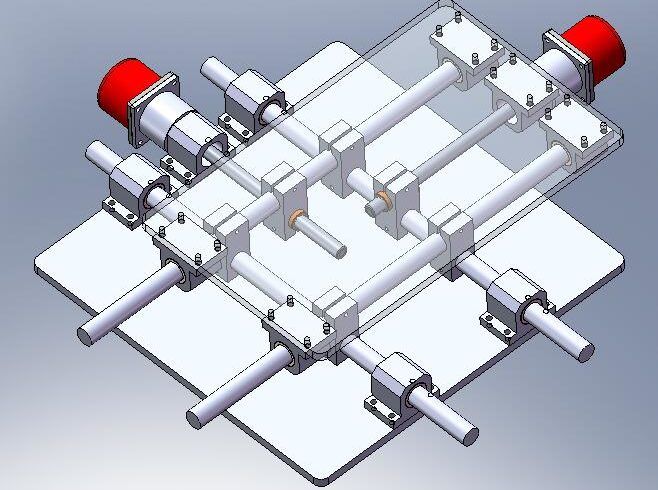

Manual milling attachment

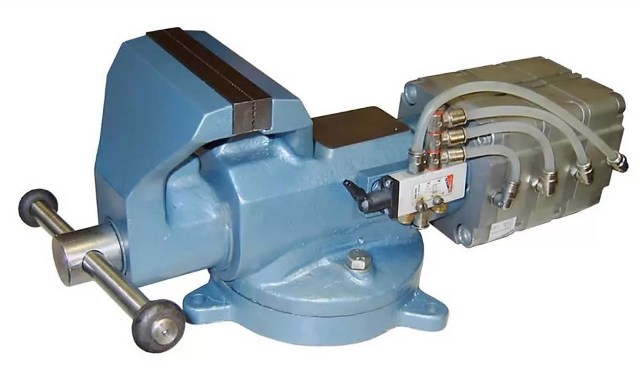

The rotary vise, thanks to the rotary disc, has a turning radius of 360 degrees. Together with them, the part clamped in them rotates. The disc is fixed using a rod on which a thread is cut, as well as a static regulator, placed outside the turning part. To improve fixation, a recess is provided in the swivel mechanism.

A hand vise is fixed on the top of the disc. They are equipped with 2 damping plates. The rails are located perpendicularly. These are the guides along which one of the plates moves.

A threaded rod is used as a regulating element. It is welded to the center of the plate from the inside. A handle is located on the other side of the rod. This end is threaded through a tightly threaded regulator on the inside.

The distance between the plates of the vise is about 1 mm when the rod is fully screwed in. This is necessary in order not to damage the vice.

Vise designs can be of different modifications. For example, with 2 movable plates. The device has a complex mechanism. In other cases, a lever is used instead of a handle, as well as a transmission unit.

As a rule, such a vise device is used in small workshops. Locksmith tools can be repaired quickly. It is easy to disassemble or install on the machine table. It is convenient and practical to use.

