Use cases

The correct use of a screwdriver is its use according to the instructions or the established documentation. According to these documents, the main area of use is directly the ability to screw in and out various fasteners, as well as for drilling various holes.

Depending on the capabilities, one or another model can be used both in everyday life and in the professional sphere. Household screwdrivers are cheaper and have low power, while professional models have increased power, high performance and wider functionality for use.

Twisting wires

A screwdriver with a specific nozzle is excellent for twisting the separated ends of the wires. Usually twisting is done with pliers, but those who wish can use a screwdriver, using it for this purpose. The main thing is to correctly perform this tricky procedure.

Rebar tying

The screwdriver can be used to knit reinforcement using steel wire. This is widespread in construction, when various reinforced concrete structures of houses and foundations are being erected. In order to knit, take a cordless or mains tool that has a hook attachment.

Manual nutrunner-multiplier - maintenance and operation

Like any tool with which you have to work, a hand-operated load nutrunner must first of all be safe. In no case should there be sharp corners, chips, or surfaces with various irregularities in all parts that are included in the design of the nutrunner. Do not allow any overloads in the process of work. It is also necessary to ensure that the socket changeable head is always put on the body of the nutrunner very tightly.

It is important that it is secured with a screw, and that the spike on the output shaft always fully fits into the grooves of the wheelset.

Before working with any tool, you must study the instructions for use.

It is also important to prepare the instrument itself. When starting work, it is necessary to check if there is any damage or traces of corrosion on the nutrunner, it is necessary to inspect the entire surface of the tool

Before work, you need to press the nut of the wheelset with the socket head so that the spikes fully enter the grooves of the axle of the wheelsets, and only then start unscrewing.

Before turning the handle of the nutrunner, turn the head until the end spikes coincide with the grooves of the nut. Next, it is necessary to push the head over it in such a way that the spikes of the head fully enter the groove of the nut. If, after the full stroke of the key head has been used, the nut continues to unscrew tightly, you must remove the key and put on the extension so that the spike enters the groove for the lock bar from the end axle. Then it remains to re-attach the key with two screws, and you can continue to unscrew the nut.

In order to extend the service life of any tool, it is necessary to carry out preventive maintenance work in a timely manner. In addition to repair work, you need to follow some storage rules.

For example, it is important to ensure that dirt and moisture do not get on the body of the instrument. It is necessary to lubricate the lithol-24 nutrunner in a timely manner, as well as completely change the lubricant once a year.

It is generally recommended to fill 2/3 of the total free space on the inside of the nutrunner with grease.

Recommended posts

The best articles on the IVD website

Are you a professional architect or designer?

IVD. Renovation and finishing

Are you a professional architect or designer?

The site is a leading Internet project dedicated to the reconstruction and interior design of residential premises. The main content of the site is the archive of the Ideas for Your Home magazine - exclusive author's articles, high-quality illustrations, practical advice and lessons. A team of professionals is working on the project in close cooperation with renowned designers, architects and leading experts of the publishing house.

On our site you can find complex design solutions; view detailed reviews of the market for building and finishing materials, furniture, machinery and equipment; compare your own ideas with the design projects of leading architects; communicate directly with other readers and editors on the forum.

Are you a professional architect or designer?

Tool selection

The most important indicators to look out for when buying are the rotational speed and power of the screwdriver. Rotation speed affects the functionality of the device

For tightening or unscrewing fasteners, tools whose speed does not exceed 350 rpm are suitable. For drilling, you will need devices whose rotation speed is greater than or equal to 1000 revolutions

The rotation speed affects the functionality of the device. For tightening or unscrewing fasteners, tools whose speed does not exceed 350 rpm are suitable. For drilling, you will need devices whose rotation speed is greater than or equal to 1000 revolutions.

If you plan to purchase a cordless screwdriver, you should find out its type. The most common devices with lithium-ion cells are characterized by a long service life. It is recommended to choose them if the device will be used frequently.

If work using a screwdriver is rare, a nickel-cadmium element is more suitable - they are cheaper, not as prone to self-discharge as lithium-ion ones. For purely home use, network-powered devices are also suitable.

Additional parameters that will make working with the screwdriver easier and more convenient:

- illumination of the working area;

- a torque boost used to sink the fastener heads;

- impact mechanism;

- increase in rotation speed.

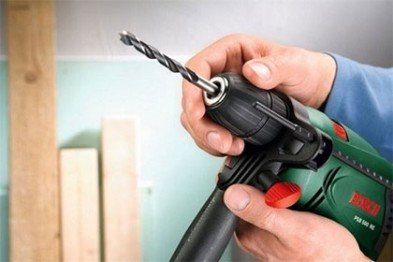

Drilling tool

The best invention for manually punching holes in walls is the hammer drill. This is not a cheap fixture, so it is not available in every home. The "lightweight" option for drilling walls is a hammer drill. It is more affordable than a punch, but its capabilities are not so impressive. You need to drill at a low speed first, gradually increasing it.

