Instructions for creating

A lawn mower for a walk-behind tractor is not so complicated, but even it can be assembled using different methods. Most often, it is still not made from scratch - attachments, that is, the mower itself is made by the factory method at the factory, while the tasks of the folk craftsman are more likely to create an appropriate cart. The task does not seem difficult even in light of the fact that drawings of such structures are freely walking on the Internet, and if you wish, you can even find training videos on how to equip such a mechanism with your own hands.

Rotary

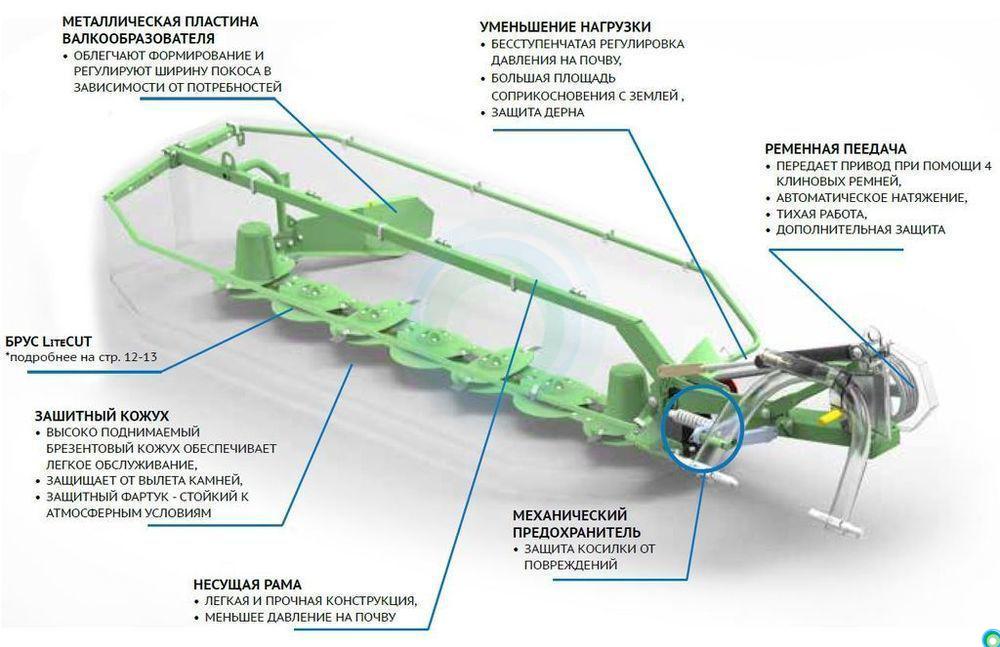

Mowers of this type are mainly used for lawn maintenance and hay making. The unit is designed for use in areas with relatively low vegetation and a small number of small bushes. The performance of the structure is estimated very high, however, it is whimsical to the presence of slopes - 10-20 degrees is already the limit for it, and lateral roll is allowed and not more than 8 degrees at all. With the simplicity of the device and the minimum risk of breakage, the ability of the unit to fold the grass in rows pleases, however, one should not forget that this particular type of mower is a traumatic one.

