Features of the test

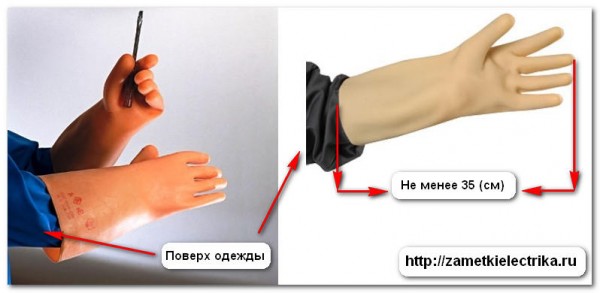

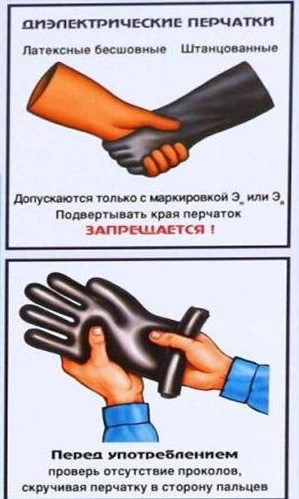

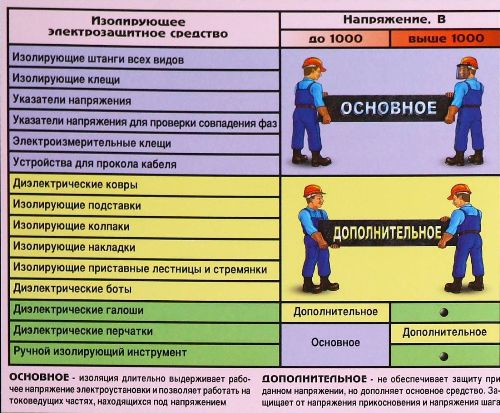

Inspection of dielectric gloves is carried out only in laboratory conditions with the participation of qualified specialists. Gloves are designed to protect hands from electric shock when working in electrical installations up to 1000 V as the main electrical protective equipment, and in electrical installations above 1000 V - as an additional one. In electrical installations, seamless gloves made of latex, natural rubber or gloves with a seam made of sheet rubber, made by punching, can be used. In electrical installations, it is allowed to use only gloves marked for the protective properties EN (for protection against electric current with voltage up to 1000 V). The length of the gloves must be at least 350 mm.

Inspection of dielectric gloves is carried out only in laboratory conditions with the participation of qualified specialists. Gloves are designed to protect hands from electric shock when working in electrical installations up to 1000 V as the main electrical protective equipment, and in electrical installations above 1000 V - as an additional one. In electrical installations, seamless gloves made of latex, natural rubber or gloves with a seam made of sheet rubber, made by punching, can be used. In electrical installations, it is allowed to use only gloves marked for the protective properties EN (for protection against electric current with voltage up to 1000 V). The length of the gloves must be at least 350 mm.

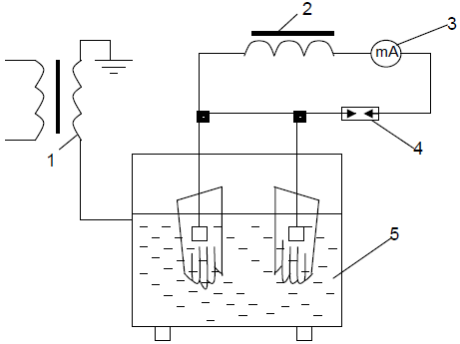

A high-voltage installation is used for the test, the gloves are placed in a bathtub filled with water.

