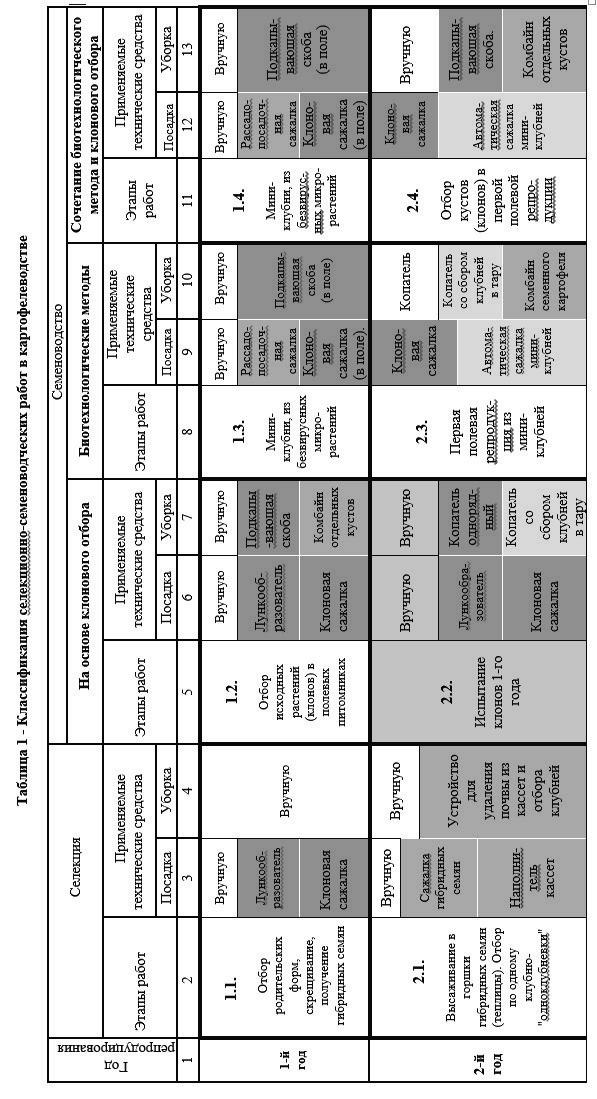

Specifications

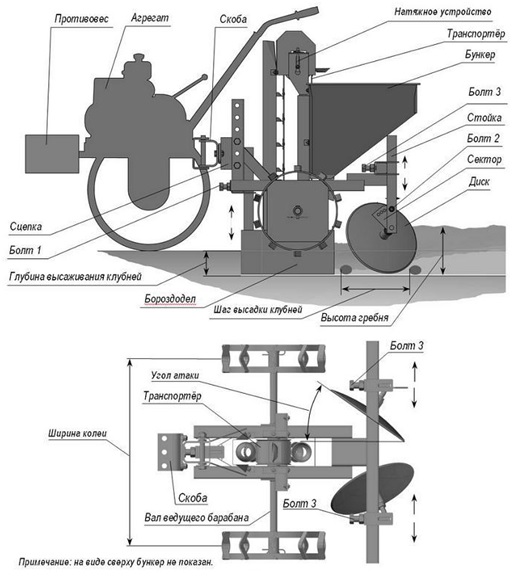

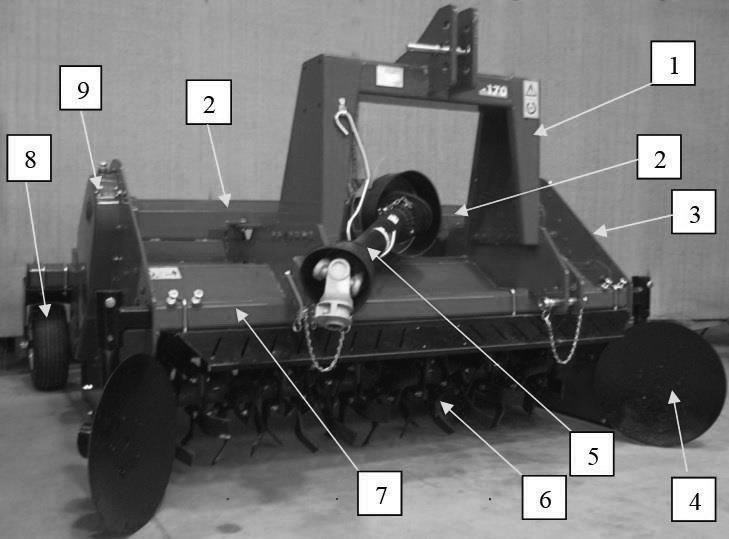

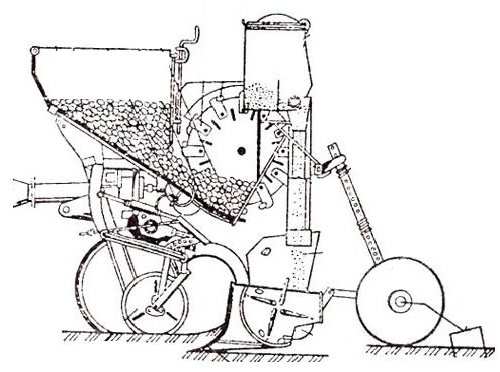

The vast majority of potato planters have approximately the same design and include the following elements.