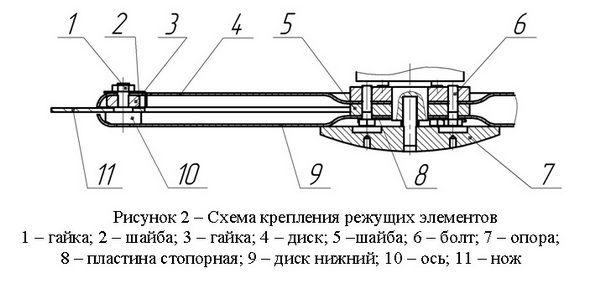

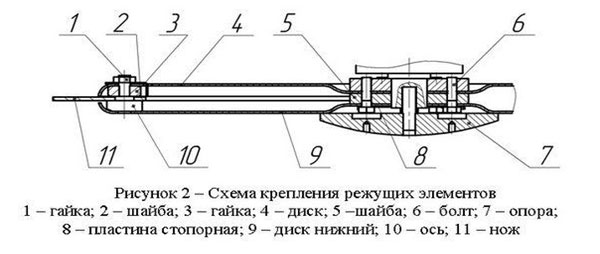

Such improvised knives are usually attached 4 pieces to each of the rotating circles - most often they are made by 2 using discs from a grain seeder. Fragments of the chain are attached to the discs at regular intervals, while they are not fixed perfectly tightly, but with a small gap of just a couple of millimeters. The latter is necessary so that the knives are maximally exposed to the centrifugal force, which will allow them to always be in a horizontal position. It is not worth fixing them more stably, and simply because when they join with something solid, they should be able to simply bounce back, otherwise the breakdown of the unit cannot be avoided.

All fastenings for rotating parts must be made of high-strength steel with a high carbon content, the thickness of the pins should not be less than 8 or even 10 millimeters to avoid damage to the device and injury. After that, it remains only to assemble the frame. The frame is usually made from a pre-prepared axle and two wheels, onto which metal corners are welded. The rotor body can be made using the same bottom from a metal barrel, it is then that the axles for rotating the discs will be welded to it.

The transmission of torque must be organized in such a way that the discs rotate in the opposite direction to each other - this is the solution that allows the mowed grass to be folded in neat rows. The last step is to install some kind of protective cover on the frame to ensure that an accidentally detached piece of the knife does not fly towards the operator.

Segmental

Such a self-made design is already noticeably more complicated in its structure, however, and it also has its advantages. Unlike rotary models, here the knives do not move in a circle, but reciprocally, since they are fixed on a shaft. This unit provides extremely low pruning of plants, removing them at the root, and also such a device will not be able to chop already cut grass, as it could happen with a rotary mower. The mechanism is convenient even in conditions of work on uneven ground, and turning on and off is not connected in any way with the walk-behind tractor, which allows you to quickly respond to potential emergency situations. Finally, such a unit hardly vibrates, which is also useful for its safety.

Product Description

Currently, there are many farms in Russia, both small and large, as well as households and dacha farmers who grow crops both for the sale of products and for their own consumption.

In this case, it is quite difficult for small farmers, truckers and trucks to acquire tractors (and in most cases it is not even necessary). For work, mini-tractors or motor units are often bought, which can significantly increase the working area (increase in productivity), for which attachments must be purchased.

In this case, if there are large and small cattle on the farm (sheep, goats, cows, etc.), then for the winter they require large quantities of hay. To cope with this task, usually the mower is purchased on a walk-behind tractor or tractor.

At the moment, there are several types of mowers, which differ in the principles of operation:

These mowers start to work both from a manual transmission from the engine block and from the rotation of the wheels when driving. Structurally, it is a frame to which a support wheel and a pair of discs are fixed. When the support wheel rotates, the knives (cutter) begin to move. As a rule, there are 1-3 similar cutting devices on mini mowers for walk-behind tractors and mini tractors. These devices can be made from anything, they can be strengthened in various ways, and their increase significantly increases the performance of the entire unit as a whole.

For example, a homemade mower with 2 or 3 knives allows you to treat several hectares of field for mowing hay. The performance of such devices is determined by the height of the cut, the area processed by such a device for a certain period of time, and the frequency of operation of the cutting elements. A home-made mower for a walk-behind tractor or tractor can be hitched, mounted or installed on the floor and attached to it, respectively. You can fix them both in front of the block and with the tractor, either from the back or from the side.

This mower is much more difficult to manufacture, operate and maintain than the previous one, but allows for a more precise cut of the grass, leaves no gap, and also improves the quality of the harvested hay as it does not destroy the plant stems. The design assumes the presence of a large number of cutting knives, which are connected to the block by means of a mechanical transmission from the engine shaft of the engine block or tractor, performing reciprocating movements. In this case, the knives run parallel to the ground, repeating its curves and grooves, which allows you to mow vegetation at the same level.

