How does a hydraulic jack work

To accurately determine the cause of the breakdown and its subsequent elimination, you should have a clear understanding of the principle of operation of the device. Fortunately, hydraulic jacks are simple enough that most of the problems can be fixed in-house. Contacting the service may be necessary in cases of serious defects or a complete lack of desire to familiarize yourself with the repair instructions. The basics of understanding the operation of the device should be laid down with an analysis of the main components of its mechanism.

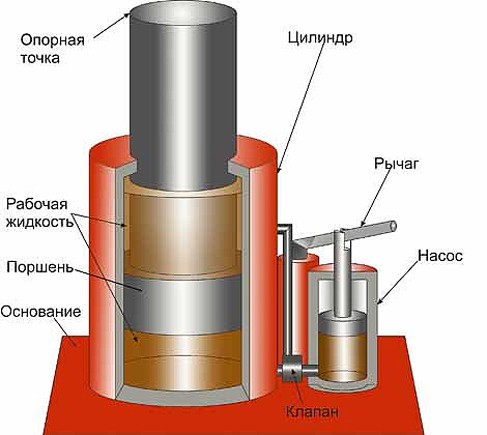

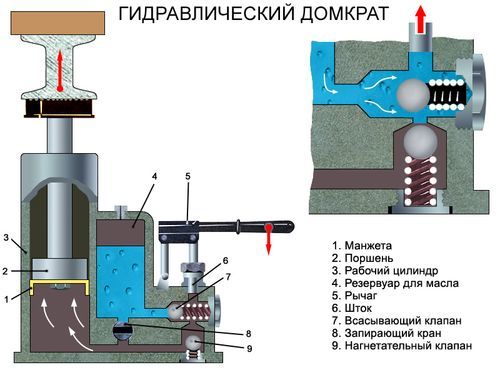

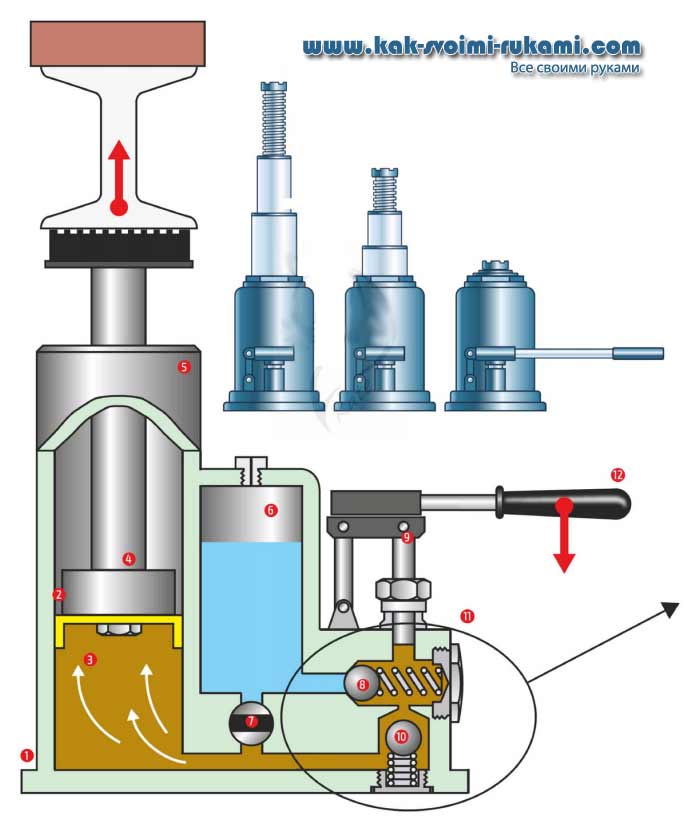

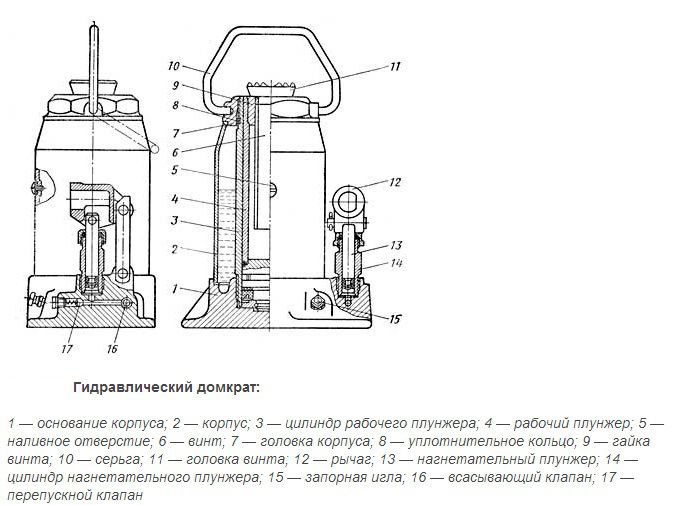

Before describing the functional elements, it is worth noting that hydraulic jacks have several subtypes and are divided into rolling, bottle and diamond-shaped. The classic type of liquid lifting mechanism is closest to the bottle type, which includes devices with a telescopic, hollow, hooked and standard stem. To form the correct basic representation, we will analyze the original model without additional modifications. So, a hydraulic bottle jack consists of the following components:

- Base of the case... Support platform for installing the device on a flat surface.

- Frame... The outer part of the hydraulic jack and, in combination, the oil reservoir.

- Plunger cylinder... A sealed chamber where fluid pressure is generated to expel the stem.