- Seed tank - made of galvanized metal with a thickness of 0.9 mm. Capacity - not less than 20 kg of seed.

- Frame with wheels - serves as the main supporting frame, it is the attachment point for all the main elements of the installation, the frame, as a rule, is single-point, less often it is offset.

- Support wheels - are needed to perform a turn of the transport of the mechanism around the site.

- The coulters are necessary for making the furrow.

- The landing gear drive - works by rotating the wheels with the transfer of torque to a metal chain, can be additionally equipped with spoons or cups fixed on the leveling brackets.

- Covering discs are special devices that allow covering the cultivated furrows with soil.

All these mechanisms can be purchased at any large store selling agricultural machinery, but some craftsmen prefer to make them with their own hands - it should be noted that the efficiency of the latter is in no way inferior to factory products. The potato planter has a slightly different design, suitable for planting sprouted potatoes that already contain sprouts. This design is characterized by the absence of a loading hopper, as well as installed vice versa. This machine is more focused on physical labor, however, and seedlings are obtained much faster too.

In addition to the features described above, many mini tractor planters have some additional adjustment options:

- landing depth control;

- adjustment of the distance between tubers;

- setting the row spacing;

- adjustment of hillers.

In addition, factory models are supplemented with specialized containers that contain fertilizer for the earth; during work, mineral feed is poured into the holes, where potatoes are then planted.

For walk-behind tractor

If you have a walk-behind tractor or want to purchase one, then it makes sense to abandon a manual potato planter and go straight to the design of a device designed specifically for a walk-behind tractor. You should always start with the frame, since this is the basis on which all further components and assemblies will be fixed. For the frame, channels (material - steel) of type 8 (dimensional standard) are used.

Such a device faces not only the task of automating potato planting, but also ensuring that the bushes are evenly distributed and covered with the correct amount of soil. In addition to making work easier, such a potato planter also improves the quality of planting.

Since the walk-behind tractor is designed for small equipment, it means that there are no special strength requirements for the bunker; you can use ordinary plywood 1 cm thick. The carrying capacity of such a device will be about 0.25-0.3 centners.

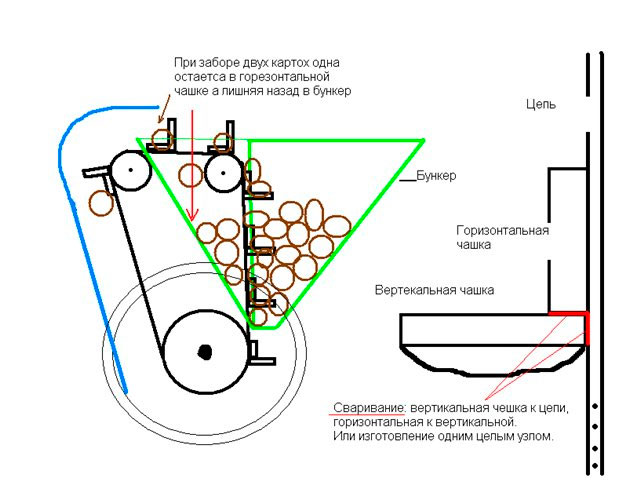

The part of the device in which the tubers will move is called the container. The main requirement for the container is the presence of an elevator, which is fixed vertically and is supplied with special bowls with diameters of 50-80 mm. The operation of the entire mechanism is carried out thanks to a chain transmission to the drive wheel. An elevator must be installed in the container, it must be equipped with bowls. In order for the mechanism to work, it is attached to a drive wheel with the participation of a chain drive.

In order for the tubers to enter the ground, a special seed tube is used, which must be placed at the bottom of the elevator and be pressed by the component that the zagreb performs.

An 80 mm sprocket is embedded in the mechanism, which guarantees the transmission through the chain. On the walk-behind tractor, a star is used twice as large in diameter - 160 mm.

Single row pot planter

To implement such a system, you can use a chain from a regular bicycle or moped. With this automation, the distance between future potato bushes will be about a third of a meter.

How the potato planter works

You can adjust the planting depth and the interval between holes.

The landing technique is self-propelled, an important condition for the wheels to adhere well to the ground and the conveyor to work properly

The plow makes a trench, then the seed falls into the hole, and special blades cover them with soil and level the surface. As a result, you get even beds and an interval between them.

It consists of a container into which potatoes are poured. In appearance, it can be both rectangular and conical, the most important part is the bottom, from which the potatoes will be fed into special baskets. They are also attached to the tape on the back of the planter.

What to look for:

- Hopper capacity, the larger the capacity, the less you will slow down the work in order to fill up a new portion of tubers. Standard bunker from 2 to 6 buckets;

- The mass of the apparatus and its productivity;

- Adjustment and maneuverability.