The knives themselves are made from rolled products. In addition, they are specially ground to ensure a long service life. The only significant drawback: such a mower on a motor block was not implemented by hand due to the great difficulties of the technical plan (optimization of the finished mower for a specific unit is not considered below). Minor disadvantages include frequent blockages of the device, which requires cleaning. It is this type of mower that is most common on large farms, so it is relatively easy to purchase an old mower, upgrade it and optimize it for use with a mini tractor or motor unit.

Principle of operation

First of all, it is worth noting that this kind of mechanism is designed for work that is carried out in meadows and fields, namely those related to mowing. Moreover, it can be not only crops that are grown in the agricultural area, but also the device is quite easily and simply able to cope with weeds, which actually also overwhelm our fields.

It is this kind of activity that is the main direction of the functionality of rotary mowers, which are a kind of trailers for the tractor that moves them.

Features of work

Moreover, this cutting device has the possibility of a kind of separation, which consists in the fact that the tool can be installed both from the side of the mower, in the front part, as well as in the rear area of the device.

As for the very start of the operation of the mower of this kind of direction, then in fact it can be produced both from the transmission of the tractor itself, and by moving the wheels of this vehicle. On a frame made of metal, a support wheel is attached, it is this wheel that has the cutting element.

Actually making its movement, it, let's say, provokes a cutting system to move, it is thanks to this kind of process that the mowing itself is carried out.

Assembly diagram

It should be noted that such a number of these elements is the most optimal and effective, as the level of productivity of the tool itself increases. And in general, rotary mowers have quite significant indicators of relatively safe and quality.

It's interesting: Review of the coolest models of Rossel mini tractors

Rotary mower

Before creating rotary-type equipment with your own hands (pictured), you must first prepare the appropriate materials and tools. There should be no problems with the material, since the most common scrap metal can be used for the manufacture of the device - old frames, spare parts from any faulty equipment, metal barrels from machine oil, and so on. All this scrap metal, minimal technical knowledge and skill with a welding machine can easily turn into an efficient mini tractor mower.

It is worth noting that this type of mower has three options for connecting to the power unit - trailed, mounted and semi-mounted.

In terms of functionality, rotary mowers can be designed to perform the following operations:

- mowing grass and laying the plant mass on a slope;

- mowing the grass and laying it in swaths;

- cutting and shredding of plant cover.

Rotary mower from available tools

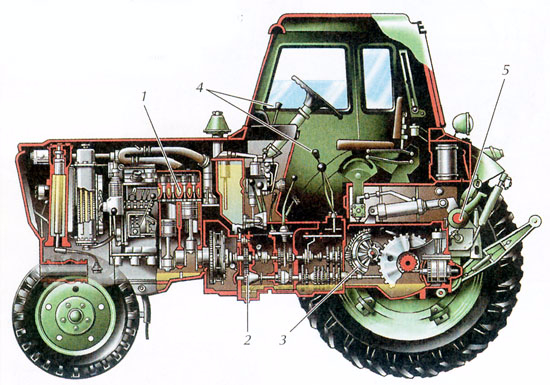

The rotary mower consists of a frame fixed on the blade discs and a protective cover. The device is driven by the power take-off shaft of a mini-tractor.

- The frame of homemade equipment is created from 40 centimeter pieces of a metal corner, connected by welding. To create cutting elements, it is possible to use knives from an old tractor rotary mower. However, they will need to be cut by 30 mm, since the thrust of the power unit will not be enough.

- 2 circles with a diameter of 390 mm must be cut from sheet metal 4 mm thick or from the bottoms of a barrel from machine oil.

- Set knives on the circles, which should rotate freely, since the cutting of vegetation occurs due to centrifugal force. For a homemade rotary mower, the lower discs with a diameter of 450 mm can be taken from an old cultivator.

- To make axial shafts with your own hands, on which disks with knives will be mounted, you will need a metal pipe with a diameter of 30 mm. You will also need bearings, one of which is mounted on the pipe, and the other for the welded pulley.

- Fasten the discs with knives on the axial shaft, weld the pulleys to the pipe and you can consider the homemade rotary mower almost finished.

