Advantages and disadvantages of these drills

Compared to conventional electric drill bits for metal drilling, these bits have the following advantages:

- You do not need to choose a power tool with a powerful drive to make holes.

- The inner sides of the hole are rough, which is not typical for other types of equipment.

- Suitable for fixing in drills, milling machines, lathes.

- High productivity of the drilling process.

- A significant amount of material is being filmed.

- High accuracy of work performance if centering equipment is used.

- Minimum noise during work.

- The large number of cutting edges increases the productivity of the ring bit.

- Drilling large holes takes much less time than other bits.

The weaknesses include a higher cost, the inability to make blind holes. Bits without diamond coating quickly become dull.

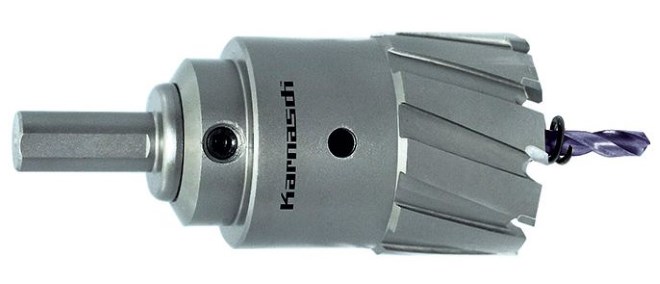

Karnash brand tools

Today it is not difficult to choose and purchase core drills for solving any technological problem, since they are presented on the modern market with a wide variety of types and brands. These can be drill bits for wood, as well as more durable and wear-resistant tools for concrete, cutters for making holes in metal products and structures.

Among specialists who often work with core drills, products manufactured under the Karnash brand are popular. The prevalence of these core drills is facilitated not only by their extremely high quality, but also by the fact that they are available in a wide range, among which you can choose a tool for solving a specific task.

Core drills Karnash

So, among the products manufactured under this trademark, one can distinguish core drills of the following series:

- Gold-Line, made of high-speed steel HSS-XE, on the surface of which a wear-resistant coating is applied using Gold-Tech technology;

- Hard-Line, the cutting part of which is made of Swedish-made carbide inserts (the expanding spiral flute of this series core drills simplifies the removal of chips from the processing zone);

- Rail-Line, the working part of which is also equipped with carbide inserts with multi-stage sharpening of the cutting edges (using the tools of this series, drilling of railway rails is carried out);

- Blue-Line and Blue-Line Pro, used for drilling hardened railways, cast iron, aluminum and stainless steel.

What to look for when choosing core drills

When choosing a core drill, the following parameters should be considered:

- the series to which the instrument belongs;

- working diameter;

- hardness of the working part;

- the greatest drilling depth;

- the size of the shank with which the drill is installed in the chuck of the equipment;

- purpose (what kind of metal can be processed with this tool);

- centering method;

- the level of roughness that the drill can achieve.

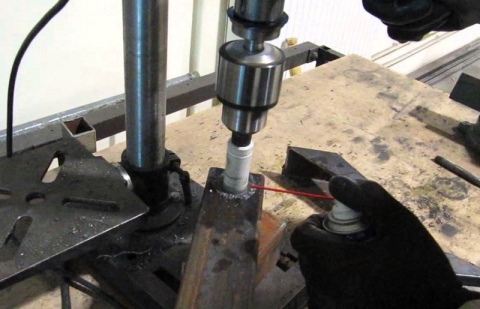

The small width of the teeth of this crown (about 4 mm) allows the use of hand tools

Naturally, the design features of the core drill should also be taken into account, whether it is made entirely of high-speed steel or equipped with brazed carbide inserts.

If a crown cutter for metal is required for intensive use and solving complex technological problems, it is better to give preference to products from proven European manufacturers. Such a tool, although it costs much more than similar drills from Asian and Chinese manufacturers, is distinguished by extremely high wear resistance and is able to serve for a long time without changing its original characteristics.In addition, the use of a quality core drill allows for higher productivity in metal processing.

