil seal on the cover so that it is in place, put the old one on top of it and tap it with a hammer.

The new one should snap into place until it stops. If there is a gap, it needs to be corrected.

Replace the second oil seal in the same way. Then, lubricate the halves of the reducer with sealant and connect according to the marks made earlier with a marker.

Break-in and start-up of the Tarpan cultivator

The first 12 hours are run-in. Do not use the unit at full capacity during this period. It is better to go through one section several times.

Initially, the clutch lever is free and the gearshift knob is in neutral.

The oil level must be checked before starting the cultivator.

To start the engine:

- move the throttle control lever to the 1/4 stroke position;

- Pull the handle of the cord slowly until you feel resistance;

- Pull the rope quickly to start the engine and release it slowly, without jerking.

If it doesn't work, try again.

Stopping the engine

Release the control lever to turn off the engine. It will return to the idle position by the return spring. Press the lever fully and the engine will stop.

Maintenance features and operating instructions

Operating instructions - the main document of the cultivator, which contains a description of the design, as well as the rules of operation, maintenance, storage and transportation. Compliance with the rules will help the owner increase the service life of the equipment and ensure a safe working environment.

First start-up and running-in

After assembly, the new cultivator undergoes a conservation procedure, which is necessary to protect the mechanisms from the effects of corrosion. Before the first start, the owner must unscrew the spark plug, rinse it with gasoline, and also turn the crankshaft 10-15 turns to remove the conservation grease.

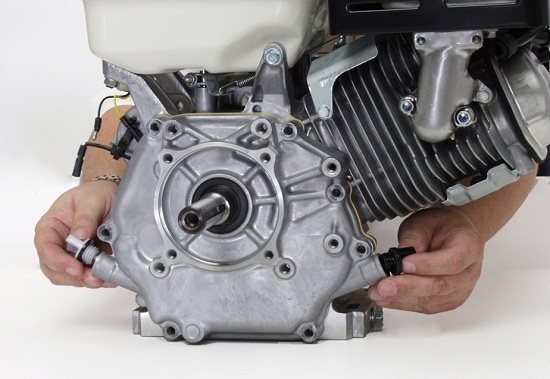

In most cases, engines are supplied without engine oil. Please remember that dry-running failures are not covered by the warranty. The oil must be selected based on the ambient temperature and the recommendations of the engine manufacturer.

During the first 12 hours of operation, the cultivator runs in - running in the friction pairs of all moving units. It is not recommended to use the cultivator at full capacity during the running-in process.

After the break-in is completed, the engine oil must be replaced, which contains shavings and other by-products of the running-in cultivator units.

Change the oil in the gearbox

According to the requirements of the operating manual, after the first 5 hours of operation, it is necessary to change the oil in the gearbox. When selecting a lubricant, it is necessary to be guided by the requirements of the operating manual.

Most gearbox models are designed for API GL-4 or GL-5 oils. The use of the wrong lubricant, for example "TAD-17" or "NIGROL", can quickly damage the gearbox.

Replacement of oil seals

During operation, under the influence of external factors, mechanical damage to the gearbox oil seals can occur, which leads to oil leaks from the mechanism. If the cultivator is still under warranty, we recommend contacting the nearest service center. An alternative option is to replace the oil seals yourself.

Before starting work, drain the oil from the gearbox. It should also be noted the spatial position of the shaft relative to the body, in order to exclude the possibility of incorrect assembly.

Possible malfunctions

| Malfunction | Probable causes |

| Heavy starting engine | · The settings of the speed regulator are out of order;

· Disrupted fuel supply to the carburetor; · Malfunction of the ignition system; · Clogged carburetor. |

| The engine gets very hot | · Clogged air filter;

· Clogged cooling system. |

| The engine cannot reach maximum rpm | · Clogged air filter; |

| The motor output shaft does not rotate | · The engine runs at low revs;

· The centrifugal clutch does not work. |

| The engine output shaft rotates at idle speed | · The clutch springs are stretched or damaged;

· Incorrectly adjusted engine governor control. |

| Oil leaks from the gearbox | · Gearbox oil seals are damaged;

· Crack in gear housing. |

If you do not have experience in repairing or maintaining cultivators, we do not recommend troubleshooting yourself. Unskilled intervention can aggravate the situation.