- To completely complete the manufacture of the device, it is necessary to mount a protective casing on top. The working width of the rotary mower is about 1150 mm.

Read also: Which is better to buy a gas heater for a summer residence: reviews

To simplify the design of the equipment, the lower discs of the homemade mower are attached directly to the frame by means of a welded joint.This hand-made rotary mower can cut grass 5-7 cm at a speed of about 10 km / h. The device is ideal for cutting grass for hay and removing plant residues.

A rotary mower is considered a fairly profitable solution for those who want to save money on the purchase of factory equipment and independently make this device for their own needs. If you don't want to mess around with a pile of scrap metal yourself and waste your time, you can always buy an inexpensive lawn mower.

Purpose

Mowers replaced hand scythes in the middle of the last century and immediately became one of the most popular agricultural implements. The mechanization of the process greatly facilitated the hay harvesting process and saved farmers from hard manual labor. Initially, mowers worked in conjunction with full-size tractors, but with the development of scientific and technological progress and the emergence of small-scale mechanization for agriculture in the form of small-sized models of mini-tractors and walk-behind tractors, the scope of equipment use expanded. And if earlier mowers were used exclusively for harvesting hay, now they are entrusted with a number of other duties.

The implements are often used for mowing lawns, lawns and tennis courts, for removing small to medium shrubs from home gardens and fields, as well as for neat swaths and weeds. Moreover, before harvesting beets and potatoes, the mower is used to cut the tops, thereby preparing the plantations for the work of potato diggers. Mowers are also used for harvesting grain, for removing weeds before cultivating virgin lands and as a chopper for branches.

How to make an electric drill-based mower

When working in a small area or if it is not possible to make a hay mower with your own hands from a chainsaw, a conventional electric drill is suitable as an energy source for the device. It is better to use a rechargeable battery to ensure autonomy of work. But if there is an industrial extension cord at hand, and the area of the site is small, use the usual one.

Parts for assembly

During operation, the motor of the electric drill, using an eccentric mechanism and a connecting rod, converts the rotation of the shaft into reciprocating movements. When attaching a movable element - cutting blades - the desired result is achieved.

It is noteworthy that, depending on the needs, a home-made mower can be made mobile on a wheel base or portable. The second is convenient for processing ornamental shrubs, which are shaped by cutting off the tips of the branches.

What is needed to assemble a portable device (according to the designations in the diagram):

- Bed made of duralumin corner 40x40x3 cm.

- Duralumin overlay.

- Sleeve.

- Movable knife.

- Fixed knife.

- An eccentric mechanism that is installed on the neck of a drill. To do this, remove the standard cartridge and replace it with an eccentric. A bimetallic mechanism is recommended - the central part is turned from duralumin, and bronze is used for the outer part.

- Engine.

Drawing of a portable model based on an electric drill

Assemble the structure in the reverse order, starting from the installation on the "neck" of the drill of the split flange, which is fixed with a clamp. This is followed by an eccentric and a steel connecting rod.

The connecting rod is fixed with a lining attached to the end of the eccentric mechanism. It is necessary to ensure that the cylindrical part of the rod slides freely inside the duralumin bar - this way it will serve as a guide.

At the final stage, the eccentric body and the mower frame are mounted and the ease of movement of all mechanisms is checked.

The photo shows a wheel mower based on an electric drill. Assembly requires a welded frame and a protective plate for the body

Wheel mower based on electric drill

Mower overview

Among the popular models, there are segment mowers for the Uralets, MTZ, Belarus mini tractors. Let's consider some in more detail.

Equipment from the Minsk Tractor Plant

Mower of Belarusian production with a working width of 1.4 meters

The mower from the Minsk Tractor Plant will easily remove vegetation on the ground with uneven terrain, slopes and hills. Model vegetation is cut to a thickness of no more than 150-200 mm. They cope well with the remains of dead wood from corn, sunflower and other hard crops.

