Cleaning the carburetor of the walk-behind tractor

Frequent failures in the operation of the power unit of the walk-behind tractor indicate the accumulation of blockages inside its carburetor. This fuel assembly constantly interacts with engine oil, gasoline and air. They contain solid fractions, tar and small debris, which can be deposited on the walls of the carburetor chambers and inside the fuel channels. In this regard, the carburetor needs regular cleaning, especially if low-quality fuel is used to refuel the agricultural unit.

Before directly flushing the carburetor of the used walk-behind tractor, you need to dismantle the standard air filter and rinse it thoroughly in clean gasoline. After that, the part will need to be dried. The operator should also inspect and clean the spark plug. If a thick layer of carbon has formed on its cap, this indicates oil seepage.

Before directly flushing the carburetor of the used walk-behind tractor, you need to dismantle the standard air filter and rinse it thoroughly in clean gasoline. After that, the part will need to be dried. The operator should also inspect and clean the spark plug. If a thick layer of carbon has formed on its cap, this indicates oil seepage.

The further procedure should be as follows:

- First, you need to carefully remove the idle carburetor from the factory device and completely drain the remaining fuel from the standard float metal chamber;

- You will then need to inspect the built-in fuel connection. If air does not pass through it, then the fitting must be blown out with compressed air from the purchased cylinder;

- Next, the operator must examine the condition of the metal float chamber and the "tongue" required to adjust the position of the float. The operator must check the level of the amount of refueling fuel that enters the chamber - its level must initially be at least 3.5 cm;

- After that, you will need to remove the needles responsible for adjusting the low and full gas - this is necessary to completely flush the nozzle;

- Next, you need to unscrew the bolts and disconnect the standard upper part of the factory carburetor from the lower one. The operator will then be able to thoroughly flush the built-in fuel supply valve;

- Then it is necessary to purge the jet with air from the cylinder. This and other elements of the carburetor must not be wiped with a fluffy cloth. Otherwise, the risk of damage to the chrome coating of the walls of the fuel assembly will increase;

- After all the parts of the standard carburetor are completely dry, it can be reassembled.

Immediately after installing the fuel unit, the operator must adjust it and smoothly start the motor of the walk-behind tractor. Next, the user will need to check the operation of the node. If the built-in engine runs as stable as possible and does not emit extraneous sounds, then the cleaning and adjustment of the standard carburetor were performed correctly.

Chainsaw repair and maintenance Friendship

Reliable parts and durable mechanisms of the Druzhba chainsaw are not able to protect the tool from breakage. The most common causes of tool malfunction are improper handling or trivial wear and tear of mechanisms.

To reduce the risk of premature damage to the chainsaw, you should use high-quality gasoline of a brand not lower than AI-80 to refuel it, in which oil for 2-stroke engines should be diluted. The proportion of gasoline and oil should be 1:25, that is, 40 ml of engine oil should be diluted in 1 liter of fuel.

The chain oil must also be of high quality. In no case do not pour waste material into the oil tank of the Druzhba chainsaw, otherwise this will lead to a breakdown of the tool lubrication system. To prevent the chainsaw chain from giving in to excessive friction, use only fresh oil from trusted manufacturers.

It should be noted that the use of a high-quality fuel mixture and lubricant does not yet guarantee the continuous uninterrupted operation of the Druzhba chainsaw. However, even if you find a malfunction, do not get upset right away. Some breakdowns are quite easy to fix with your own hands. Below we list typical malfunctions of a domestic instrument and ways to eliminate them on their own.

Chainsaw carburetor adjustment Friendship

- To find the highest engine idle speed, slowly turn the screw marked “L” clockwise. Once you find the maximum RPM, turn the same screw ¼ of a turn back. If after that the chain on the bar continues to rotate, then turn the screw marked "T" counterclockwise until the saw unit stops completely;

- Turning the screw marked with the letter "H" will adjust the required power and rpm. To do this, you need to connect a tachometer to the Druzhba chainsaw and by turning the screw "H" find the optimal number of revolutions specified in the instructions. Immediately after that, turn screw “H” ¼ turn counterclockwise;

- Then you need to make a fine adjustment of the engine idle speed. To do this, turn the “T” screw until the saw chain starts rotating. Immediately then turn the screw “T” in the opposite direction until the chain stops completely.