Model range overview

Motor-cultivators Tarpan compares favorably with other similar models with a kind of prefabricated structure - the agricultural machine can be conveniently transported to the place of work disassembled: power unit + gear component.

Modern cultivators are equipped with Honda and Briggs & Stratton engines - reliable, economical, requiring minimal operating costs. In the Tarpan family of motor cultivators, there are also models with Chinese Zongshen and Loncin engines, which allows us to produce competitive equipment at budget prices.

The first Tarpan-01 appeared in 1993. The car was equipped with a 6.2 hp two-stroke engine. Despite various design flaws, it was quite popular. A few years later, a new modification Tarpan-03 was developed, which is in demand to this day.

Tarpan TMZ-MK-03

The unit is equipped with an American 6 hp engine. with a motor resource of 1000 hours. Thanks to the worm gear, 1 speed is provided. The cultivator is designed to perform agrotechnical work on all types of soil. The cutters provide processing of strips with a working width of 35-100 cm.

Cultivator Tarpan TMZ-MK-03

Due to its low weight of 45 kg, the machine is very maneuverable. The ergonomic steering wheel can be adjusted for the operator's height and the length of the handles, it is possible to operate the cultivator from the side without trampling the newly plowed area.

Specifications

| Weight, kg | 45 |

| Dimensions (LxWxH), mm | 1300x700x1060 |

| Warranty, month | 36 |

| Cultivation width, cm | 30-70 |

| Engine | Briggs & Stratton I / C 6.0 |

| Oil volume in the gearbox, l | 0,6 |

| Cultivation depth, cm | 20 |

| Number of gears | 1/0 |

| Reducer | single-stage, worm gear |

| Drive unit | gear |

| Clutch type | dry, automatic, centrifugal |

| Rotation speed of cutters, rpm | 120 |

| Type of | Briggs & Stratton I / C 6.0 Vertical Shaft |

| Fuel | petrol |

| Engine displacement, cm3 | 190 |

| Cooling | active air |

| Fuel tank, l | 3,8 |

| Power, h.p. | 6 |

| Launch system | manual |

Motor-cultivator Tarpan TMZ-MK-031

The cultivator belongs to the light group - its power is 3.5 HP, weight is only 28 kg, tillage width is 50 cm at a shallow depth of 14 cm. This modification is convenient when working on small plots of land, in greenhouses, or in a garden. The unit is distinguished by good maneuverability, very easy to use due to its low weight.

Motor-cultivator Tarpan TMZ-MK-031

Specifications

| Rotation direction of cutters | direct |

| Number of cutters included | 4 things. |

| Tillage width | 50 cm |

| Cultivation depth | 14 cm |

| Cutter diameter | 240 cm |

| Engine power | 3.50 h.p. |

| engine's type | gasoline, four-stroke, cylinders: 1 |

| Reducer type | worm |

| Number of gears | 1 forward |

| Transmission type | single stage |

| Clutch type | belt |

| Weight | 28 kg |

| Dimensions, LxWxH | 1210х510х1020 mm |

We will demonstrate the high functionality of this small but rather efficient unit in a video review:

Cultivator Tarpan TMZ-MK-04

Lightweight compact unit with 6.05 hp Briggs & Stratton engine. designed for processing medium-sized land plots. Very easy to operate.