Spare parts are always available in any quantity. Service points are located in all major cities. The warranty for models from the manufacturer's factory is 3 years. Technical characteristics of the equipment for the minitarctor Belarus:

| TX | Models and their indicators | ||

| 1,4 | 1,6 | 1,8 | |

| Working productivity, ha / h | 0.9-1.2 | 0.9-1.2 | 0.9-1.2 |

| Dimensions during operation, cm | 240x67x66 | 260x67x66 | 280x67x66 |

| Transportation dimensions, cm | 88x67x165 | 88x67x185 | 88x67x205 |

| Surface treatment in width, cm | 140 | 160 | 180 |

| Weight in standard basic configuration, kg | 125 | 130 | 135 |

| Permissible speed of the minitractor during operation, km / h | 5-9 | 6-10 | 6-10 |

| Grass residue after bevel, height, cm | 0,6-0,8 | 0,6-0,8 | 0,6-0,8 |

| With what frequency PTO rotates, rpm | 540 | 540 | 540 |

| Admissible power of the minitractor, h.p. | 12-18 | 12-18 | 18-40 |

It is more profitable to buy directly from the manufacturer or through official dealer stores. The price in December-February is 5-10% lower.

Chinese 9G models

China segment mower

Chinese manufacturers offer their own version of the segment finger mower. Outwardly, it differs little from the well-known Belarusian, but it is lighter at times. Designed for mini tractors with three-point front PTO shaft. The work is carried out from the belt transmission of equipment. The model line includes mowers for mini tractors with power from 12 to 25 hp.

| TX | Models and their indicators | ||

| 9G 1.4 | 9G 1.6 | 9G 1.8 | |

| Working productivity, ha / h | 0.5-1.0 | 0.9-1.0 | 0.9-1.2 |

| Dimensions during operation, cm | 240x67x66 | 260x67x66 | 280x67x66 |

| Transportation dimensions, cm | 88x67x165 | 88x67x185 | 88x67x205 |

| Surface treatment in width, cm | 140 | 160 | 180 |

| Weight in standard basic configuration, kg | 106 | 110 | 115 |

| Permissible speed of the minitractor during operation, km / h | 5-9 | 6-10 | 6-10 |

| The remainder of the grass after mowing, height, cm | 0,7-0,9 | 0,7-0,9 | 0,7-0,9 |

| Admissible power of the minitractor, h.p. | 12-18 | 12-18 | 18-40 |

You can buy only from dealers and outbids. Many models are presented on used ads. The prices are lower but worth inspecting and checking before purchasing.

How to make a rotary mower for a tractor with your own hands

To make a rotary mower, you will need the following materials and tools:

- wheels with a diameter of 450 mm;

- wheel axle;

- metal pipes and corners (optional thickness and diameter);

- sheet metal;

- pulleys, knives, bearings;

- rubber belt;

- welding machine;

- drill;

- bolts and nuts.

Let's figure out how a rotary mower for a tractor is made with our own hands.

You can use scrap metal for a rotary lawnmower. It is imperative to know what type of connection the mini tractor has. In total, there are 3 types of homemade connection to the tractor:

- hinged;

- trailed;

- semi-mounted.

First you need to weld the frame, attach discs to it, and knives on them. Close all this with a protective cover. It will be good if you have old knives from a tractor rotary lawn mower. They just need to be cleaned of rust, if any, sharpened and welded to the discs. The discs themselves can be made from a barrel or 4 mm sheet metal.

Now we make axial shafts from a pipe with a diameter of 3 cm. We attach one bearing to the pipe. It remains only to attach the discs with knives to the axle shaft, weld the pulleys to the pipe, having previously fixed the second bearing on them, and the lawn mower can be considered ready. In order for a home-made rotary mower to be completed on a tractor, you need to attach a protective metal casing to the entire structure - a shield.

This grass cutter can handle grass 5-7 cm high. It can mow the grass to make hay and remove unwanted harmful plants.Such a mower is considered the most profitable and cheapest. You can, of course, buy a factory mowing machine for a mini tractor, if you do not want to load yourself with self-manufacturing and searching for material, but homemade rotary mowers for a mini tractor will last much longer.

