The principle of operation and the main types of potato diggers

All types of potato diggers operate according to the same method: sharp teeth cut into the soil at a certain angle and push the tubers to the surface, after which the roots are easily collected by hand. There are two types of such attachments - active and passive.

Passive potato diggers are simple and low cost. They are attached to the walk-behind tractor using couplings; you can purchase it at almost any gardening store. Their other name is universal lancet potato digger. Looks like a shovel with teeth at the top. The pointed end is dug into the ground, and together with the potatoes, it falls on the teeth.

Excess soil crumbles, potatoes remain on the surface of the shovel

When buying, pay attention to what kind of soil the equipment is suitable for - hard or soft. The advantages include low cost, reliability, ease of use.

The disadvantages are the use of manual labor and low productivity (at best, no more than 90% of the crop can be raised to the surface).

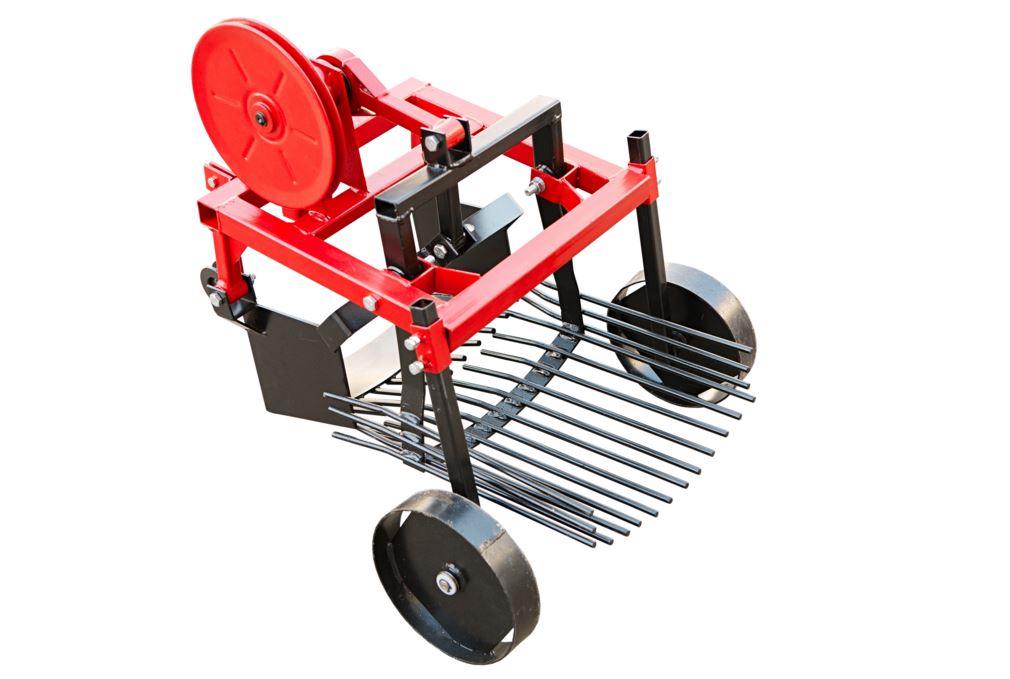

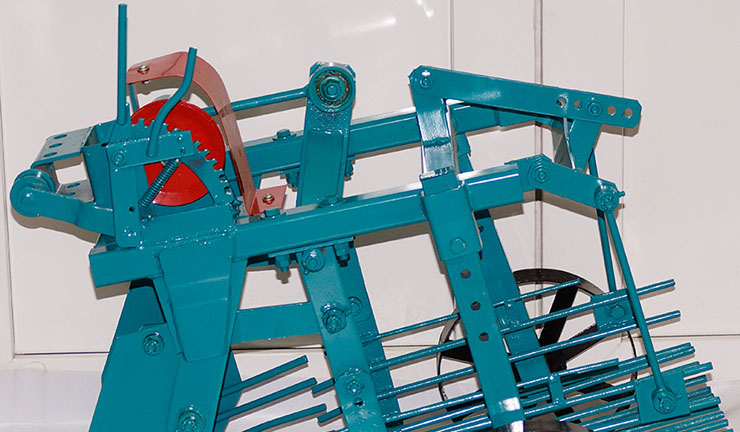

Active models of potato diggers are divided into vibrating (screening) and conveyor ones. It is connected to the walk-behind tractor through a belt (if the equipment is not adapted for installing belts, it is necessary to purchase a belt adapter), a power take-off shaft or a special gearbox. Vibration models, they are also roaring, work according to the following scheme: a layer of earth is pryed off with a knife and transferred to a vibration platform, where the earth crumbles from root crops. Such models have proven to be quite reliable and effective.

