Types of circulars

All circular saws are designed for fast sawing and a smooth cut. This is an indispensable tool for any builder or summer resident, but in order to find the best option, you should master a little theory. So, there are several varieties of hand-held circulars, which differ in the principle of influencing the material.

Submersible circular

One of the varieties of circular hand saws used for creating grooves, removing grooves, slots, etc. With its help, it is very easy to make a hole in the countertop for the sink - the design of the tool allows you to work not only from the edge of the material, but also anywhere else.

The submersible circular saw is indispensable for floor renovation and roofing work. To get an even cut without chips, the work with a manual circular should be done in two stages: first, the blade goes to a shallow depth, and on the second run, it cuts the material completely. The tool allows you to make both perpendicular cuts and at any given angle.

One of the most popular models, the Makita sp6000set, is notable for the fact that it does not have a lower guard, and the cutting element is located above the base plate. Thus, when turned on, the circle is lowered and cuts the material. The cutting depth can be controlled and varied at your discretion with millimeter precision.

Battery circular

Cordless circular saws and other stand-alone tools are in great demand, since they do not need power from the mains, and therefore are mobile and convenient to use. Such a tool will be especially useful for high-altitude work, where there is no way to supply power and you have to "fight" with the ubiquitous wires and extension cords.

Until recently, the main problem of all cordless saws was insufficient battery capacity, which was not enough for continuous continuous operation of a powerful tool. For inexpensive models, this situation has not changed, so a good battery circular should be sought among professional lines of a high price category. Experts recommend immediately choosing a saw equipped with two batteries: one in operation, the other on charging. One of these models is the Makita hs300dwe. It takes only 30 minutes to fully charge the batteries, ensuring non-stop operation and high productivity

If we consider other technical parameters, such as power and speed, you should pay attention to the GKS 36V-Li saw from the German manufacturer Bosch - it makes cuts up to 54 mm deep and is very easy to use.

Metal circular

Most circulars are designed to work with wood, but you already know that if you put a special disc with reverse teeth on the tool, you can cut some types of metal. However, there is a separate class of circulars designed specifically for cutting metal. In essence, these are advanced woodworking tools that work well with metal and great with wood and other less hard materials.

Metal tools, such as a grinder or angle grinder, usually have an abrasive wheel on them. In the circular, a toothed disc made of extra strong steel is used, which gives a lot of advantages over other devices. So, labor productivity increases several times, because it is faster and more convenient to work with a saw. As a result, labor intensity is reduced, because the circular has a support sole that takes the load on itself.The saw makes much less noise than the same grinder, while it does not heat the metal and does not let out sparks. It is much safer to work with this tool than with an angle grinder, since the cutting element is almost completely covered by the protective cover.

Cutting discs for circulars for metal have a high resource, and therefore they last for a very long time. For this reason, the cost of cutting metal products is almost penny, and the quality is high - the cut is smooth and without burrs.

In the west, almost all professional builders and home craftsmen use circular saws for metal, but they appeared on the domestic market relatively recently. Nevertheless, Russian experts have already appreciated the comfort of working with such a powerful device. One of the most remarkable models, the EVOLUTION 230 EXTREME is able to accurately and quickly cut steel sheets up to 12 mm thick or steel pipes with walls up to 4 mm thick. Accordingly, the saw copes with wood and polymer materials just jokingly.

