Varieties, choice

By purpose, shovels are divided into:

- Bayonet. They are used for digging up soil (vegetable gardens, trenches, holes). During operation, the working surface may become dull. They require timely sharpening.

- Shovels. They are used to move materials subject to flowability, as well as work related to loading and unloading. Sharpened in rare cases.

- Sapper. Such a tool has found a narrow application for performing special tasks in combat situations.

Bayonet-type products differ from their counterparts in their shape. The working part is made in the form of a rectangle, or tapers at a certain angle. For sharpening edges of various shapes, the same methods are used, depending on the type of work. They do not have instructions in which the manufacturer indicates the base material. For the manufacture of tools can be used:

- steel with a high carbon content;

- steel with the addition of stainless elements;

- alloy steels;

- titanium and alloys of various metals.

The shank is made from any type of wood, as well as some light metals. The working part is performed by hot stamping, while it is necessary to further process the metal surface by hardening. When viewed, no cracks, burrs or chipping are allowed. The handle is securely fixed to the metal. When bending the shovel as a result of pressing, it is considered defective.

Determining the right moment

Without experience, people often go from one extreme to another and either sharpen the saw every few days or once a year. Determining the need for sharpening by time is the wrong approach.

There are a number of signs that indicate that the teeth are dull:

- The blade regularly gets stuck in the wood.

- When sawing, the sound changes, it becomes more "dull".

- The shade of the teeth changes.

- The resistance of the material increases significantly.

- The ends of the teeth are noticeably rounded.

- The blade leaves the cutting line.

Expert opinion

Dmitry Levin

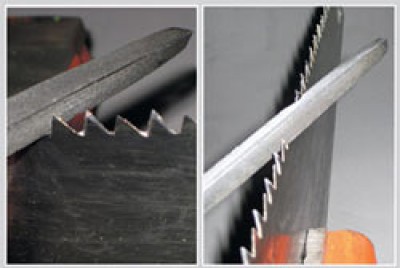

Hardened teeth cannot be sharpened. It is easy to distinguish them: they are blackish with a slight blue tint.

Useful Tips

You can increase the service life if you alternate manual sharpening using a special machine. The latter allows you to accurately align the sharpening angles on the machine. The seam depth should not be too great.

It is necessary to observe safety measures that allow you to cut wood of any size with maximum efficiency and with a minimum level of danger to humans:

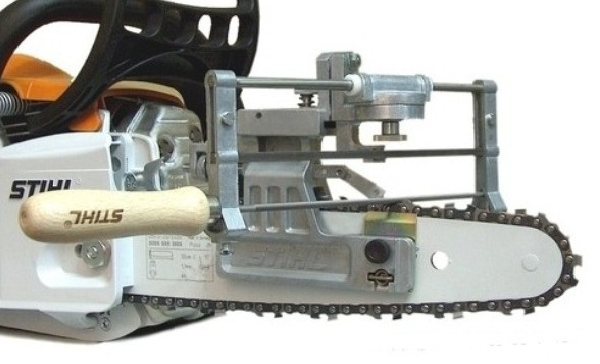

- Before assembling the chain tool and installing the headset, it is recommended that you familiarize yourself with the rules of use. This is due to the fact that each tool has its own characteristics.

- It is necessary to carry out work using a saw in gloves and goggles.

- For work, it is recommended to choose tight-fitting clothing made from natural dense materials and the most reliable footwear.

- It is necessary to cut wood using a chainsaw in a stable and safe position, while the material itself must also be positioned as steadily as possible. Installing the toothed stop on the log will help ensure stability.

- During operation, the saw must be held with both hands, constantly monitor the cutting process.

Modern chainsaws are used in domestic and industrial environments

At the same time, it is important to maintain productivity and high performance indicators of the tool, which directly depend on the condition of the sharpened chain set.

How do you sharpen a chainsaw chain: do you prefer handicraft methods or entrust this business to professionals?

When to sharpen and how to find out

After examining the saw chain, the foreman decides whether it is time to sharpen the tool or not.

As a rule, the saw chain loses its performance properties during intensive work. Things can get to the point that the chain will have to be resharpened several times in one day. The contact of the saw with the ground can also be the reason. In fact, quite a few times to strike the saw chain on the ground and you can stop all work. The chainsaw will simply stop going into the tree. By the way, one of the signs of a dull saw is the appearance of small chips.

Dull chainsaw chain

The sooner measures are taken to sharpen the chain, the longer it will last. It is quite easy to understand when regrinding is required. The feed change will take place. A chain with correctly sharpened teeth will retract even with a small effort, but if during operation you have to exert a greater feed force, then this means only one thing, the teeth have lost their sharpness.