Keep in mind that brickwork is well resistant to constant pressure, but it begins to crumble from impacts. Drilling with a conventional drill will be very slow because it will be difficult for the drill to grasp the hard brick. The drill will get very hot.

In order not to be disappointed in the purchased hammer drill, pay attention to its minimum characteristics:

- The power should not be less than 600 W.

- Rotation speed up to 2500 rpm.

- Gradual speed control.

- Reverse. Needed to rotate the drill in both directions.

- Keyless chuck. Allows you to change drills without a special key, which is always not at hand.

- The presence of a shock mode. The drill will not reach the hammer drill, but it will help to quickly achieve the desired goal.

- Any tool has instructions. You need to familiarize yourself with it and follow the indicated recommendations. Otherwise, unpleasant consequences in the form of breakdowns or injuries are possible.

How to prepare for work?

The first thing you will need to do in order to get started is to remove the screwdriver from the case or suitcase and check for visible damage, chips or cracks. If you notice that something is wrong with the tool, then in no case should you use it, as it may be unsafe.Be sure to make sure that the battery of the screwdriver is charged, or the screwdriver itself is connected to the mains. When these conditions are met, the screwdriver is turned on to idle and check the correspondence of the rotation of the nozzle and the thread on the fastener. If all the conditions are met, then you can safely start work.

Be sure to select and properly fix the bit or drill depending on where and how you are going to work. How to fix them, we mentioned above when we talked about changing the nozzle.

When using the device directly, you must also follow a number of simple rules and requirements.

Pay close attention to the screwdriver itself. There is a special scale on it, turning which it is possible to regulate the power of the instrument

When you turn the dial, set the mode you need, focusing on what kind of work you are currently doing.

Modes:

- twisting;

- unscrewing;

- blocking.

Switching between these tool capabilities is fairly easy and straightforward. It is only necessary to hold the screwdriver by the handle located above the battery. Most often, the handle is covered with a material that is rubberized. That is why such a machined handle is safe to work with and guarantees that the screwdriver will not fall out of your hand while working. For greater reliability, the tool is fastened to the hand with a strap.

How to use a screwdriver correctly

Standard drills perform many functions:

- tightening fasteners,

- screwing it in,

- drilling holes.

There is a technology that should be followed to avoid making mistakes in each of these jobs, as well as adjusting the instrument before starting to perform them. It includes the main points:

- correct preparation;

- replacement of nozzles;

- setting the speed of the torque;

- how to screw in and tighten the fasteners correctly;

- direction of rotation of the chuck.

Let's consider each of them in more detail.

Preparation for work

Before you start using your assistant for its intended purpose, you need to understand its kit. They may be different for different models, but the basic set is usually the same:

- a case in which everything is stored;

- battery charger;

- removable battery;

- a set of nozzles (depending on the price category, their number may vary).

Having chosen the purpose for which the device will be used at the moment, you should:

- adjust it depending on the thickness of the wall (or other surface),

- set its power,

- select the appropriate drill / self-tapping screw,

- charge the instrument.

Before contacting the surface, it is recommended to make several idle turns, paying attention to the correspondence of its speed and the direction of rotation of the nozzle to the thread of the fastener

Performing a nozzle change

You should understand the design feature of the device. The element into which the nozzles are inserted is called the chuck. It can be inserted (depending on the purpose):

- drills (to make holes);

- bits (there may be several of them, depending on the different shapes of the edge) in which, in turn, are installed:

- screwdrivers,

- self-tapping screws.

Bits can be of the following forms:

- straight edge. Designed to perform work with a slot (fasteners in which there is one slot. The choice of such a bit depends on its length, depth);

- cruciform. From the width of the slot of the fastener and the size of its head, it is this shape of the bit that is selected.

To exclude the possibility of licking the slots of the fastener, you should carefully install it so that the edge fits snugly into the slot.

To change the bit, you need to use a simple method to strengthen the cartridge in the bit. For this you need:

- take a nozzle and a bat,

- unscrew the cartridge (its movable part);

- insert it,

- turn the chuck all the way.

Setting the torque

Adjusting the torque makes it possible to set the rotational speed of the screwdriver. Accordingly, the larger it is, the stronger the power will be, and from this faster and deeper you can screw a self-tapping screw or drill into the desired surface.

