Types and models

Currently in stores you can find split gloves for various types of welders. The main ones include several options.

Kevlar gloves

These varieties can be produced in two variations. They can be in the form of a five-fingered protective glove, which is firmly sewn from two different materials - such samples are also called combined.

Two-toed models

Such protective gloves outwardly resemble thick insulated mittens. Such gloves can significantly reduce the load on the hand during welding. It is these samples that provide maximum protection against temperature effects on human skin. They are most often used in electrode welding.

Three-toed models

These mittens have a separate space for the thumb and forefinger. Like Kevlar gloves, they can be produced in two different variations. The first assumes an insulated protective product, the length of which starts from 35 centimeters. They have an extended flare, so they can be quickly and easily removed if necessary. Warmed varieties are made with a lining of faux fur, high-density cotton fabric. The second option involves combined gloves: they are produced with small inserts from a textile base, placed on the back. Special reinforced areas will be located on the palms. The inner lining is also most often made from cotton fabric.

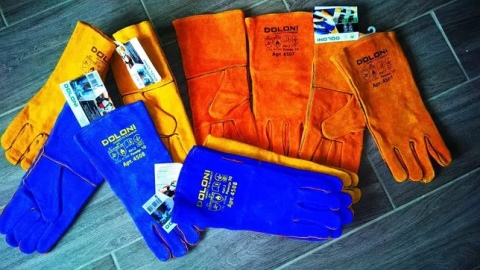

Today, manufacturers can offer a large number of such protective gloves for welders. The most popular models among consumers include a number of samples.

Gigant SPL1

This model will be the best option for workers in metallurgical production. They provide excellent skin protection against hot splashes and welding sparks. These gloves are made from split leather and have no lining. The length of the model is 35 centimeters.

"KS-12 KEVLAR"

Such split models have an increased level of fire resistance, in addition, they are rather difficult to cut through, burn with a flame. Gloves are available with thick insulation. The palm has an extra soft padding for maximum comfort during welding.

Gigant LUX SPL2

This protective model for welders, made of high quality split leather, perfectly protects the skin from hot splashes and sparks during work. These mittens are made without insulation material, but at the same time they still have a rather high density. The total length of such products is 35 centimeters.

"ATLANT STANDARD TDH_ATL_GL_03"

These welders are made of softer material. They have an extra layer made of fleece. And they also have a warming lining, it is created from a mixed fabric (it contains polyester and natural cotton). The seams on the product are additionally reinforced with small split leather inserts.

Gigant "Driver G-019"

These solid-grain models are specially designed to protect the skin from the effects of cold temperatures, punctures and possible cuts. The sample is made of high quality split (its thickness should not be less than 1.33 mm).

Gigant "Hangara G-029"

Such combined split products provide good protection from low temperatures, from contamination formed during welding.They are distinguished by a special level of strength and durability.

Split for welding robe: pros and cons, features

Many professional and novice performers opt for split leather costumes. This material has a lot of advantages, so necessary for fabrics used for sewing special clothing:

Many professional and novice performers opt for split leather costumes. This material has a lot of advantages, so necessary for fabrics used for sewing special clothing:

- providing a high level of protection against sparks, splashes, scale, high temperatures, open fire, heat radiation;

- high density and strength;

- moisture resistance;

- resistance to mechanical damage;

- able to withstand contact with chemicals;

- presentable appearance;

- easy to use; does not hinder movement, provides comfort;

- throughout the entire service life, retains its protective properties.

Important! Split does not have significant drawbacks.

However, it should be noted that this material is characterized by a rather low air permeability and a relatively high cost. Costumes made of tarpaulin and broadcloth are more affordable.

In winter

As a material for use in winter, the split has all the necessary advantages:

- the density of the material provides thermal insulation and prevents hypothermia;

- ease of wearing allows you to complement the set with warm linen or a regular work suit;

- moisture resistance allows the performer not to be afraid of atmospheric precipitation;

- when operating in winter, the low permeability of the material is considered an advantage.

No flaws were found, so the split suit will be an excellent option for workwear for use in low temperatures.

Summer

Split, due to its low air permeability, is not the best option for use in summer.

Split, due to its low air permeability, is not the best option for use in summer.

However, if the performer still wishes to purchase a suit made of this material, either one-piece models with ventilation holes or combined sets should be chosen. Examples will be analyzed further. Read more about summer suits here.

In the demi-season

Split has a porous structure, so it is quite hygroscopic. However, in the production of non-combustible equipment, the split is processed, which makes it completely waterproof. This is precisely the main advantage of the split file during operation in spring and autumn.

Model varieties and lining

When choosing the type of leather gloves and the desired model, a man needs to pay attention to two parameters - size and sewing material. The size can be determined according to the method described above, and as for the quality, experts believe that the best models of leather gloves are made in the Czech Republic, Hungary and Romania.

A good accessory will be sewn from solid leather, but not from patches.

Further, when choosing, you need to view the following indicators:

- seams;

- coloring;

- cut.

Do you wear leather gloves?