The second type of lawn mower is segment lawn mower. Such equipment is much more difficult to manufacture with your own hands, because its action is driven by a crank mechanism. One of the cranks is connected to the crankshaft of the power unit. Knives are attached to the side of the crank. The knives are like 2 saws connected to each other, and they work like scissors - they just cut the grass.

In order to make a segment model for a mini tractor with your own hands, you need to take into account the stages of the sequence of its creation.

The optimum segment width is considered to be 72 mm. It is necessary to install the gearbox on a metal base. It has a shaft to which the hub is attached. A pulley must be installed on the shaft, and a wheel on the frame, which will prevent the mower from digging into the ground, and also set the desired mowing height. A segment mower for a mini tractor is driven like a rotary one - through a power take-off shaft. The most important thing in the operation and use of a rotary or segment model is to observe safety precautions.

Required tools and materials

Considering that the schemes for the manufacture of mowers, which will be given in our article below, were invented taking into account the use of scrap materials, any of these components can be replaced. If you are unable to get any of the specified materials, but have an idea how to replace it, you are free to make changes to our offer.

We offer only an indicative list of what may come in handy:

- welding;

- fasteners;

- metal corners;

- the bottom of an unnecessary iron barrel or any other piece of metal of a similar shape;

- several cutting plates;

- axle for wheels;

- wheels.

Conclusion

The modern world is diverse in its manifestations. No matter how much conservatives scold him for obsession and mass consumption hysteria, even they admit that he gave a lot of new and useful things. First of all, here we mean a variety of technical innovations and achievements, some of which have truly become a technological breakthrough in some areas of the computer industry and agriculture in particular.

Previously, a person had to do a lot, primarily physical, efforts to plow a field or mow grass in order to feed his cattle. The new world made it possible to partially free a person from stress, to make his hard part not so routine and ordinary.

A lot of new products have appeared, if we take into account agriculture, these are various walk-behind tractors, cultivators, lawn mowers, tractors and mini tractors with numerous attachments and accessories. For mowing a grass surface, for example, they came up with various rotary mowers, which greatly simplify the whole process, which in the past would have been spent not a single day.

Here, I would like to mention the rotary mower for the Neva walk-behind tractor, which you can assemble with your own hands if you follow the instructions that you will find here.

In general, rotary mowers for mini tractors can have a lot of differences between themselves. It means that some of them are adapted for mowing a grass surface in mowing, others are used for fine chopping of grass, etc. Another innovation in the field of agriculture is the stiga robotic lawn mowers, which make it much easier to care for your plot.

They also differ in the regions producing this product. At the moment, production has been established in many European countries, China and Russia.

If you decide that a rotary mower is not for you, read “segment mower for a tractor - characteristics, models, prices”.

It is clear that the price will also depend on where exactly this or that rotary mower for a minitractor is produced. The most expensive models, as you might guess, are produced in European factories that meet the latest technical and equipment requirements. Some of the most budgetary options can be purchased on the Chinese market of rotary mowers, while Russian manufacturers most skillfully combined price and quality, which is at its best in domestic models. By clicking here, you can familiarize yourself with the price of a Polish rotary mower - this miracle of technology will help you in your difficult lawn care struggle.

And how to make a mini-tractor with your own hands with an engine from a walk-behind tractor, see the article.

Conclusion

The advantages of technological progress make it possible to significantly simplify the already difficult life of a rural person. Specialists of companies specializing in the production of agricultural machinery have thought over and implemented a great variety of technological innovations that amaze with their multitasking.

The segment tractor mower is undoubtedly one of such innovations.

It helps to simplify the task of cutting grass, making hay, which is very important in rural conditions. But one must be careful in choosing such a technique and trust only well-known manufacturers who have proven themselves from the best side.

You should not be lazy to find out more about the specific model you are interested in, ask the seller about the characteristics, inquire about the availability of a product certificate. After all, a segment mower is a rather expensive thing, which you need to buy once and for life, so you need to approach the choice with all responsibility.