Planting potatoes with a regular and two-row hiller

Hillers for motoblocks there are several types:

- single row, forming only one furrow in 1 pass;

- double-row, forming two furrows in 1 pass;

- disk.

The device and principle of operation of the listed equipment are largely similar, since all hillers are designed to perform the same task.

Therefore, such attachments are recommended for use on light soils. Planting potatoes with a walk-behind tractor with a hiller is performed in several stages:

- Grousers are installed on the wheels.

- Unfold the hiller wings in accordance with the selected track gauge.

- They pass through the site, forming grooves with ridges.

- Potatoes are placed in the grooves, placing them at a distance of 20-25 cm from each other.

- Remove the lugs.

- The hiller's wings are spread as far as possible.

- They pass between the rows, filling the furrows with soil.

Planting potatoes with a walk-behind tractor with a two-row hiller is a little more difficult. But just as in the case of a single-row, the unit is re-equipped before starting work:

- install lugs;

- attach the hitch;

- attach hinged mechanisms.

The next step is to set up a two-row hiller

It is important to find the correct distance between the working parts of the equipment. Standardly it is 60-65 cm, t

That is, the width of the future bed. When cutting furrows, each hiller should be exactly in the middle of the row spacing. Further work consists in placing the tubers in the grooves, followed by backfilling the furrows.

Specific points when using a planter

When working with potato planters, a number of rules must be followed.

This is more important for those who have no experience in this type of work. Beginners often get crooked rows and, when digging in furrows, they turn the tubers onto the surface of the soil.

This is due to the inept use of attachments for the walk-behind tractor. The advice of experienced gardeners will help to overcome difficulties:

It is important to maintain the same distance between the tubers: potatoes planted at a depth will sprout for a long time.

Ripper discs should be buried no more than 15 cm into the ground.

For uninterrupted feeding of potatoes into the furrow, it is necessary to maintain the distance between the wall of the hopper and the end of the spoon. The width of this gap depends on the size of the tuber.

For small potatoes weighing 30-50 g, a distance of 3-5 mm is sufficient, for larger ones (weighing 50-80 g) - 10-12 mm.

The planting depth is set by adjusting the height of the rippers relative to the wheel axis.

The planting density with a synchronized drive depends on the rotational speed of the discs with the chain with spoons installed on them. The regulation is carried out by changing the position of the spoons or by adding a chain.

The lineup

There are a lot of potato planters from different companies on the agricultural machinery market, designed for aggregation with a variety of devices. These are homemade potato planters for MTZ.

It is not surprising that there is a certain problem of choice, because you need to pay attention to several aspects at once:

You have the amount of money that you are willing to spend on the purchase of this unit.

Performance you are interested in, because some models are designed for planting potatoes in relatively small areas, and more powerful units for planting in large gardens.

It is necessary to take into account which model of the mini tractor you have in stock. The fact is that different models may have a completely different principle for connecting additional equipment.

Therefore, using one type of potato planter may not work with your mini tractor.

The time period during which the potato planter can work without interruption.

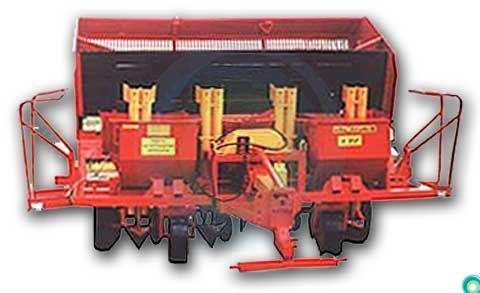

Double row potato planter

Understanding these points will greatly simplify the issue of choosing a particular potato planter. Only after that, you can go to the store for the unit you are interested in.

Potato planters are considered additional equipment, so it is easier to choose them, based on which tractor or mini-tractor they are capable of being aggregated to. This is the most important point to make the right choice.

The potato planter for the MTZ 132N minitractor belongs to a single-row type, designed for planting potato tubers on land plots. This unit can be used on the soil that was previously plowed.

In addition to joining MTZ 132N, this potato planter can be aggregated with MTZ 082 and MTZ 082BS.

What characteristics are important when choosing a potato planter?

The principle of operation is the same for all models: when the tractor is moving, the openers of the potato planter cut the soil to the required depth, the tubers are fed into the resulting trench with the same interval, and then the disc dumps fill the furrows. As a result, the bed turns out to be even, the planting density, as well as the row spacing, is the same. You can plant both smooth and ridge methods.

Single row mini tractor potato planter

Single row mini tractor potato planter

You should know which tractor will work "in tandem" with the potato planter. If its power does not exceed 10 hp, you can safely purchase a compact small model, for example, the Ukrainian KSC-3 weighs only 72 kg. For a tractor from 10-20 HP more heavy equipment is purchased, for example 2SM-1 (Xingtai company). With a tractor power exceeding 20 HP you will need a potato planter weighing more than 200 kg: it was originally designed for a significant sowing area. Here you can recommend Xingtai 2CM-2 with a lot of additional functions.