- Working plunger... Retractable element with stop at the end.

- Oil filling hole... Located in the upper, lateral part of the device body.

- Screw... Retractable element for increasing the lifting height of the jack. Twists into the plunger.

- Body head... Threaded connection that fixes the position of the body in relation to the cylinder.

- Sealing ring... Seals the oil reservoir, preventing fluid leakage.

- Screw nut... The upper part of the body head with six edges for easy unscrewing.

- Earring... Convenient element for manual transportation of the jack. Not present on all models.

- Screw head... The end part of the stem, abutting against the load.

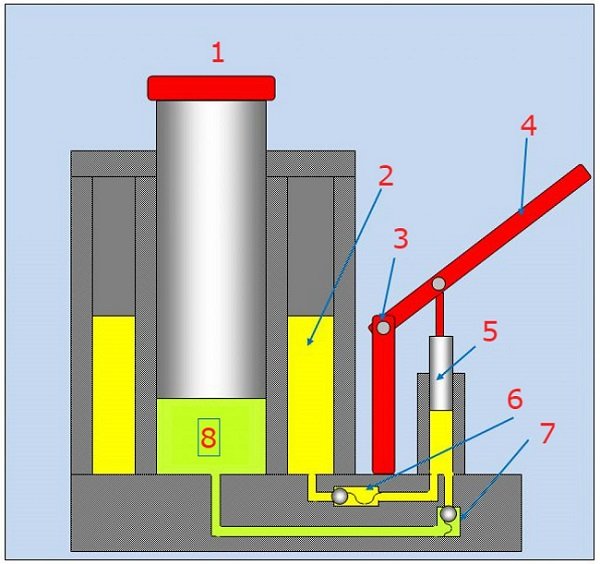

- Lever arm... Removable element of the hand pump, increasing the force of impact several times. In most cases, it includes a special groove for unscrewing the shut-off valve (more on it later).

- Discharge plunger... The main pump element, driven by a lever. Pumps liquid from one reservoir to another.

- Pump cylinder... Sealed chamber and intermediate link in pumping oil between tanks.

- Stop valve... Serves for combining / isolating the oil reservoir with the plunger cylinder.

- Suction valve... It regulates the movement of liquid inside the device, allowing it to flow in only one direction (only for suction into the pump cylinder).

- Bypass valve... The opposite of a suction. Allows the pump plunger to squeeze oil out through itself, but does not let it back in.

