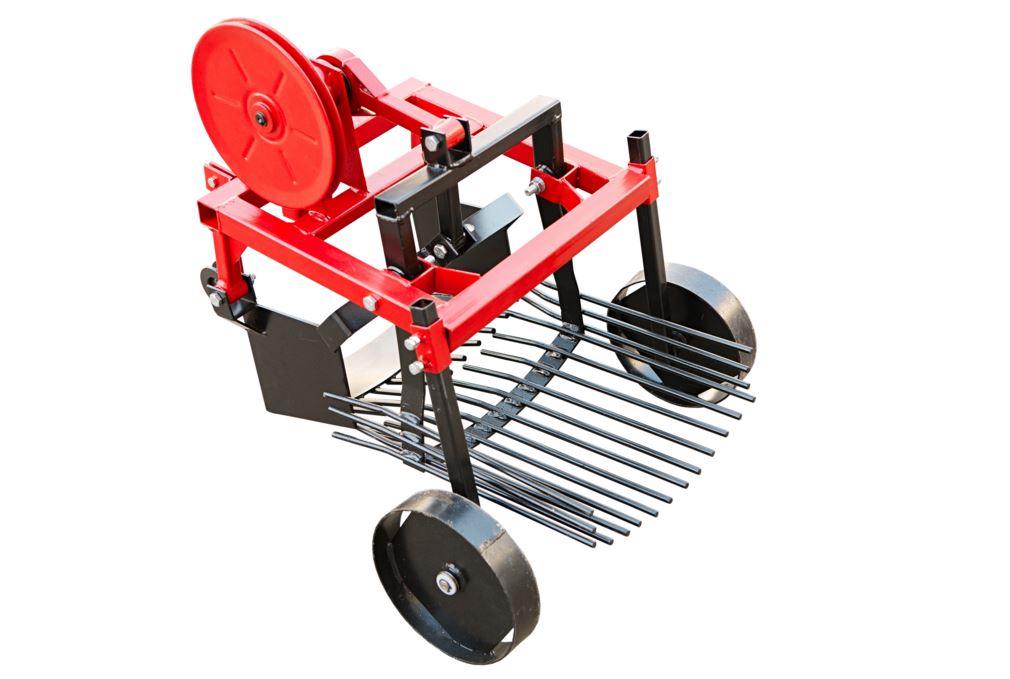

Self-made potato digger

The most convenient high-quality model will be a vibrating potato digger for a mini tractor. This section provides instructions on how to make it. In the process of self-creation of this unit, it must be borne in mind that the durability of the mechanism is ensured by the quality of the steel used and the strength of the connections. The latter can be achieved by bolting or welding.

Frame

The basis on which the entire structure will need to be fixed in this device is a rectangular frame. It is made from a 4 x 4 cm square pipe.It is welded in such a way that a rectangle of 80 by 100 cm is obtained.

On this frame, you need to install the fasteners going down. They will be equipped with a share, vibration grid and wheel holders. A mechanism will be installed on top of it that will vibrate the basket.

Homemade potato digger

Ploughshare

This knife will lift potatoes mixed with soil to be processed into the basket. Mounts for it are located on the sides at the front of the frame. A ploughshare is usually a strip of strong steel that needs to be bent accordingly. In this case, the middle should be located horizontally, the edges should look up. The front edge of the share must be well sharpened.

Wheels

Here they are not only a means of transportation, but also allow you to adjust the depth of the ploughshare. The hubs are attached to vertical metal pipes with a cross section of 3 by 3 cm.

Two square pipe sections are welded to the rear of the frame from the sides, located vertically. Their cross-section should be 4 by 4 cm. The vertical struts from the wheels are threaded into these pipes and fixed with bolts. The wheels are on an axle, which, apart from them, is no longer attached to anything.

If the owner has a desire to increase the depth at which the share works, then for this it is enough to move the vertical wheel struts up a little. If it is necessary to reduce this depth, then the wheel heights will need to be corrected in the opposite direction.