Two-row mini-tractor potato planter with fertilizer hopper

Two-row mini-tractor potato planter with fertilizer hopper

The structure of the undercarriage and the weight of the potato planter are also selected depending on the nature of the cultivated land. For sticky, swampy soil, light versions are preferred to avoid equipment sinking into the ground. On hard rocky soils, heavy equipment with forged metal wheels will work fine. Also, in these conditions, an automated potato planter will show itself well.For loose soils, it is better to choose a unit with a high ground clearance, and so that it easily clings to the ground, you need rubber wheels with a tractor tread.

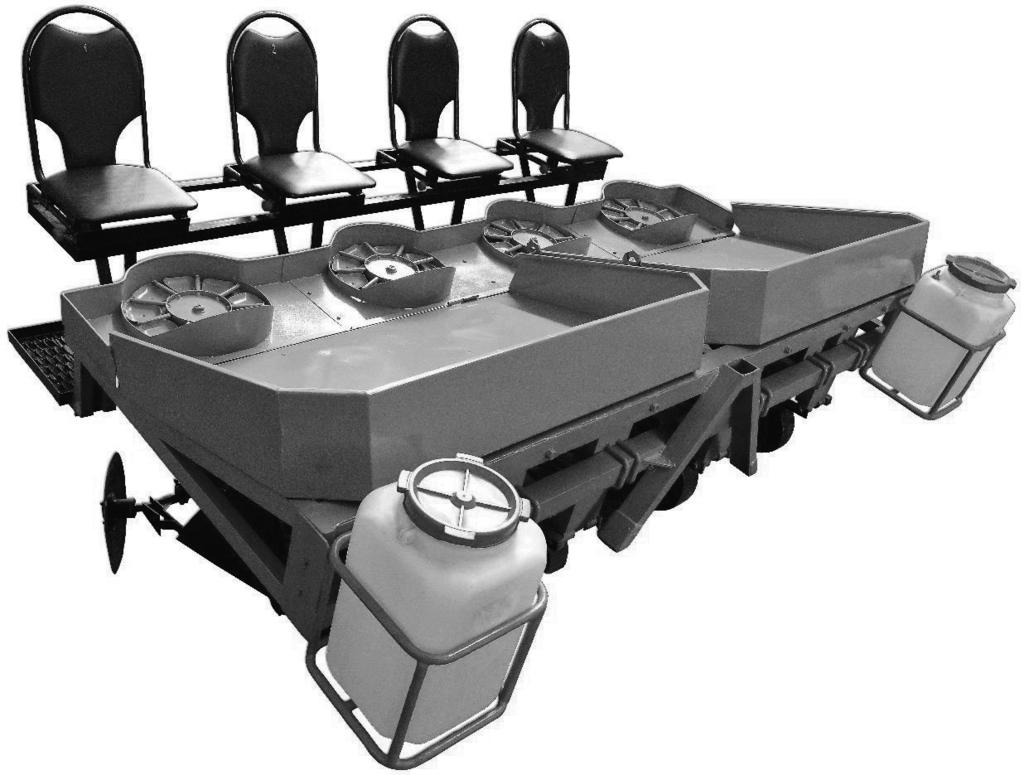

Fully automated models are produced, where a person is only required to add potatoes to the bunker in time and with manual control, equipped with a seat for the operator. In the first case, the landing speed increases, in the second, its parameters can be adjusted as quickly as possible.

It is important to know how the potato planter will be connected to the tractor, for the Belarusian models have a simple connection system, whereas with the patented Husqvarna technology system, the connection is carried out in seconds. And of course, when buying, you should check the quality and integrity of the anti-corrosion coating and welds, evaluate the build quality

You should not spare money to purchase a potato planter, because if you can somehow do without the rest of the vegetables, then the Russians have long become a staple food product, they are planted everywhere and a lot, so the potato planter becomes an indispensable assistant in this laborious process

And of course, when buying, you should check the quality and integrity of the anti-corrosion coating and welds, and evaluate the build quality. You should not spare money to purchase a potato planter, because if you can somehow do without the rest of the vegetables, then the Russians have long become a staple food product, they are planted everywhere and a lot, so the potato planter becomes an indispensable assistant in this laborious process.

User manual

Recommendations for using potato planters are quite similar to each other, differing only in minor points. Do not put more fruit into the tuber hopper than stated in the technical characteristics of the unit. The potato planter must not be transported fully loaded.

Before starting work, you need to make sure that the wheel track of the mini tractor and the potato planter completely coincides.

- It is necessary to carry out preliminary preparation of the soil before using the potato planter on it. It means that the land must be plowed, loose structure.

- After passing the first row, you need to adjust the degree of immersion of the openers, the depth of the potato tubers, as well as the distance between them.

- It is necessary to inspect the working units of the unit every 8 hours of continuous operation.

- After the completion of the work, the unit must be returned to its normal state, i.e. clean it from dirt, vegetation residues, etc.

- In addition, you need to inspect the fasteners. If necessary, tighten the bolts and check the condition of the wheels.

- If you will not be using the potato planter for a while, then it is necessary to reduce the tire pressure, as well as remove the roller chains that are on the planters.