On the conveyor potato diggers, instead of a vibration platform, a special belt is installed. Moving along it, potato tubers are well cleaned of adhering clods of earth. Such equipment is intended for models of heavy and medium class motoblocks. According to the principle of work - to dig and clean - the types of potato diggers are quite similar to each other.

How to do it yourself?

Everyone can buy a potato digger for the Neva walk-behind tractor. Each of them has a very simple design and different advantages. To make your choice a little easier, you can do it yourself. Moreover, special costs and efforts will not be required. To make the simplest model, it will be enough to take an ordinary old shovel and a few reinforcing rods. If there are no rods, then the teeth from the unnecessary pitchfork will do.

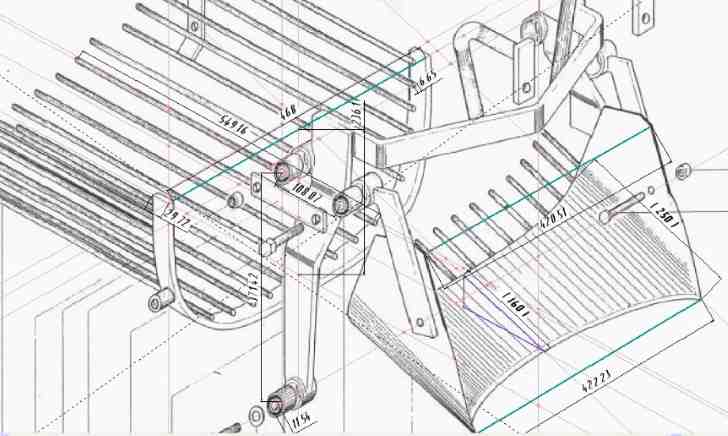

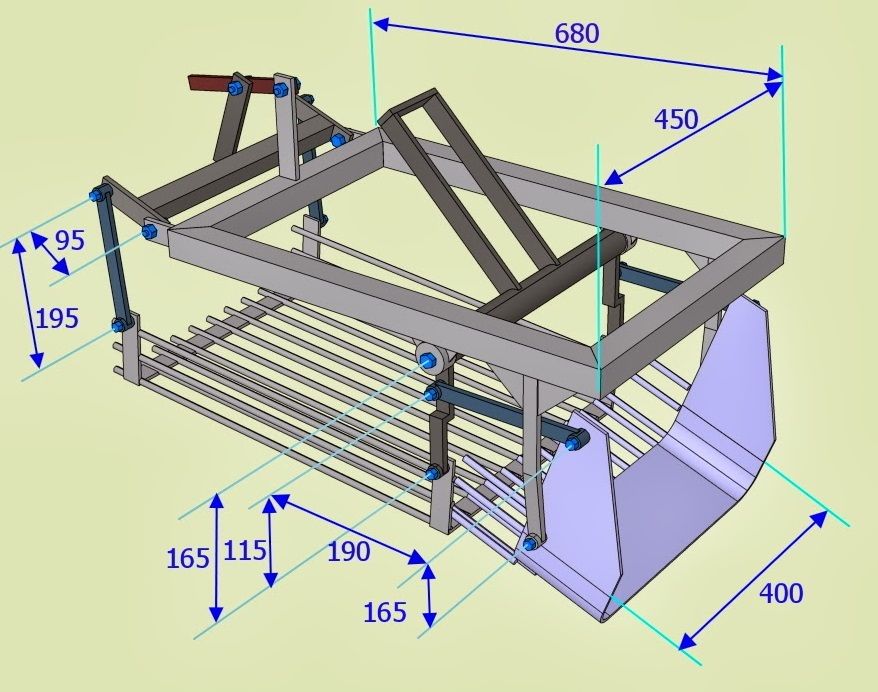

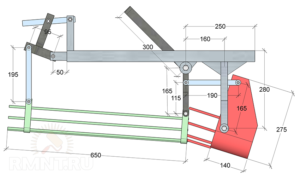

But a homemade vibrating potato digger will require not only the study of the walk-behind tractor, but also well-made drawings. In addition, it must be remembered that such a structure will eventually be able to cope with different soils: both light and heavy.