Features and working principle

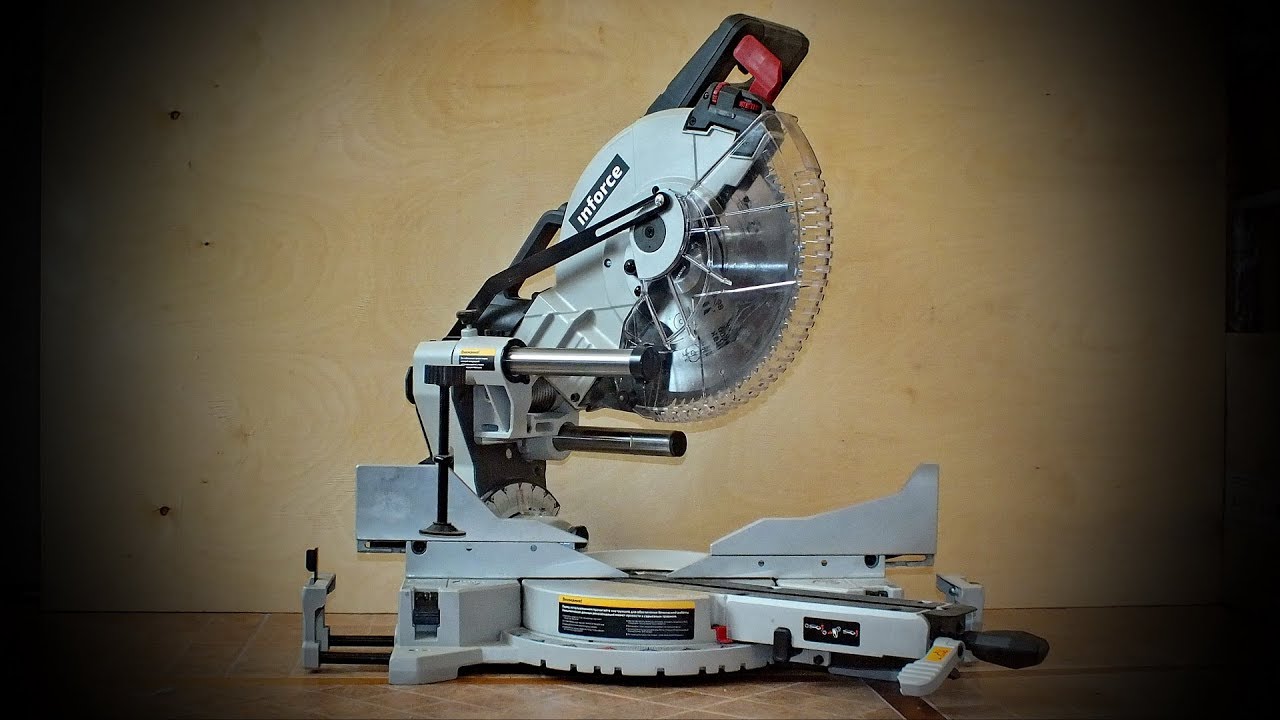

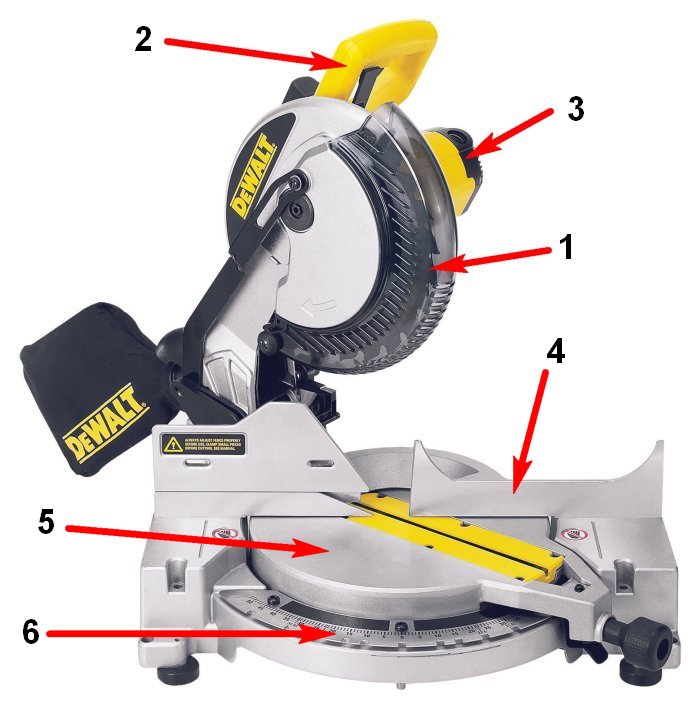

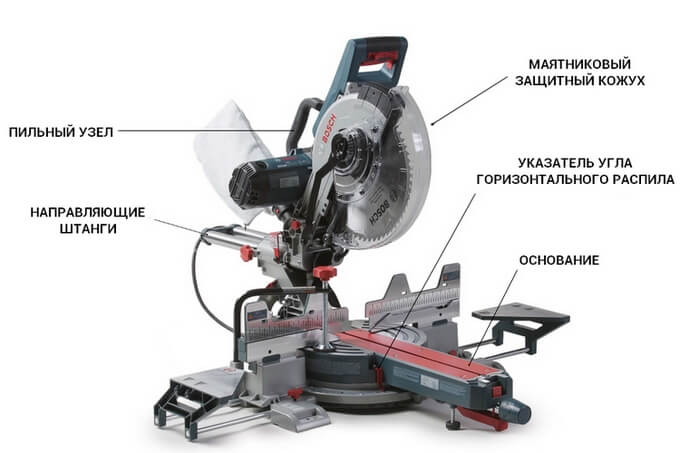

A miter saw for wood is usually used to cut small parts that require cutting at a specific angle. For example, this can be the creation of openings for windows and doors, laying floorboards, creating furniture, or assembling the roof of a building. The device can be used to work with laminate, plastic, and aluminum. A miter saw usually has four main parts: base, saw blade, motor, handle, and is secured to the casting bench with fasteners. Since the disc takes all the load, it is usually made from the most durable materials. It starts to work after pressing the button located on the handle.

The miter saw motor can be of several types and be collector or asynchronous. The asynchronous engine is responsible for quiet operation and extended service life, but the collector drive does not require much maintenance and is quite easy to repair. The motor is located either to the right of the disc or to the back. The principle of operation of trimming is to transfer a rotational impulse from the engine to the cutting blade, that is, the disk. The speed of rotation, as well as the power, are determined depending on the material used and other factors.