Mini tractor potato planter: what to look for?

What is it made of

When you come to the market or store for potato planting equipment, take your time to buy the first one that suits you in terms of performance.

When you come to the market or store for potato planting equipment, take your time to buy the first one that suits you in terms of performance.

Be sure to take some time to inspect the potato planter for build quality and weld strength. This is especially true for products supplied from Ukraine.

Breakdowns during work and finding the right repair tool will take time and money. Therefore, one should not be lazy, it is necessary to carefully examine every centimeter of the structure.

Be sure to study the brochure and ask the seller about such an important point as corrosion protection, which is used by the manufacturer of this type of equipment.

The Xingtai company, before applying paint and varnish coatings to its products, treats their metal parts with a special anti-corrosion compound, which allows you to maintain the strength and presentable appearance of the equipment for a very long time.

Method of connection with mini-tractor

Did you know that the characteristics of a tower crane depend on the way the jib is extended?

From the following article, you can learn how to choose a gasoline self-propelled lawn mower for a summer cottage.

At the following address

Husqvarna, on the other hand, equips its vehicles with a patented add-on system that allows you to change attachments in a matter of seconds.

If you decide to buy such highly specialized agricultural equipment as a potato planter, you should take into account all the nuances that may arise during work, and based on them, make your choice.

Carefully read the reviews on specialized forums, visit several stores. Think carefully before making a purchase, and it will not disappoint you.

You can see how a single-row potato planter for a mini-tractor works from the video:

Making a potato planter

First, weld the channel frame structure. You get 2 spars, fastened together by 3 strips of steel. On the front, an arch with forks is firmly welded, which are directly directed to the center rod. Then we fix the bracket by welding, there will be a container for potatoes.

For this tank, take a thin piece of plywood, about 13 mm. Next, we make the walls of the bunker and connect them with corners. We fix our bunker to the bracket.

Take the wheelbase itself from unnecessary equipment, the hubs are well welded on them and 2 bearings are worn.

The sower can be made from a tube with a diameter of up to 9 mm, the thickness must be at least 3.5 mm. Attach a furrow cutter to the bottom of the pipe.

Insert the seat into the finished frame, be sure to cover it with a warm and soft cloth.

As we can see, you can make or buy a potato planter, but it will definitely make life easier for the farmer. Since the landing time will be reduced, and physical, hard work will not be needed.

Description

Potato planters and Potato diggers for the walk-behind tractor are universal attachments that allow mechanized planting and harvesting of potatoes in a short time without the cost of human resources. More and more summer residents, garden owners and small farmers prefer to grow potatoes with a walk-behind tractor.

All procedures, from preparing the soil for planting potatoes, cutting furrows, seeding tubers, further hilling bushes, as well as harvesting, are performed by this unit. If you have a walk-behind tractor and there is no planter, you can also plant potatoes, then a plow or hiller will be used.

Homemade constructions

Considering that the average cost of potato planters varies between 15,000-30,000 rubles, many farmers prefer to use homemade products. Making a potato planter at home is not difficult: the design of the equipment is quite simple.

Homemade potato planter

On the network you can find a lot of options for self-assembly of a potato planter. Here is one of them:

- As a basis, you will need to make a steel frame. This element can be welded from pieces of channel # 8. The frame looks like this: longitudinal spars are connected by three transverse rods.

- Immediately think about the equipment. In particular, a fastening fork must be welded to the front rod, brackets for sealing discs must be installed, and an axle for a wheelset must be welded. To install the wheels, you can use a thick-walled pipe with bearings pressed at the ends.

- Then you need to install the seed tube. In our case, this is a 100 mm pipe equipped with a furrow cutter at the bottom.

- We make a seed hopper from waterproof plywood. Plywood can be replaced with steel sheets, but this will significantly make the structure heavier.

- Covering discs can be removed from the SO-4.2 seeder ready-made. The wheelset can also be obtained ready-made by removing it from a broken garden cart.

Please note that a homemade potato planter, made according to the above scheme, is quite cumbersome. Therefore, the design is not suitable for working with mini-tractors with a capacity of less than 12 liters.

with.

TELL YOUR FRIENDS

User manual

All recommendations for working with potato planters are similar to each other, regardless of the model used, the difference remains only in some points. The main recommendations are as follows.

- Do not add more seed to the tuber hopper than indicated in the instructions for use.

- Do not move the potato planter fully loaded.

- Before starting to use, make sure that the wheel track of the potato planter and the mini-tractor is the same.