Note! It is advisable to prepare at least two pairs of wheels for work. The first of them should be rubber-mounted

It is suitable if you have to work on soft or damp soil. The second is wheels with a steel rim. They will be handy if the soil is hard.

Net

It consists of metal rods parallel to each other. The distance between them is such that potatoes cannot fall out between them. In the mesh, the rods are parallel to the direction of travel. In the transverse direction, they are held together by narrow steel strips, to which the rods must be welded. Their edges are curved upwards and are attached to special holders that are attached to a mechanism that vibrates the basket.

Net for potato digger

Mini tractor clutch

In front, a mechanism is attached to the frame by welding, designed to be attached to the minitractor as a suspension.

Vibration mechanism

A basket is connected to it. Vibration is provided by rotating a small disc with a rod perpendicular to it. The disc rotates, the rod provides up and down movement of the basket. The higher the rotation speed, the more intense the vibration.

This disc, as provided in the drawing, is connected via a transition mechanism to a large wheel that is located on the side of the frame. It is connected by a rubber pulley to the minitractor motor, which thus provides vibration.

Important to note! If additional fasteners are installed to increase the strength of the potato digger mechanism, this will make this device more reliable and durable. Using a potato digger makes digging out potatoes a stress-free job

In addition, the quality of work will be higher compared to using a conventional shovel.

Using a potato digger makes digging out potatoes a stress-free job. In addition, the quality of work will be higher compared to using a conventional shovel.

vote

Article Rating

Appointment

The mini potato digger helps the owner to extract the potatoes from the ground to the surface.

The principle of operation that is applied here is as follows:

- The ploughshare plunges into the ground to a depth greater than that at which the root crops are located.

- When the minitractor moves, it picks up potatoes mixed with the ground.

- This mixture is gradually moved backwards and onto the grate.

- There, the earth is poured into the soil, and the potatoes move further back and fall to the ground.

- After that, it is enough to walk across the field with a bucket and collect potatoes from the surface of the earth.

Potato digger for mini tractor

Note! If we compare it with digging up potatoes with a shovel, then in this case labor productivity is significantly higher, and much less physical effort is spent. The use of potato diggers gives the owner the following advantages:

The use of potato diggers gives the owner the following advantages:

- Thanks to the fact that when cleaning is spent much less effort, it is possible to pay more attention to the quality of work. When using such units, the loss of potatoes is much less than with manual harvesting.

- Although the mechanism does an important part of the work, it nevertheless ensures thrift in relation to the harvest. Root crops are practically not damaged here.

- Cleaning not only requires less effort, but is done at a much faster rate.

- The mounted potato digger has a simple and straightforward operating principle. At the same time, the operation of such a suspension device does not cause difficulties.

- For those who do not have sufficient financial resources to purchase, or those who like to make their own hands, there is an opportunity to make a homemade device.

- The potato digger can be used not only as a suspension for a mini tractor, but also used with a walk-behind tractor or a conventional tractor.

- There are not only such tractor designs, when root crops are removed from the ground, but also others, where the potatoes fall into a special tank.

- In such devices, you can easily adjust the depth of immersion of the share, depending on the need.

It is important to note! One of the important advantages of such units is their versatility. With the help of these devices, you can collect not only potatoes, but also other root crops

What to look for when choosing?

The potato digger is designed to loosen the lower layers of the soil and bring root crops to the surface, however, the principle of operation of each of them is different.

The potato digger is designed to loosen the lower layers of the soil and bring root crops to the surface, however, the principle of operation of each of them is different.

When choosing a particular model, you should pay attention to parameters such as:

The power of a mini-tractor - if the unit is designed to cultivate up to 2-3 hectares of land, it makes no sense to buy the most powerful potato diggers in terms of productivity, which will constantly slow down due to incompatibility of equipment with each other.

The volume of cultivated areas - if you plan to harvest a large amount of crops, it is rational to pay attention to vibrating potato diggers with additional equipment in the form of a trailed one. So the potatoes, after removing the soil, will immediately fall into the container.

Manual labor is minimized. When it comes to processing a 6 hectare garden, then you can use the most primitive models, saving the family budget.