The adjusting ring is located near the chuck and is marked with the numbers corresponding to each speed. They should be set based on the density of the material in which the hole will be made. During operation, you can switch speeds, and their strength will depend on the pressure on the start button.

For a certain material, you need to choose your power, for example:

- drilling drywall, you can set a value from 2 to 4;

- when working with dense wood, it is recommended to set the maximum possible number.

Screwing and tightening fasteners

It is necessary to make the setting following a simple sequence.

- the nozzle is inserted into the slot (screw, self-tapping screw);

- the screwdriver is turned on with the start button;

- when the nozzle is screwed in, it will automatically shut off.

- the control lever on the device is set to the reverse direction;

- the nozzle is inserted into the slot;

- by pulling the trigger, twisting will take place.

Chuck rotation direction

All screwdrivers have a release mechanism that changes the direction of rotation, because it can work both by screwing in the fastener and unscrewing it. The switch has a value corresponding to the twist (forward or backward).

Switching must not be performed during the operation itself. If it becomes necessary to change the direction, you need to stop working and be sure to wait until the screwdriver motor has stopped completely.

To block operation (for example, when changing parts), the switch must be set to the middle position. In this mode, for safety, the device will not be able to turn on at all.

Design and characteristics

Outwardly, as well as in mechanical action, the screwdriver resembles a drill. The difference is low rotation speed / high scrolling torque. In addition, fixed speed indicators are set on screwdrivers (on drills, they are adjusted independently). Speed control is essential for safe and quality tool performance. The chuck stops moving when the screw is fully tightened. Despite the stop of the chuck, the engine is still in action.

For a particular type of work, a certain speed / mode of operation is calculated. There is a function of reverse, tightening, unscrewing screws (as well as nuts, screws, screws, soft materials). Craftsmen use screwdrivers all the time. In some cases (working with drywall, assembling the interior, creating a partition), the tool increases the speed and productivity of work several times.

Diagram of a cordless screwdriver device.

Diagram of a cordless screwdriver device.

Screwdrivers are designed according to the same principle. Basis of construction:

pistol grip (for leading hand operation);

little weight;

launch key that starts / adjusts the rotation;

power source - mains or battery (note that the battery is more massive and more expensive than the tool itself);

capacity is limited by the total weight of the instrument;

time of continuous work - about 3 hours;

spare battery available (depending on model).

Tool selection

If you are going to drill a hole in a concrete wall, you need to get ready to work properly. I advise you to start by choosing an instrument. In such a situation, there are only two possible options - an impact drill or a hammer drill. Naturally, a hammer drill will be a preferable solution, because the initial function of this tool is to punch concrete or stone, create holes of various diameters.

A feature of the tool is the ability to create holes of large diameter, while a standard drill cannot step over the threshold for drilling holes with a diameter of more than twelve centimeters. If it comes to such a non-standard material as foam concrete, it is worth giving preference to a drill, since the wall will be irretrievably damaged if you act on it with a perforator.

A hammerless drill will be completely useless for such work; moreover, the tool may be broken in the process.

Of course, if drilling several holes is such a big necessity, then in the absence of a hammer drill, you can get by with a drill, which will allow you to drill a concrete wall with certain skills. However, if long-term work is expected, then it is still worth purchasing the right tool.

Thus, you will save a lot of time and effort, because you do not have to mess around for a long time in order to drill a wall with a device that is not designed for such heavy loads. If, nevertheless, for some reason you had to use a drill, then it is worth remembering one feature of working with it - use only a victorious drill for concrete, whose tip is coated with a spray created on the basis of hard alloys.

There are craftsmen who know how to make a hole in concrete with a screwdriver. This is quite possible if you choose a suitable tool, for example, the Milwaukee 2604. With the proper skill, such a device will provide you with both hammer drilling and screwing in. It is quite suitable for all sorts of little things, but it will not work for a large amount of concrete work.

How to make a wrench from a screwdriver

For various reasons in household matters, you may need to unscrew a couple of dozen nuts. It is quite expensive to buy a wrench for such a fleeting need, but you don't want to turn it manually when you have a good old screwdriver at your disposal. It performs the main rotational function, it remains to remake it for unscrewing the nuts. Everything is extremely simple here.

To make a nutrunner from a screwdriver, you need a special adapter for bits and the attachments themselves, the size of your nuts. Adapters cost around 300 rubles and are sold in most hardware stores. When all the components are at hand, we clamp the adapter shank in the chuck, put on the desired nozzle and use a homemade nutrunner from a screwdriver.

The better to drill

As already mentioned, there are several ways to drill a concrete wall, we will consider each of them in more detail.