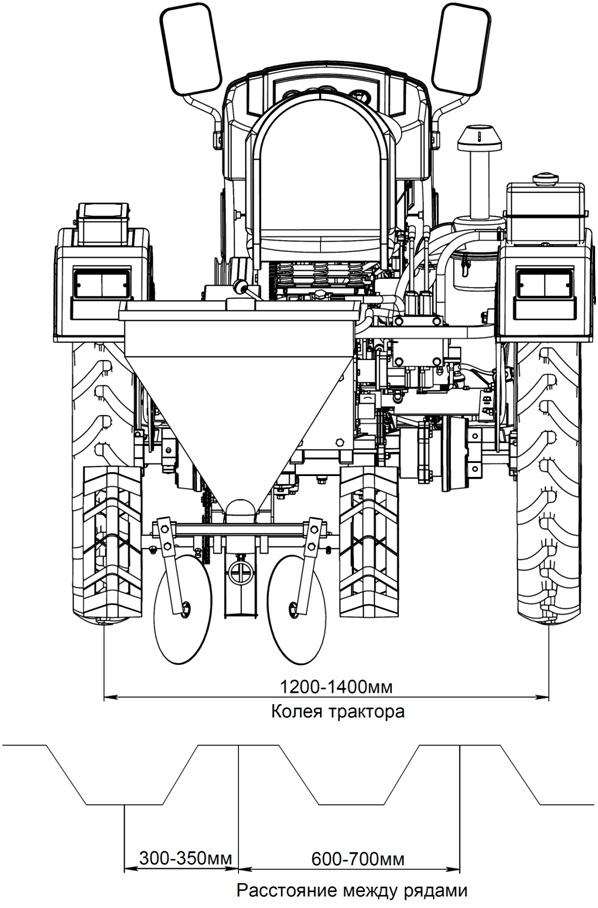

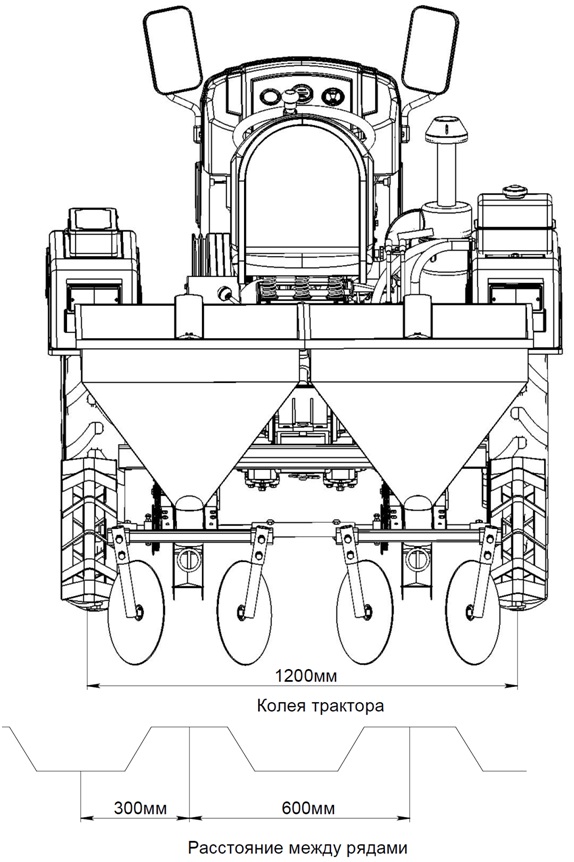

The next agricultural season will begin very soon, and it is important to properly prepare for it. Gardenshop has prepared recommendations for using potato planters and diggers with SCOUT and Fighter mini tractors

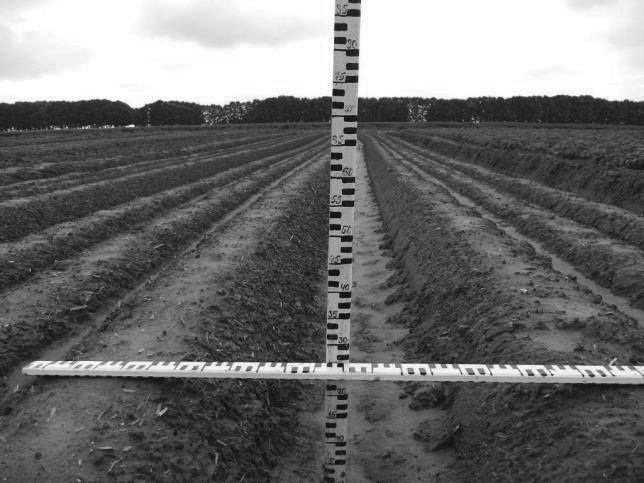

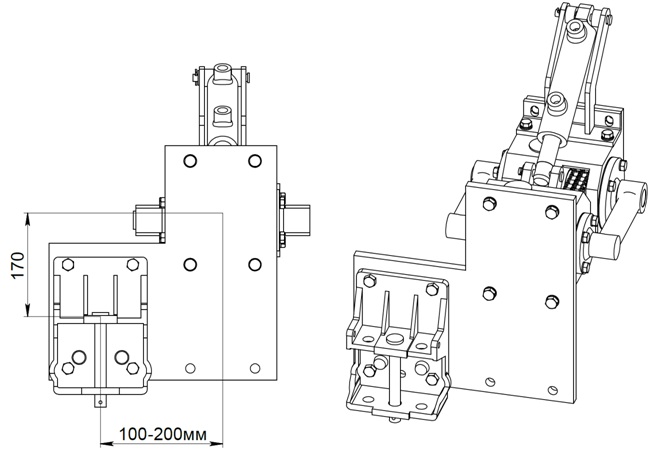

It is generally known that for the best yield, potatoes are recommended to be planted at a distance of 600-700 mm between rows. When planting tubers using SCOUT and Fighter mini tractors using PL-20, PL-50 single-row potato planters, you will need an adapter plate that will allow you to achieve the required row spacing.

