How to plant an ax on a hatchet

A wooden ax, as the weakest part of a tool, always wears out faster than a metal ax. He begins to dangle, and this is not just an inconvenience in work, but also a danger. We will tell you how to correctly change the hatchet and attach an ax to it.

Most often, birch is used to make a hatchet, as a tree is quite hard, but at the same time affordable and easy to handle. Beech and ash are also used. The workpiece should be brought to the size you need so that the ax sits comfortably in your hand.

Important! The wood for the ax must be well dried. If the workpiece is made by hand in winter, then be sure to keep it warm for two to three days before the nozzle.

Of course, ready-made hatchets are most often bought. The price can range from 20-80 rubles for the simplest polished workpieces to 3,500 rubles for a hand-carved ax. For the preparation of firewood and an independent nozzle, of course, simple, but high-quality hatchets are suitable, in which case there is no need to pay for expensive options.

To attach an ax to a hatchet, you need the blanks themselves, five wedges, a hacksaw for wood (some craftsmen use a hacksaw for metal so that the width of the grooves for the wedges is minimal), a marking pencil, a rubber or wooden hammer (mallet), a piece of gauze and epoxy resin ...

Important! The wedges should be made of a harder wood than the ax. You can take larch, oak, beech (if the ax is made of birch)

One wedge will be wide, four will be narrow. To process them and fit the ax to the ax, you will also need a grinder.

At the first stage, the outline of the ax nozzle is outlined on the hatchet, lines for the cuts of the grooves are highlighted.

Important! The ax should sit as tightly as possible on the ax; it is necessary that it protrude from the eyelet by at least one centimeter. The protruding piece of the ax after the racking will turn out to be of a larger diameter, this will allow to firmly fix the metal part of the tool and avoid the risk of its dismounting during operation

The protruding piece of the ax after the racking will be of a larger diameter, this will allow the metal part of the tool to be rigidly fixed and avoid the risk of its dismounting during operation.

Experts advise to slightly bore the eye of the ax before the attachment under the cone from the side of the ax. For this, a file is used. This ensures that the ax does not slip off after wedging.

The cuts in the hatchet should be 2/3 of the depth of the eyelet. Do not forget that one centimeter protruding above the eye should be added to this indicator. The cuts are made carefully with a hacksaw according to the markings applied. The direction of the fibers of the wedges is parallel to the narrowing so that they do not break on impact.

Before placing the blade on the handle, apply two to four layers of gauze soaked in epoxy resin, which will perfectly fill in all the irregularities. The protruding, excess pieces of gauze are cut off. The wedges are also lubricated with epoxy before inserting into the cut grooves. It is advisable to pour the resin into the grooves themselves, by about a quarter. This is done after the attachment of the ax.

You can hammer in the wedges with a rubber or wooden hammer, saw off the protruding parts. The main danger at this stage is to split the ax by driving the wedges too hard.

Epoxy resin has many useful properties. First, it acts as a reliable glue. Secondly, it is resistant to water and therefore does not allow the ax to get wet.Thirdly, the epoxy does not shrink, and after drying it forms a strong monolith that fixes the ax to the ax.

Epoxy hardens in heat for a day, but it is safer to wait a week before using an ax.

We admit that it is somewhat more difficult to put an ax on a hatchet than to sharpen it. There are other ways, besides the one described by us, for example, with three wedges, with a cross. As for the basic requirements for the blanks and the tool itself, follow the GOST 1400-91 "Hatchets for construction axes".

Ax Care: Practical Tips

Four common forms of blade sharpening.

For a long service life of the ax, it is necessary to provide it with proper storage and care.

- Protect the instrument from water. Like any other tool of labor, water is terrible for him. That is, you need to store the ax in a dry, not necessarily warm room.

- Sharpening. The force of the blow applied to the ax and the quality of the work done depends on the correct sharpening. Accordingly, you should sharpen it with high quality and try not to drive the blade onto the stones. Also, do not stick into the ground.

- Case. For neat carrying and protection from dullness, you should do it yourself or buy a leather case.

Hatchet making

Although the handle of an ax looks like a simple product, it can be made in a variety of ways, the choice of which depends on the tools and materials available.

Manufacturing methods

Most often, the ax is used by people living in rural areas and in summer cottages. The tool is often used not only for its intended purpose, but also for other works. This leads to the fact that the axes simply do not withstand such exploitation, and they have to be changed from time to time. You can correctly make an ax handle as follows:

- Electric tools designed for working with wood (circular, planing and grinding equipment).

- With a hand tool using an ax, a plane, a rasp.

There are many lovers of handicraft with wood, therefore, preference is given to traditional instruments. After all, it is a plane, an ax and a chisel that allow you to enjoy the procedure and enjoy the result.

Instruments

To make a handle for an ax, you need to prepare the following list:

- dry board or chock;

- hacksaw;

- axe;

- rasp;

- pencil;

- chisel;

- hammer.

The handle is made as follows:

You can learn more about making an ax handle from the video.

Handle finishing and impregnation

The finishing of the handle is done with fine sandpaper. The wood is sanded, removing small irregularities and bringing the surface to a perfectly smooth surface. Some craftsmen use glass instead of sandpaper. To add exclusivity to the hatchet, it can be decorated with carvings or other decor.

Since the handle is made of wood, like any other product, it is susceptible to rotting. Most often, problems arise with improper storage conditions of the instrument. Therefore, after manufacturing, it should be protected from the negative effects of the external environment.

The best option is to impregnate the handle with drying oil or linseed oil. The substance is applied to the wood and left to dry. The procedure is repeated until the oil is no longer absorbed. It should be borne in mind that in order to extend the life of the hatchet, such processing must be periodically repeated.

