Diy lug wheels

For today, the best option would be to use one of several options:

- Manufacturing from old discs. In this case, it is enough to take standard, already used car disks as a base. You also need to find a working supported axle and weld steel plates to the edge. The size should be optimal for the disks. This is due to the fact that in the future a lug is attached to them. The connection is carried out using bolts, and the edges of the plates must not come into contact with the rim in any way. The main structural element is the lug plates. The best solution would be to make them from old corners. To do this, it is enough to cut the required parts with a grinder, and then weld to the rim every 15 cm.

- Manufacturing from a balloon. The method does not entail difficulties. It is enough to find a used gas cylinder and cut out circles with a diameter of 30 cm and a width of 6 cm. Further actions are carried out according to the principle of the first option.

Everyone has the right to choose the most optimal option for himself, starting from the presence of certain elements.

How to make an all-terrain vehicle with your own hands from a walk-behind tractor

Light home-made all-terrain vehicles are called "pneumatics" or "karakats". The best passability is provided by large cameras.

Stages of creating an all-terrain vehicle:

- Selection of the basis of the machine.

The frame of the URAL or IZH motorcycle can serve as the basis. The machine is based on IZH, more maneuverable. And many opt for this particular option. Such a car moves well off-road.

- Manufacturing of suspension and rear axle.

To obtain an independent rear and front suspension, the side members are connected by a brace, a steering sleeve and a special rack. Such a suspension ensures smooth running, and any type of all-terrain vehicle should have it.

- Wheel fastening.

Any light all-terrain vehicle should have a truck camera. It is attached to the suspension using a metal hub. Low pressure chambers from KamAZ trucks, their trailers, as well as URAL vehicles are used. This provides ease of steering and increased travel safety.

- Installation of systems and engine.

When the suspension with wheels is installed, the motor of the walk-behind tractor is produced. At the same time, the clutch, brake, gas emission system is connected.

Upon completion of the assembly, the all-terrain vehicle is tested. If everything is normal, you can start operating it.

Homemade all-terrain vehicle and its use

All-terrain vehicles-pneumatics showed excellent cross-country ability on marshy terrain, river beds and mud. They have good buoyancy, so a small water obstacle can be overcome without difficulty on such an all-terrain vehicle.

As a rule, a pneumatic can accelerate to 75 km / h.

How to make wheels with your own hands

Having dealt with the types of tires, you should learn how to make the same, but homemade. The first thing to consider is that in any case you will not be able to make wheels for a walk-behind tractor from scratch. You will need a base - old pneumatic wheels from a car, for example, from "Oka" or from "Niva". In this matter, it all depends on your choice or the availability of suitable material. And by the way, farmers do not recommend buying a new set of tires for rework, as they are not cheap and as a result you will not be able to save a decent amount by doing the rest of the work yourself.

Paired wheels are often made, where an additional weighting agent can be placed inside. Let's start with this option.The tandem version is a quick and efficient wheel conversion that is available to many. You will need 4 wheels with a good base made of stainless steel (by the way, the masters have tires from Moskvich). You also need to have iron plates with you. The process itself is carried out in several steps.

- The rubber tire is removed from the base.

- To the rim on which the tire is put on, it is necessary to weld several iron plates, up to 5 cm wide. Usually, a square is formed from the plates, which is welded to one of the sides of the rim.

- Next, the rim from the second wheel is welded to this square. Thus, you connect the two rims to each other using plates and welding.

- In the last step, the rubber is reinserted onto the rims.

That's it, you've got the kit you need. As you can see, their main advantage is their large width. Thanks to this, they look less like wheels from a car, and more like an option for a walk-behind tractor.

The second option, how to strengthen pneumatic wheels, is to increase their wear resistance due to additional materials. In this way, you can remake the wheels of a transport vehicle such as a motorcycle or ATV. In general, you will need larger tires than a regular passenger car. Large chains can be used to increase rigidity.

Let's move on to the process itself: chains need to be welded to pneumatic wheels. You can try pairing them with rubber or an iron rim. Next, you need to make notches on them so that they imitate the lugs. The result should be similar to purchased metal wheels.

You will have to tinker with this method so that the chains are tightly held and do not fly off during work. This is where blocking chains with a rim comes in handy, which can be done with steel fasteners and hooks.