The use of a dull chain is not permitted. By the way, this is a safety requirement. And the process will require significant muscular effort from the lumberjack. As a result, this leads to a decrease in the quality of the cut, an increase in the amount of fuel used and an accelerated development of the chain.

Set of teeth of a hacksaw

The movement of the blade must be free, for which the saw teeth are set at the same value.

To reduce the coefficient of friction and the clamping of the hacksaw in the cut, its width must be greater than the thickness of the working blade, otherwise the metal heats up and expands, which leads to the saw to jam.

The setting of the hacksaw teeth is performed by bending the cutters to the sides.

Using pliers does not allow you to get the same angle of inclination - with such a tool you can only cut firewood.

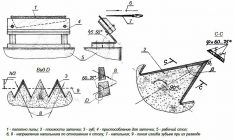

To spread the cutters evenly and get an even, neat cut, a homemade setter is used.

To make it, you need a metal plate of arbitrary shape with a thickness of 2-3 mm.

In a simple way, several slits are made to indicate the thickness of the web.

The prong is gripped into the hole and bent back until it reaches the selected stop.

In the second version, a cut is cut in the bar with a metal file, and two holes are drilled to install the limiter.

Turning the sector to the sides allows you to adjust the bend angle.

The figure shows a simple model and wiring with an emphasis.

The diagram of the device is intuitive, easy to manufacture and use.

It should be noted that the hem width has its own parameters.

How to determine when it is time to sharpen a hacksaw

An experienced carpenter can tell when the saw is ready to sharpen by:

- the sound of sawing a tree changes;

- the teeth change their shade.

A number of signs are also available to the less experienced:

- increased material resistance;

- it is difficult to maintain the perpendicularity of the cut;

- the blade does not adhere well to the cutting line, the line deviates or bends;

- the blade gets wedged in the wood.

Before sharpening the saw, it is imperative to separate the teeth, that is, to ensure that they are deflected from the plane of the blade at a certain angle. Correctly set teeth ensure a kerf wide enough to prevent the blade from getting stuck in the material. If the teeth are too set, the kerf will be too wide, this will increase the loss of material, the pulling force, and also reduce the accuracy. If you sharpen the saw correctly on wood, it will restore its working qualities.