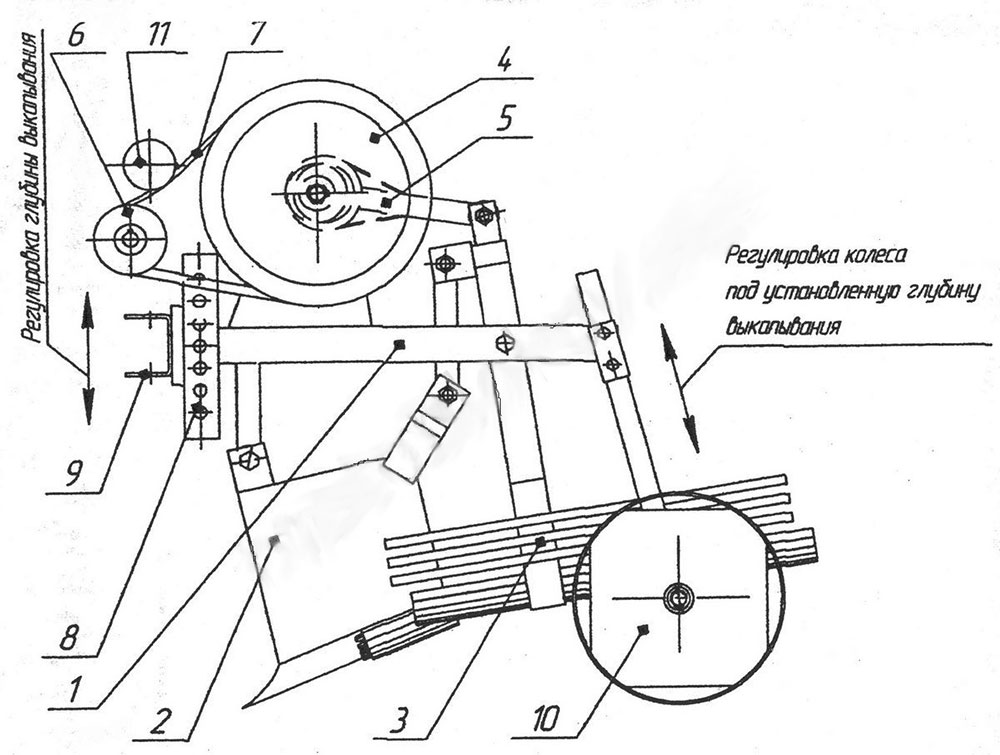

To start working on a digger, you need to know what elements it consists of. First of all, this is the chassis, then the frame itself, some suspension elements, as well as the adjusting rod. Having familiarized yourself with them, you can start developing drawings, where you need to specify in detail all the dimensions of the future structure.

After that, the work on the model itself begins. It can be done in several stages.

- The first thing to do is design the frame. To do this, you need any pipe available at home with a suitable size. After that, it needs to be cut into pieces and then welded.

- Next, you need to install jumpers, which are needed in order to be able to install rods to control the entire structure. They must be fixed at a quarter of the entire length of the frame.On the opposite side, the wheels are attached.

- After that, you can start installing vertical racks. To do this, in the place where there are already jumpers, it is necessary to attach two small squares, moreover, metal. Next, the racks are placed, which in the end should be connected with a small strip made of metal.

- Then you can start making the ral. One blank is attached to the posts, and the second is attached to the other side. After that, they must be welded together and bent into the desired shape.

- Next, a lattice is made. To do this, a rod must be attached to the rail, and its second part must be removed and attached to the rods.

- At the end of everything, you need to install the wheels, and then start adjusting the traction system.

Of course, for many gardeners, it will be difficult to make such a non-standard home-made design. In addition, it is possible that the factory unit will be both stronger and better. However, having made a digger at home, it can be adjusted exactly to those soils that are on this site.

In any case, the choice remains always open. Make it in the direction of a purchased digger, or construct it from improvised means, saving a little money.

Equipment care

Despite the simplicity and reliability of most diggers, they need quality care. So, after operation, it is necessary to clean all the parts of the device from soil, especially wet. The unit must be stored in a dry place. All moving parts of the equipment should be lubricated regularly to protect them from excessive friction. All technical work must be carried out on the product removed from the walk-behind tractor. You need to store it in a stable position.

Choosing a potato digger, in accordance with the characteristics of the site, the volume of work and budget, is not difficult. The versatility of popular models, their ease of installation and operation will help to harvest potatoes, onions, carrots, beets with minimal labor and time costs.

