Hose reel option - homemade

Such a reel is practical, since the hose does not need to be wound up and separately connected to the container. It is already connected to it. Now how to do it.

In order to make such a hose holder in the garden, we need plugs, as in the photo below, and a piece of PVC pipe.

We will also prepare a handle and two racks as in the photo.

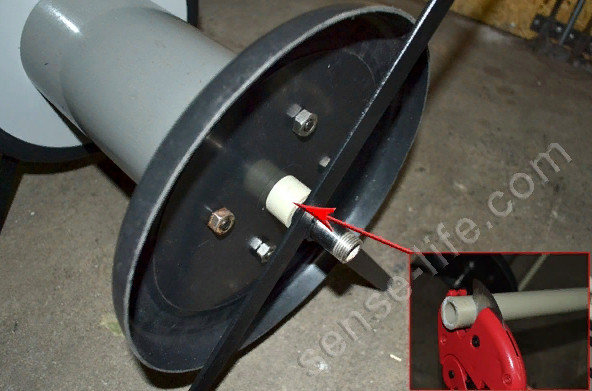

The middle of the spool will have a part that receives water from the side, and the middle will be connected to the hose.

Four studs and a tube with a mount are attached to the first side of the reel.

Next, the second sidewall is screwed on, and a piece of pipe is put on the eyes.

For the frame, we use the same axes and PVC tubes.

On the sides we make washers from PVC pipe scraps.

Here's a coil learned. The design is convenient and easy to manufacture.

Water supply hose connects from the left side.

Assembling the reel drum

To make a drum, you need two plywood (10 mm) discs 50 mm, two discs 0 140 mm from a board 20 mm thick, 8 strips 265 mm long, duralumin tube 18 mm and 450 mm long. Thus, the coil width is 285 mm.

I drilled a small (5 mm) hole in the center of all discs. I put a nail through the hole of the large disk and strung a small disk from the board onto it. Having smeared the adjoining surfaces with glue, fastened the small and large discs with self-tapping screws. I connected the resulting two sidewalls with strips using self-tapping screws and coated the joints with PVA glue. I drilled the central holes of the discs to Ø 18 mm and inserted a duralumin tube, which serves as the axis of rotation of the coil. A removable handle for winding the hose can be fixed in the duralumin tube of the drum.

Selection Tips

When buying a reel, you should focus on which hose will be used in the work. It is more rational to use professional hoses for irrigation, they have a good margin of safety (service life up to 12 years)

Such products have the following advantages:

- they are flexible, easy to fold;

- go around various obstacles at sharp angles;

- do not "freeze" from ice water.

When choosing a reel for winding, you should pay attention to the following parameters of the hose:

- section;

- length;

- what material the thing is made of.

As an agricultural tool, the hose and reel must be of the same brand, this compatibility ensures that no leaks occur. When choosing, it is recommended to use the following criteria:

- Type of fixing the hose to the wall.

- What wheels are present on the mobile model.

- What is the mount for the stationary versions. They must be strong and withstand heavy loads.

- If the sleeves are long, then it makes sense to use a base that has larger diameters and widths.

- What material is the product made of.

- What primer and enamel the device is painted with.

- What metal is the coil made of. Models made of stainless steel last longer, they can withstand heavy loads and are not subject to corrosion.

The support frame of the "trolley" must be wide and made of strong metal, in this case it will be stable, will not turn over from various loads when the hose is pulled. The wheels of the "trolley" should be wide, this will provide a comfortable and smooth movement.

How to make a hose reel

This video shows how a reel is made, which makes it convenient to wind and unwind a garden hose at a summer cottage.The hose is not pinched during storage, it is easy to unwind, the device stands on small wheels and is therefore mobile.

With the beginning of the irrigation season, every year there is a problem of winding and unwinding the hose. Therefore, it was decided to make the device from simple materials for storing and transporting the hose.

The reel is made of 2 bicycle rims on a movable axle from 12 mm smooth rebar. Welded into the tubes. With good lubrication, the drum rotates perfectly. It is set in motion with a handle.

Dimensions.

The width of the device is about 30 centimeters, the length of the spoke is about 20 cm. Such dimensions allow you to fit three layers of hose, about 40 meters, and at full load up to 70-80 m. The reel is mounted on wheels for easy transportation.

In the next video we will show you a reel of polypropylene pipes for hoses for watering in a garden in a vegetable garden. It was decided to abandon the metal structure in combination with wooden parts in order to make it as lightweight as possible and make the reel portable.

Used 25 mm tubes. These are the usual cheapest polypropylene pipes, and part of the handle is made of fiberglass reinforced pipe. It took about 1 meter of such a pipe.