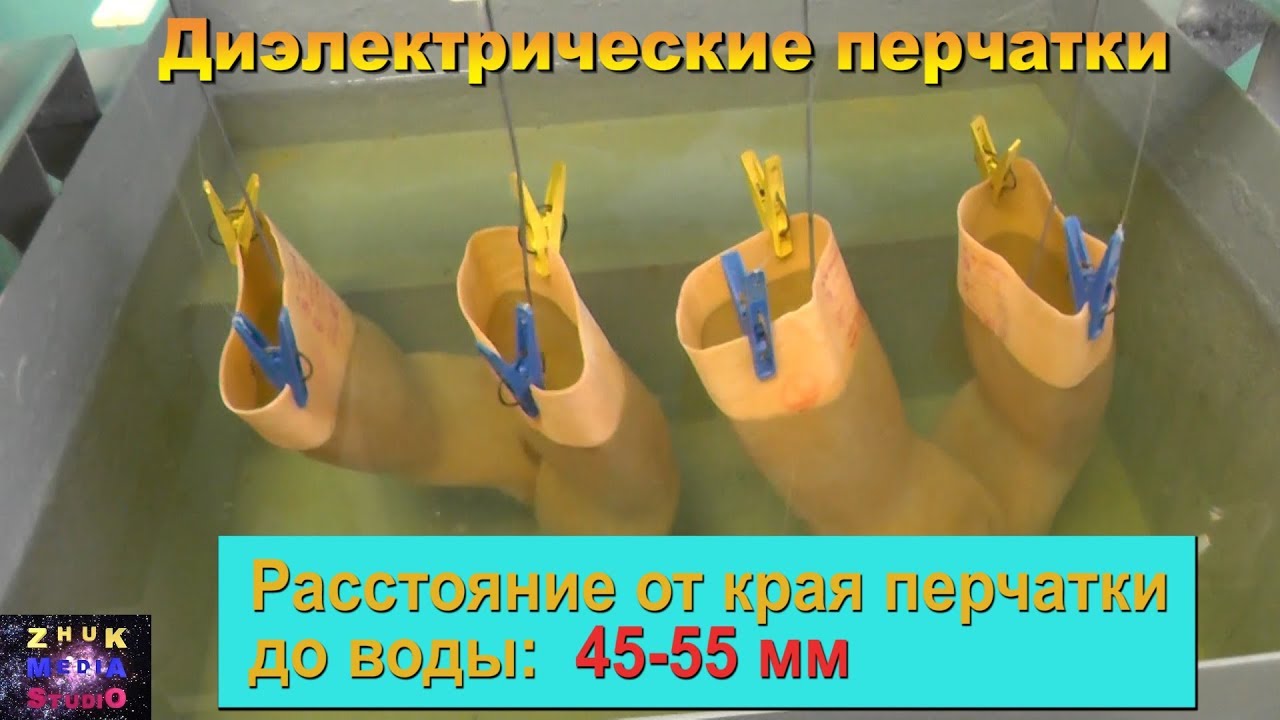

During testing, dielectric gloves are immersed in a metal vessel with water having a temperature of 25 + 10 degrees C °, which is also poured into these products. The water level both outside and inside the products should be 50 mm below the top edge of the gloves. Protruding edges of gloves must be dry. One terminal of the test transformer is connected to the vessel, the other is grounded. An electrode is lowered inside the gloves, connected to ground through a milliammeter. A schematic diagram of testing dielectric gloves is shown in the figure:

Rice. Schematic diagram of testing dielectric gloves.

1 - test transformer; 2 - choke; 3 - milliammeter; 4 - spark gap; 5 - bath with water.

After testing, only those PPE that transmit a current of no more than 6 mA can be put into use. Often during the procedures, a factory defect is revealed. In this case, the PPE is disposed of.

It is worth considering a number of nuances when using:

- Only clean gloves can be put into operation;

- Dust and dirt are excellent conductors, so dirty products pose a high level of hazard during operation;

- To eliminate the problem, gloves are thoroughly disinfected, cleaned with soap and soda.

Only dried devices can be used.

Test of strength

Testing insulating gloves is a necessary measure during their use. Such a check (verification period) is carried out once every six months (the frequency of the check depends on the marking "Ev" and "En").

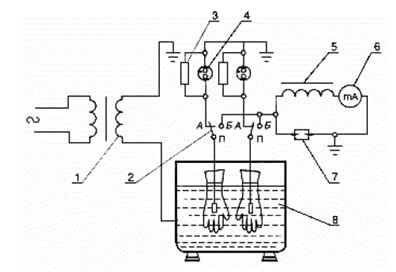

Scheme for testing mittens, bot and galoshes for strength:

- 1 - test transformer;

- 2 - switching contacts;

- 3 - shunt resistance;

- 4 - gas discharge lamp;

- 5 - throttle;

- 6 - ammeter (mA);

- 7 - spark gap;

- 8 - a container with water.