How to make a homemade potato digger for a walk-behind tractor

Before you start making a potato digger for a walk-behind tractor, you should decide what kind of digger you want to have on your farm. This largely depends on the density of the soil, since, for example, a simple lancet digger can easily handle light soils. With a soil with a dense structure, a simple digger will not help you much - here a design with a conveyor mechanism is more appropriate.

It is quite easy to make a simple potato digger - it does not require special knowledge and skills.

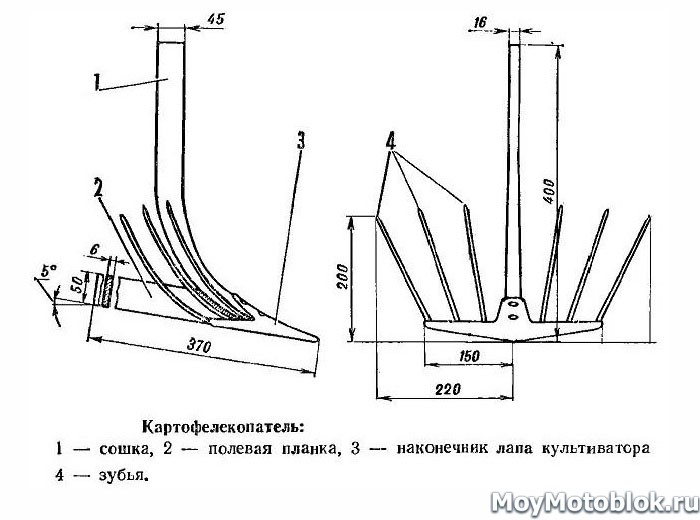

Drawing of a fan potato digger for a walk-behind tractor

The lancet bipod can be cut from an old shovel, and fork teeth or rebar are used as guide rods.

Required tools and materials

To make a vibration-type walk-behind potato digger, it will take a little more time and skill, as well as special tools and equipment.

So, we need at our disposal:

- welding machine;

- angle grinder (grinder);

- electric drill and drills for metal;

- a set of keys;

- sledgehammer (heavy hammer);

- level, caliper, square,

When everything is available, you can start manufacturing the unit.

The following materials will be required:

- U-shaped metal profile (channel # 8);

- sheet steel with a thickness of about 8 mm;

- steel or iron rods 10 mm in cross section;

- iron corner (rolled metal);

- metal pipe for racks;

- fasteners - plates and steel bolts with nuts # 10;

- roller chain;

- wheels - metal or rubber running.

Manufacturing and assembly of a potato digger

The design of a vibrating potato digger for a walk-behind tractor includes:

- frame base;

- digging share;

- suspension system;

- adjustment thrust;

- lugs or wheels.

Let's start the assembly of the motoblock unit with the manufacture of individual components.

- The frame is welded from an iron channel # 8 and an angle of 63 × 40 mm.The length of the frame should be approximately 120 cm.

- We weld one channel at a distance of one third from the beginning of the frame, and the second at a distance of approximately 1/6 from the front edge. The channels will serve as the basis for attaching the regulating part of the digger.

- Weld metal racks of different lengths, starting from 50 cm (hereinafter - 40, 30, etc.), to the side edges of the frame on both sides vertically to the ground at a distance of 10 cm from each other. The base for the lattice rods will be welded to these posts.

- Weld the remnants of the channel to the short struts on both sides of the frame. As a result, you should get two rigid triangles on which the share will be attached.

- Cut out a plate of the required length with a width of approximately 30 mm from sheet metal and weld one end of it to any of the resulting triangles. Let it cool, then bend it with a sledgehammer and screw it to the second triangle with bolts.

- For the manufacture of a ploughshare, metal plates, an old plow or a piece of pipe with a diameter of 200 mm cut along the length are suitable. We bend it like a plow and make a rounded sharpening of the part, so as not to cut potato tubers during work. We fasten the share to the elevator casing on four bolts, tightening the nuts securely.

- We cut the reinforcement into rods of the required length so that one end can be welded to the metal plate, and the other freely protrudes beyond the frame of the walk-behind digger. We weld the rods to the metal plate, leaving the other end free, at a distance of 4-5 cm from each other. On the sides of the elevator, sheet metal strips can be welded on top of the rods so that the tubers do not fall out on the sides.

- The free ends of the reinforcement are welded onto a metal bracket made of a metal strip or a pipe of a small section. The mobility bracket is attached to the end of the frame with hinges.