Adjusting the carburetor as instructed will allow you to reduce fuel consumption of the Druzhba chainsaw and protect its parts from excessive wear.

How to set the ignition on the Friendship chainsaw?

To properly repair the tool, you need to carefully study the manual for its operation. As the instructions for repairing the Druzhba chainsaw indicate, to install the ignition, you need to remove the cover to which the starter is attached and turn the magneto so that the marks on it and the adapter match. After that, the Friendship chainsaw will start much easier.

Cleaning the carburetor

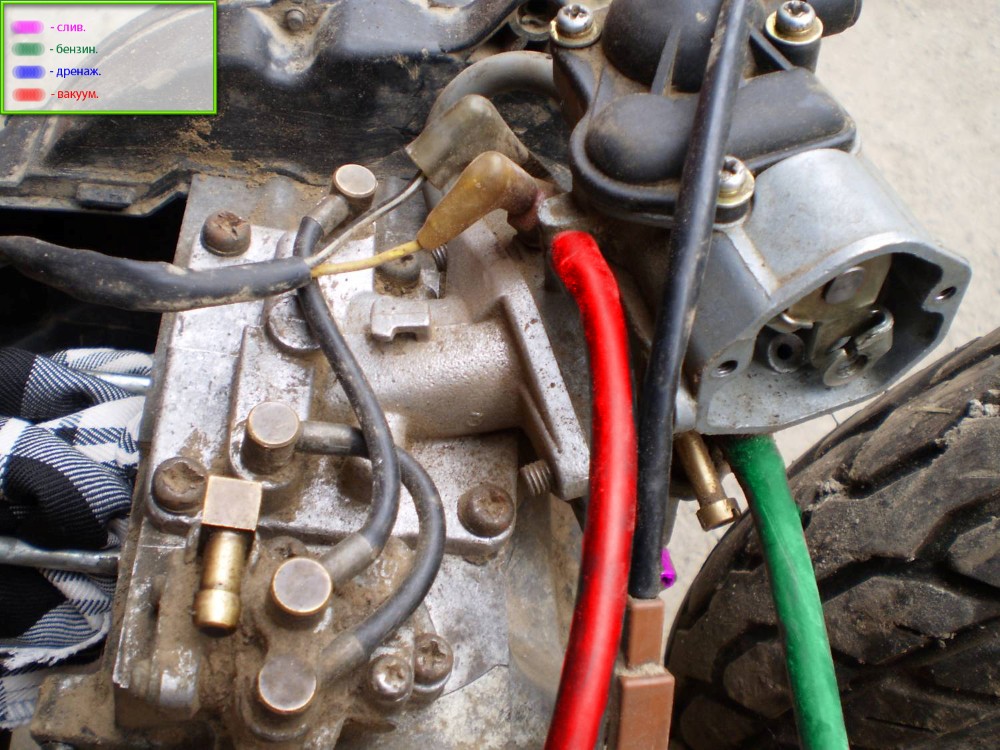

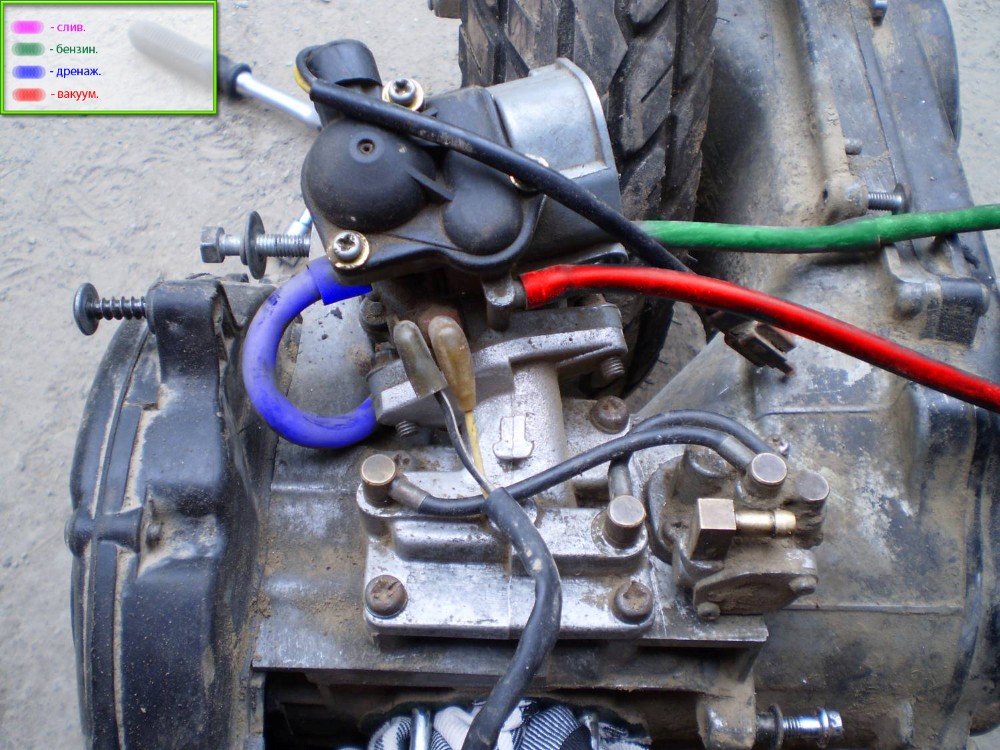

To adjust the level, the carburetor on the walk-behind tractor is completely cleaned of dirt beforehand. Before starting work, drain the fuel from the gas tank. To do this, unscrew the drain plug or remove the supply hose. Gasoline is poured into a clean canister or plastic container. Before refilling, it is advisable to pass the flammable liquid through a filter. After emptying the fuel tank, dismantle the supply hose, dry it and blow it off with compressed air.