Type of cultivated soils - loose chernozem soils are well cultivated by most types of potato diggers, while loam and sandy soils will require units with a pruning knife.

Prices - in most cases, the price is formed not only from the performance and availability of additional functions of the unit, but also from the manufacturer's brand

Here it is important to decide whether you need a high-quality unit that will work for wear and tear and will last for more than a dozen years, or the simplest and most inexpensive model for use in the garden is suitable.

The presence / absence of weeds in the field - some models are equipped with additional knives, which, together with the stalks, remove weeds, simultaneously performing their main functions. As for the conveyor types of potato diggers, they can constantly become clogged with grass and slow down the harvesting process.

Expert opinion

Kulikov Vladimir Sergeevich

It should be understood that the control of vibrating potato diggers is quite complicated and can cause a number of difficulties for beginners. They are also quite bulky and take up a large amount of space, which is not very convenient when processing a personal plot.

How to choose?

The criteria for choosing a potato digger should be associated with the device of your mini-tractor.

For example, if the capacity of the unit is not enough, it is better to pay attention to simple models. At the same time, one should not expect high work results from such a tool.

However, spending money on the purchase of a device will turn out to be rational. Having at your disposal a powerful motor-tractor, you can think about purchasing a vibration-type digger with additional devices. Such a technique will simplify the work associated with harvesting root crops, but will require a large investment.

You should also compare the size of the site. Vibratory diggers are bulky. They are often not suitable for processing 5–6 acres of an ordinary vegetable garden. Controlling a mini-tractor with a connected vibratory digger is more difficult. The vibrations will give off and feel good.

In addition to the main selection criteria, you can take additional ones into account:

- soil properties;

- the amount of cultivated land;

- availability of finance.

Peculiarities

Any potato digger is designed to pull potatoes to the surface of the soil. The specificity of all devices is identical and is not associated with either the brand or the model. Despite the large number of variations, devices are divided into vibrational and simple ones.

Simple diggers are passive devices that work like a shovel or plow. Teeth or rods are simply welded to the parts. The plow goes deep into the soil, loosens and overturns. The potato rises on the rods, remaining on the surface.

On the conveyor, potatoes are cleared of soil - clean vegetables are easier to collect. The drum mechanism is a rotating fan that throws the tubers to the sides. The drive of this fan is connected with lug wheels. Each farmer comes up with new and more convenient devices for his farm.

Homemade potato digger for the t-40 tractor video

Homemade wood splitter "Dragon" on t40 | Topic author: Maxim

Questions / answers about the wood splitter.

Alexander (Tuponile) Max is healthy! How are you? Have you posted the new video yet? The other day your wood splitter looked shrkirovany? Is it worth 50? And the belt is slipping or what? Can you explain that and how I will be very grateful !!!

Alexander (Tuponile) ANSWER: Hi.

Videos come out on Sundays). Yes, it's worth 50. The load is very large, any belts will slip.

Roman (Karniella) Hi Maxim, I wanted to know what is the gear ratio on the NSh 50, what is the speed of the pump, and the parameters of the hydraulic cylinder. Michael.

Maxim (Rupchand) Roman, at the pump about 2160 rpm. The thickness of the cylinder rod is 50mm, the stroke is about 600mm.But for the absolute accuracy of the stroke, I need to measure it, but unfortunately I cannot do this now. I will provide accurate data in the near future.

Roman (Karniella) Maxim, right

Roman (Karniella) Put an electric engine 7, 5 kW 1440 rpm, pump NSH50 (new), distribution 346ZH (from the Ivanovets crane based on KRAZ, to lower the legs) the problem is as follows: the engine turns at idle speed, but it is only necessary to supply oil to the cylinder the engine gets up to stasis.

Before that, I put the 6kW engine at 960 rpm in a belt drive + old NSh50 (pump rpm were 500-600), everything worked, but quietly, I think it's because of the distributor. Am I thinking right?

Maxim (Rupchand) Roman, there is not enough power to turn the NSh at high revs. I find it difficult to answer why it does not work with a change in speed, but the NSh-50 requires a significant engine power for the wood splitter.