In this case, the spool with the axle can be easily disassembled, except for the handle and the axle. We also needed plumbing cuffs 50x25. The coil itself is very high quality, durable and the pipe fits very tightly in it.

See another article on how to make watering automatic.

Without what not to get a harvest - life-giving moisture

Seriously though, do not be fooled by the small area of the land plot. It will not be possible to save on such necessary equipment as a garden hose on a reel. Bitter onions, cracked carrots, small cabbage heads, fancy-shaped cucumbers - all this is the result of insufficient soil moisture.

Move the mechanism to the desired location, unwind the hose, connect to a water source, turn on the water, water the garden, reel in the hose, put the inventory in storage ... Follow this extremely simple instruction and keep your spine healthy for years to come. Such a garden is a pleasure, you must agree!

A more practical solution (for a very beloved wife) is to purchase a reel on wheels. Such a design is completely easy to operate, because thanks to the wheels, the mechanism does not need to be lifted - it is convenient for very young and elderly gardeners, women in position. There are models suitable for use on land plots of different sizes.

Trolley legs

I made the legs from two corners. One side of the corner, stepping back from the edge 20 mm, bent at an angle of 135 degrees inward of the corner, the other bent 45 degrees outward. The corners can be checked with a protractor or a protractor. I put the corner formed in this way on the protruding profile of the base, cut by 45 degrees, and attached it with rivets.

To make a holder for the drum, I bent one shelf at two corners so that the resulting brackets freely fit the aluminum tube - the spool axis. The holders were fixed on the racks of the U-shaped frame at a height of 270 mm from the base. At the last stage, I secured the door handle on top of the U-shaped frame.

Additional applications

By the way, now it turned out that since two barrels, the old and the new, are not far from each other, you can pour them with the same hose, simply by throwing it from one holder to another, which is very convenient.

In addition, the same hose is also put on the third low holder next to the bucket. In this case, the end of the hose acts as a spout for an ordinary water tap, since you can wash your hands above the bucket or, if necessary, you can quickly wash something else, such as vegetables, fruits or berries.

When the watering season is over, all holders can be pulled out of the ground, cleaned, and stored in a shed until next season.

Well, that's all for me! Good luck to everyone in the fight for the harvest!

Homemade reel for a garden hose from the Knauf profile

Tired of manually winding up garden hoses in the country. One hose - 40-45 meters. The main watering 3/4. The other - 15 meters with a pump for pumping out the well.

Turning the hoses back and forth every time is no longer a joy.

A finished coil for such purposes costs from 1,500 rubles, depending on the brand and quality. You can find it cheaper - I met it for 860 rubles, but the quality is disgusting.

From the materials I decided to use Knauf guides - fortunately, I have a few of them left - ceiling guides 28x27 and rack 60x27.

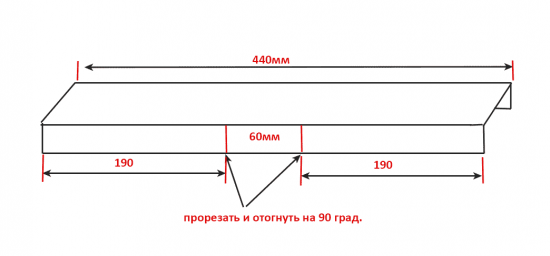

I had a couple of pieces of rails 28x27 154cm long. I decided to use them as a “rim” of the reel wheel. ”I decided to leave 2-3 cm on each side for overlap and fixation. Divide the remaining distance into 8 line segments to make an octagon. I decided not to bother with the circle.

As a result, the side of the octagon turned out to be 185mm and 35mm remained for the overlap. In this case, the "diameter" of the coil will be 440-450mm.

I cut a couple of crossbars from the rack profile for the resulting octagon. In one of them I cut out a groove 60mm wide, bent the "ears" to the side and made a crosspiece.

Fastening was done on sharp screws "bugs" 9mm long.

Then I put on these crosspieces a "rim" made of a 28x27 profile and fixed it with the same screws. In the places where the profile intersects, I made additional fastenings with a cutter. so, just in case.

On the reverse side of the crosspiece, I made an insert in the center from pieces of the same profile. I only cut the side off a little so that the profile "drove" into the profile and fixed these inserts on the sides with the same screws "bugs". You can see this in the photo above.

Knauf made four crossbeams for connecting the resulting "steering wheels" from the same rack-mount profile. He used pieces of 320mm length. On each side, I made cuts of 25 mm and then bent the edges into which I then screwed in the "bedbugs" screws. All the interfering curved edges of the rack-mount profile were bent and leveled with a hammer. If necessary, trimmed with scissors for metal.