An additional element that is often lacking for the convenience of working with a walk-behind tractor is an unblocker, sometimes called a differential. Since the instrument itself is heavy, it is often difficult to control it, namely, to turn in different directions. In this case, an unblocker comes to the rescue - a special device that is attached to the wheels and increases their maneuverability in difficult areas.

The unlocking tool is installed to the output shafts of your walk-behind tractor using bolts. During operation, it reduces the turning radius of the entire machine and increases the track width. If you use a mini tractor on a regular basis, then this thing is simply irreplaceable. You can make an unblocker yourself based on bearings, but in fact - the game is not worth the trouble. On the market they can be found in a wide variety of variations, and unlockers are inexpensive.

The most important thing is to find a specialist who will advise on a good product.

So, if you have a need for new "shoes" for a walk-behind tractor and there is an opportunity to use tires from an ordinary car or motorcycle, why not give it a try. This article lists the simplest and most popular options, but it all depends on your experience and skills. In fact, the solution is very simple, you only need welding and a little skill. But for a good result, consult with experienced craftsmen before starting work.

For information on how to make wheels on a walk-behind tractor with your own hands, see the next video.

Let’s block ads! (Why?)

What are wheels?

A wheel is a rotating and transmitting undercarriage element located between the tire and the hub.

Vehicle wheels are divided into single and twin wheels. A single wheel is mounted on one hub and carries one tire, while a twin wheel has two rims mounted on one hub and carrying two tires.

The following types of wheels are used on cars:

- disc wheels

- wheels with collapsible rim

- compound wheels

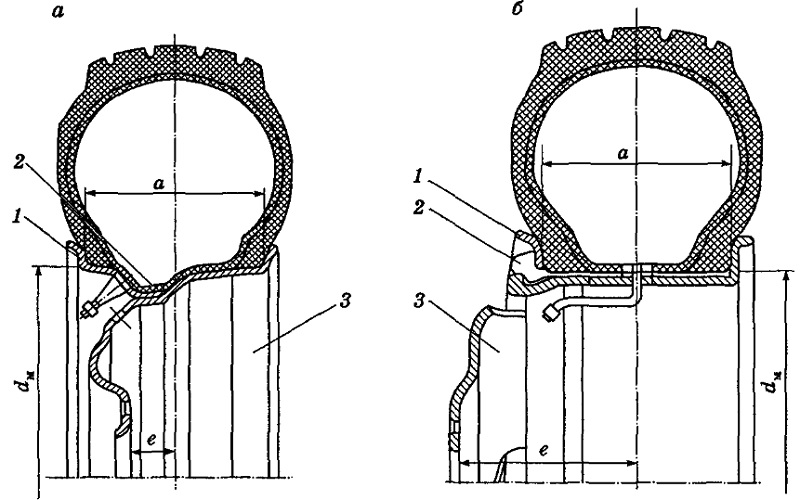

A disc wheel is a non-separable unit consisting of a rim of a rim.A disc wheel of a truck can have a composite rim, one of the sides of which consists of a removable split lock-fit ring and a removable bead ring, which together form a rim. The options for the design of disc wheels are shown in the figure:

A collapsible rim wheel is a wheel in which one or two collapsible rims are attached directly to a hub developed to the size of the rim. These wheels are widely used on heavy vehicles and buses.

A compound wheel consists of two elements, each of which includes a part of the rim. After assembly, the elements form a rim with two flanges. Such wheels are used for large-size wide-profile tires and tires with adjustable pressure.

The wheel rim size can be designated as follows:

The wheel-to-hub connection ensures the transmission of torque and the centering of the wheel on the hub. Fastening of stamped disc wheels of passenger cars is performed, as a rule, using bolts or nuts with a tapered centering surface. The centering of the cast wheel disks is carried out along the landing belt of the hub. The fastening unit includes studs and unified nuts, equipped with freely rotating washers, which exclude the possibility of damage to the disc. Bolts may be used instead of studs and nuts.

The connection of the disc wheel to the hub of trucks is carried out using studs and nuts with a spherical bearing surface or studs and uniform nuts with freely rotating washers.