- If desired, the elevator can be replaced with a cleaning drum. It is made in the form of a half-cylinder from metal strips and reinforcement.

- We install a reduction unit that will allow you to change the inclination of the elevator and the angle of inclination of the share. The reduction unit is attached to the slider bar with bearings.

- We fasten the rod of the connecting bridge with the help of sprockets. We weld metal discs onto it from both ends and fasten the wheels.

- The potato digger is attached to different types of walk-behind tractors in the same way as for other equipment.

Whichever type of digger you choose, in any case, home-made potato diggers for a walk-behind tractor greatly facilitate agricultural work and at the same time help to significantly save on the purchase of an industrial digger.

Description

Potato planters and Potato diggers for the walk-behind tractor are universal attachments that allow mechanized planting and harvesting of potatoes in a short time without the cost of human resources. More and more summer residents, garden owners and small farmers prefer to grow potatoes with a walk-behind tractor.

All procedures, from preparing the soil for planting potatoes, cutting furrows, seeding tubers, further hilling bushes, as well as harvesting, are performed by this unit. If you have a walk-behind tractor and there is no planter, you can also plant potatoes, then a plow or hiller will be used.

Views

Depending on the technological features, there are several types of potato diggers: fan, screen, drum, conveyor, conveyor, vibration. Each of them is designed for certain types of soil and volumes of the cultivated area.

Fan

Fan

It got its name due to the arrangement of the rods in the form of a fan. The working mechanism has the form of a plow, from which equidistant rods extend.

The principle of operation is simple: the plow sinks into the ground, under the influence of the traction of the walk-behind tractor, the potatoes rise from the depth and fall on the rods, where they shake off excess soil and lay down on the garden bed with a carpet.

The advantages are ease of manufacture and low cost. The disadvantages include the rapid wear of the rods and their breakage when used on hard soils.

Rumbling

Rumbling

Has a more complex design with additional wheels and support points. Contains a grate that is inclined at an angle relative to the soil.

The potato digger is deepened below the location of the potato, after which the potato rises to the surface, excess soil on the trellis is removed, and the root crop is located on the surface of the earth.

The advantages include the ability to get the most cleaned potatoes from the ground. The disadvantage is low productivity.

Tympanic

Tympanic

It is a complex mechanism that simplifies the work of the landowner to the maximum. With the help of a plow, which goes deeper into the soil layer, the potatoes are lifted and hit the grate, after which they are transported into a rotating drum. Then the potatoes are additionally cleared of the ground and put into the box.

There is another principle of operation of a drum potato digger: a knife cuts a layer of soil together with potatoes and captures it in a drum, where, under the influence of constant movement, excess soil is sifted out, and the potatoes are poured out onto the ground.

The advantage is the ability to handle large areas, as well as the transportation of potatoes directly into containers. There is no need to additionally collect potatoes from the surface of the ground. The disadvantages include the inability to use on hard soils.

Conveyor

Conveyor

It consists of two main parts: a conveyor, along which potatoes move and a flat cake, with the help of which a layer of soil with a root crop rises. Not suitable for wet and sticky soils.

The disadvantage is the inability to use in fields where there are weeds. The stems of the plants fall into the conveyor, wind up and slow down the work of the potato digger.

Conveyor

Conveyor

The potato digger is a bucket with a deepening, in the center of which a conveyor belt is installed.

Root crops are lifted together with the soil, transferred to the belt, where the remains of the earth are removed. Next, the potatoes are laid on the surface of the ground.

The advantage is the ability to process several beds at the same time. The potatoes are clean and with minimal damage.

General information about the mechanism

The potato digger is a special trailing device for a walk-behind tractor or mini-tractor, which allows you to separate the tubers from the soil and dump them to the surface. After that, it remains only to collect the tubers in a suitable container. The potato business will thrive with such a device thanks to mechanization.

Device types:

- ogival;

- rattling or vibrating;

- conveyor.

The arrow-type potato digger is simple in design and can easily fit any mini tractor. There are no movable parts in the device, which simplifies manufacturing. The digger cuts the soil with a knife. Further, the earth falls on steel rods, from where visas are poured. The fruits of the potato are retained by the twigs and fall over the ground in their pure form.

The arrow-type potato digger is simple in design and can easily fit any mini tractor. There are no movable parts in the device, which simplifies manufacturing. The digger cuts the soil with a knife. Further, the earth falls on steel rods, from where visas are poured. The fruits of the potato are retained by the twigs and fall over the ground in their pure form.

