Features of the use of nozzles for concrete

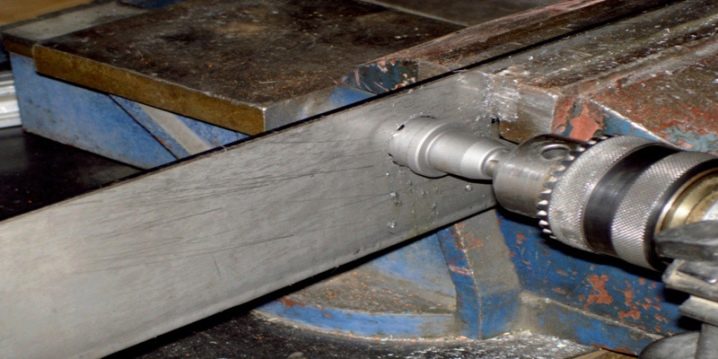

If the shank of the selected crown matches the clamping device of the hammer drill, it simply needs to be positioned and secured in the working position, no adapters are needed. You can start drilling the concrete at the mark.

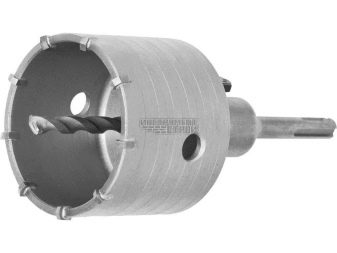

Drilling with a carbide bit

The nozzle can be equipped with a center drill or not. If there is one, then the point is placed at right angles to the concrete plane in the zone where the middle of the hole will be located. If the structure of the cup does not provide for such a drill, then the circle of the incisal edge is pressed against the concrete. Begin drilling without effort - the cutting edge must select a shallow tunnel and straighten its direction. When it can be seen that the nozzle is properly positioned, the tool is pushed forward with pressure.

It is not necessary to remove the drill until it has drilled the concrete to the required depth or the bottom of the crown rests against the wall. From the holes that are not made through, a roll of cut concrete is picked out with a lance. For gear nozzles with carbide solders, the main thing is to correctly determine the order of operation of the hammer drill. Excessive heating of the edge should not be allowed, therefore, after one or two holes, it is necessary to allow the device to cool down.

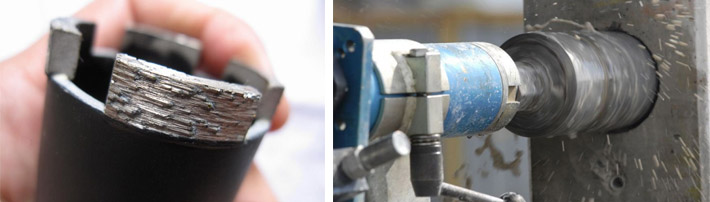

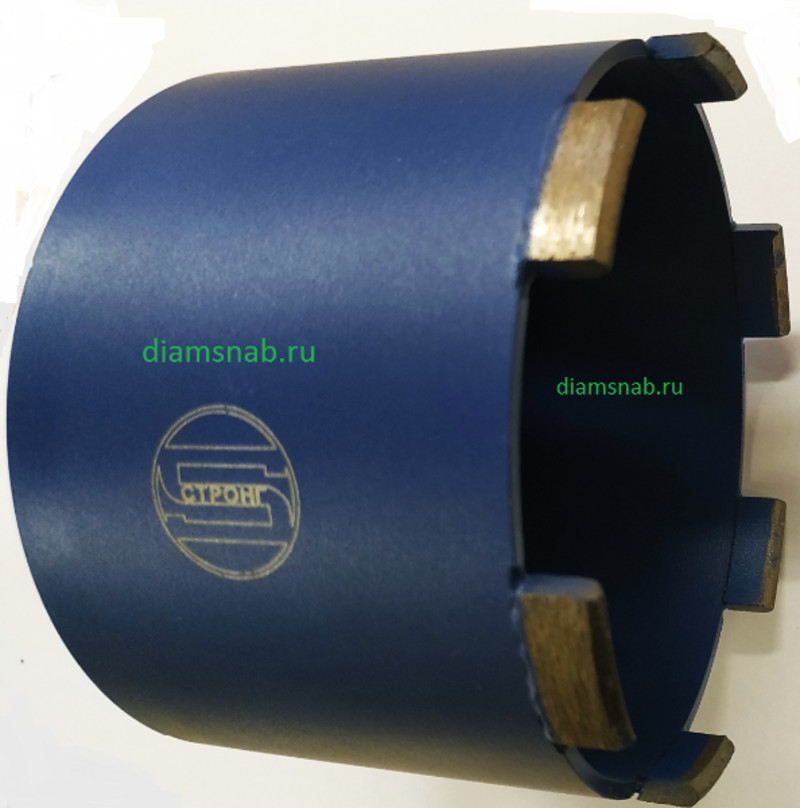

Drilling with a diamond core bit

If it is necessary to prolong the operating time of the nozzle on reinforced concrete, it is required to use water spraying, which cools the cutting part. This is especially true for fixtures with soldered edges, as they will fall off when heated too much. Such crowns are practiced for more sophisticated fittings than a manual hammer drill. It is fixed on reinforced concrete, and the operator only has to feed the drill, making the hole deeper.