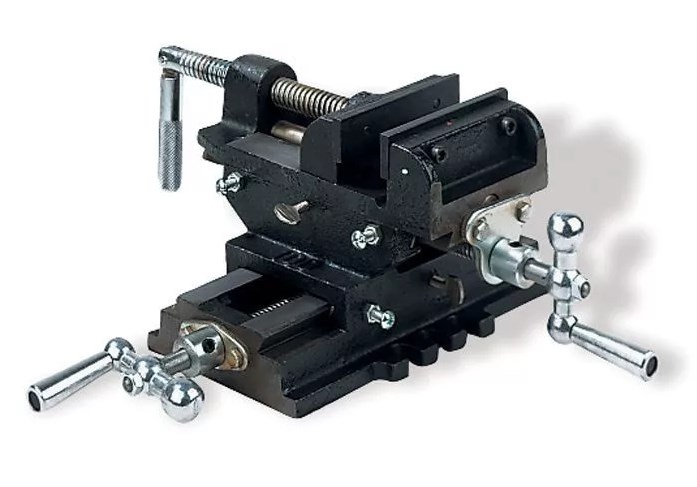

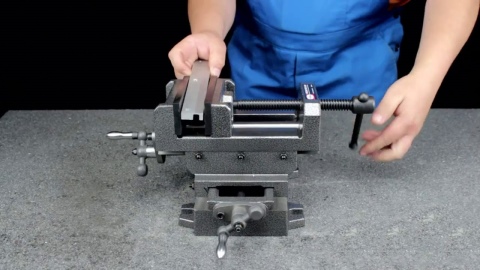

Using devices on a mobile platform

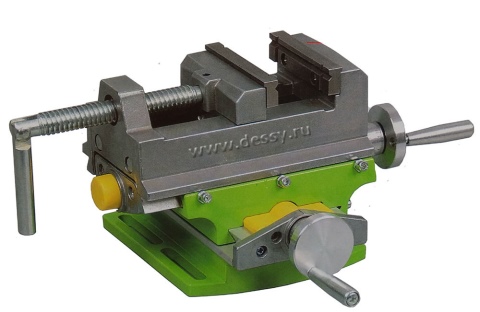

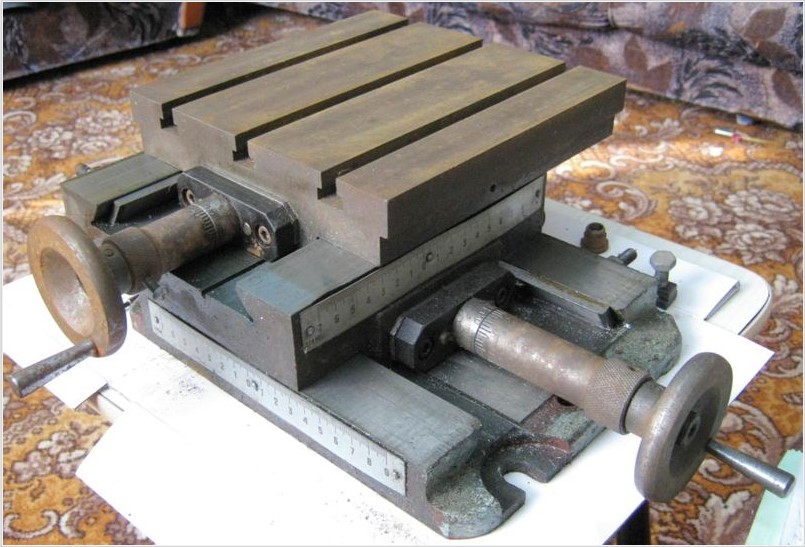

The principle of operation of devices of this type is to use a movable base. The base is able to move in 2 planes, which significantly expands the possibilities of processing parts of especially small size requiring special precision.

When processing large workpieces that do not fit between the jaws, special steel clamps are used, which are attached to the machine table and the workpiece is placed between them and rigidly fixed. In one of the clamps, the jaw is installed using an adjustment mechanism, which allows the final fixation of the workpiece.

Model overview

Vices for a locksmith's table are divided into two main types: swivel and non-swivel.

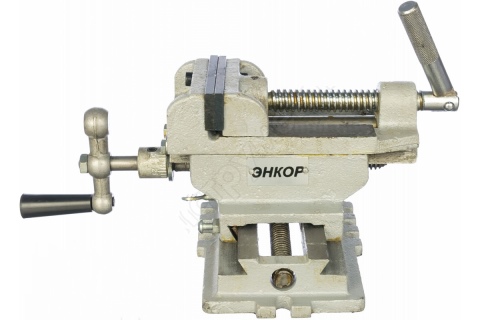

Rotary (or coordinate) can be rotated 360 degrees. The design allows you to drill several holes without taking the part out of the jaws. Cross vise, equipped with cross guides, and allowing the product to move at an angle with both longitudinal and transverse feed, are called two-coordinate.

Another type of vise - globular (sine) or three-axis - works with a part in three axes, which allows you to drill holes at different angles in much less time.

In the equipment market, the Chinese vice Kobalt 246-012 has proven itself among the rotary biaxial vice. The owners note the high quality, fixation without deformation of the product. The disadvantage is the awkward grip.

A new addition to the cross-jig vice is the BG 6368 3 ″ / 75 tool. This model perfectly grips cylindrical parts thanks to a special two-axis groove, has screws for backlash (in the amount of three pieces) and high quality. However, the main disadvantage is its small size.

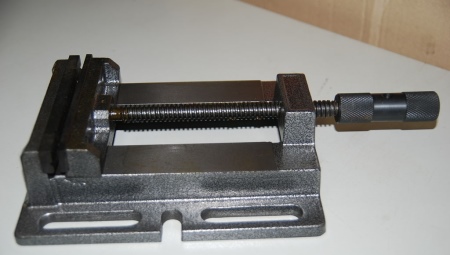

Fixed vise is otherwise called stationary. Looks like a base with welded jaws and a handle. The part is fixed strictly in one position. A fixed vise can be easily made by yourself.The most common type of fixed vise is machine vise. The vice is attached to the machine with bolts that fit into the special T-shaped slots of the table.