Such a device is effective only on soft and dry soil. Wet soil will be trimmed into lumps, which will prevent the potatoes from separating from it. This will require additional efforts. The simplicity of the design should not bribe farmers in the northern regions - the device simply will not work. However, a homemade potato digger for a lancet-type mini-tractor is done quickly, even without drawings - this is a significant advantage.

The vibration-type mechanism (it is also called roaring) consists of a share, a barrel and a drive. This is a productive device, but difficult to manufacture. Moving parts add to assembly problems. Operating principle:

- A ploughshare undermines the ground along with the fruits.

- The material falls on the table from the twigs, where the earth looses and wakes up through the sieve.

- On the opposite side, tubers are poured over the ground.

The vibrating table complicates the design, but allows you to work on hard and wet ground. Thanks to vibration, the clods of earth are broken, and the fruits become relatively clean.

The vibrating table complicates the design, but allows you to work on hard and wet ground. Thanks to vibration, the clods of earth are broken, and the fruits become relatively clean.

Installation with a conveyor allows you to work on any type of walk-behind tractor or mini-tractor. The design is similar to a shaker digger, but there is a conveyor right behind the share. Its purpose is to support the tubers on the platform for better cleaning of adhering soil. The device is more practical than a vibratory digger and is suitable for all types of soil. On soft loose soil, it is not advisable to use a digger with a conveyor.

The choice of design must be made depending on the type of soil on which to work. The rule is simple: the lighter the soil, the easier you need a potato digger. You can also make a conveyor, but it will not be useful on dry sand. These will be unnecessary costs. However, if you need to make a potato digger for a mini-tractor with your own hands, the drawings and dimensions should be selected so that the mechanism harmoniously fits the traction device.

Varieties

There are several types of potato diggers. The principle of operation is the same for everyone, but some differences still exist. All of them need to be considered in more detail.

Simple

The potato digger itself is a simple shovel, which has two small roundings, as well as teeth. They are on top of the structure.

The sharp part of the digger plunges into the ground, after which it lifts the potatoes onto the twigs, where the earth crumbles, and then moves it to the ground.

Rumbling

This type of construction is a vibrating digger. It is more complicated than the previous one. She has a share, as well as a grate that can sift potatoes. It is located on digger wheels. Subsequent actions are identical.

If we talk about the advantages, then they are available in both diggers. So, simple ones will cost much cheaper, but on top of that, they are both reliable and very easy to use. However, screen diggers are more productive.

Conveyor

This type of construction is a vibrating digger. It is more complicated than the previous one. She has a share, as well as a grate that can sift potatoes. It is located on digger wheels. Subsequent actions are identical.

If we talk about the advantages, then they are available in both diggers. So, simple ones will cost much cheaper, but on top of that, they are both reliable and very easy to use. However, screen diggers are more productive.

Such a digger is an attachment to a walk-behind tractor, which distinguishes it from other types. Therefore, it is often also called fan or ribbon. Such a digger has a moving belt. Through it, the potatoes are fed upward, where the earth crumbles, while it is not damaged at all.

Fan potato digger

This is a passive type nozzle. It is versatile and easy to use. It is not equipped with rotating parts, which guarantees its reliability - the mechanism will not become unusable due to heavy loads.

Looks like a normal shovel. Has a pointed bottom edge. The teeth are located at the top edge. It works like this: the sharp part enters the soil. The teeth take out the root crop along with the soil. The potato falls on the teeth, clods of earth fall on them and crumble, the fruit falls to the ground from the other side.

Advantages:

- work is done efficiently, even at very high speeds;

- can function at low power;

- easily fits onto the walk-behind tractor.

This type has its pros and cons.

This type has its pros and cons.

The disadvantage is that part of the crop may remain underground due to the shallow digging depth (15 cm).

This attachment is great for working in loose, crumbly soils, as well as for harvesting in small areas where high power is not required.

Potato digger KKM-1

This model is of the vibration type. The potato digger KKM-1 is designed for the improved Neva walk-behind tractor.

Components of the structure:

- ploughshare;

- sieve lattice.

The grate is placed on support wheels.

This device consists of several elements

This device consists of several elements

The ploughshare cuts off the soil layer. The layer is on the grid. The vibration ensures a thorough sifting of the earth lumps through the rods of the sieve grid. The potatoes, along with the tops, are thrown onto the ground following the movement of the unit.

KKM potato digger models are used to work in areas where the distance between rows is at least 60 cm. This is a rather heavy unit.