Mikhail (Raghuvir) Hi Maxim, if you put 3 or 4 knives on the wood splitter, will it pull or not?

Maxim (Rupchand) Mikhail, greetings! Will pull if the knives stand through the gap.

Mikhail (Raghuvir) Thank you very much

Ruslan (Gana) Maxim, good evening, max I want to create such a miracle for myself on the tz-4k-14 mini tractor because of this a couple of questions, 1 why the drive to the NSh directly from the tractor was not done .. 2 which one can put NSh 32 or 503 you welded the main riser from iron sheets or used a square4 what is the height, width and approximate weight of the main frame, without a conveyor and a firewood lifter. 5 which channel you used 10 or 12 on the conveyor and what is the length of the conveyor6 is the oil heated in the heat in advance thanks

Maxim (Rupchand) Ruslan, greetings! 1) The drive through the gearbox must be installed because for normal operation we need at least 2 thousand rpm... 2) Better nsh50 because it is more efficient, but requires a powerful engine. 3) a profile was cooked from two corners. 4) the width and height were made arbitrarily for the required size of firewood and the length of the hydraulic cylinder. 5) 10, length about 1, 3 - 1, 4 m. 6) did not notice that it was warming up.

Vasily (Sanandana) Maxim, good day. I have such a question, I looked at the review of your cleaver, and an idea appeared to do something like that, but there are doubts, for example, if you put NSh 32, the distribution of the p-80 into 3 sections, put the cylinder in a prone state, and without any conveyor and other things, just to prick, and I almost forgot the main thing that this whole thing can only be done on a Chinese mini tractor from a vom, we have 540 rpm., a minute

Maxim (Rupchand) Vasily, that's how everyone is doing it in principle, but it will probably work a little slow. For NSh you need 2000 about minimum

Vasily (Sanandana) Maxim, thanks.

Ruslan (Gana) Maxim, hi max, another question about the wood splitter, do you have guides on rollers on knives, why should the knife not spin? and is it possible without them, thanks

Maxim (Rupchand) Ruslan, yes, so that the knife does not twist and break off, because without guides the knife will behave freely and its fastening will break off. You can't do it without guides.

Ruslan (Gana) Maxim, I will collect according to your macar only the knives will stand from below, and the cylinder will press from above with a straight sheet, below there will be a conveyor to take away, dreams and plans are such, I have collected the material, only welded from me is not crazy

Maxim (Rupchand) [post419 | Ruslan, then it is better to immediately attach the knives to the Hz, so it will be more convenient and much faster to stab.

Tags: Homemade potato digger for tractor t-40 video

YuMZ, MTZ.K700.T150.T25.T40.DT and other tractors | Topic author: Tanya

We have cultivated Tanya (Abhipri) Sasha with us since April, as they sowed and to this day there is no rain three drops will fall and that's it, the corn has already spun in some places, and even a strong wind

Sasha (Maro), the rains helped us a little for winter crops, everything is waist-deep and there is no rain for corn, we also use frigates for irrigation

Tanya (Abhipri) Wheat this year is feeble, and we only watered cucumbers and tomatoes

.

Varieties according to the principle of work

Depending on the equipment and design, potato diggers are of the following types:

Fan - used for harvesting in dachas and vegetable gardens. The design is primitive: rods in the shape of a fan are welded to the hiller that loosens the earth. The soil layer rises to the top, the tubers fall on the twigs, where they are shaken off and laid on top of the ground.

Drum - has a complicated design in the form of pruning knives, a grate and a drum, where the tubers are cleaned from excess soil directly. Can be used on all types of soil

Of the shortcomings, it is important to cancel the high percentage of damaged root crops, due to the mechanical action of the lattice drum.

Vibrating (roaring) - the cleansing of potatoes from the ground is carried out due to the vibrations of the unit. The disadvantages include the need to use manual labor to collect root crops, since the lattice structure does not provide for the transport of potatoes into a prepared container

Used for small agricultural land. Difficult to manage.