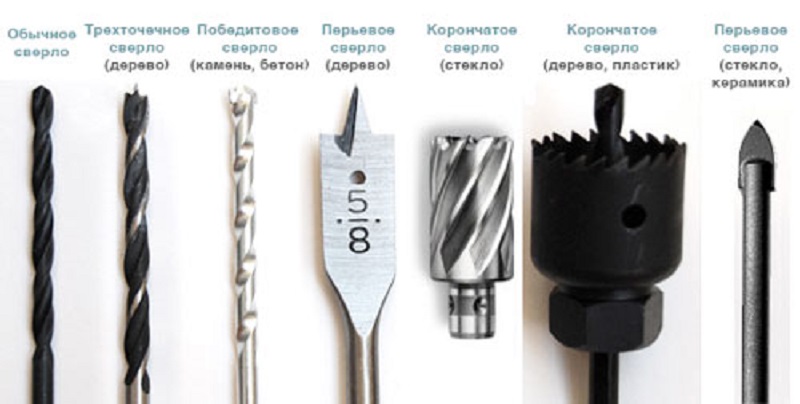

Types of crowns for metal

The core drill is used for drilling both small holes with a diameter of 12 millimeters or more, and holes with a diameter of 200 millimeters or more. There are many different classifications of drills, depending on the defining parameter.

By the type of tool or machine for installation on which the drill is intended, they are divided into the following categories:

- Drill crowns - have a cylindrical or hex shank, designed for processing sheet or thick-walled metal, usually limited to a diameter of up to 50-65 millimeters.

- Drills for work on magnetic drilling machines, have the appropriate type of shank, are distinguished by increased strength indicators.

- Bits for installation on conventional drilling machines have a standard design and differ in the type of shank.

Depending on the design and material of manufacture, crowns for drilling metal are divided into the following types:

A tool made of high-speed tool steel does not have additional surfacing on the working part or a hardening coating, cutting properties are achieved due to the strength characteristics of the metal and a certain sharpening of the teeth

These crowns can be re-sharpened, but it is important to maintain the original angle of the tooth profile.

Bits made of steels with low strength characteristics, but having carbide surfacing on the cutting edge. Their disadvantage is the inexpediency of re-sharpening the tooth.

Larger diameters will be cheaper than HSS of similar diameters.

Useful Tips

Here are some guidelines to help you achieve correct and high performance drilling.

1. Center the drill correctly.

Mark the hole along the markings (do not use the ejector pin for this), place the ejector pin in the recess and turn on the magnet. After that, check the position of the pin again, as it happens that when the magnet is turned on, the tripod moves.

The fixing of the drilling point for diameters 12 - 15 mm is very important. For larger diameters this is highly recommended.

2. Select a speed.

Choosing the right rotational speed is very important

Pay attention to the inadmissibility of working with excess of the recommended speed. The minimum permissible speed is approximately 25% lower than the recommended

Carbide drills are more sensitive to excessively low speeds, resulting in increased vibration and tooth chipping. HSS and powder steel drills fail when the recommended values are exceeded by more than 20%.

3. Apply the correct feed.

When starting drilling, reduce the feed to half the recommended (see table below). Remember that too much pressure on the drill will not increase speed - use carbide drills and high speed machines to increase productivity. If you have to apply significant force, the drill may be blunt or the material being drilled is too hard.

| Material | Cutting speed, mm / min | Feed rate, mm / rev |

| Structural steel 50 kp / m2 | 40 – 60 | 0,08 – 0,12 |

| Steel 50-70 kp / m2 | 30 – 50 | 0,08 – 0,12 |

| Stainless steel | 18 – 45 | 0,08 – 0,10 |

| Cast iron | 65 – 95 | 0,12 – 0,20 |

| Non-ferrous metals, aluminum | 100 – 550 | 0,22 – 0,45 |

| Special alloys | 10 – 30 | 0,05 – 0,08 |

4. Control during drilling

If the machine is not equipped with a chipbreaker, periodically remove the drill and clean it from chips. In this case, you should use a special hook. Drilling of light materials is done in one step.

When drilling holes deeper than 15-20 mm, follow these guidelines:

- upon reaching a depth of 15-20 mm, remove the drill from the hole and clean the shavings from it;

- fill the hole cavity with grease;

- drill at a low feed until the chips reappear on the outside;

- do it all over again.