Specifications:

- weight - 40 kg;

- dimensions - 700 × 700 × 600 mm;

- travel speed during operation - 1.1-2.1 km / h;

- digging depth - 20 cm;

- capture area width - 39 cm;

- turning radius - 3 m;

- productivity - 0.2-0.5 hectares / hour.

Advantages:

- effective on a heavy soil surface with solid soil (20 kg / cm);

- on the soil littered with stones (8-9 t / ha);

- does not require unnecessary waste of fuel;

- high productivity.

Disadvantages:

- high price;

- the impact of vibrations on traction is the smallest.

Selection options

Potato diggers differ in the following parameters:

- Dimensions - the greater the length and width of the working mechanism, the greater the productivity of the potato digger. Narrow attachments are more suitable for single beds in the household, while wider counterparts with a grab are used for harvesting potatoes from more than a hectare of land.

- The method of cleaning potatoes from soil - this factor is taken into account, depending on the characteristics of the soil of the region where it is planned to use the potato digger. If loose black soil is easy to push, then loamy and sandy soils need additional cleaning.

- The principle of operation - taking into account this indicator, the productivity of the device is determined.

- The presence / absence of additional wheels - large units must have an additional support point, otherwise it will be difficult for the walk-behind tractor to perform its main work.

- Mounting methods - the best option is the screw method of attaching the potato digger to the walk-behind tractor. This allows the device to be disconnected at any time. Some models are attached exclusively by welding.

Many farmers also pay attention to the brand and price. These two indicators are not key, but largely determine the productivity of the unit.

Basic models

Here are considered the main models for the Neva walk-behind tractor.

Vibrating potato digger model

Specifications:

- weight - 36 kg;

- dimensions - 710 × 680 × 730 mm;

- speed - 2 km / h;

- productivity - 0.15-2 hectares / hour;

- digging depth - 20 cm;

- capture area width - n / a.

The main advantage is that it digs out every potato, while the speed remains as high as possible.

Model KVM-3

This model is a vibrating modular screening machine. Attaches to the pulley on both the left and right side.

A distinctive detail is the static knife. It attaches to the main frame. The connection takes place through an adapter that creates vibration. Due to the powerful vibration, the mechanism cuts deeper into the ground, shaking off clods of earth from the tubers better.

Specifications:

- dimensions - 900 × 670 × 560 mm;

- weight - 34 kg;

- productivity - 5-20 acres per hour;

- digging depth - 20 cm;

- the width of the girth area is 39 cm.

The advantage of the model is the ability to work on very heavy, difficult ground. This is possible thanks to the knife.

Model Poltavchanka

Poltavchanka is a vibrating screen model. It is universal and suitable for work with all types of motoblocks.The set includes a belt and a pin. It can be mounted on the left, right and on the back.

The potato digger is designed to work with medium gravity soil and moisture content not exceeding 30%.

Specifications:

- dimensions - 950 × 790 × 800 mm;

- weight - 34 kg;

- productivity - 25 hectares / hour;

- speed - 2 km / h;

- digging depth - 25 cm;

- the width of the capture area is 40 cm.

The advantages of the mechanism are: light weight and compact size, which allows you to carry the potato digger on your hands.

Homemade hillers and potato diggers

What someone has managed to collect, someone will be able to repeat!

Craftsmen do not sit idle and have long come up with ways to save a little money and come up with a hiller or potato digger themselves. In this case, they make it themselves. Sometimes the result exceeds even the initial expectations, sometimes not. It all depends on your skills and abilities.

After all, this is not a simple mechanism, but a whole system that must work accurately. And in this case, no one gives a guarantee for the equipment.

However, their design is so simple that people even came up with whole drawings of how to assemble a potato digger with their own hands.

And if suddenly, according to the drawings, something is not clear in terms of fastening or something else, then you can always find detailed video manuals on the topic "how to make a potato planter at home"

They have detailed instructions on what to do and in what sequence.

But in order to do this, you need serious skills in terms of working with metals.