Conveyor - has one of the most complex structural structures. The ploughshare located at the front cuts the soil layer with potatoes and feeds it to the conveyor lattice base, where the roots are cleaned. When processing fields with weeds, there is a high probability of clogging the conveyor and stopping its movement.

As for the type of construction, the potato diggers are double-row and single-row. In the first case, it is possible to process two rows of potatoes in one pass of the mini-tractor. Single-row machines are more suitable for processing small vegetable gardens.

Which potato digger for your mini-tractor will you choose?

Single row

Making a fan potato digger for a mini tractor

The idea of making your own fan potato digger for a mini tractor is quite realizable even for beginners. Skills of working with special tools are not required here, and for those who have never worked with electric welding it is worth trying to learn.

First you need to understand the design, any information will help here. You can look on the Internet, since there are enough home-builders, or you can visit exhibitions or salons selling agricultural machinery. In Moscow, for example, there are permanent stands at VDNKh dedicated to small-scale mechanization of agricultural production

Here it is worth paying attention to two points - the dimensions of the elements and the manufacturing options. As production options, it is advisable to use separate prefabricated elements, for example, a rack with a hitch

Materials and tools

When working, you will definitely need:

- Bulgarian;

- Welding inverter or any other welding machine, even gas welding;

- Roulette;

- Kern;

- Hammer;

- Pliers;

- File;

- Metal brush.

To make a potato digger with your own hands, you need a welding machine You may need:

- Hacksaw for metal;

- Drill;

- Clamps for the convenience of welding;

Of the materials you will need:

- Profile pipe 60x60 mm;

- Sheet metal 4-5 mm thick;

- Steel plate 4-5 mm thick;

- Round rod with a diameter of 8 mm or steel reinforcement of the same diameter;

- The support wheel, if it is provided for in the design, is better to take on bearings with a shaft;

- Channel for coupling.

Blueprints

Finding drawings on the Internet is easy. And when working, you can use ready-made drawings, just download and print them. But before cutting the metal, it is recommended to simply depict on a sheet of paper how the individual nodes and parts will look, how and where they will be attached.

For beginner DIYers, it is recommended that before starting metal cutting, transfer all dimensions to cardboard and assemble a cardboard model. This technique will help you to clearly see all the problem areas of the structure.

Manufacturing steps

It is recommended to start the assembly process with the manufacture of the plow body. The frame and the hitch are welded from the profile pipe. In the work, it is imperative that after all the elements have been cut, they should be assembled into a single structure with several welding points. The final welding is recommended after all defects have been corrected.

The plow share is best made from two parts of the body and the cutting plate. The body is assembled from sheet iron, but the cutting plate is attached on a bolted connection or on rivets.

At the final stage, the fan rods are welded to the plow body with plowshares. At the weld point, seams are made on both sides. The length of the seam is at least 5 cm. A template made of a wooden wedge will help to speed up this process, with the help of it another rod is fixed to the fixed rod and fixed with several welding points.

After assembly, it is recommended to try the potato digger in practice, not necessarily on the garden bed, you can simply go through one or two furrows to make sure that the assembly is correct and to find weaknesses in the structure.

How to make a potato digger with your own hands

If you don't want to spend money on buying attachments, you should try to assemble it yourself from scrap materials. The following is an instruction for making a simple potato digger.

Required materials and tools

To create a homemade potato digger you will need:

- frame;

- lattice;

- a pipe with a diameter of 20 cm for making a share;

- ready-made chain mechanism for fastening;

- steel or rubber wheels;

- welding;

- Bulgarian;

- sharpener;

- bolts.

Drawings, diagrams

There are a large number of schemes for the manufacture of attachments, but it is better to choose a scheme for assembling a vibrating potato digger. This simple design does not require a high level of skill. Only minimal knowledge of welding is required.

Step-by-step instruction

The following diagram will allow you to assemble a reliable potato digger from simple materials:

- For the frame, you need a corner with a section of 60x40 mm. Gussets-reinforcements of the corners of the frame and other units are cut out of a steel sheet with a thickness of 6-8 mm. All parts are fixed by welding or bolts. It is good if fastening methods are combined.