The power of the unit is a very important indicator, since the more powerful the saw, the larger the diameter of the saw blades is, which means that it will be possible to process larger workpieces. Alternatively, such a device can even be suitable for cutting logs. However, it should be borne in mind that both the weight, and the size, and the price in this case increase. Experts recommend choosing devices with a power of 1.6 kilowatts and a speed of 6000 revolutions per minute. The disc diameter ranges from 4 to 13 centimeters.

Battery miter saw Makita DLS600 Z

It is not always possible at the construction site to connect the power tool to the mains. In this case, the Makita DLS 600 Z miter cutter with a lithium-ion battery (purchased separately) will help. This is a miniature novelty that has a lot of functionality typical of chain saws.

Makita DLS 600 Z is compact - its weight is only 6.6 kg. With its small dimensions, it allows you to get straight or oblique cuts with high cleanliness and accuracy. Sawing capacity at an angle of 45 ° is 30 mm, which is optimal for most finishing work.

The brushless motor, due to its minimal losses, provides an efficiency of about 90% and has a long service life. The device includes a light, a dust bag, a holder for a hex key. Users note the convenience of this unit, the disadvantage is the rather high price.

Miter saw with or without feed, which is better?

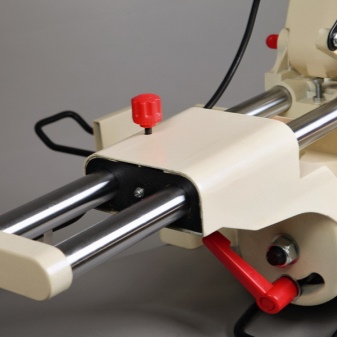

An additional broaching option is as follows: a saw blade is mounted on two parallel rails, which is able to move freely along them.

A miter saw with a broach is used when working with wider sheets, since they are characterized by a rather high cutting width of the part being trimmed. Broached cross-cut saws are usually equipped with fine teeth, which makes them easier to handle parts made from artificial components.

The miter saw with a broach can have a laser pointer or illumination and some other convenient functions, and also stands out for its large dimensions and weight.

When choosing this type of rig, keep the following important details in mind. Often, high power saws have more features.

Do not forget to pay attention to such an indicator as "idle speed" - it reflects the potential of the tool when processing various building materials. If this figure is higher, then there are more opportunities for crosscutting, and even with low power, a high speed will give greater productivity.

Also important characteristics of saws are: weight and dimensions, saw blade diameter, safety and ergonomics. The tool should be as easy to use as possible. Rather heavy equipment makes work difficult and leads to quick fatigue. For safe operation of the saw, a protective cover is included that covers the sharp blade.

The saw blade acts as a cutting part, its main indicators are the outer and bore diameters. The outer diameter, as a rule, should be at least 20 cm, but it is better when it is larger. In typical models, it is 21, 25 and 30.5 cm. The inner diameter is three cm. Often, the properties of the saw blade may differ. For example, a trimming disc is attached to the machine, and using guides, it can be rotated to any desired angle, both in the horizontal and vertical planes. Combination miter saws guarantee a fixed position of the work bed for a given number of degrees.

The width and depth of cut are important indicators of an electric miter saw. They reflect the materials for which the selected saw is suitable. There are household and professional electric saws. The cutting depth for these two saws does not differ significantly. The main difference is that a professional tool can handle much larger sheets than a household one.

All real sawing tools, including combination miter saws, are high-end products and guarantee 100% accuracy and reliability. The increased comfort in work helps to qualitatively facilitate work and quantitatively increase its productivity. The offered wide range of power tools allows you to make the best choice and purchase the equipment that is most suitable for repair work.

What is a miter saw.

The purpose of the miter saw is clear already from its name - facing (in other words, transverse cutting) of long parts: platbands, baseboards, fillets, moldings, etc. A master unfamiliar with a miter saw will probably be surprised - all of the listed parts are perfectly cut with a circular saw, and if you need to cut cleanly and at a certain angle, you can use a hacksaw and a miter box. So it is - it is the hacksaw and the miter box that is designed to replace the miter saw, for which it is sometimes called the "electric miter box".

Anyone who has ever had to connect platbands and skirting boards "in a mustache" knows that this is not as simple as it might seem at first glance. Without the proper skill, even with a miter box, making a perfect 45-degree cut is not easy. And if the part is not flat, but of a complex shape? If it is a wide outer platband or a decorative element and it simply does not fit into any miter box? And what if the joint angle is not straight and you need to cut not at 45 degrees, but, say, at 57 degrees? And if you also need to cut at an angle to the vertical? A hacksaw on a swivel bed will not help here either.

So it turns out at the junction an ugly gap, which has to be covered with putty and masked with a color scheme in the color of the details.

But with a miter saw, such problems cannot arise, and any craftsman who has tried this tool will never return to a miter box and a hacksaw. Moreover, now on sale there are not only expensive professional models, but budget household ones, which are not much more expensive than an ordinary circular saw, and at the same time are capable of providing a previously unattainable quality of connection "in a mustache" of parts of any shape.