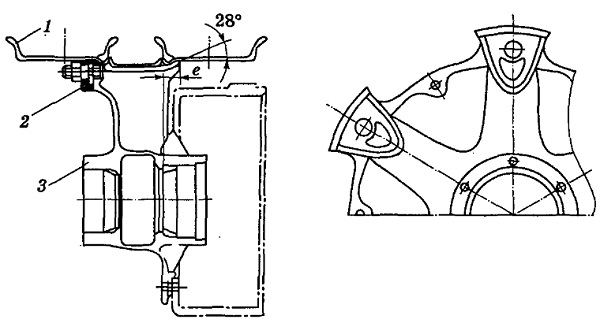

Fastening of wheels with a collapsible rim is carried out by special fasteners (clamps), which press the tapered seating surface of the rim to the corresponding surface of the hub, which has an inclination angle of 28 °.

A pneumatic tire is a resilient shell designed to be mounted on a wheel rim and filled with pressurized air. The main element of the tire is the tire, which directly takes the load on the tire from the road. It consists of a frame, tread, belt, beads and sidewalls.

The carcass is the power part of the tire, consisting of one or more layers of cord attached to the side rings.

Tread - the outer rubber part of the tire with a relief pattern, which ensures the tire's grip on the road and protects the carcass from damage.

A breaker is a part of a tire consisting of layers of cord or rubber and contributes to a more even distribution of loads acting on it over the wheel surface.

The beads are the rigid parts of the tire that hold the tire on the rim.

Sidewalls - a rubber layer that covers the side walls of the frame and protects it from mechanical damage and moisture penetration.

By the design of the carcass and belt, diagonal and radial tires are distinguished. According to the method of sealing the inner cavity (when assembled with a rim), tires are chamber and tubeless.

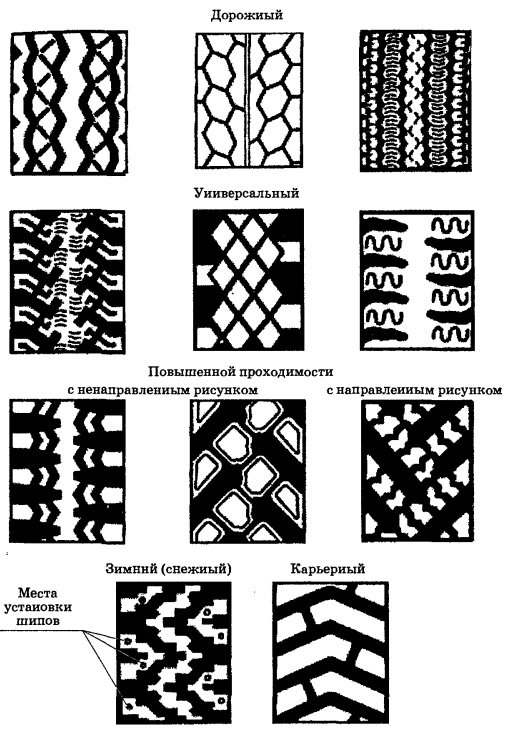

Tires are distinguished by the type of tread pattern:

- with a road pattern in the form of checkers or ribs, separated by grooves; intended for use mainly on roads with improved capital coverage

- with a universal pattern in the form of checkers and ribs in the central zone of the treadmill and lugs along its edges; designed for use on roads with improved and lightweight coverage

- with a cross-country pattern, in which there are high lugs, separated by notches; designed for off-road and soft terrain

- with a winter pattern with sharp edges of the protrusions; designed for use on snowy and icy roads and can be equipped with anti-skid studs

- with a directional pattern, not symmetrical about the radial plane of the wheel

- with all-season pattern

Dimensions of lugs for motoblocks

The heavier the equipment, the better and more practical it is.The high-class, heavy-weight equipment is allowed to work even on hard ground, with which a light mini-tractor copes with considerable work. Heavy mini tractors require the same not small lugs. In general, the scale of the lugs depends on the size of the walk-behind tractor. The height of the equipment can be from 310 to 700 mm, and the width from 100 up to 200 mm. The dimensions of the lug must be selected based on the modification of the unit. The scale of certain models is presented below.