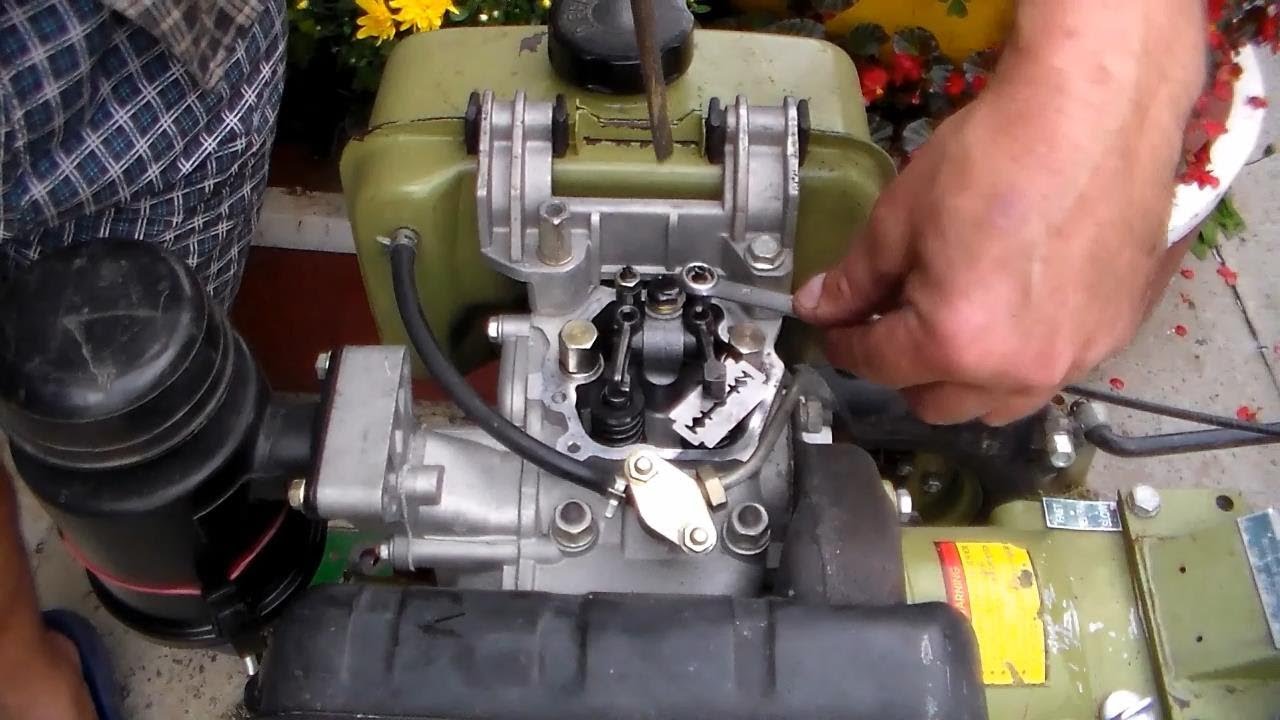

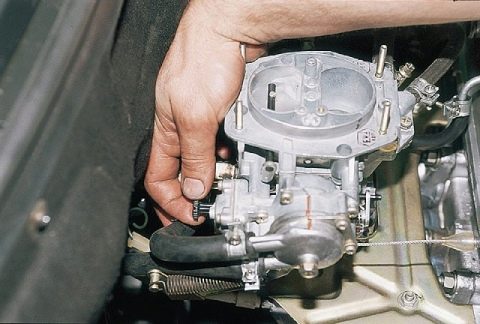

The remote control is attached directly to the cylinder head. To remove the dosing mechanism, dismantle the air filter with the supply pipe. Then the throttle actuator is disconnected, the fasteners are unscrewed, the carburetor is removed from the seat. Remote control cleaning:

- Dismantle the body of the filter-settling tank. At the bottom, unscrew the fixing bolt, take out the glass. Inside it, oily deposits are cleaned out, everything is thoroughly wiped and dried.

- A float chamber is made in the lower part of the body. In its center is the main fuel jet, which is unscrewed with a screwdriver. There is a small sleeve underneath, which is also removed. To remove the float with a closing needle, the support shaft is removed with pliers.