The essence of the device is based on pumping liquid from an oil reservoir into a cylinder with a plunger. When the lever is lifted, a portion of oil is sucked into the pump cylinder, and when lowering, it is squeezed out into the main cylinder of the lift. Due to this, pressure is generated in the main compartment, which expels the piston.

The main thing is that no air gets into the compartment, which can reduce stability and overall efficiency. It is for this reason that the hydraulic bottle jack does not work horizontally. However, even in this type of device, there are models that allow lifting in various positions.

Unit repair

In case of oil leaks, it is recommended to find the damaged area on the housing, seal it and refill with a fresh portion of filtered oil. All measures related to the restoration of the working condition of the units must be carried out in accordance with the manufacturer's instructions.

If the manual mechanism refuses to lift the load, the reason may be an insufficient volume of fluid, excess air in the cylinder, rust particles, deformation of the stem.

To do this, unscrew the cylinder cover screws, remove the drain valve and piston, clean the inside of the cylinder from dirt, clean the bleed valve, check the tightness of the ball to the hole under the valve. It is forbidden to use old used oil. It must be drained by pumping the lever. The mechanisms are flushed with kerosene. After that, gaskets and cuffs are replaced, fresh working fluid is poured.

After assembling and filling the unit, it is necessary to carry out a test hydraulic system under load on the subject of detecting a leak and the presence of an airlock in the system. The air can be released through the drain valve. The pumping procedure and maintenance of the unit is simple. The owner of the device can independently cope with the repair of the lifting device, repair the lever and at home, pour oil into the hydraulic system.

Unlike a hoist assembled in a domestic environment, a factory jack has high power and efficiency up to 80%, ease of operation, and can withstand working loads up to 200 tons. A hydraulic device made from improvised means will cost less, but it should be made by a specialist who understands hydraulics.

Originally posted 2018-04-06 09:26:10.

The main stages of disassembly and repair

It has a large number of fasteners, it must be disassembled in the following order. You do not need any special tools for disassembling the mechanism and its subsequent assembly. First, unscrew all fasteners using wrenches, then remove the oil drain valve and the piston itself. Carefully inspect the valve, check its condition. If the ball and gaskets are worn out, then they must be replaced with new parts.

Drain the oil, clean the mechanism from foreign objects and rust, flush the system. Flushing is done using a special liquid that is sold in hardware stores. You need to make it several times in a row, since this process is quite complicated. After flushing, you will need to fill in new oil, otherwise the hydraulics will not work.

When filling, the container is filled with new oil to the brim, after which the pump is pumped and new oil is topped up. It is necessary to pump it several times until the oil is filled in sufficient volume and bubbles stop appearing. After that, the condition of all rubber bands is checked, if necessary, they are changed to new ones. The assembly of the unit is carried out in the reverse order. After assembly, do not forget to check its functionality.

When changing the oil, the device should not be subjected to any stress, so you can carry out the work easier and faster. It is necessary to disassemble, inspect, change oil and worn parts several times a year. It is better to use the tool in a dry and warm place; for the winter season, fill in synthetic oils.

So, if necessary, disassemble the jack yourself, there is nothing complicated about it. You will be able to identify most of the breakdowns yourself and fix them. Basically, malfunctions occur due to the need to change the oil or blockage of the system. If you monitor the condition of the tool regularly, you can avoid many breakdowns. To prolong its service life, it is recommended to use a high quality special oil, which is used for industrial equipment.