Neva

You need to purchase walk-behind tractors that can adapt to each attachment, or, more simply, universal. However, what to do when the farm already has a Neva mini-tractor, which is by no means considered universal. The wheels of this device for working with soil have scales from 340-360 to 90-110 mm, and on the Neva MB 480-500 x 190-200

When producing a homemade hook for the Neva, you need to take into account that the height should be 340-360 mm, and the width should be 90-110

Firework

In this case, you can assemble the lug according to the same scheme as the Neva. The sizes of the Ugra MB or Salute wheels are from 480-500 to 190-200 mm. Thus, the lug must be made 48-50 cm in length and 19-20 cm in width, in the same dimensions it is made on the Oka MB series.

Centaur

The wheels in the Centaur are similar to those in the Neva walk-behind tractors. Their difference is that the Centaur's wheel length is eleven cm longer than on the Neva. In the production of a lug, it is necessary to make it 450 mm long and 110 mm wide, the same dimensions for the models Zirka, Vityaz, Aurora, Bulat. Such a hook will fit the Centaur 2060 and 2090, and in addition to various units with similar dimensions. In a shopping center, the cost of similar lugs is 2000-2500 rubles.

MTZ

Despite the fact that MTZ walk-behind tractors are made in Belarus, the cost of such units is quite considerable. The approximate price of a lug for MTZ is from 4000 to 5000 rubles. The fact is that the wheels of these motoblocks are quite large, their size is 540-600x130-170 mm. To make a lug for an MTZ walk-behind tractor with your own hands, you must follow the instructions described earlier and make the values corresponding to these wheels, that is, 540-600x130-170. The same dimensions are used for Agro models.

Cayman Vario

The French company Cayman produces excellent walk-behind tractors, the price of which can exceed 60-70 thousand rubles. Also, the additional equipment on them is by no means low cost. The price of a lug for the Cayman Vario is from 5 to 7 thousand rubles. Their size is 460x160 mm, there are also elongated 600x130 mm. The same dimensions are used on the Caiman Elite, Compact, Eco, Promo, Primo, Q Junior series. You can also make a lug yourself, although a person who has allowed himself to buy such a walk-behind tractor will be able to purchase any equipment for it from a store.

Oka

Oka walk-behind tractors are domestic production, a fairly common product in the territory of the Russian Federation. Farmers and hobbyists are increasingly trying to make additional equipment just for such units. When making a lug on the Oka, the length must be 450, and the width is 130 millimeters. The manufacturing scheme is the same as with other walk-behind tractors - everything is extremely simple. In the store, the price of such equipment is about 2500 rubles. But why waste money when you can do everything at home.

Bison

The Bison is a massive, impeccable mini-tractor that tackles many tasks on the farm. Only the best suspended special equipment is attached to it. The size of its wheels is 700x200 mm, the dimensions of the lug are similar. In addition, certain modifications of the bison accept lugs with a size of 700x100 mm. For this reason, it is possible to tinker the lugs of each of these values. However, it is recommended to produce 700x100, as it is more suitable for household needs. Dimensions 700x200 mm are mainly suitable for the purpose of working on virgin soil. The cost of the Bison lug in shopping centers ranges from 20 to 50 thousand rubles.

Cascade

Another domestic manufacturer of special equipment. Motoblocks of this company are also very famous. For this reason, it will be useful for many to find out what diameter the lug should be for such a device.Height - 460-680 mm, width - one hundred and one hundred and ninety-five millimeters.

Pneumatic tires are good or bad

Real pneumatic tires are a unique rubber that differs in all-terrain qualities and in its characteristics is comparable to powerful tracks, adopting the principles of low pressure on the ground, high cross-country ability along a given difficult route, regardless of snow, or mud, or swampy swamp. When pneumatic wheels are mounted on off-road vehicles, the tires can even act as floats, allowing the vehicle to float.

Pneumatic tires

Pneumatic tires

It turns out that while driving on pneumatic rubber, the pressure on the roadway will be minimal, as if a person's foot had stepped there, and not a wheel of a multi-ton car. This "lightness" allows you not to fall through, overcoming marshy areas, snow, mud on the road, bumps on the track.

If you think about why pneumatic tires are needed, then you can define the following functions:

- "Understand" the complexity of the roadway and overcome all obstacles

- mitigate shocks and bumps that are felt by the car from bumps and pits in the road

- provide the best grip

Typically, low pressure tires consist of a sealed inner "bag" filled with compressed air. And the existing protective rim interspersed with steel tape protects and ensures the contact area with the road. At first glance, everything is provided for reliable movement, and this will manifest itself if the rubber is used correctly, and there is no increase in pressure inside the tire.