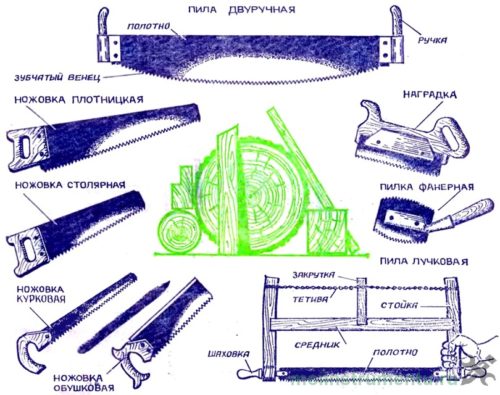

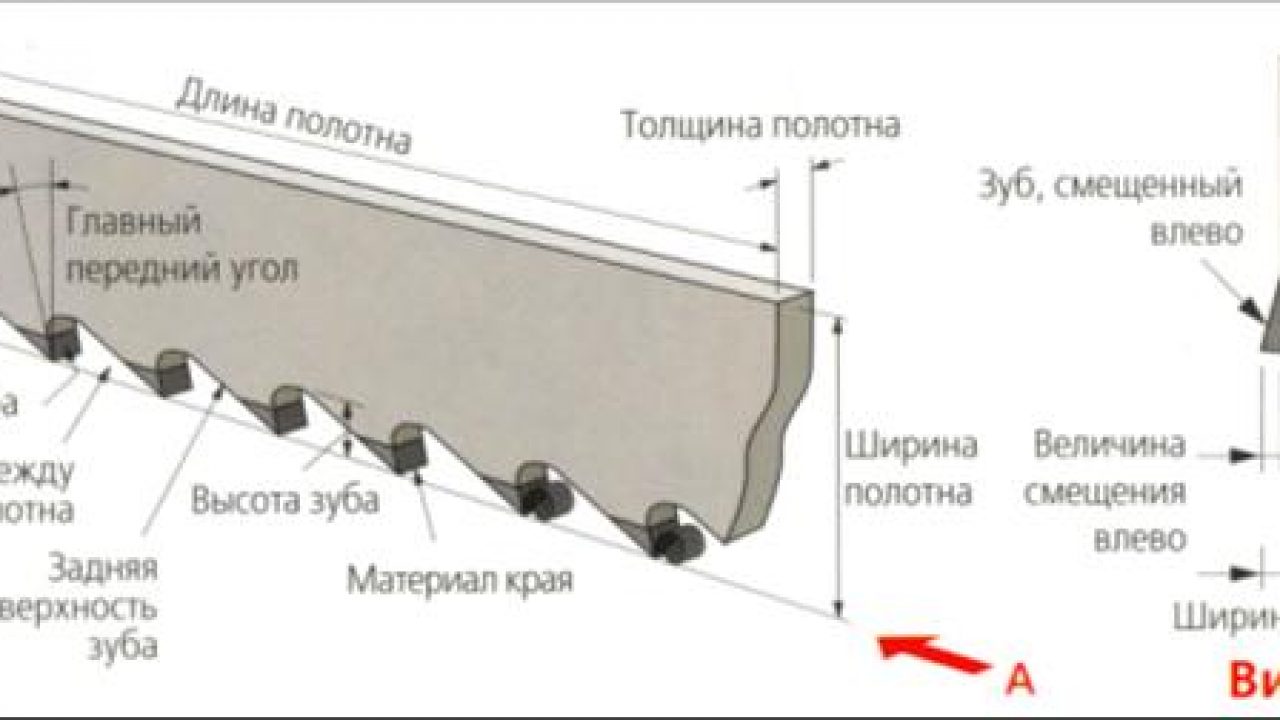

Hacksaw device

During sharpening, the following geometrical characteristics of the teeth are restored:

- step;

- height;

- profile angle;

- bevel angle of cutting edges.

General saw sharpening technology

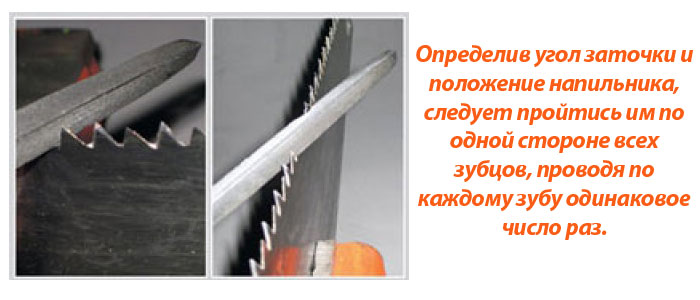

The hacksaw is fixed in the prepared clamp in the most convenient position for work, after which you can start work in accordance with the following rules:

The file handle should be held with the right hand and the end of the file should be held with the left. The tool must be directed towards the teeth. Returning the file to its original position should not be accompanied by abrasive action on the teeth. That is, the correction is performed only in the "away from you" direction. As for the pressure, it should be soft, smooth and, most importantly, even. The main problem that many people face when sharpening cutting and piercing tools on their own is the different degree of sharpening in different areas. How to sharpen a hacksaw at home to ensure the same correction of all teeth? As already noted, one should strive for uniformity, but this is not enough.

It is important that each tooth receives approximately the same number of passes with the same direction and file height.

Tooth setting

The teeth deviate from the plane of the blade in a checkerboard pattern, for example, all even ones to the left, all odd ones to the right. Only very experienced carpenters are able to cut saws in wood "by eye". This skill comes after several hundred diluted saws. For less experienced craftsmen, it is better to use a special tool - wiring. The simplest version of the tool is a flat plate made of strong metal with a slot, into which the blade goes in tension, with minimal clearance. The saw blade should be clamped in a locksmith's vice. The teeth should protrude slightly due to the jaws. The teeth, one by one, are clamped in the groove of the tool of the plate and bent in the middle. The routing angle must be constantly monitored. First, all even teeth are bent in one direction, then all odd ones are in the other. At the end of the wiring, you can spread the sponges to the width of the wiring and stretch the canvas between them. If any of the teeth are bent more than necessary, they will touch the vise. They need to be fixed.

Tooth setting

Canvases with hardened teeth are not subject to spreading.

How to understand that the chainsaw chain is dull, and it is time to sharpen it: signs

The long service life of any chainsaw depends on proper care and use, including the chain headset. The good performance of the latter affects the performance of the device and performance parameters. Failure to sharpen in time can cause some problems in the operation of the saw itself. Most often these are:

- curves cuts;

- heavy loads on the saw, as a result of which the wear of the device parts increases, and hence a decrease in the service life of the entire device;

- increased fuel consumption.

There are other signs of chain bluntness:

- the speed of the tool has decreased;

- rough and sharp sawdust is formed;

- it is necessary to make great efforts to cut wood;

- the chain is stretched or sagged.