Jack does not work. I was lying in my garage, and then I urgently needed to lift it ... and it doesn't work for you! What can you do with it, but quickly? 1. Let's test it idle: with the locking screw unscrewed 10 swings, turn it all the way (without fanaticism), swing. Options: - raises by 1/3 of the height and stands up. That is, there is little oil. We unscrew (or pull the rubber with pliers) the filler plug, measure the level - flush with the hole, for others it is even higher. motorboat is possible, industrial is necessary. - lifts very slowly when the handle is lowered, and when it is lifted, it falls. We look at the oil. Unscrew the plugs and the discharge plunger body and look for a foreign body - a piece of rubber / plastic, do not lose the springs-balls, water has flowed out - for service. - does not raise. We look at the oil - we are looking for a blockage - to the service. - oil flows out. We stretch - we clean in the search for a jack model (if SHAAZ 8t / SHAAZ 12t you have no chance) - to the shops (repair kit) - they politely send ** - to the service. -lifts very slowly, holds it. Raise it by 1/4 of the stroke, release the neck plug, tighten it securely (fum - tape to help). Or dilute with 10% kerosene. 2. Testing under load: - does not hold the load. Unscrew the locking cl. There is no ball - we put it from the bearing Ф 6 mm. There is no ball, but there is a cone on the screw (well, you have old stuff!) - grind to the turner and adjust the saddle. For those who did not identify their hydraulic jack, a photo to help:

SHAAZ 5t. telescopic.

SHAAZ 3t telescope.

3 Comments 3

No matter how rich the experience of a specialist, and no matter how confident he is, sometimes he needs to consult with someone. Communication on the vastness of the Internet network has become familiar to us for a long time. A variety of netizens - be they a professional or a knowledgeable hobbyist - can post life hacks (simple helpful tips on different topics) on the net that can be applied to your home.

What are the advantages of using forum resources?

- A constant stream of interesting information about new building ideas.

- Simple and helpful building tips.

- The ability to communicate with interesting people, experienced masters of their craft.

- Recommendations on the choice of tools or materials.

- Also, a pleasant plus is the lack of advertising, because users are the same consumers as you are.

About this article

wikiHow works like a wiki, which means that many of our articles are written by multiple authors. Volunteer authors worked to edit and improve this article to create this article. Number of views for this article: 95,568.

Categories: Transport

English: Add Oil to a Hydraulic Jack

Español: agregarle aceite a un gato hidráulico

Italiano: Aggiungere l'Olio a un Martinetto Idraulico

Português: Lubrificar um Macaco Hidráulico

Bahasa Indonesia: Menambahkan Oli pada Dongkrak Hidrolik

Français: ajouter de l'huile à un cric hydraulique

Deutsch: Öl in einen hydraulischen Wagenheber nachfüllen

What types of hydraulic jacks are there?

There are 6 main types of hydraulic jacks. All varieties are very easy to use, but due to their characteristics, they are not common everywhere. Most often, you can find bottle types of hydraulic jacks, since it is small in size and does a good job with the tasks.

Bottle jack

The design of the apparatus is quite simple, but at the same time the device is capable of lifting from 2 to 100 tons. Due to the small size of the case and its specific appearance, the device was nicknamed bottle-top. The compact size allows you to carry the jack in the trunk of a car and use it in any conditions.

Among motorists, single-rod equipment is the most common, but it has a low lift height.

For professional workshops or people who are interested in lifting loads to a higher distance from the ground, a design with two or three rods can be used.

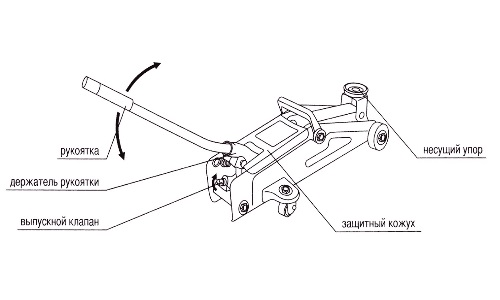

Rolling jack

It is very similar to a trolley and has 4 wheels, which are very convenient for moving around the workshop. The device has two cylinders communicating with each other with two channels with valves. The device is very convenient for lifting a car in a car service or any other cargo.The main disadvantage of the jack is the inability to work in the field and on uneven surfaces.

Hybrid Jacks

There are jacks that combine the function of rolling and bottle machines. Two load platforms allow you to cope well with the task of lifting loads in any operating conditions. The jack is controlled by pedal and lever, making it easy for the master to work with it.