Before starting the test, it is necessary to set the switch from the corresponding contacts to position A. This is necessary in order to establish the absence (presence) of breakdown using the signal lamps. If there is no breakdown, then the switch is moved to position B and the electric current that passes through the gloves is measured. If the passing current exceeds the norm, then such gloves go to waste. Those gloves that were rejected are strictly forbidden to use in work! Since they will be unable to protect a person from electric shock. When the test is over, the leggings are dried.

The verification scheme can be slightly changed, but the essence remains the same. Now we will consider another test method, where we will tell you how to use the installation for testing gloves.

So, the dielectric material of the gloves can be checked by an example: water is poured into the container of the tested device and into the sample (gloves). Its temperature ranges from 10 to 40 degrees Celsius. The distance from the edge of the glove to the water should not exceed 55 millimeters. Keep the edges of the gaiters and containers dry.

The voltage that goes to the container body and the electrode, which falls inside the glove, has its own requirements and is equal to 6 kV. The test lasts one minute. The milliammeter should show the value of the current that passes through the arm - 6 mA.

The dielectric material from which the gloves are made should dry after testing. To do this, they are placed in a special tank, such as shown in the photo below:

After drying, a test stamp must be put on the electrical insulating gloves, on which the date of use of the protective gloves (the date until which the material is suitable) must be written. For example:

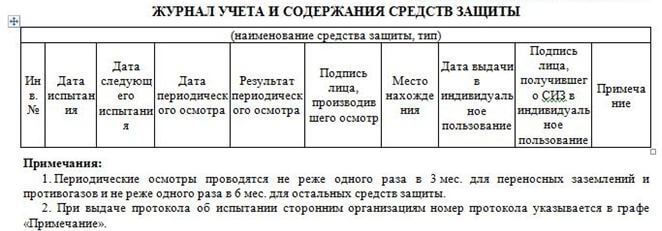

The stamp must be clearly visible and must be applied with indelible paint. Then it is necessary to enter the information in the log, which indicates the test of protective equipment. The log looks like this:

After completing all the listed procedures, if there is such a need, a protocol is issued, which indicates the inspection of electrical insulating arms. A sample protocol looks like this:

We also recommend watching a video that clearly demonstrates the technology of testing dielectric gloves:

What are gloves

The main device that can prevent electric shock when performing any work is, of course, it is dielectric gloves. Such products are considered the primary means of protection if the voltage does not exceed 1000 volts. If this figure is higher in the network, gloves are considered additional protective equipment.

In any case, it is strictly forbidden to work as an electrician without gloves. In addition, such items are relied upon to be periodically checked for integrity.

Rubber for the manufacture of such personal protective equipment is selected taking into account the requirements of GOST. Dielectric gloves, of course, should be as reliable as possible. In most cases, an electrician's gloves are seamless. That is, products of this type cannot disperse at the most inopportune moment.

Sometimes there is still a seam on these gloves. But in products of this type, it is obligatory covered with sheet rubber. Only latex dielectric gloves according to GOST cannot have a seam. Compared to rubber, this material cannot be considered too reliable in terms of tears and punctures.

Of course, dielectric protectors should, among other things, be as strong as possible. For example, according to GOST, dielectric latex gloves, since they are not considered too reliable, cannot be used to work with high voltage networks. In this case, a durable rubber should be chosen.

In addition to rubber and latex, manufacturers, as already mentioned, sometimes use silicone for the manufacture of personal protective equipment. Gloves of this type are even more durable than rubber ones, and do not conduct current at all. Therefore, products of this type are usually used for operation in networks with very high voltage.

The shape of an electrician's glove resembles an ordinary rubber glove with five fingers. They are commonly referred to by electricians as dielectric mittens. Sometimes, in the production of various kinds of work, dielectric gloves with two or three fingers can also be used.

In any case, domestic products of this type are labeled as "Ev" or "En" during production. Any other rubber gloves made in Russia cannot be considered dielectric. That is, it is impossible to use simple rubber accessories that are not marked accordingly where current protection is needed.