Thus, it is impossible to evaluate a tire of this class one-sidedly, revealing its negative or praising its merits. You just have to understand - it has a certain scope, practical value, and does not serve as fun, "fashionable thing." You just need to understand its features, study the design and use it correctly for the good, and not for the sake of bravado.

Wheels on the walk-behind tractor

More and more gardeners-owners of walk-behind tractors are making changes in the running gear of their units with their own hands. This allows you to increase the throughput of the cultivator, adapt it to all the most diverse types of soils, successfully widen the track and all much more, something that is not always included in the capabilities of the factory complete set.

Motor-cultivator "Neva"

Motor-cultivator "Neva"

Wheels for motoblocks are of the following types:

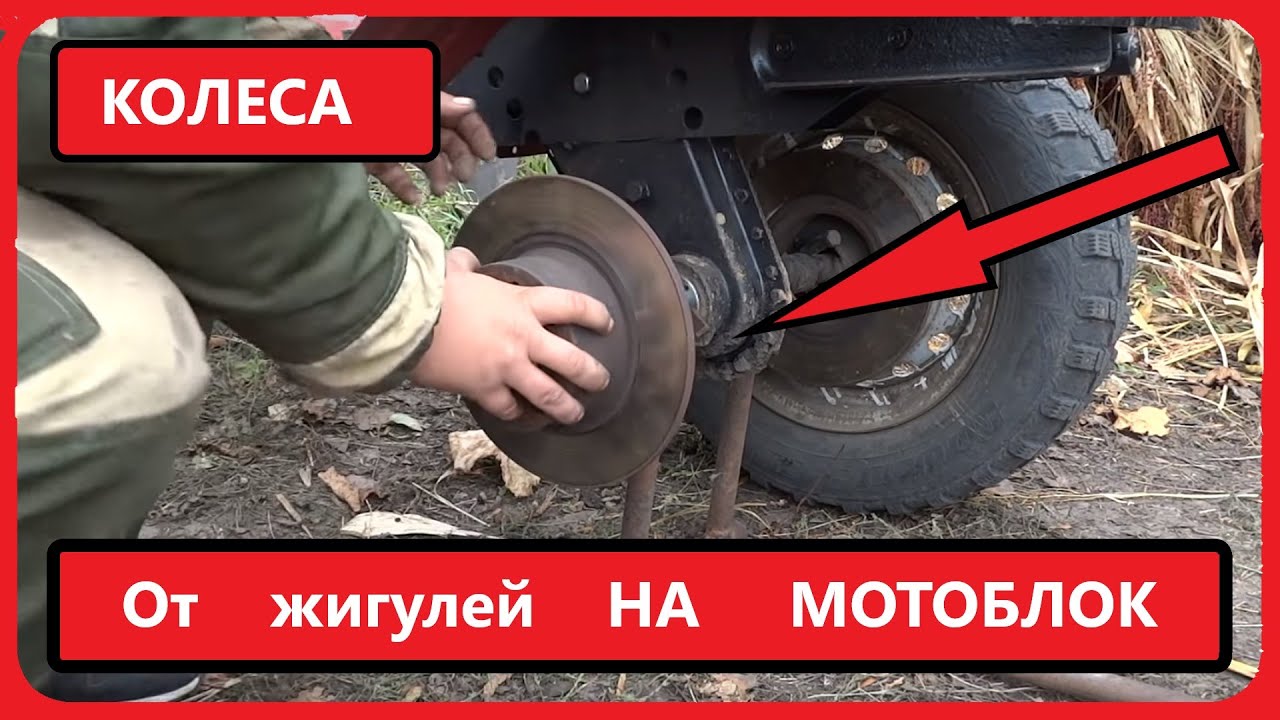

- pneumatic, used for plowing and removing roots from the soil, as well as for transporting the cultivator. Often, instead of factory narrow ones, they are installed from Zhiguli, Oka and Moskvich cars;

- metal or lugs are ideal for clay soil as they have steel teeth for excellent flotation in soft soil;

- solid rubber tires are also installed on mini-tractors, due to the aggressive tread pattern they have increased cross-country ability;

- support - as a rule, this is one support wheel that takes on all the load from the engine;

- paired, helping to increase flotation on difficult terrain and significantly increase speed.