Rhombus jack

Although the device is quite rare, its functionality is amazing. The lifting platform looks like a diamond, which is why the device was named that way. The device copes well with lifting loads and can withstand loads of up to 50 tons. All supporting elements are connected by hinges, so that the reliability of the device can be tested for years. The device is compact and can be easily transported to the desired location.

Hook jack

The device is very similar in structure to the bottle jack, but its difference is the ability to lift cars with low ground clearance.

This is interesting: How to choose an air compressor for painting, garage, home

Recommendations

Those companies that produce motor lubricants sometimes additionally produce hydraulic fluids for cars and trucks. These fluids can be used to fill not only the jack, but also the brake systems. In addition to the usual special oil, industrial types of oils are sometimes used (such as I-12A, I-30A, I-50A). However, here you need to be careful and have a good understanding of cars or carefully study this topic: some oils are prohibitively viscous and are not suitable for every device. They can also damage the jack by causing corrosion.

In general, the device can work even if water is simply poured into it, however, this way the surface will quickly become covered with rust and it will most likely be impossible to return to previous work. Those who like to fill in ordinary engine oil in jacks will face the same problem, just later: water also accumulates in the device from ordinary engine oils. Over time and it will fail.

In order for the forklift to function properly, the hydraulic fluid must be changed regularly. It is inconvenient for one to work - here it is better to take someone as your assistant

Before starting to infuse liquid, it is important to first carefully study the instructions for using the device and do everything as indicated in it, since, depending on the type of device, changing the liquid can take place in different ways. Without special need, it is better not to disassemble the device completely once again, as there is a risk of losing the ball or ruining the valves

It is strongly discouraged to fill the jack with liquid containing alcohol. The use of alcoholic liquids will also lead to corrosion and further malfunction of the device. In addition, no valves other than the outlet must be opened. Opening the non-return or overload valves can harm the bearing or the spring, so even in such a simple operation as changing the oil in the device, you should be extremely careful and accurate.

It is recommended not to spare money for filling. It is better to take it more expensive, but with positive characteristics (viscosity, composition), then it will need to be changed less often, and the lift will last longer, since it will not rust and deteriorate soon. Experts do not recommend mixing expensive and cheap liquids, as this will only worsen the effect.

As soon as there is less oil than the device requires, you will immediately notice how much more difficult it will be to lift heavy objects. This is the first signal that you need to top up or change the special solution. After the primary signs of a malfunction have been detected, it is advisable to eliminate it as soon as possible, then the device will always be in optimal working condition, and the car owner will be able to avoid accidents that may occur due to a device malfunction.

See below for how to pump a hydraulic jack.

Species overview

Today, several types of this tool are used. Many people think that in principle there is not much difference than filling the jack.You can fill in any product that is intended specifically for hydraulic equipment and tools, in particular for jacks. This is partly true, but each type of oil has its own specific properties that can be useful or even necessary in certain conditions. There are currently several different types of oils on the market with different characteristics.

Glycolic

These oils are approved by many experts. They do not contain any harmful or foreign impurities in their composition. However, the cost of such funds is quite high. The products are highly efficient and lubricate well. Despite being water-based, they also have high anti-corrosion properties.

An important advantage of such oils for hydraulic jacks is that they can be used at any ambient temperature. Even down to –30 °. There is one more feature: glycol oils can be poured not only into hydraulic ones, but also into other types of jacks and other devices.

Petroleum or mineral

Such products are available on the market in the widest range, and their price is often significantly lower than the cost of other types of these products. But mineral oils are not in high demand among real professionals. The fact is that they are created practically from oil waste, and in them the level of viscosity and the level of the lubricants themselves are quite low. The use of such funds is considered perfectly acceptable.

Synthetic

It is these funds that are most preferable to use. They are commercially available in various versions, each with its own unique characteristics. To create such oils, complex multicomponent substances are used, which at the output allow obtaining products that meet the highest quality and safety requirements.