How can an employee, in direct use, determine that electrical protective equipment has been performance tested and is suitable for use?

| According to operational test reports |

| By stamp or marking on the protective equipment |

| By entry in the Testing Log of Protective Equipment |

| By the appearance of protective equipment |

How should protective equipment that fails the test be labeled?

| The test stamp shall be crossed out with red paint. |

| The test stamp shall be crossed out with black paint. |

| Test stamp shall be crossed out with white paint |

| Protective equipment must be mechanically damaged |

In what electrical installations do you need to wear dielectric gloves when using the voltage gauge?

| In an electrical installation with a voltage higher than 380 V |

| In electrical installations with voltages up to 1000 V |

| In electrical installations with voltages above 1000 V |

| In electrical installations with voltages above 10 kV |

In what electrical installations can test lamps be used as voltage indicators?

| In electrical installations with a voltage not higher than 380 V |

| In electrical installations with a voltage not higher than 220 V |

| In electrical installations with a voltage not exceeding 1000 V |

| The use of pilot lamps is prohibited. |

What should be the time of direct contact of the voltage indicator with the monitored live parts when checking the absence of voltage in electrical installations with voltages up to 1000 V?

| Not less than 3 s |

| Not less than 5 s |

| Not less than 8 s |

| Not less than 10 s |

How long should dielectric gloves be?

| Not less than 350 mm |

| Seamless gloves length - 300 - 310 mm |

| Length of gloves with seam - 310-320 mm |

| Double-fingered gloves length - 320-340 mm |

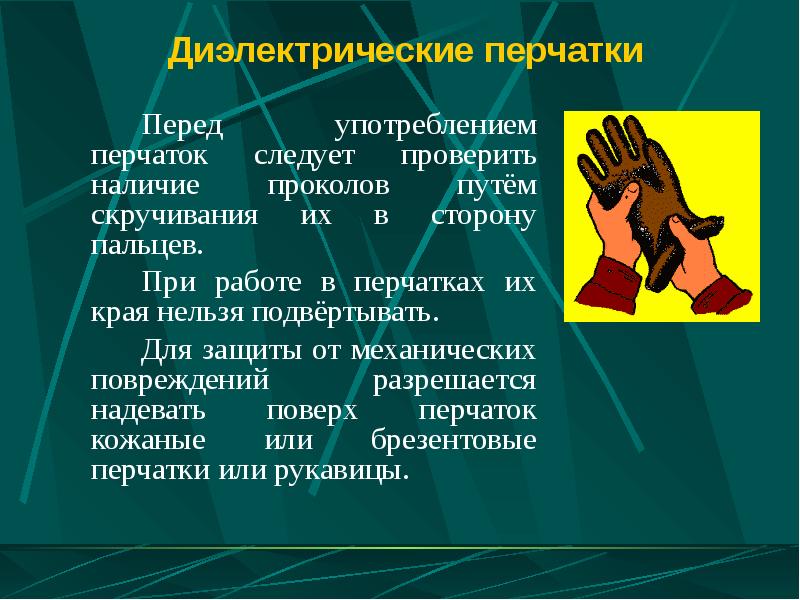

How are dielectric gloves checked for punctures prior to use?

| By twisting them towards the fingers |

| By stretching and visual inspection |

| By immersion in water and checking for air bubbles |

| By electrical tests |

How should dielectric shoes differ from other rubber shoes?

| Height |

| Grooved sole |

| Lined |

| Color |

386-22. What are the requirements for the appearance of dielectric carpets?

| They should be flat, multi-colored, up to 1 m wide |

| They should be with a grooved front surface, multi-colored, up to 3 m long |

| They must have a corrugated front surface, one-color with a minimum size of 500 x 500 mm. |

| There are no special requirements |

How often should dielectric rugs be tested?

| At least once every 6 months |

| At least once every 12 months |

| Tests are carried out depending on the performance group: by pulling carpets between electrodes or immersing carpet samples in a bath with water |

| In use, carpets and coasters are not tested. They are examined at least once every 6 months, as well as immediately before use. |

For how long before use must dielectric carpets be kept warm in a packed form after storage in a warehouse at a negative temperature?