One of the best stationary vices is the Sparta 186255 tool. Owners note the compact dimensions, impressive clamping force, reinforcement in places subject to deformation. The cast iron base has one drawback - if the bolts are tightly tightened, the lugs can deform.

Russian-made "Enkor 100" - machine cross vise. Sturdy construction, comfortable grips and hardened jaws. Among the disadvantages is an unpresentable look.

Peculiarities

The main feature of all vice is ease of use and simple design.

A large number of different models are offered on the modern market, which are complemented by various functions and accessories.

However, the basic vise model includes:

- the base of the vise, which should be quite strong, therefore, most often it is made of high-strength steel or thick cast iron;

- fixed jaw (bed) welded to the base;

- a movable jaw connected to the lead screw;

- a screw with a lever that moves the movable jaw, securing the part;

- pads that are attached to the jaws and can be of various shapes.

Purpose and application of rotary vise

Machine rotary milling vise are required in order to be able to process the part from the back side.

Despite the fact that in the process of work the tool moves, and not the workpiece, it is impossible to process its reverse side without a rotary mechanism.

The reason is that it is not visible.

In addition, a vise is necessary for the following reasons:

- Thanks to such a device, the workpiece surface to be machined will always be in the foreground.

- In some cases, the tool cannot be moved. Part movement is required. For example, in the case of making a round product.

- If the vice is turned at 90 degrees, then it is more convenient to fix the workpieces in them. Then they return to their original position.

A vise for a milling machine is usually included with the equipment. It is much more convenient for a milling operator to process parts if they are available.

Such kits are used:

- In workshops with a small area. Furniture fittings or small metal products are manufactured here.

- In large factory halls. Large items are processed and manufactured. These can be turbines or car parts.

The use of special tools for processing parts

When processing parts, it is required to perform various types of work using machines of various types, on which machine fasteners are installed:

- machining centers (turning, milling work);

- milling machines (milling work);

- surface grinding machines;

- drilling machines;

- electroerosive machines;

- CNC machines (milling, turning).

According to the degree of adjusting clamping force when fixing the workpiece, fasteners can be classified:

- using a hydraulic booster mechanism;

- using a pneumatic drive;

- using a screw drive.

Fixing devices machine tool (pneumatic) equipped with a hydraulic drive are used when carrying out work when it is required to fasten the workpiece with the application of great effort. In some types of devices, the hydraulic cylinder used makes it possible to partially compensate for the vibration that occurs during the cutting operation.

The use of various drives makes it possible to achieve high precision in processing parts and automating the manufacturing process of products.

The use of a machine vise allows:

- create an increased degree of fixation of the workpiece during processing;

- ensure high reliability of parts processing;

- to carry out long-term operation of equipment while maintaining quality indicators.

The use of various types of machine vice allows you to perform a wide range of different operations related to the processing of parts.

Sinus vise

Sinus vise is designed to fix the workpiece at the required angle with respect to the plane of the table. To calculate the installation of a certain angle, a formula is used by which the height of the spacer is determined, due to which the required angle is achieved. In the calculations, an indicator is used - the sine of the angle on the basis of which this type of device is named. A KID (gauge block) is used as a spacer.

To set a certain angle, special sinus tables can be used, on which devices for carrying out working operations are attached.

Inclined sinus machine vice

Sinus vise curved longitudinal type 6555

Sinus machine vice POZOS

There is and is used a method of installing a part at an angle using angular measures. But this method is used when it is necessary to process only at a slight angle.

A method has been developed using magnetic sinus tables, where the processing angle is set by adjusting the table tilt angle using electromagnets. Magnetic steel tables are mainly used for surface grinding and high-precision cutting.

When carrying out the most complex types of processing, 3-axis angular steel devices are used with the help of which the fixation of the workpiece is adjusted in 3 planes and at any angle. The devices are capable of fixing the workpiece in the planes: 1. ± 45 °; 2.from 0 to 90 °. With respect to the base, the angle of rotation of the workpiece can be changed from 0 to 360 °.

Purpose of the tool

Such a device ensures the safety of the running process.

The main purpose of the vise is to securely hold the workpiece so that drilling is performed with maximum precision.

Many OEMs do not include a vise with their machine tools. This is because such devices are not always required. In addition, machine tools increase the cost of equipment. This explains the refusal of some manufacturers to include them in the equipment package.

A vise may not be required if the workpiece to be machined is made of wood or plastic. Such elements can be held by hand. For metal parts, the presence of a vice is a prerequisite for drilling. Without such a device, it is not only inconvenient to perform work, but also unsafe. In addition, without a vice, it will not be possible to drill a part at a certain angle.