I tried to bend it in two options - you can see it in the photo. By and large, it makes no difference how to do it. IMHO

In the center of the "wheel" I made marks of the center and drilled through holes with a diameter of 10 mm. Also marked the future center part. I chose a distance of 160mm.

Then I attached all the resulting crossbeams to the seats.

Then he fixed the second "wheel".

In one corner of the 28x27 profile I drilled a small hole to rotate it on the stand in the future. In a trial test, I rotated the coil with a short screwdriver.

To test the coil, I drilled a hole a little more than 10mm in the birch and screwed a 10mm hairpin into it. I put a coil on it and then I will cut the birch.

The coil turned out to be quite stiff and not heavy. Perhaps plywood would have been heavier.

A 3/4 garden hose with a length of a little over 40 meters was wound on a reel. Since I was a little late with the weather and did not have time to remove the hose earlier, the water in it froze and had to wind up the hose with water. This affected the ease of rotation of the coil. I had to rotate it with my hands. The hairpin bent a little.

When removing the coil from the pin, the edges of the profile clung to the thread of the coil. Then it will be necessary to either screw the bar inside or use the pipe - I'll see later.

In general, I am satisfied with the result. It remains to make a normal stand and a couple of smaller coils - the benefit of the profile is still there.

Below you can watch a couple of videos.

Storage advice

In order to properly store the hose and reels in the country, it is recommended to follow several rules. It is not recommended to connect the hose to the reel inlet pipe, although the reel has a hose. In hot seasons, do not keep the hose and reel in direct UV light, this will prolong their service life.This recommendation is especially relevant for hoses that are made of PVC and silicone.

While winding the hose on the drum, disconnect it from the water supply system, let the water drain. A coil should be placed between the clamps, methodically rotated, while cleaning the hose from dirt with a cotton rag. The reel and hose can last for decades if stored properly. Rubber hoses have a service life of up to two decades, PVC hoses are cheaper and withstand a service life of up to 10 years. In the cold season, hoses are stored rolled up on the walls, away from rodents.

During spring and summer, hoses and reels are stored under a shed. The hose can also be left on the ground. Make sure that the hoses are not kinked or kinked. In company stores you can find forged "holders" or clamps, which are conveniently mounted on vertical planes. Often they are made in a decorative style, which can also carry aesthetic functions and safely allow you to store reels and hoses. It is convenient to use an old tire for storing reels and hoses, it is able to protect from dirt and dust.

For information on how to make a garden hose reel with your own hands, see the video below.

Holder making

Well, now I will show you how such a holder is made. To make it, we need the following accessories:

Materials and fasteners:

- Wooden plank 2-2.5 cm thick, 4 cm wide, and 80-90 cm long.

- A piece of steel corner 25x25 mm, 40-45 cm long.

- Two wood screws 4x20 mm.

Instruments:

- Drawing and measuring tools (pencil, tape measure and square).

- Jigsaw with a file for a figured cut.

- Electric drill-screwdriver.

- Drills for metal with a diameter of 4 mm and 8 mm.

- Screwdriver bit PH2, for driving screws.

- Sandpaper.

Holder manufacturing procedure

First, we saw off a plank of the required length, and at one of its ends, we make such a curved saw cut for putting on the wire brace of the hose.

Next, we drill two through holes with a diameter of 4 mm in the steel corner. We make one hole at the very end of the corner, and the other after about 20 cm.

Then, using a metal drill with a diameter of 8 mm, countersink these holes for countersunk screw heads.

Now it remains to screw the corner with screws to the bottom of the board.

And now our holder is ready!

However, it is still very desirable to paint it. In order to be clearly visible, I chose yellow paint.

And now our holder is finally ready!

How to do it yourself?

For gardeners, an irrigation hose is vital, and a reel is also needed to reel it. It is not necessary to buy it in a store, you can make such a node yourself, it will cost a little. To make a homemade hose reel, you need to consider what material is best to use. For the core, a piece of pipe, a steel strip, a 22x5 mm mount may be suitable. With the sidewalls, things are a little more complicated. The material must be durable, which would not be afraid of moisture and temperature extremes.

Some craftsmen mount lids from large basins or pans, this does not seem like a bad idea, the metal is quite strong there. Before starting the installation, drawings should be made (they can be found on the Internet), it is recommended to put down the exact dimensions of the future device in them. In old metal containers, the bottom is cut off, an indent is made from the edge a couple of centimeters. This option also seems quite acceptable.

Most often, the following are used for these purposes:

- old basins;

- containers from washing machines;

- large pans.