Not really

Gloves should be dyed throughout their thickness and uniform, and it is also important that the garment has a small number of solid seams. High-quality genuine leather gloves can only stretch in width, but not a millimeter in length

Modern manufacturers when sewing leather gloves offer three types of linings:

- no lining or thin silk lining for spring and autumn;

- jersey lining for demi-season models;

- suede and fur lining for winter.

But it is better to refuse gloves with a lining of synthetic origin. An exception may be the “thinsulate” material, which retains heat and is 100% hypoallergenic. High-quality gloves easily take the silhouette of a hand, do not restrict movement, and after being removed they return to their original shape.

How to choose leather gloves: basic criteria

The quality of the material is of key importance. It should be remembered that natural leather does not look perfect. On its surface there may be wrinkles, cracks, creases.If there are no such small defects on the surface of the product, then this indicates additional processing, which is mandatory for leatherette or for low quality natural material.

The appearance of the skin is also important.

- Pig skin. The advantages of this material are wear resistance and strength. These gloves do not rub and allow the skin of the hands to breathe. But products made of pigskin quickly absorb moisture and immediately deteriorate from this. Therefore, during precipitation, it is better to leave such gloves at home.

- Lambskin. This material is very soft, thin and elastic. Models of elite brands are mainly made from such raw materials.

- Deer skin. These gloves are durable, elastic and do not absorb moisture. The material is soft and retains heat well. Alas, such a model is extremely difficult to find today.

- Kid's skin. A feature of this material is a more porous structure than other types of leather. These gloves are tough and practically do not stretch.

- Suede leather. This material is durable and soft to the touch. The products look stylish. The only drawback is the difficult care.

Good quality leather gloves are never made from pieces and scraps. Since, due to the large number of seams, the product crawls and loses its attractive appearance in just a couple of weeks. Remember, leather gloves should only have solid parts.

As for the color, the natural leather is characterized by a slight difference in shades. This is due to the peculiarity of the structure of the material.

When choosing leather gloves, the lining also deserves attention. First of all, you should determine for what weather you are buying a product.

And based on this, choose the lining material.

- Fine silk is good for early fall or late spring.

- Knitwear is the perfect solution for late autumn and early spring.

- Fur or artificial filler (thinsulate) is a great option for the winter.

It is best to give preference to natural gaskets. For example, wool, cashmere, angora, fur.

Views

It is important to note that, according to their design, leggings can be of several types. so

Split five-fingered leggings are one of the most versatile models that are used in welding and other assembly work. One of the most important advantages of this type of gloves is that they do not impair the mobility of the fingers, which makes them very comfortable in the toe area. In addition, this type of clothing is characterized by reinforced genuine leather inserts. The inner part of the gloves is made of a comfortable, breathable fabric called cotton. The length of the split five-fingered leggings is 35 cm.

Further. Another type of gloves is double-fingered split leather gloves. The advantage of this type is that they reduce the stress on the welder's fingers during work, with the exception of the thumb and forefinger. Their protection against high temperatures is quite high, but they are poorly protected from punctures. Most often, this type of gloves is used for electrode welding.

There are also three-fingered split leggings. All their indicators and scope are completely similar to two-fingered models.

In addition, there are a few more optional models. They make split and insulated leggings and combined ones. The first type is characterized by the fact that their length is most often more than 35 cm, and fur, fleece or high-density cotton fabric is used as a lining. Also, the bell of these models is larger than that of the others, which means that in an emergency it is easier to remove them.

The second type differs in that it has a textile insert on the back of the hand, as well as a reinforced area on the palm. The production of the inner lining is made from cotton fabric, and a double layer of split leather or tarpaulin is used as a reinforcing layer.

Characteristic

Kitchen utensils are often cleaned with special chemicals. It is well known that all powders and dishwashing liquids cause serious damage to the delicate skin of the hands. Even simple cold or hot water can affect the condition of the skin, making it dry and rough.

Dishwashing gloves are a special product designed to provide protection for hands during the process of washing and cleaning kitchen utensils.

In order for the safety and comfort of the hands to be at a high level, gloves must meet the list of requirements.

- High degree of strength. Products must be resistant to foreign objects and chemicals.

- Endurance and durability. Protective equipment must withstand the load for which it is intended for as long as possible.

- Quality material. The feeling of comfort of the hostess depends on the material, because the use of high-quality fiber in the manufacture of this protective equipment allows you to feel those objects that are in your hands when washing.

- The right size. If the hostess refuses dimensionless gloves and chooses her size correctly, then she will not even feel the means of protection on her hands, but at the same time they will be protected.

The economic market is very large and varied.

Description

At their core, cotton gloves are personal protective equipment. They are used in order to protect hands from all kinds of injuries, as well as to make work more convenient, comfortable and safe. Most often, this means of protection is worn in the process of performing various kinds of work, for example, in such areas of human life as:

- metallurgy;

- loading and unloading works;

- oil and gas industry;

- agricultural work;

- car service and many others. dr.

In order for gloves to be of the highest quality and perform all their functions, they must comply with a number of standards.

Selection criteria

When choosing leather work gloves, it is important to consider a number of factors that determine their functionality and durability. Sometimes even the highest quality models are simply inconvenient to operate.