| For at least 24 hours |

| Within 16 hours |

| Within 8 hours |

| Within 3 hours |

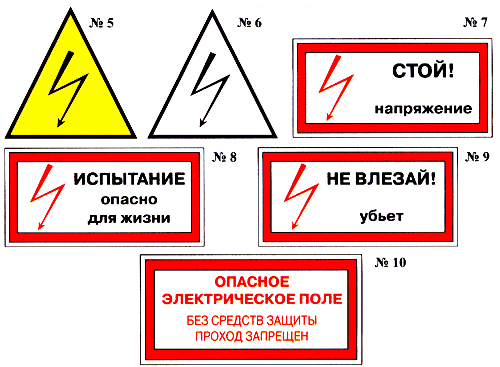

What posters of electrical safety should be rigidly attached to shields for temporary fencing of live parts that are energized?

| Warning posters “STOP! VOLTAGE" |

| Prohibiting posters “DO NOT OPEN! PEOPLE WORK " |

| Directional posters "GROUNDED" |

| Mandatory posters "COME IN HERE" |

How often is the employee responsible for the condition of protective equipment

Need to inspect portable grounding?

| Once every 3 months |

| Once every 6 months |

| Once every 12 months |

| Once every 24 months |

What steps must be taken before each use of rigid insulating ladders?

| Should be inspected, wiped with a lint-free cloth, and the bowstrings should be covered with a thin layer of silicone paste |

| Should be inspected, wiped with a lint-free cloth moistened with soapy water or alcohol-acetone mixture (1: 2) |

| Should be inspected, wiped with a lint-free cloth soaked in white spirit |

What personal protective equipment for respiratory organs (RPE) should be used in closed switchgears to protect workers from poisoning or suffocation by gases generated during the combustion of electrical insulating and other materials during accidents and fires?

| Isolating gas masks |

| Filtering gas masks |

| Particulate Respirators |

How to store gloves?

Of course, dielectric gloves must not only be used correctly, but also stored according to the instructions. This will lead to an increase in their service life. In addition, proper storage is a necessary safety measure, which should not be forgotten when working with current. The following conditions exist for storing gloves:

• The area where the gloves are stored must be dry and well ventilated. The temperature should not exceed 25 ° С, but also not be below zero.

• Air humidity also matters. It should not be more than 75%.

• Under no circumstances should gloves be allowed to come into direct contact with sunlight.

• Gloves should be kept more than 1 meter away from heating appliances, all kinds of oils, acids and alkalis. These substances can damage the material from which the gloves are made.

The semi-annual glove test mentioned above is also of immense importance. Gloves are sent to a laboratory where they are tested for compliance with all safety standards and regulations. For testing, it is necessary to fill a metal vessel with water. The water temperature must match the room temperature. The gloves are placed in the dishes with fingers downward, while they are filled with water.

Further, the gloves are tested with a special device with tension. This check takes 60 seconds. Voltage electrodes are placed directly into the glove. If the light bulb comes on, it can be judged that the dielectric glove has lost its properties. Otherwise, a second check is carried out. A special ammeter is used to measure the current. If it does not exceed 6 mA, gloves are allowed for further use due to their safety. If this indicator is exceeded, gloves are considered unsuitable. After this diagnosis, the gloves must be dried. The necessary research documents are filled in and the date of the next inspection is attached to the gloves.

When working with electrical appliances, the first thing a master should think about is his own safety. Dielectric products are the best the industry has come up with to date. The advantages of dielectric gloves are that they are available and have proven their effectiveness for several years. By using gloves in accordance with the regulations, the maximum level of protection can be achieved. And their correct storage and timely diagnostics will make their operation long-term and safest. Anyone who uses or intends to use dielectric gloves should keep this in mind.

Answers from experts

PAVEL BADALOV:

Kaneshno! But the voltage is not higher than 1000 volts

maxim eyes:

Yes! ! But only if there are no holes and passed the test !!!

Andrey Subach:

Yes, if they have been verified.

MVI:

It will not work calmly. You will worry anyway. I would also throw a rubber mat on the floor under my feet. And so - why grab the wires. I cleaned it and put it in the machine and that's it.

Artyom Iskhakov:

you can do it, but you need to observe safety measures, if you don’t know, it’s better to read them first

Ben Zvi-Ari:

I touch 220 fingers quite calmly, standing on a dry floor and not touching zero. And I even replace machines, sockets and bags without switching off the phase. Many do this. Gloves work well in closets. And I can do without them.