- The carburetor body (with pre-removed plastic parts) and jets are placed in acetone or white spirit for a day. Polymer components are washed with clean gasoline, cleaned with a soft brush, then dried thoroughly.

- Soaked parts are cleaned of plaque with a rag, and the metering holes - with a thin needle or wire.

- The assembly is carried out upside-down.

Carburetor device

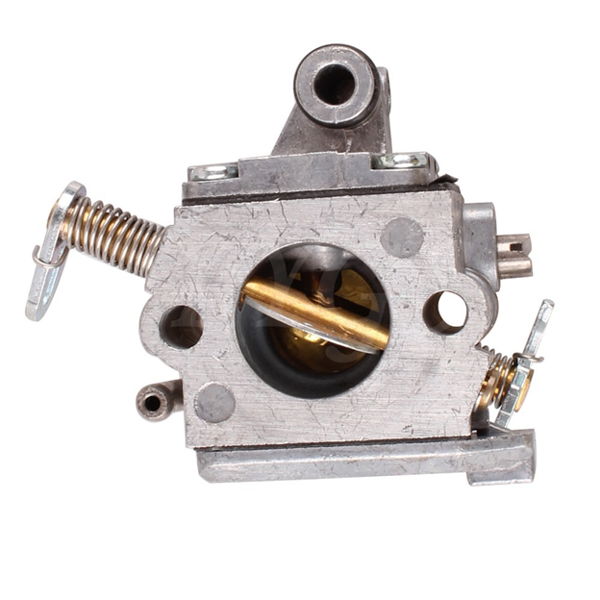

The design of the Neva agricultural machinery carburetor is quite simple. Its study will not be particularly difficult, but at the same time it will subsequently make it possible to easily make not only adjustments, but also repairs - if such a need arises. This part includes the following components:

- a float associated with a locking needle valve;

- float chamber;

- a chamber in which the fuel is saturated with air;

- diffuser and fuel spray system;

- throttle valve;

- air and fuel valves.