5. Application of cooling lubricants (coolants)

It is important to use good quality cooling lubricants during drilling. As a rule, liquids are used - coolant

The use of drills with DURABLUE coating without the use of coolant is allowed, the service life of the drills in this case, in comparison with the same conditions, but with the use of coolant, is reduced. When drilling holes with a diameter of more than 37 mm, the use of coolant is strongly recommended in any case.

Adequate cooling is especially important when drilling hard-to-cut and heat-resistant materials, stainless steel. In these cases, arrange for a coolant supply from the inside and outside.

6. If the core is stuck inside the drill

The reason for the sticking of the core inside the drill is usually:

- too much pressure during work;

- lack or insufficient cooling;

- incorrectly selected rotation speed:

- drill wear;

- ejector spring worn or bent ejector pin.

Very often the core falls out by itself after it cools down. In any case, do not put significant effort into extracting it:

- first try to take it out, shaking it slightly with your hand (wear gloves so as not to cut yourself);

- secondly, using an awl or screwdriver, evenly from all sides, lightly tapping with a hammer (see figure).

- you can also remove the drill and lightly tap the pin on a hard surface.

7. Drilling materials with non-parallel planes

The main hazard is drill exit, so reduce feed before completing drilling. It is also recommended to use HSS or powder steel drills.

When using machines with automatic feed, switch them to manual.

Where are they used?

Drills of this type can be used on equipment with low power. For example, the use of a magnetic machine, the power of which varies from 800 to 1000 kW. If you use a hole drill on it, you can get a hole with a diameter of 30 to 35 mm. If a twist drill is used under the same conditions, then at the same power the hole will be much smaller.

Working with such drills does not require much physical effort and special preparation, and the accuracy and quality of the machined surfaces will be much higher, since the roughness of the hole is reduced. It is possible to make overlapping holes. During operation, only through holes are obtained.

During operation, the drills emit a minimum of noise. With their help, in combination with other tools, you can:

- perform multi-tool processing;

- get holes in concrete and stone structures, in ceramic tiles and natural stone;

- perform horizontal drilling for laying utility lines.

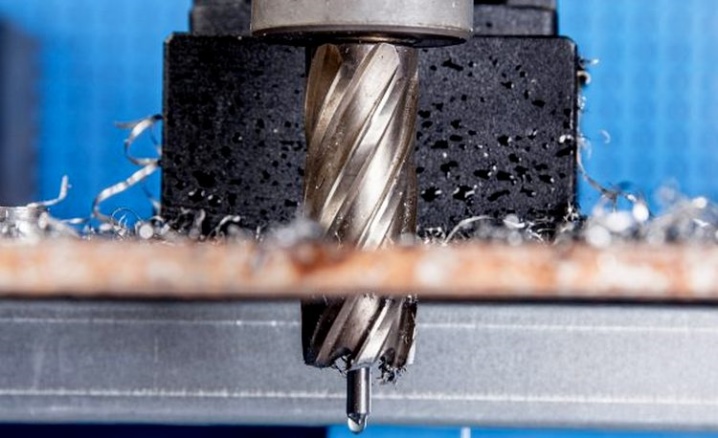

Device

A core drill is also called a hollow or ring drill, since it looks like a hollow cylinder. Used for drilling round recesses in metal and wood products. During operation, removes material around the circumference of the hole, leaving drilling residues in the center. These drills are an excellent alternative to expensive options with low efficiency.

The drills are characterized by high performance, have a rather complex configuration, which consists of a shank, connecting screws, a pilot drill and the working crown itself. To assemble one structure from these elements, it is necessary to insert a pilot drill into a metal shank and connect with screws. Then the drill with the shank is installed in the crown, and the resulting structure is fixed.

Thanks to this, the tool has a long service life with high drilling accuracy. All quality standards and dimensions of core drills are indicated in the corresponding GOST.Failure to comply with these standards is punishable by law.

DIY wood crown

Any master can face a situation when a drill of a suitable diameter is not at hand. For work that does not require high precision and accuracy, a wood crown for an outlet can be made independently in a couple of hours. The list of materials is minimal: a metal pipe of the required diameter, a "fist" from a door hinge, a drill, a screw, a rectangular steel plate.