Cultivator Tarpan TMZ-MK-04

Specifications

| Class | light |

| Type of | cultivator |

| Tillage width | 56 cm |

| Number of cutters included | 4 things. |

| Direction of rotation of cutters | direct |

| Cultivation depth | 20 cm |

| Engine make and model | Briggs and Stratton 12/802 |

| engine's type | gasoline, four-stroke, cylinders: 1 |

| Engine power | 4.45 kW / 6.05 HP |

| Engine volume | 190 cc cm |

| Reducer type | worm |

| Number of gears | 1 forward |

| Transmission type | single stage |

This cultivator is equipped with a 2.2 kW electric motor. Despite its low power, it has enough weight to handle large areas. The width of the cultivated land during cultivation is 35-70 cm, the depth is 20-30 cm. The agricultural machine is rationally aggregated with various attachments, and the possibilities of application are limited only by the length of the electric cord.

Popular unit modifications

The most popular configurations are Tarpan TMZ-MK 03 and Tarpan TMZ-MK 04.

Motor-cultivator Tarpan TMZ-MK 03

Specifications:

- Engine Manufacturer - Gasoline 4 Stroke Briggs & Stratton;

- Engine power - 6.0 hp;

- Clutch - dry, automatic, centrifugal;

- Reducer - single-speed, worm gear in oil bath;

- Capture width - 350, 700, 1000 mm;

- Overall dimensions (control handles folded) - 1300x700x1060 mm;

- Weight - 45 kg;

- Number of cutters included: 4 pcs.

- Rotation direction of cutters: straight

- Cultivation depth: 20 cm

- Engine power: 4.45 kW / 6.05 HP

- Engine displacement: 190 cc cm

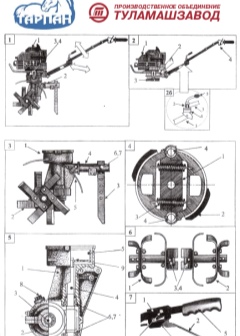

Cultivator device Tarpan TMZ MK-03

The cultivator Tarpan TMZ MK-03 has a modular design, so it can be easily transported between the house and the summer cottage. This model with a Briggs & Stratton engine can be almost completely disassembled, the attachments and the motor itself can be dismantled. The single-cylinder four-stroke engine of the unit develops a power of 6 liters. with., and its resource fluctuates within 1 thousand engine hours. There are also other modifications on the market equipped with Japanese motors. For example, the TMZ MK-04 model is supplied with a Japanese Honda engine, which develops a power of 5.5 liters. with.

The transmission of engine speed to the working element is carried out by means of a worm gear. In practice, it shows itself to be much more reliable than belt and chain transmission. The design of the gearbox is located in an oil bath. Despite the high degree of reliability, the gearbox has one drawback - it allows you to move only in one forward gear.

The width of the covered strip can be adjusted depending on the type of attachments. If the unit works as standard, then the width will be 75 cm.With an additional canopy, the width can be increased to 1 m.Cultivator Tarpan TMZ MK-03 can be used with the following equipment:

- Lawn mower;

- Rake;

- Hiller;

- Rotary cutter;

- Plow;

- Flat cutters;

- Ice cleaver.

Rotary snow blowers can also be used. The range of snow throwing will be 5 m. The physical mass of the unit without additional equipment is 45 kg. Light weight and height-adjustable handle bars greatly simplify the operation of the model.

It is also worth noting another modification option - Tarpan TMZ-ML 03 Champion. It is powered by Chinese Champion engines, making it much cheaper than the previous two. Another budget option is the Tarpan TMZ-MK 03 unit, which has a Chinese Zongshen XP 200 engine.

Among other variations with a Japanese engine, it is worth noting the Tarpan TMZ-MK 07 model. It costs much more than all previous configurations, since it allows you to use a variety of oversized attachments, including a wide snow blower.

The domestic market of agricultural machinery is not too rich in motor cultivators

Therefore, as soon as the Tarpan TMZ MK-03 motor-cultivator appeared on sale, it immediately attracted the attention of farmers. This model is a versatile and powerful enough unit that successfully copes with many tasks.