Alexander Kryukov:

read "INSTRUCTIONS FOR THE APPLICATION AND TESTING OF PROTECTIVE EQUIPMENT USED IN ELECTRICAL INSTALLATIONS WITH 153-34.03.603-2003"

GT:

Glove Tests In service, only electrical tests are performed on gloves.

Once every 6 months, gloves should be tested with an increased voltage of 6 kV for 1 minute, the current through the glove should not exceed 6 mA.

During the test, dielectric gloves are immersed in a metal vessel with water having a temperature of 25 + 10 ° C, which is also poured into these products. The water level both outside and inside the products should be 50 mm below the top edge of the gloves.

The protruding edges of the gloves must be dry. One terminal of the test transformer is connected to the vessel, the other is grounded. An electrode is lowered inside the gloves, connected to ground through a milliammeter. During the test, the switch "P" is first set to position A in order to determine the absence or presence of breakdown by the signal lamps. In the absence of breakdown, the switch is set to position B to measure the current passing through the glove. The product is rejected if the current passing through it exceeds the norm or there are sharp fluctuations of the milliammeter needle.

In the event of a breakdown, turn off the defective product or the entire installation.

At the end of the tests, the products are dried.

The electrical strength of the rubber is at least 10 kV / mm, and what thickness of the gloves is not known, the level of humidity is also, but I think it is possible to consider 20 kV, they are not guaranteed to hold, those that are at 1 kV and test 9 kV have passed.

BANNED:

It is written on them. Put it twice as high. Why waste time on trifles, four times!

yes no clicks:

they are additional means of protection means up to 380 and then mister case

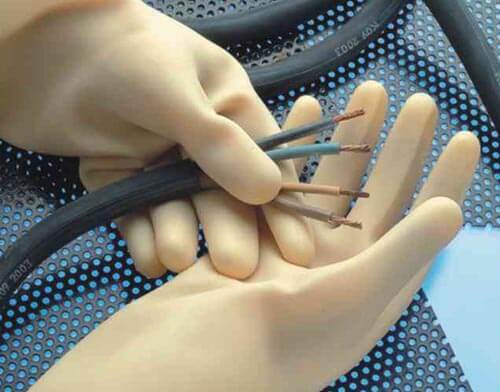

Test procedure for dielectric gloves

As it has already become clear, dielectric gloves that do not have mechanical damage are subjected to special electrical tests. For this, there must be a specially equipped laboratory. The electrical test of dielectric gloves is necessarily carried out in water, which allows you to achieve better test results, since in this case even minor minor damages can be detected.

To fully test dielectric gloves, we need the following things:

- 1. Bath with water

- 2. Electrical installation (laboratory)

The testing process itself is quite simple. We take the glove and place it in the bathtub, then fill the bathtub with water. The inside of the gloves must also be filled with water to the same level as outside. The glove should be positioned in water in such a way that its protruding edges are 45 - 55 mm dry, i.e. the water level both outside and inside should be at least 4.5 - 5 cm from the edges.

Please note: the bathtub must be metal, if there is no metal bathtub, use any metal vessel you can find, the main condition is that a glove can be placed in it. The water temperature in the vessel must be at least +25 degrees Celsius

After that, one of the transformer terminals must be connected to our metal bath and must be grounded. And inside the glove we immerse an electrode connected through a milliammeter to the second terminal of the transformer.

What is the voltage applied to dielectric gloves? The voltage used in the tests shall be 6 kV. In this case, the value on the milliammeter should not exceed 6 mA. The duration of such a test is at least 60 seconds.

Pay particular attention to the following: When starting the test, the switch must be in position A.This position will allow you to check the presence of breakdowns in the dielectric glove using special signal indicator lamps

If there is no breakdown, the switch is moved to position B. Directly in this position, the value of the current flowing through the dielectric glove is measured.