In total, a metal circle with a diameter of 35 cm is required for the sidewall of the coil. A frame is created from a metal strip, and scraps of a thin-walled pipe are welded in the center. Sometimes, for greater rigidity, fragments from PVC pipes are inserted. A circle with a diameter of 142 mm is drawn in the center, 4 holes are drilled.To exclude kinks of the hose when attaching to the axis, a fitting is used, a watering hose is attached to it. It is even better to mount a tee, in this case there is "freedom of maneuver", you can bend the hose at any sharp angle. Excess holes can be filled with foam or silicone.

Studs are best cut from reinforcement “8”. To attach the frame, you can use the same pins; fragments of PVC pipe are put on them as handles. The connector is pulled over the hose, connected to the axle and wound. During winding, be careful not to kink the hose. If everything is done correctly, then the product will not be inferior in strength to the branded copy. You can also put wheels from the washing machine so that you can move the unit around the workshop room. A hose with a diameter of 4 cm is quite suitable for such a reel.What is the benefit:

- the drum clears the working space;

- increased mobility if the drum is attached to the wheels;

- the time for unwinding and installation is reduced;

- no creases occur;

- convenient to store in any utility room.

The second option is a budget one, plywood is used, which can be coated with a special primer, then painted with oil paint. Such processing will extend the life of plywood by 3-4 times. The side walls of the future drum are cut in the form of circles from plywood (10 mm), diameter 435 mm. Holes (14 mm) are drilled in the center, they will be used to install a drum in them.

The axle can be made by taking a metal rod or pin with a diameter of 10 mm. A certain length margin should be taken into account, it should be greater than the distance between the sidewalls

It is important to correctly distribute the cross braces. They are made from rails (size 26x11 mm, only 8 pieces)

The slats are located evenly around the entire circumference.

Self-tapping screws are used to fix the rails using corners (two pieces per one rail). The pusher lock is made using a special pad. This is a board (20 mm), in which a 12 mm hole is drilled, then the rectangular section is sawn in half. The resulting halves are attached to the outer sides of the sidewalls. The pusher is made of a steel plate (thickness 2 mm), size 12x110 mm.

The pusher is fixed with a screw that goes through the axle, positioned in such a way that the axle protrudes 45 mm outward. The easiest way is to attach the stand, for this you will need board trimming (14 mm wide), the gap between the supports is 45 mm. They are fixed with transverse wooden dies. The stand is fixed on a vertical plane using clamps, brackets, corners, etc.

At the base of the supports, a "landing" groove should be created so that the knot does not jump off, a special lock is made, which is cut from a steel strip (thickness 2 mm, width 20 mm). After manufacture, the drum should be field tested. Before starting work, it is recommended to carefully check all joints and knots, there should not be any backlash or poor fasteners. If everything is fine, then you can connect the hose. The drum can also be made of PVC pipes, for this only the farm needs a special welding unit for PVC products. Typically 30 mm pipes are used. The advantage of such a product:

- not subject to corrosion;

- has good strength;

- lightweight, easy to transport.

Manufacturers and models

There are several brands that have proven themselves at their best. Product prices are quite high, but the coils have a long service life, they are reliable and work flawlessly. These include the Gardena and Hozelock trademarks.

Gardena reels have automatic winding, the hose does not twist, does not "break". The coil support is reliable, the construction is stable. The system has compact parameters, has an ergonomic hose handle.The product can be taken, for example, on a camping trip, used in summer cottages, used in the production workshop of a small enterprise.

The Hozelock reel is designed for hoses that can withstand increased pressure. The reel is made of modern innovative materials that can work in aggressive environments. Models can have both inertial winding and automatic. The drums can be moved on platform carts, there are also stationary structures. Before buying, it is recommended that you carefully familiarize yourself with the performance characteristics, see how the device works in various environments. For example, in the chemical food industry, the following material is used:

- durable PVC;

- stainless steel.

Hozelock drums are price-performance-wise, and they are quite acceptable.

Reel Drum Cart

I assembled the cart from duralumin square profiles with a side of 20 mm using corners and rivets. It consists of two parts - a rectangular base and a U-shaped frame with a door handle. Base dimensions - 350 * 330 mm, the height of the U-shaped frame is 700 mm. The peculiarity of the trolley is that the edge of the base rests on two legs in the form of corners with wheels fixed in such a way that they do not reach the ground a little. The wheel diameter is 30 mm. If you take the frame handle and slightly tilt the trolley, then it will stand on wheels - and you can easily and effortlessly roll it along behind you, like a modern suitcase.

The U-shaped frame is attached to the base with reinforced corners. It does not stand in the middle of the base, but at a distance of 100 mm from the edge with wheels. It is convenient because it is easy to tilt the cart and start moving. Moreover, in the working position, good structural stability is ensured. I easily pulled out 20 m of the hose - and at this time the cart stood rooted to the spot.