Perforator

When using a punch or impact drill, they must be switched to impact mode, a working tool with a victorious tip is inserted and it must be directed perpendicular to the wall surface.

If the drilling of the holes takes a long time, then periodically it is necessary to wet the drill so that it does not overheat too much.

After you have drilled to the required depth, you need to pull the working tool back without turning off the hammer drill. To clean the finished hole from dust, it is necessary to deepen and pull out the drill several times.

With an ordinary drill or screwdriver

If you do not have the tools described above, then this work can be done using a conventional electric drill or a powerful screwdriver.

To complete the drilling, you will need more time than using a hammer drill, but you can do it yourself.

In this case, in addition to the drill and drill, you will also need a punch. First, a small indentation is made in the place of drilling using a punch and a hammer.

After that, a working tool is inserted into it and begins to drill. If the drill stops, break hard areas again with a punch and continue working.

Although a regular electric drill or screwdriver is not suitable for working with concrete, if you do not have a hammer drill, you can make several small holes with these tools, but you need to use a spear drill with a carbide tip, usually used for tiles.

Diamond drilling

This is the most effective way of making a hole of the required diameter in a concrete wall simply and quickly.

To perform these works, you will need special equipment, consisting of the following elements:

- electric motor;

- a stand that is securely fixed to the base;

- drill bit.

It is not necessary to cool the drill during operation, as water is supplied to it, which not only cools the tool, but also prevents dust from forming.

If specialists work, then together with the specified equipment they use a vacuum cleaner with which they remove dust and water.

Since the price of such equipment is very high, it is impractical to buy it for domestic use. If it is necessary to make a hole with a large diameter, you can always invite specialists for this.

Concrete drilling tips

Before drilling, it is necessary to carry out some manipulations with the tool. I advise you to carefully check the drill chuck for dirt, which, if found, must be removed as soon as possible using a piece of dry cloth.

If you neglect this condition, then while you are drilling, various problems with the serviceability of the tool may arise. When inserting the drill into the chuck, make sure that it enters at a right angle, and the shank rests against the bottom of the chuck, otherwise the wall will remain intact.

Indeed, the most serious problem that a concrete wall can present is finding the wall on metal reinforcement. Most often, such situations occur when concrete is drilled to a great depth. In this case, the reinforcement is processed with a punch, after which you can continue drilling.

Another option for solving this problem, when, for example, a concrete floor is covered with metal reinforcement, is the use of a drill for metal, which can be easily supplemented with any impact drill.

Due to the fact that you cannot drill for more than fifteen minutes with a home-used tool, a break of the same length must be taken every quarter of an hour. During this break, both the concrete and the tool used are cooled. One of the features of the inclusion of the tool in work on a concrete break after such a break is the treatment of the drill with water. For example, a screwdriver with a water-dampened drill is guaranteed to last longer, having managed a huge number of work tasks.

Often, during the drilling process, the wall begins to crumble from the other side. Simply put, the concrete layer separates the plaster layer from itself. Such processes should be avoided by all means, as they can lead to the fact that the concrete layer will be damaged and the process of its destruction will begin.

To keep the concrete in its original form, it is only necessary to slightly slow down the speed of the tool, thereby reducing the intensity of its impact on the wall.

This precaution ensures that the concrete layer of the wall remains intact.

Another nuisance that happens while the drill is working on the concrete layer of the wall is the jam of the drill. Never try to remove it by actively loosening the tool in the wall. Not only will the concrete layer of the wall collapse because of this, but the sting may also break off - the upper part of the tool.

The equipment must be disconnected as carefully as possible, replaced with a drill bit with a smaller diameter and start drilling the concrete around the stuck one.This procedure can take a long time, but it will preserve not only the integrity of the wall, and the operability of the stuck drill after removing it.

So, in our article, we took a closer look at how to drill a concrete wall. With the right selection of tools and functional components for them, you can easily make holes in concrete. Moreover, this work will be done as efficiently as possible, at no extra cost and very quickly.

Tool use cases

A screwdriver can not only twist and unscrew fasteners. So that the tool does not stale, you can find a lot of uses for it.

Is it possible to use a screwdriver as a drill

Drilling with a screwdriver is possible only if this mode is provided by the manufacturer. Then drilling is safe. Read the instructions carefully. On the coupling, this is the last position or the drill icon.

Drilling mode designation

In screwdrivers with a drilling function, a keyless or key chuck is installed. A magnetic or snap-in chuck will not be able to hold the drill and ensure safe operation. Proceed as follows to replace the equipment:

-

In a double sleeve keyless chuck, hold the rear sleeve and turn the front sleeve counterclockwise.

-

If there is only one clutch, then turn it.

- The cams will open. Insert the drill.