A little explanation to the diagram:

- 1 - Installation transformer

- 2 - Switch

- 3 - Milliammeter

- 4 - Gas discharge lamp with shunt resistance

- 5 - Metal bath with water

- 6 - Electrode

If the warning lights show a breakdown, the tests are stopped, the whole circuit is disconnected. If the glove passes a current in excess of 6 mA, the tests also end, the glove is rejected.

| Any electrical installation staff has to pass exams. And on exams, they often ask a question about the methodology and timing of testing dielectric gloves. How easy is it to remember all these numbers? It's very simple, you need to remember four sixes (6x4): |

| 1. Frequency - once every 6 months |

| 2. Voltage - 6 kV |

| 3. Allowable current - 6 mA |

| 4. Duration - 60 seconds |

If, as a result of tests, dielectric gloves are found to be fit for use, then they must be thoroughly dried. After that, a test stamp is applied to the gloves, and they are sent for storage and subsequent use.

By the way, dielectric galoshes and a bot are tested using the same technique and scheme.

What to do if gloves fail the test

If for some reason the gloves did not pass the test and were rejected, then you need to deal with them as follows. The stamp is crossed out with red paint (if it was there, if it was not there, just cross out the gloves crosswise). After that, they are withdrawn from service; it is strictly forbidden to store unsuitable personal protective equipment.

There is a special instruction that regulates the procedure for testing dielectric rubber products, as well as their further fate. The laboratory conducting such tests should have a logbook in which all results are recorded.

Usually it bears the name "Test log of protective equipment made of dielectric rubber (gloves, boots, dielectric galoshes and insulating pads)" according to Appendix 2 "Instructions for the use and testing of protective equipment used in electrical installations SO 153-34.03.603-2003".

{SOURCE}

What is the time frame for the tests

In the Rules for the technical operation of electrical installations (PTEEP), in chapter 3.6 "Methodological guidelines for testing electrical equipment and devices for electrical installations of consumers", it is clearly stated in what time frame the test should be carried out and the parameters of electrical equipment and installations should be measured. They are determined by the customer's technical manager.

The basis for performing such operations is Appendix No. 3.

In this case, it is necessary to take into account the recommendations from the manufacturer of the devices, the conditions of the area in which they are installed, as well as their technical condition. Equipment test times are recommended. If necessary, they can be changed by a decision made by the technical manager of the consumer. In addition, during the acceptance tests, specialists are obliged to follow section 1 of the "General rules" of chapter No. 1.8 of such a document as "Norms of acceptance tests" of the 7th edition of the "Rules for the arrangement of electrical installations.

The insulation resistance of the components, which are part of the power grids, must be measured in accordance with the 3rd appendix PTEEP.

According to it, insulation should be measured:

- electrical wiring (in particular, networks that provide lighting in rooms that pose a threat to life and health, as well as equipment located outside) - no more than once a year (in certain cases, this period is once every three years);

- crane and lift equipment - once a year;

- stationary electric stoves - once a year (while the stove must be in a heated state).

Work related to testing and measuring other elements and devices is carried out in accordance with the system of scheduled forced repairs. It must be approved by the customer's technical manager.

On the timing of trials in health-related institutions

So for organizations involved in the healthcare sector, tests are carried out:

1) parts of grounding devices are checked once a year after putting them into operation, and then at least once every three years;

2) the circuit between the earthing switch and electrical medical equipment that has been grounded is checked once a year or, if the electrical medical equipment has been rearranged;

3) the resistance of grounding systems is checked once a year.

When to carry out preventive tests of explosion-proof electrical appliances, it is determined by the person who is responsible for the consumer's electrical equipment. In this case, the operating conditions must be taken into account. Its frequency should not be less frequent than prescribed in certain Rules for checking the technical condition of electrical installations.

If installations with a solidly grounded neutral, the voltage of which is not more than 1000 Volts, are located in places where explosions can occur, during overhaul, maintenance and tests between repairs, they are measured at least once every two years.

First of all, the measurements should concern the resistance of the "phase-0" loop of the power receivers that belong to this installation and are connected to all assemblies, an electrical cabinet, etc. It is also necessary to check the current ratio (SC), due to which the operation of electrical protective devices is ensured ...

If the protective electrical equipment refused to work, an unscheduled check is carried out. When it is rearranged, you should check its connection to the grounding device, and if equipment with a voltage of up to 1000 Volts is being rearranged, then also the connection with a solidly grounded neutral, as well as the state of the "phase-0" loops.