Types of drill bits for concrete rock drills

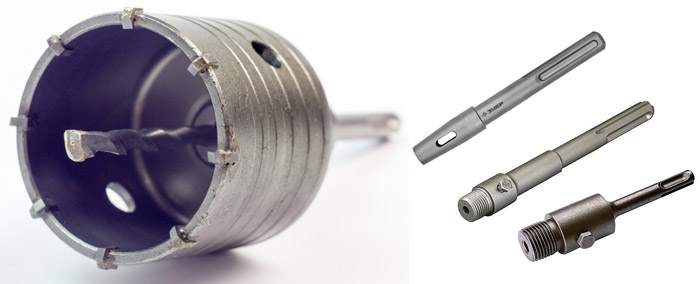

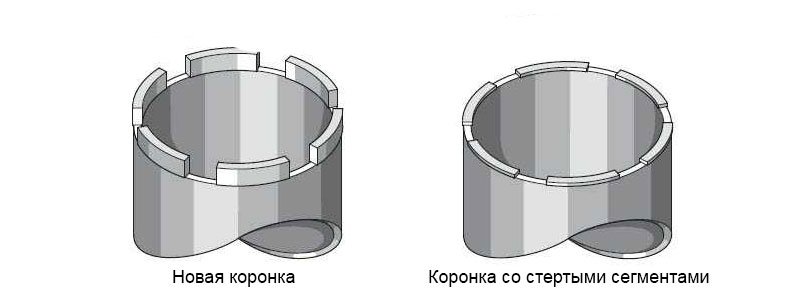

The crowns are produced only from hard alloys of metallic materials, which make the product strong, durable and effective. It is not uncommon for beginners to wonder what purpose the crown has a centering drill for? Precise holes can be made with this drill. Its absence can lead to vibrations during drilling - the hole will be deformed, distorted and uneven. Bits are classified according to shank design. They are available in the following types.

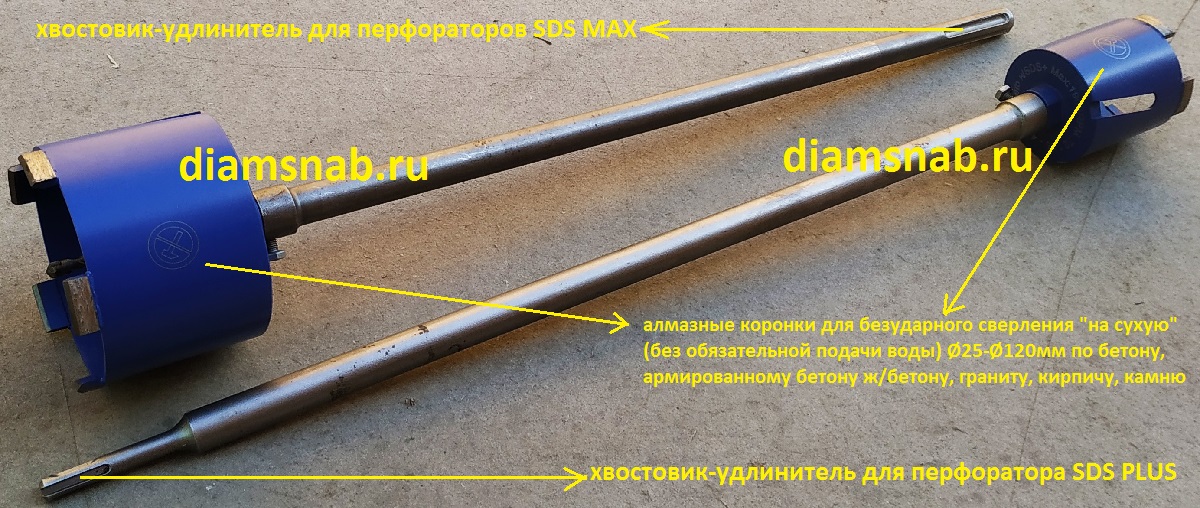

SDS-plus - models that are installed in household rotary hammers.

Crowns differ between themselves in the material from which the cutting area (teeth) is made. There are 3 product options.

Pobeditovye - for the manufacture of teeth for the crown, an alloy of cobalt and tungsten is used in a ratio of 8% and 92%. The characteristic properties of these nozzles are resistance to high temperatures and long-term loads. They are used on reinforced concrete or brick.

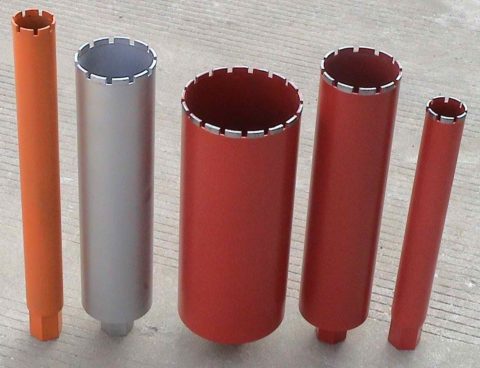

Diamonds are among the most expensive, but also effective. Diamond drilling tools have a number of positive qualities: they are not afraid of meeting with metal. That is why it is possible to make a hole in reinforced concrete only with tools of this type. There are many modifications on sale with various diameters. In addition to the especially popular 68 mm concrete crown, devices for concrete 100 mm, 110 mm, 120 mm, 130 mm and 150 mm are also in demand. Equipment with such a large diameter is used for drilling holes in reinforced concrete or brick walls for pipes.The quality of the resulting hole is very high: there are practically no chips, cracks or other surface flaws.

Nozzles that have holes on the side walls of the bowl are dry. Closed bowls are considered wet and must be wetted with water during drilling. It is possible to wet both samples of nozzles with water, since this will not only increase the service life of the devices, but also reduce the accumulation of dust formed during the drilling work.

Based on the drilling technology, the nozzles are additionally divided into non-impact and impact bits. The first option is suitable only for functioning in the drilling mode and is often used for electric drills. Impact devices can be operated using the function of a jackhammer on the rock drill.