- Turn the sleeve counterclockwise to clamp the drill in the jaws.

-

There are three holes in the key chuck. Insert the key into them in turn and turn until free rotation. The teeth of the key must mesh with the teeth of the chuck.

- Rotate the chuck counterclockwise to disperse the jaws. Remove the old drill and insert the new one.

- Screw in the cartridge first. Then tighten each hole with a wrench.

Other application

Using various attachments, the tool can perform the following work:

-

to polish;

-

chamfer bolts;

-

work from any angle and in hard-to-reach places;

-

sharpen knives;

-

securely and quickly tighten the self-tapping screws, working with one hand. For this, a nozzle with a tape magazine of self-tapping screws is provided;

-

install rivets;

-

cut corrugated board with turbo shears;

-

light a fire with a hairdryer.

There are many more uses for this tool. But remember to work with goggles and gloves.

Manufacturers

Makita BHP452

Two types of drilling are available:

Feature: battery charging is completed within 20 minutes. The amount of braking / rotation is independently adjustable, depending on the needs and goals. Built-in LED flashlight. The leader among screwdrivers in terms of speed and ease of switching modes.

Metabo PowerMaxx SB

Cordless impact driver. The main differences are:

Cordless impact driver. The main differences are:

- light weight;

- high performance;

- compactness;

- ergonomics;

- high torque;

- multifunctionality (can perform a certain list of works);

- autonomy.

The percussion instrument is suitable for:

- drilling of walls made of any material;

- installation / dismantling of building elements and structures.

In terms of tool construction, the Metabo Power has 2 speeds (soft / hard torque). LED illumination, special belt clip, reverse mode, high work intensity. Charging can be carried out both mobile and autonomously.

DeWalt DCD985M2

The difference between this screwdriver is:

The difference between this screwdriver is:

- powerful impact mechanism (drilling 13/60 mm holes in concrete, 16 mm holes in stone);

- 3-speed gearbox, the speed of which is adjustable by the consumer;

- for the torque mode, you can select 1 desired combination of 22;

- a rotational speed unit built into the tool gives additional control over the process;

- LED backlighting;

- specially designed chuck to drill a variety of materials;

- functionality (closely related to technical characteristics);

- Compatible with fasteners to drill metal / wood / stone / concrete.

Bosch Uneo

Cordless screwdriver capable of drilling masonry / making holes in concrete monolithic blocks / screwing in screws. Feature of the tool:

Cordless screwdriver capable of drilling masonry / making holes in concrete monolithic blocks / screwing in screws. Feature of the tool:

- the ability to drill at a speed of 0.9 J;

- weight is 1 kg;

- battery charge speed - 3 hours;

- makes holes in concrete in a few seconds, the charge is enough for 70 screws;

- the speed is independently regulated;

- the cartridge can be replaced with any similar one (other brands can be used);

- 6-point cartridge.

How to work in swirling mode?

Before starting work, you need to prepare the tool. If it is running on battery power, you need to put it on charge.

The next step is setting the bit. To choose the right nozzle, you need to take into account the size of the fastener head and the type of slot. Bits differ in type and diameter:

- slotted. Most often used. Designed for tightening countersunk head screws with a slot for a flat screwdriver, screws. Tip width varies.

- Cross. With their help, self-tapping screws, countersunk head screws are twisted and unscrewed. The tip has 4 radial diagonal ribs.

- Hexagonal. It is used for fasteners, the head of which has hexagonal recesses. Screws and screws of this type are used in the assembly of furniture and appliances.

- For bolts and nuts. A nozzle with a tip, inside of which a hexagonal recess is made. With it, the tool is used as a wrench, screws, screws, bolts are tightened.

There are other attachments, but they are less commonly used. How to change or remove the bat altogether? Having determined which bit is needed, insert it into the cartridge. The installation method depends on the type of cartridge. In a quick-release nozzle, insert it as follows: twist the chuck counterclockwise until the distance between the cams increases. Push the end of the nozzle between them, turn the cartridge clockwise so that the cams close and securely fix the part.

In a screwdriver equipped with a turnkey chuck, the process of changing the nozzle is more complicated. First, a key is inserted into a special hole on the device, rotated counterclockwise to loosen the clamp. Insert the bat, fix it by turning the key clockwise.

The next step is to test the functionality of the tool. If the screwdriver is powered from the mains, connect it to an outlet. Press the start button, check if the bit is scrolling. The rotation speed is adjusted using the same button, weakening or increasing the pressure. The tip of the bit is inserted into the recess on the head of the fastener, and the start button is pressed.

If you need to unscrew the self-tapping screw or screw, switch the reverse button.