Synthetic oils, designed for filling in hydraulic jacks, allow not only to keep the devices in good working order for a long time, but also to extend the service life of the tools by several years. At the same time, there are never sudden situations in which the jack fails.

When should the hydraulic jack oil be changed?

Each jack will eventually need an oil change, often depending on how often the lift is used.

First of all, if you notice that the plunger starts to lower slowly under load. This can happen immediately after you have lifted the load, or after a while. If this happens, it is a clear sign that you need to add oil to your jack. In addition, your jack may need an oil change if the plunger cannot be fully raised. Both of these situations can be caused by the oil in the cylinder being dirty or simply not having enough oil in the cylinder due to oil leakage or other factors.

Scope of application

A hand-made hand lift greatly simplifies the repair, preventive and tuning work related to vehicles, and will help in the construction and restoration of capital structures. The presence of a compact jack saves the owner of the car from the need to visit a service center or buy a factory-made device. The lifting forces of the mechanism allow the following manipulations with the load:

- fix;

- move;

- lift up.

When planning the manufacture of a jack, it is necessary to take into account that the device cannot lift loads "from the floor", it is impossible to adjust the lowering level in its design, the mechanism must be transported only in a vertical position. The hydraulic system needs constant maintenance

In the process of working on the device, it should also be taken into account that the factory jack will work cyclically, and in the event of a breakdown, repair measures will require significant financial costs. A device assembled in one's garage, in the event of a failure, can be replaced with another device of its own assembly, but its degree of reliability is reduced several times.

Device, features of the use of a bottle-type jack

The illustration shows the components of the hydraulic lift.

The entire structure fits inside the reservoir with the working fluid. The lifting rod in the down position is completely recessed in the body. The lever handle is removable and does not take up much space in the transport position. Therefore, this type of jack easily fits in the trunk of a car.

IMPORTANT! Store bottle-type hydraulic jacks upright. Otherwise, the working fluid may leak .. A device capable of lifting a solid off-road vehicle (force 5 tons) - has dimensions (taking into account the unfastened handle) no more than a bottle of wine with a volume of 0.7 liters

One person can handle such a jack

A device capable of lifting a solid SUV (force of 5 tons) - measures (taking into account the unfastened handle) no more than a 0.7 liter bottle of wine. One person can handle such a jack.

Advantages:

- Easy to operate and maintain;

- High efficiency - up to 80%;

- Low effort on the working handle;

- Smooth operation due to the use of liquid;

- Possibility to control the lifting height with high precision;

- High reliability due to the absence of rotating and rubbing parts with effort;

- Lifetime - apart from O-rings, there is nothing to wear in the bottle jack;

- A good indicator of safety in work - in the event of a breakdown, a sharp fall of the lifted object or throwing a part of the tool towards the side is excluded;

- Wide range of applications, not limited to the operation only in cars.

Disadvantages:

- The jack body height is practically equal to the lifting height. This is typical for single-rod designs; telescopic (multi-rod) options are free from this drawback. This feature is partially compensated for by the extension screw, which is unscrewed from the stem. Due to this drawback, the initial lifting height starts from 20-25 cm. This limits the dimensions of the device;

- Slowness. One cycle of operation of the injection pump provides a lift to an insignificant height. The higher the lifting capacity, the more movements of the handle must be made to lift;

- Inability to accurately control the height of the lowering of the load;

- Work only in an upright position. In a tilted or horizontal state, air will enter the hydraulic system, and it will have to be pumped;

- Large mass of the device, taking into account the working fluid;

- The high cost of the product.

To work with low initial heights (for example, cars with a low landing), a rolling jack is used. It works according to a lever scheme, and a hydraulic cylinder is used as a driving force, as in a conventional bottle jack.