Fig. 1. Installation of the adapter plate.

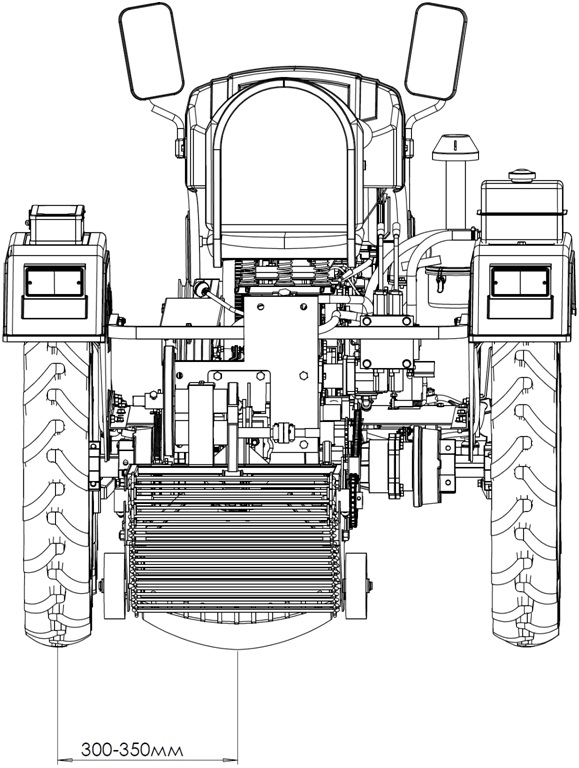

This design shifts the axis of the potato planter by 100-200 mm to the left, which, together with the expandable track of the tractor, will provide the required distance of 300-350 mm from the center of the wheel to the center of the potato digger.

Fig. 2. PL50 potato planter on a Scout motorized tractor, using an adapter plate.

To speed up the process of planting potatoes, we recommend using the PL50 / 2 double-row potato planters, while you do not need an adapter plate, and the potatoes can be planted with an optimal distance between rows - 600 mm.

Fig. 3. Planter PL50 / 2 on the Scout tractor.

Potatoes planted using small equipment are most efficiently dug out using a conveyor or screening potato digger.

In this case, you also need to shift the potato digger to the left by 100-200mm using the adapter plate so that the tractor wheels move along the aisles, and the potato digger knife along the bed.

Fig. 4. The transporter potato digger on the Scout motorcycle tractor.

Rational use of attachments for a mini tractor will not only reduce labor costs when growing potatoes, but also provide a decent harvest in the fall.

We bring to your attention a video with an example of the operation of a potato digger using the SCOUT technique.

Setting up a potato planter

Before starting work with a potato planter, you should check the technical condition of this equipment, the strength of the joints and working units, after which the unit is adjusted in accordance with the condition of the soil in the cultivated area. In almost all planters for mini tractors, you can adjust and set a specific distance between tubers, planting depth and spacing between rows. To adjust this product, adjust the depth of the openers and hillers, planting density, row spacing, height and shape of ridges and fertilizer dosage.

How to choose a potato planter in a store

The choice of a potato planter is influenced by its compatibility with your walk-behind tractor. Some firms adhere to a policy of using this device only with their own self-propelled equipment. But some models are very versatile and fit all walk-behind tractors.

In addition to compatibility, the following factors are important:

- weight and ergonomics;

- productivity;

- ability to adjust and customize.

The capacity of the hopper is also important, which can vary from two to five buckets of planting material. The larger the hopper, the less often you will stop to reload potatoes, but the increase in weight will reduce the maneuverability of the device.If your area is small, choose a single row potato planter.

The two-row device has a higher productivity and is designed for processing large planting areas. Some options have additional containers for fertilizer applied with potatoes.

Planting potatoes with a potato planter

Planting potatoes using a walk-behind tractor and specialized equipment is much easier than using a bucket and a shovel. The potato planter consists of several structural elements:

- bunker for potatoes;

- seed feed mechanism;

- devices for loosening the soil;

- disc mechanism for filling the furrow.

There are several types of devices for planting potatoes, but they all work on the same principle: they form a depression in the soil and immerse the potato in it. Thus, the mechanization of manual labor is carried out, which allows you to process a large area in a short time with less effort. Planting with a potato planter and walk-behind tractor consists of several stages:

- Prepare the soil in the way that is most effective for this type of soil. This can be plowing or harrowing.

- Carry out the adjustment of the potato planter: adjust the depth of the furrows and the width of the row spacing.

- Seed potatoes are poured into the hopper.

- Install the walk-behind tractor in the right place on the site and start the engine.

- The tubers are planted.