In any case, before buying, people browse information from the Internet and read reviews about equipment for harvesting and planting potatoes, here are some of them:

Yuri:

“Planting work began, and it was necessary to go out into the garden for work. And I got a hernia in the winter. So any weight became a hellish stone. And you need to sow the harvest. Therefore, I decided to spend money and buy a walk-behind tractor with a potato planter. And I am honestly 100% satisfied, it is many times easier than monotonous work with a shovel. "

Vitaly:

“For a long time I had a walk-behind tractor at home, which I mainly used for tillage before and before planting. I stumbled upon the Neva potato planter in a store. And then he became interested in her. I looked at the prices on the Internet and decided that it was very expensive for me. Then I fired up to make it myself. 2 weeks of hard work and voila. Now I enjoy using my potato digger. "

Conveyor for better cleaning

The vibrating digger simplifies the cutting of the soil layer with potatoes. However, cleaning the tubers from the remnants of the soil is not always successful, since the cut layer moves along the rods under pressure. There is no additional impact, and the rods are often clogged, which creates inconvenience during the digging process - you have to make stops for cleaning.

The vibrating digger simplifies the cutting of the soil layer with potatoes. However, cleaning the tubers from the remnants of the soil is not always successful, since the cut layer moves along the rods under pressure. There is no additional impact, and the rods are often clogged, which creates inconvenience during the digging process - you have to make stops for cleaning.

A conveyor is a moving part in a potato digger, where soil with tubers is supplied. This mechanism allows you to separate the cut layer. As a result, the tubers are clean, with practically no adhering soil. The conveyor can be directed into the receiving hopper, which eliminates manual labor in the field.

In general, the design is similar to a vibratory digger, only instead of rods there is a conveyor. It is made of metal rods or tubes that are parallel to each other. They are installed in a movable rim or chain. The conveyor can be made of steel mesh or rubber fabric.

In general, the design is similar to a vibratory digger, only instead of rods there is a conveyor. It is made of metal rods or tubes that are parallel to each other. They are installed in a movable rim or chain. The conveyor can be made of steel mesh or rubber fabric.

The mechanism is driven from the agricultural machinery shaft through a gearbox. The torque is then transmitted through a chain or gear train. Before making such a device, it is better to study the factory diagrams. Craftsmen present many designs, and each strives to offer something original that improves the mechanism.

Steps to create a conveyor digger:

- Frame manufacturing.For this, a steel profile with a rectangular section is used.

- The ploughshare knife is made of sheet steel.

- The rollers for the conveyor belt are attached to the frame.

- Assemble the conveyor belt and install.

- Brackets for the gearbox and chain or gear drive are installed, after which the devices themselves are attached.

- Put the wheels.

A homemade digger for a mini-tractor when installing a receiving hopper will allow you to mechanize the entire harvesting process. The main thing is that you don't need to spend a lot of money to create such a device. The necessary material can be found at home or in a landfill. As a last resort, you can use the old mechanisms.

Manufacturing and assembly of a potato digger

On the Internet, you can find ready-made or create your own drawings for assembling a device. The main parts are as follows: a base (frame) for fastening parts, a plow for digging the ground, an attachment system, adjustable traction, ground hooks or other suitable wheels. Lugs, by the way, can also be made by hand. The process of assembling a potato digger begins with the manufacture of parts, and it takes place in several stages:

- Frame welding. It is made of channel No. 8 and a metal corner, the total length of the base should be approximately 1 m 20 cm.

- Then two more channels are welded: the first one - one third from the beginning of the frame, the second - at a distance of about one sixth from the edge, which will be located in front. They will be equipped with an adjusting rod of the mechanism.

- On the sides, on both sides, metal racks are welded, the distance between them should be about 10 cm - they will serve as fasteners for the future grille.

- The remaining channel should be attached to the extreme posts, you should get two triangles, on which the plow will subsequently be attached.

- Next, a strip of the required length with a width of about 3 cm is cut from a metal sheet, it is first welded to one of the triangles. After complete cooling, the strip is bent with a sledgehammer and welded to the second triangle.

- A ploughshare can be made from a metal plate, a piece of pipe, or an old plow. It is attached to the elevator casing with 4 bolts, the nuts are tightly tightened.

- The armature is divided into rods of the required length. On one side they are welded to a metal plate, the distance between them should be about 5 cm. Additional rods or plates can be attached to the sides so that the tubers do not fall in different directions. The second part of the rods is attached to a plate or pipe, which should be attached with hinges for free movement.

- Then the reduction unit is installed. It will allow you to change the angle of inclination of the elevator and plow as needed.

- The wheels are attached to the vehicle's connecting bridge.

- Fastening the potato digger to the walk-behind tractor is similar to the fastenings of other attachments.

It's interesting: how to plant potatoes with a walk-behind tractor.

Whichever model the gardener chooses, one thing is certain - modern technology can greatly facilitate the work of the farmer and save a lot of time.