The task of the float, connected to a needle-type valve, is a kind of regulator function that determines the volume of gasoline in the float chamber. When the amount of fuel decreases, the float goes down and opens the valve, which “lets in” a new volume of fuel into the chamber, replenishing it to the required amount. As the chamber fills, the float rises and closes the valve when the filling is required, preventing excess fuel in the chamber.

In this video, you will learn how to disassemble a carburetor:

The function of the atomizer located between the float and mixing chambers is to distribute the fuel into the mixing chamber, in which it is saturated with air. Air enters this container through the inlet pipe. It is worth emphasizing here that the gasoline level in the float tank should always be a few millimeters below the outlet channel.

This is important, because when the engine of the unit is turned off, the fuel should not spill out of the float chamber, not only being on a flat surface, but also when the walk-behind tractor is on a slope

Varieties of "Kopeyka" carburetors

Jets for carburetors of cars VAZ 2101, VAZ 2103, VAZ 2106, VAZ 2107

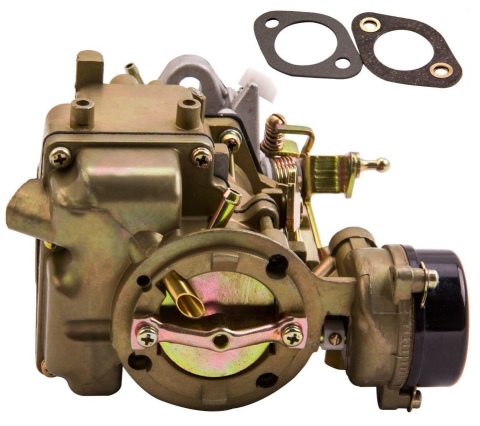

During the production of the VAZ 2101, several modifications of carburetors were installed in its system. They differ in the size of the nozzles, as well as the presence or absence of a vacuum corrector. In early Zhiguli models, a carburetor was installed with an ignition system without a vacuum corrector.

The most common carburetor on a VAZ 2101 car is the DAAZ 2101-1107010 carburetor model. A vacuum corrector system is already used here. All carburetor modifications can be adjusted in a similar way. But it is impossible to install a model with a vacuum corrector instead of a design without it, or vice versa. Carburetors of well-known brands DAAZ / Weber, Ozone, Solex are also often used from non-standard carburetors, I would like to highlight Solex 21073 and Solex 21083.

Calibration data for carburetors DAAZ 2101-1107010-01, 2101-1107010-03, 2105-1107010-20, 2105-1107010 10:

| Parameter | Carburetor model and chamber number | |||||

| 2101-1107010-01 | 2101-1107010-03 | 2105-1107010-20, 2105-1107010 10 | ||||

| 1st | 2nd | 1st | 2nd | 1st | 2nd | |

| Diameter, mm: | ||||||

| diffuser | 23 | 23 | 23 | 23 | 21 | 25 |

| main fuel jet | 1.30 | 1.25 | 1.30 | 1,30 | 1.07′ | 1.62 |

| main air jet | 1.50 | 1,90 | 1.50 | 2,00 | 1.70 | 1.70 |

| idle fuel jet and transition system | 0.50 | 0.45 | 0.45 | 0.60 | 0.50 | 0.60 |

| idle air jet and transition system | 1.70 | 0.70 | 1,70 | 0.70 | 1.70 | 0.70 |

| Accelerator Pump Spray Hole | 0.40 | 0,40 | 0.40 | |||

| accelerator pump bypass jet | 0,40 | — | 0.40 | — | 0.40 | |

| Ecomostat fuel jet | — | 1.50 | — | 1.50 | — | 1.50 |

| air jet ekonept | 0.90 | — | 0.90 | 1.20 | ||

| econostat emulsion jet | 1.70 | — | 1.70 | — | 1.50 | |

| air jet trigger | 0.70 | — | 0.70 | 0.70 | — | |

| second chamber throttle valve air jet | — | — | — | 1.20 | 1.00 | |

| Sprayer calibration number | 4 | 4.5 | 4 | 4 | 3.5 | 4.5 |

| Emulsion tube calibration number | FI5 | FI5 | F15 | FI5 | F15 | F15 |

| Accelerating pump feed for 10 full strokes, cm3 | 7±0.25% | 7±0.25% | 7±0.25% | |||