That is why you need to pay attention to the following points

Appointment. Models for electric welding differ markedly from those used for loading and unloading. When working with fire, high-temperature equipment, split options are used

It is important that the degree of protection corresponds to the intensity of the load.

Number of fingers. Usually it differs only in the Krags.

There can be 3,2 or 5 of them, depending on the seasonality of use and other features of the product.

The presence of cuffs. In ordinary gloves, they are short, in specialized ones - for metallurgy, welding, they are high, reaching the forearm.

Operating conditions. For standard temperature conditions, ordinary thin-lined gloves will suffice. Warmed fur is purchased for the winter period.

Protection class. It is identified by the EN 388 marker. The higher the number indicated, the better the gloves will be able to protect the hands from external hazards. Models with good performance are not afraid of cuts, punctures, and tears. If chemical resistance is required, the product must be labeled EN 374 and letters indicating the name of the substance from which it can protect.

The size. Since leather products do not have the ability to stretch, you need to carefully monitor the compliance of their parameters with the length and girth of the hand. They are indicated in millimeters on the packaging or stamp of the product.

Reflective inserts. They are necessary if work is to be carried out at night.

All these points will help to understand the problem of choosing working leather gloves, to find a suitable model for use in production.

An overview of Elementa work gloves in the next video.

Varieties of skin

As it has already become clear, outdated life hacks regarding the definition of natural leather are ineffective today. A modern man definitely needs to understand what kind of leather many wardrobe items are made from, including gloves. Today, manufacturers most often use several types of leather - goat, sheep, deer, pork, hence the types of men's gloves are determined.

Laik leather

According to many men and experts, the best skin is kid skin, which is made from sheep and goat skins. To the touch, it will be soft, elastic, delicate and pleasant, most often such leather is used in the production of gloves by manufacturers in Italy and the UK. But in Russia, this leather is not so popular, since the reproduction of sheep and goats here is quite insignificant.

Pigskin

Pigskin has excellent characteristics, despite the fact that it is denser and rougher than the previous version. The skin absorbs moisture, allows you to keep warm, while allowing air to pass through. But due to the ability to quickly absorb moisture, such a material should be wetted as rarely as possible so that the gloves do not lose their strength, novelty and original shape. Yes, and domestically produced gloves are enough, you can not spend fabulous sums on imported accessories.

Deer skin

Of these options, deerskin is the ideal solution, since it matches the characteristics of both sheep, pork and goat skins combined. The structure of the skin is soft, flexible and elastic, while thin, breathable, but retained warmth. But deerskin gloves will cost much more than the previously mentioned models, and the best deerskin is made in Canada, USA, Germany, Italy, France and Finland.

Common types

Cotton gloves with a dotted PVC coating. The composition of these gloves is 100% cotton with a small addition of polyester to give them better elasticity. Their main advantage is high strength and durability of use.

This type of protection is necessary when working with slippery materials, and they are also indispensable for auto mechanics, for workers at construction sites and in household use (fishing, hunting, performing various land works.

Rubber coated gloves effectively protect hands from chemicals during various construction and repair work. Distinguish with single and double coating.

Nitrile gloves are resistant to aggressive effects of various paints and varnishes and acids. It should be noted that nitrile or "synthetic rubber" as it is also called, is a hypoallergenic material. Gloves have high elasticity and memory effect.

Split gloves are most often used when working with welding machines, providing thermal protection, but they are also used when carrying out various construction work, as they protect hands well from various types of mechanical damage.

Protective gaiters of this type have an elongated part that fully protects the hand from splashes of hot metal, sparks during welding. There are also insulated leggings to protect the welder's hands in the cold season.

Dielectric gloves are indispensable when working with current, especially when there is no way to de-energize the network. The material from which this type of gloves is made does not conduct current.

Nylon gloves are always seamless, which creates high comfort and sensitivity when working in high-precision industries. These gloves can even be worn by jewelers and restorers.

Vibration-resistant gloves are designed to reduce vibrations when working with various types of power tools; they are made of high-tech material with an insert in the palm part.

Medical gloves protect the hands of medical personnel and patients from various infections.Such gloves are disposable and are often made from natural latex and are covered with starch and talc inside.

For protection against chemical burns and universal

Latex. Provides protection against the harmful effects of certain chemicals. Often used in contact with slaked lime, as well as in soap making and in other industries.

The latex coating can be smooth or rough, while the embossed structure has an anti-slip effect. They are resistant to mechanical damage and excellent resistance. These are the best gloves for jobs that require good hand sensitivity.

Nitrile. This type protects against burns, cuts and other possible damage. The material has increased elasticity.

They are disposable (gloves are thin, but can protect against chemical attack) and reusable (in this case, a nitrile layer is applied to the HB base, which gives the gloves additional strength and heat-shielding properties).

Neoprene gloves are used to protect against the harmful effects of a wide range of chemicals. They are impervious to gases and moisture.

The material neoprene is a synthetic rubber that has been designed to resist oils. In terms of plasticity, gloves are not inferior to latex ones, and in terms of wear resistance they will compete with nitrile gloves.