The reasons for the decrease in the effectiveness of the functioning of the jack

Before proceeding with the pumping of hydraulic equipment, it is required to determine the reasons for the deterioration of its operation. The normal functioning of the jack can be impaired as a result of dirt and air ingress into the working cavity of the tool. A corrosion process that damages the surface of the working cylinder can limit the capabilities of the jack. The most common reasons leading to the need to pump the jack are:

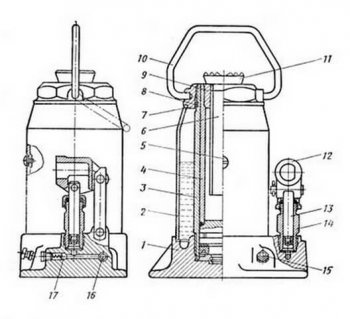

Details of the hydraulic jack.

- the appearance of air bubbles;

- internal corrosion of the device;

- high load that caused bending of the hydraulic rod;

- contaminated oil filled into the jack causing damage to the mechanism.

In order to get rid of these defects, a certain list of works should be performed in the following sequence:

- Unscrew the fasteners carefully and completely.

- Remove the valve responsible for the process of bleeding the working fluid.

- Remove the primary piston, inspect its surface for damage.

- Carry out an inspection of the equipment, in which to check the condition of the gaskets, balls on the valves, in case of their unsatisfactory condition, replace the components.

- Wash the mechanisms included in the jack structure from dirt and foreign elements.

- After assembling the mechanism, fill in new oil and bleed the jack.

Types of hydraulic jacks

For various fields of activity, various types of lifting devices were created, which were distinguished by their ease of use for certain and specific types of work. Hydraulic jacks are divided into the following types:

- bottle is the most common type. Such devices of various modifications lift loads from 2 to hundreds of tons. They are very popular with drivers and are used in almost all areas of the economy. Structurally, bottle jacks are divided into single-rod and double-rod jacks. Single-rod ones can work only in vertical position, double-rod ones - in any direction;

- rolling - rolling under the load during operation. It got its name from the similarity to the cart. The control is carried out using a lever, which rotates to regulate the oil valve. Disadvantage - it can only work on a flat and hard surface;

- hook - designed for lifting low-profile cargo from a low height (for example, a railroad rail);

- hybrid and diamond - used mainly by car services. These are various combinations of bottle and rolling jacks.

Main requirements for hydraulic oil

Hydraulic compositions for lifts are divided into three main groups: glycol; synthetic; oil.

Hydraulic compositions for lifts are divided into three main groups: glycol; synthetic; oil.

Also, such oils are popular for servicing aircraft, ships, marine equipment, engines, shock absorbers.

Almost all types of hydraulic fluids are made on the basis of base oils, which are produced by refining petroleum fractions. Then the base base is cleaned and special additives are added to it. These additives prevent the hydraulic oil from foaming and provides the mechanism with protection against oxidation and corrosion.

When choosing oil for a jack, you need to pay attention to some indicators:

- The viscosity of the composition should be medium. The oil should not be too viscous or too thin. The ease of movement of parts in the equipment depends on this indicator.

- Liquid filterability is another important parameter. The oil should pass well through the filter without foaming. Filtration of hydraulic fluid is necessary to clean it from various impurities and gases.

- The viscosity index or temperature index of the oil is also important and should be of great importance.

- The anti-corrosion characteristics of the composition must be excellent, otherwise the mechanism will fail very quickly.

Properly selected hydraulic oil will not be affected by the chemical composition of the environment and high temperature fluctuations. The fluid will not oxidize and protect the mechanism from premature wear.

Features of the use of hydraulic oil

In the warm season, the mechanisms can be filled with any type of oil, but in winter it is recommended to stop the choice on a synthetic composition. This is due to the fact that the synthetic liquid will not freeze even in severe frost, which means that the equipment can be safely used.

The hydraulic oil should be changed at least twice a year.If the equipment is used systematically, then it should be flushed every month, while changing the old hydraulic composition to a new one. In this case, the jack will work for many years without any repairs.