- A lattice of rods and steel strips with a diameter of about 10 mm is cooked. The finished structure is connected to the shaft, and the fixation points are fixed with bolts.

- A pipe with a diameter of 20 mm is cut with a grinder, a ring is made from it. The resulting product is processed with a sharpener. The sharp share is fixed to the frame and the elevator with bolts. The diameter of the fasteners is 10 mm.

- Install the hubs on the sides of the hinge.

- The ready-made trailing mechanism is fixed.

- Wide wheels are mounted. Better than 2 pairs.

The assembly of equipment is carried out only on a flat surface. Use a serviceable tool, without burrs and chippings.

h2> Specifics of using a mounted potato digger

Regardless of the type of attachment used, the potato digger works according to the standard principle:

- The device is mounted using a standard canopy at the rear of the mini tractor;

- When working, the ploughshare plunges into the ground by 25-30 centimeters, after which the tubers, together with the ground, move to the transport mechanism;

- The potatoes are cleaned from soil;

- The peeled tubers are thrown back onto the ground. After that, it is enough to collect the potatoes.

It is difficult to overestimate the advantages of using a potato digger:

- Minimal crop losses during harvesting;

- Lean work - the structure of the tubers is not damaged;

- High harvesting speed;

- The design of the device is very simple, so it is easy to maintain and repair. You can also make a potato digger with your own hands;

- The hinged device can be attached to various agricultural machinery: mini tractors, walk-behind tractors, tractors;

- Some modifications of diggers are equipped with a storage hopper, into which potatoes fall after cleaning.

How to make a potato planter with your own hands

Consider what is homemade potato planter for mini tractor.

With the onset of spring, potato tubers are prepared for planting in the ground. To facilitate the process, use a special planter. The potato planter for a mini tractor can be single-row or double-row.In addition, they are simple, without support wheels and with wheels. The single row technique is adapted for planting tubers in one row. In the case of a two-row, two rows are processed and sown at the same time. The row spacing can be adjusted.

You can make models with grousers. In such a unit, the function of the wheels is performed by lugs. They, thanks to a chain mechanism, set in motion a conveyor belt for feeding tubers. To create even rows, the device has a disc hiller and a plow for forming a furrow.

The two-row potato planter for a mini tractor is well combined with mini tractors and has a hydraulic drive. Unlike the single-row planter, this model has two bunkers for filling the planting tubers. The amount of capacity depends on the model of the unit.

Planting potatoes with a mini tractor fully automates the work. This is a very handy device, but unfortunately many people cannot afford it. You can make such a device yourself, while maintaining the principle of conveyor work.

To make a potato planter with your own hands for a tractor, you will need:

- container or bunker for filling planting tubers;

- frame with wheels;

- ditch digging device;

- tape with attached bowls for grabbing potatoes;

- discs for backfilling planted tubers.

First, a frame with wheels is assembled, to which all other parts will be attached. After that, a fastener is welded to connect the unit to the tractor and a longitudinal axis is installed on which the bunker will be held. It can be made from wood, or you can use any suitable container, for example, a tank from an old washing machine. A metal pipe with a spacious opening can be used as a seeder.

Before starting the assembly of such a unit, be sure to read the relevant literature or watch a video. It is not worth taking on the structure without a preliminary drawing. Digger for planting potatoes, made by hand, can be designed for a tractor, or maybe for combination with another device. Often, after assembly, the cost of manufacturing the unit is more expensive than expected, and the price difference with the finished equipment is so insignificant that it is better to purchase ready-made equipment.

See "How to assemble a homemade mini tractor with a Ural engine

A self-made potato planter must be assembled without errors, otherwise the sowing process will be labor-intensive and long. The calculation should include absolutely everything: row spacing, distance between planted potatoes, planting depth, etc.

Review of the best models

Russian-made potato diggers are endowed with excellent technical characteristics and show good performance. Let's consider the most popular models.

"Scout"

This is a conveyor potato digger for high quality pre-processing of vegetables.