| The distance of the float from the carburetor cover with a gasket, mm | 7.5±0.25 | 6.5±0.25 | 6.5±0.25 | |||

| The gap at the dampers for regulating the starting device, mm: | ||||||

| air damper | 8±0.5 | 7±0.25 | 5 | |||

| throttle | 0.75 | 0.85 | 0.75 | 0.85 | 0.7 | 0.8 |

Power system design

One of the components of the internal combustion engine is the fuel system. It is necessary for the uninterrupted supply of the engine with fuel. The system consists of a gas tank, fuel line, filters and carburetor. The latter doses gasoline to maintain a given crankshaft speed, depending on the operating modes of the walk-behind tractor. A gas tank is necessary for storing a supply of fuel in it. Fuel lines connect all components to each other, and filters clean the fuel from impurities.

The most complex and critical part in the internal combustion engine is the dosing unit. The carburetor device installed on the walk-behind tractor allows the user to adjust the quality of the fuel mixture entering the engine.In general, the control system consists of the following:

- Float chamber. It contains the parts responsible for the preparation of the fuel mixture. Gasoline accumulates in the receiving glass, which acts on the float. The latter, upon reaching a predetermined fuel level, by pressing the shut-off needle, shuts off the fuel supply.

- Mixing chamber. In it, the air entering the engine is saturated with fine gasoline dust. The latter is formed due to the rarefied atmosphere in the mixing chamber. The reduced pressure draws fuel from the float chamber, which, passing through the metering nozzle, is atomized in the air stream.

- Throttle body. This unit regulates the crankshaft speed. The damper closes the passageway through which air enters the cylinder. The larger the section, the faster the ICE output shaft will rotate. The position of the damper is adjusted by means of a steel cable attached to the handle of the walk-behind tractor.

- Idle speed regulator. Typically this is a metal or plastic screw that supports the throttle actuator. Screwing in the governor increases the engine idle speed.

For your information! Depending on the manufacturer and purpose of motoblocks, their remote control can be equipped with additional elements. But, regardless of this, all nodes work on the same principle.

Carburetor, malfunctions, adjustment

Below is an algorithm for tuning the carburetor on a Neva walk-behind tractor with a Subaru engine.

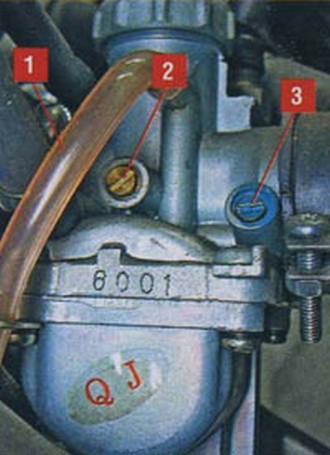

Carburetor adjustment diagram

The diagram shows three screws that are responsible for the amount of fuel supplied.

- Screw 1 - the number of full throttle turns;

- Screw 2 - number of turns of idle throttle;

- Screw 3 - is responsible for idling.

To adjust the carburetor, you must perform the following manipulations:

- Tighten screws 1 and 2 up to the stop;

- Then unscrew them about 1 turn;

- Turn on the ignition and warm up the engine;

- Then put the throttle control lever until the engine is turned off (that is, until the speed is at the minimum level);

- Set the minimum idle speed with the third screw;

- Then set the maximum idle speed with the second screw;

- If necessary, correct the minimum speed again by adjusting the position of the third screw;

- Perform the last two points until stable engine operation is obtained;

- If there are interruptions, tighten the first screw again until it stops and unscrew it by one and a half turns.