- In the "fist" with the help of a vise, it is necessary to drill a hole corresponding to the diameter of the drill.

- On the side of the “fist”, at a distance of at least 1 cm from the edge, make another threaded hole for the fixing screw.

- Along the edge of the pipe, using a grinder, it is necessary to make cuts that imitate teeth.

- Weld a plate on the back of the pipe, in the center of which make a hole for the drill.

- To assemble the structure, a drill is inserted into the "fist" and fixed with a screw. The lower part of the drill fits into the crown, and the upper part into the chuck of the tool (drill or screwdriver).

Characteristic

The core drill appeared in the early 1970s and was invented by Diz Haugen. At first, such drills were not perceived by people and were ignored. Haugen offered his invention to various manufacturers, but they showed no interest in him. Only ordinary assemblers of metal structures became interested and decided to try the know-how in action.

At that time, drilling machines with conventional drills were used, which were distinguished by a large mass, and at least two workers were required to work. During the drilling operation, there were a lot of inconveniences, and sometimes the worker was even thrown off the structure. After Haugen proposed the core drill, a lighter construction of the drill was created, which weighed about 13 kg.

What is a core drill? This name refers to a hollow attachment or nozzle that has the shape of an empty cylinder inside, designed to work with non-ferrous metals and steel. Core drills are designed in such a way that the recess is cut in the metal only along its contour, for this there is no need to use equipment with high power.

By drilling with such a drill, you can get a hole with excellent roughness in the inner part. This is very difficult to achieve with similarly designed tools. Ring fixtures are used in various types of equipment, and these are not only drilling, but also milling and turning machines.

You can also use them in conjunction with other tools, that is, perform multi-tool processing. This drill allows you to remove a large amount of metal being processed in one go. Thanks to the fact that the ring cutters are made of high-strength and high-speed steel, the work is carried out at high speed and maximum accuracy. During operation, annular cuts have minimal noise, and a large number of cutting edges in its working part ensure high productivity of this tool.

There are two types of these drills for metal: these are HSS teeth bits and carbide bits. Toothed bits are less productive and less expensive, and which are made of carbide materials are designed to work at higher speeds and are used for drilling carbide and high chromium steels.

The most budgetary ones are bimetallic bits for metal, their cutting part is made of a quick cut, and the main body is made of simple structural steel. Compared to conventional drills, crown counterparts have a fairly high cost.

What are they used for?

Core drills are widely used to produce through holes in sheet metal, wood, plastics, drywall, plywood, chipboard. The simple technology of drilling large diameters, with the minimum possible application of force, made these drills an indispensable tool not only for the above materials, but also for other types of work. Drills for special purposes are used for:

- obtaining holes of the correct shape in concrete and stone building structures;

- drilling ceramic tiles, natural stone, sheet glass and other fragile materials;

- horizontal drilling when laying utility lines;

- production of flat circles and cylindrical blanks without turning.

For this, in some cases, the design of the drill (drill) provides for the lengthening of its working part by adding appropriate inserts.

For working with concrete, only diamond-coated or brazed core drills are used. There are 2 groups here:

C1 - the crown withstands loads during operation up to 5 MPa.

C2 - the crown can withstand loads during operation up to 2.5 MPa.

Based on the equipment you have, it is worth choosing the crown group itself.

Drills TL300 from RUKO

The TL300 drills produced under the RUKO trademark are well known to the domestic consumer. The drill of this model range can be chosen for its affordable cost, as well as high quality and reliability. The drills of this series, having a cross-point sharpening in accordance with the DIN 1412C standard, are produced with a diameter of over 3 mm. The TL300 drills are sharpened at 130 degrees, and select models in this series can be coated with titanium nitride, titanium aluminum nitride and other materials.

Drills of the RUKO trademark

Models of this series belong to the category of multipurpose, but their optimal characteristics are suitable for drilling metals that are prone to the formation of medium to long chips.

Models of this series (HSS-G) are optimally suited for the formation of holes in parts made of carbon, as well as cast iron, copper and aluminum alloys.

Models HSS-EE, in addition to the above metals, can also be selected for acid-resistant steels. Even more versatile are the HSS-G TiN and HSS-G TiAIN drill models, which can be selected for drilling titanium and titanium alloys.