How to do it yourself

If you do not have the necessary funds to purchase a new potato planter, then it makes sense to think about making this unit on your own.

Do it yourself

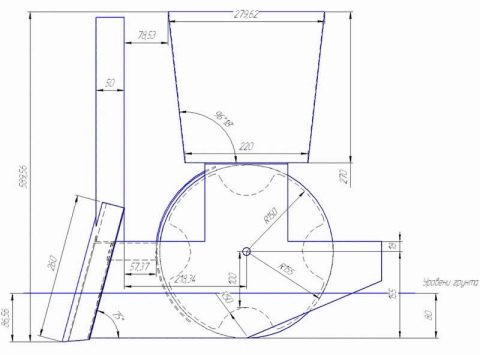

Indeed, a do-it-yourself potato planter for a mini tractor, the drawings of which are widely presented on the Internet, is the way out of a crisis situation when there is a constant lack of money.

In addition, the very purchase of a mini tractor is a rather costly business, after which there is practically no free money left. Where then think about buying a potato planter in a store, you must try to recoup the previously made investments. Therefore, the design of a home-made unit is fully justified.

At the same time, the procedure is actually the same, regardless of the type of minitractor:

A homemade potato planter for a mini tractor, the sizes of which can be very different, is made from those available tools that you have in stock. The whole point is in the minimum cost, so this is natural.

Frame

- At the first stage, the construction of the frame will be manufactured, to which other components will be welded. To do this, we need channels # 8, of which two longitudinal spars are welded, connected to each other by three transverse steel strips.

- In front of the structure, you need to weld an arch with fastening forks directed to the central link of the unit.

- The frame is reinforced with two steel inclined beams, which must be fastened to the middle of the arch located in front. Next, you need to fix the support on which the seat will be located, made of a 50x50x5 mm corner.

- It is attached to the spar with your own hands. A plastic type bracket must be welded to the inclined beams. It is to these beams that the potato hopper will be attached.

- The bunker will be made of four 12 mm thick plywood sheets. It is necessary to cut out equal parts, and then we fasten them together with steel corners. You also need to apply drying oil, and when it dries, paint it with waterproof paint.

- The inside of the hopper can be covered with rubber so that the tubers are not damaged by the walls of the tank. Using a pair of bolts, we fix the hopper to the bracket.

- The ripper and wheel axle will be located at the bottom of the frame.

- The wheel axle will have to be done on your own.

- The base will be an ordinary steel pipe, along the edges of which pins are installed. Their dimensions will have to be adjusted to the diameter of the pipe used, but this is not difficult.

- Holes need to be made in the steel pipe, into which special pins will be installed, where spikes will be inserted. At the end of the assembly process, they need to be welded.

- The wheel axle must be secured with steel clamps, with four M16 bolts.

Hubs need to be welded onto the wheels, on which two bearings will be located on each wheel. Next, we put the bearings on the spikes, protect with a gasket consisting of felt, which will not allow excess dirt to enter.

Thus, we get a semi-automatic potato planter for a mini tractor, made by hand. It is semi-automatic because a person will sit on the potato planter itself, who will throw the tubers into the corresponding seed conduits.

Therefore, this design must be supplemented with a seat on which one could sit comfortably. It is made from ordinary boards, which are then covered with foam rubber and sheathed with leatherette.

A home-made potato planter for a two-row mini tractor will be a slightly more complex design, because more components and parts of the unit will have to be designed. But, on the Internet, there are quite a few detailed drawings indicating the exact dimensions, which will greatly simplify this task.

Models

As an example, consider the technical characteristics of popular models.

2MBS-1

This model is manufactured by the renowned mini tractor supplier XINGTAI. The potato planter is suitable for working with equipment with a capacity of 12-18 liters. with. This is a one-row model with adjustable planting depth, two hoppers for seeds and organic fertilizers.

The potato planter weighs 105 kilograms, the planting width varies between 250-270 mm. Note that the productivity of the equipment is about 0.3 hectares / hour, which determines the use of small and medium-sized areas.

KS-2MT

This is a two-row model of domestic production. Equipment weight - 115 kg, productivity: 0.2-0.25 ha / hour.

KS-2MT

Of the technical features, we can note two seed bins, with a total capacity of 70 kilograms, adjustable row spacing (65-75 cm), planting density of 5 tubers per one running meter.

Conclusion

Planting potatoes is one of the main types of work in the countryside. This is quite understandable, because it is possible to live without fresh meat and vegetables, but without potatoes it is quite problematic, because almost every dish, one way or another, contains it in its composition.

It is this circumstance that "forces" summer residents to plant potatoes every year. The use of potato planters for these purposes is not yet so common, especially among private owners of country houses.

But large agro-industrial complexes, and even ordinary farmers with fairly large land holdings, have long adopted this type of attachment for a mini tractor.

It is the use in combination with this unit that potatoes can be planted quite quickly in areas that are not limited to a couple of hundred parts.

And a vegetable seeder will help to cope with the planting of a smaller seed.

We also recommend paying attention to such a useful device as a garlic planter.