Peculiarities:

- compatibility with mini-tractors "Scout", equipping with a three-point suspension system and a power take-off shaft;

- connection to models T-12, 15, 18, 24 and 25 is permissible, but using a drive belt of the corresponding class;

- adjustable knife depth up to 28 cm;

- power indicators - from 12 to 25 liters. with.;

- power take-off shaft speed - 540 rpm;

- drive belt type - B2360, B25550 or B2600;

- travel speed - from 2 to 7 km / h.

The cost of attachments starts from 20,000 rubles.

KKM-3

This roaring potato digger for connection to MTZ-132N is designed for digging and spreading vegetables on the soil surface.

The model provides for adjustment of the immersion depth of the teeth.

Peculiarities:

- productivity - 0.05-0.2 ha / h;

- speed - 1.1-2.1 km / h;

- soil capture depth - 20 cm;

- required drive - PC-3;

- cost - from 12,500 rubles.

The technique has shown itself well in working with wet and hard soils.At the same time, it is able to loosen the soil littered with stones up to 8-9 t / ha.

4UD-1

A roaring potato digger for extracting vegetables from the soil and partially separating them from the ground, followed by laying them on the surface of the field.

Peculiarities:

- suitable for working in tandem with mini-tractors and tractors of the class from 0.6 tf with a capacity of more than 20 hp. with.;

- installation takes place on the rear three-point hitch using the PTO drive;

- pick-up depth - from 15 cm;

- speed - up to 6 km / h;

- productivity - up to 0.225 ha / h;

- type of construction - single row.

The cost of the model starts from 1,800 rubles.

Bomet Z-655

The vibrating potato digger with rear discharge has a compact size (1.7x1.5x1.15 m), therefore it is used on small flat or hilly land plots with medium compacted and light soil.

Peculiarities:

- compatibility with any mini-tractor models with a capacity of more than 15 liters. with.;

- power take-off shaft speed - 540 rpm;

- soil capture depth - up to 20 cm;

- working speed - 5 km / h.

Side discharge allows the crop to be placed 50 cm from the main trench. This ensures that all tubers rise without any damage. The cost of the model is from 65,000 rubles.

Wirax

Single-row conveyor potato digger for any mini-tractors of traction class 0.9 with a capacity of 20-35 hp. with. Cultivates only loose soil without stones.

Peculiarities:

- soil capture depth - up to 25 cm;

- working speed - 8 km / h;

- the ability to work on surfaces with a slope of up to 6 °;

- completed with two Italian-made rubber-fabric conveyor belts;

- cost - from 60,000 rubles.

KK-1

The single-row type transporter potato digger is suitable for connection to heavy walk-behind tractors and mini-tractors with a capacity of 18 hp or more. with.

Peculiarities:

- capture width - 65 cm;

- digging depth - up to 25 cm;

- working speed - 4 km / h;

- connects to the equipment "Salute", "Ugra", "Neva";

- cost - from 55,000 rubles.

Device and principle of operation

The drawings that are freely available on profile portals, of course, facilitate the task associated with creating a device, but a detailed knowledge of the principles of equipment will also be useful.

The potato digger device includes the following parts:

- an iron frame on which the constituent parts are attached;

- wheels;

- shafts;

- ploughshare;

- transport components;

- lattice.

The frame is the heart of the whole device. It takes the main load, so the steel used in its manufacture must be strong, and the welded joints must be of high quality.

The grate where vegetables are cleaned is also called an elevator. It is made from steel rods. A shaft is attached to the steel grate, the power of which determines the degree of vibration. The resulting structure is placed on the frame and secured with bolts. Next, knives are made that will cut the ground. They need strong curved steel. For homemade products, a piece of pipe is often used. The part is cut and unbend. Then its edge is sharpened.

A single shaft with bearings or separate hubs can serve as a wheel attachment. Wheels can be ordinary tires. There are also iron options equipped with lugs. The type of final attachment to the mini-tractor will be associated with the features of your existing model of equipment. A self-made trailing mechanism must fit the factory tractor device.