How to handle the carburetor if the walk-behind tractor has not been used for a long time

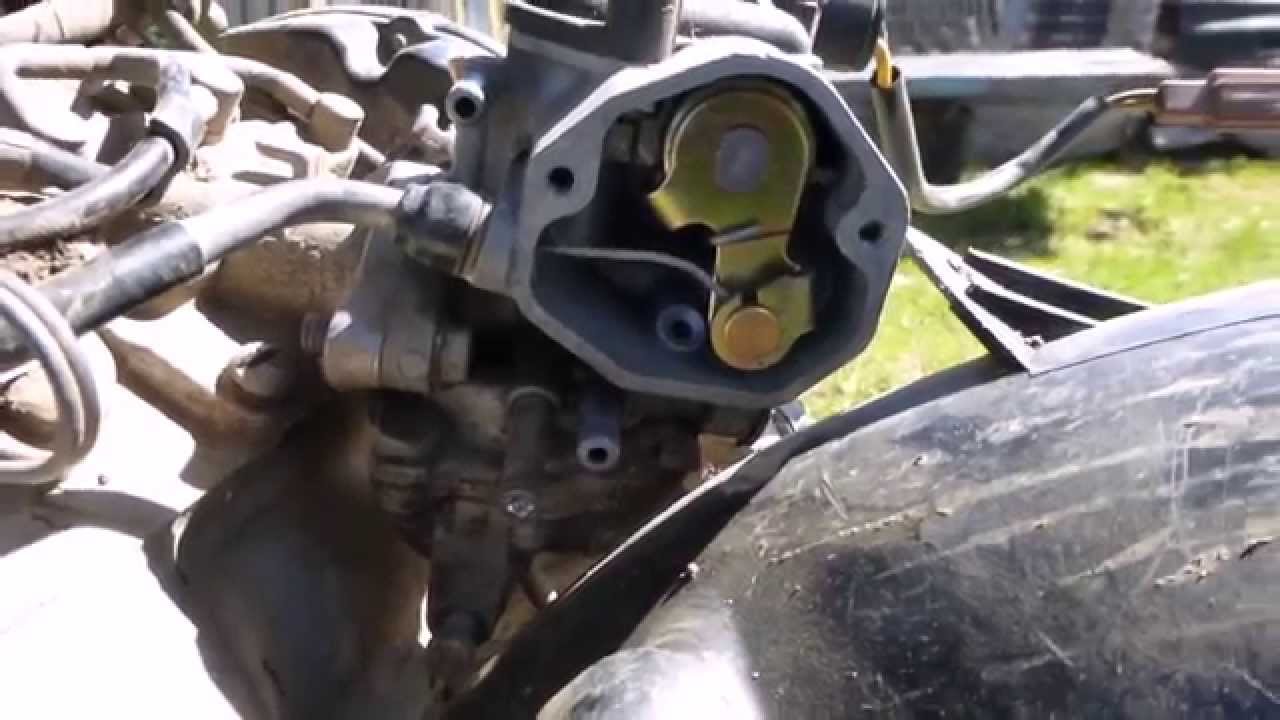

To start the walk-behind tractor Cascade with KMB 5, which has not been used for a long time, you must first check and clean all parts.

This is interesting: setting up the carburetor of the walk-behind tractor.

A similar event is held in the following order:

- We unscrew and disconnect the carburetor from the engine.

- We clean it from accumulated dust; a soft brush and gasoline are suitable for this.

- We unscrew the fitting and the float.

- We wash the filter and all other fuel cells with clean gasoline.

- Using compressed air, we carry out a purge.

- We check the dryness of all components of the carburetor.

- We carry out the reverse assembly of the device and install it in its place.

A device such as a carburetor does not need to be completely cleaned and adjusted daily, but for optimal engine performance, it is advisable to regularly monitor its condition.

The most common cause of uneven engine performance is a dirty carburetor. This often happens due to the use of low-quality fuel. Another reason for the poor performance of the engine is the failure of the wire that connects the accelerator pedal to the carbon fiber. You can determine a similar problem and its cause yourself.To do this, it is necessary to fold the wire, and if the engine normalizes operation, the reason lies precisely in the wire, and not in equipment contamination. In this situation, the drive must be replaced.