How wedging is performed

Many beginners think wood wedges should be the same wood as the handle. However, this is a misconception, because the tree must be very durable. It is also necessary to take into account the direction of the wood fibers, which must be parallel to the saw cut on the ax. This will prevent the wood wedge from breaking when driving into a deep cut.

Epoxy is poured into the cuts made and fills all existing cracks and voids.After it hardens, you can drive the wedges. First, wooden wedges are driven in, and then metal wedges. The minimum distance between the wedges should be about 0.4 centimeters. The metal wedge must be bent so that it covers the wooden one.

It is a newbie belief that wooden wedges should be of the same wood as the handle. But this is not the case.

First of all, the wood must be strong. The direction of the fibers must also be taken into account. It should be parallel to the taper of the wedge. This direction will prevent the latter from breaking when driving into the cut. The broken wedge does not perform high-quality spreading of the ax to the sides. Successful wedging is considered when the wedge has completely filled the entire kerf space and cannot be removed.

When making wedges, it is important that the dimensions of the transverse products correspond to the size of the lug. In some cases, the lug may have gaps

You can fix them with gauze or a bandage soaked in epoxy resin. The epoxy material protects the wood from getting wet and performs a reinforcing function. To perform the reinforcement, it is necessary to wrap several layers of gauze around the upper part of the handle before attaching the ax. The resin is poured into the cuts and fills all existing voids and cracks. After it hardens, wedges are clogged. At the same time, wooden wedges are driven first, and then iron wedges. The distance between them should be at least 0.3 cm. The iron wedge at the end is bent with one edge so as to cover the wooden one.

Preparatory stage

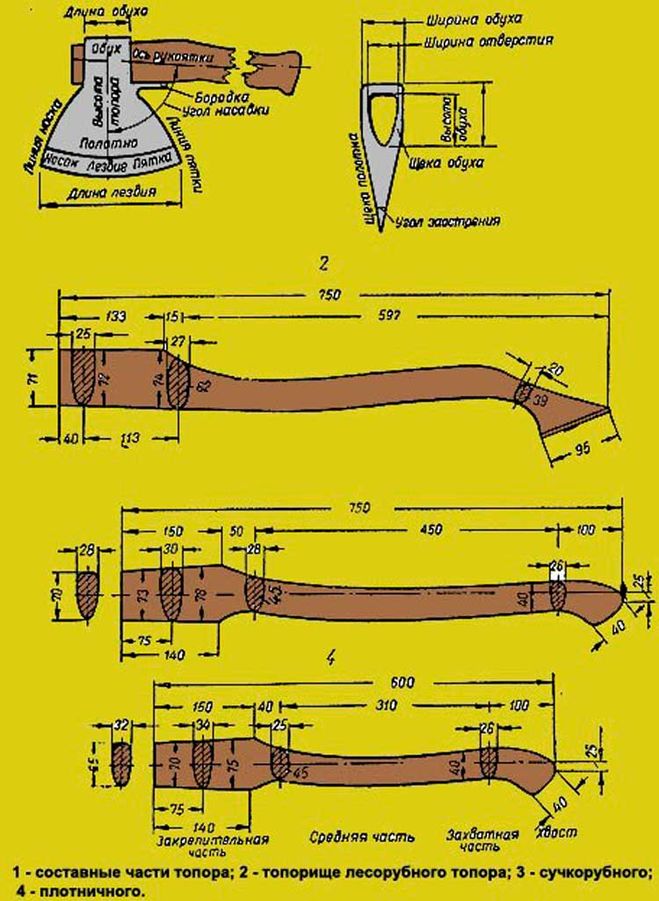

Blueprint for making a hatchet.

Each work, even the simplest one, consists of several stages. Ax assembly is no exception. In order to get a ready-to-use tool, you must:

- pick up an ax;

- fit it correctly under the eyelet;

- make the required number of cuts;

- prepare wedges, wood or metal;

- plant an ax;

- wedge the ax in one of the ways.

The first four stages can be considered a preparatory stage.

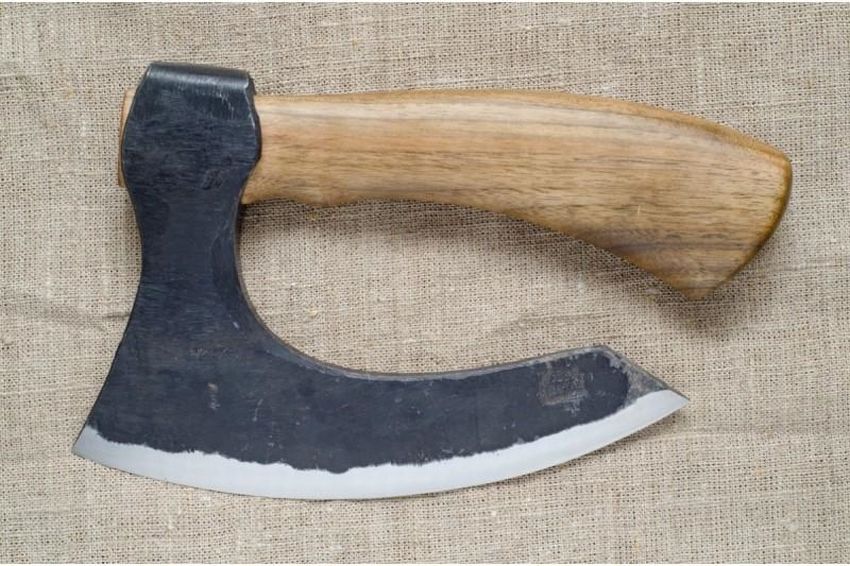

So, before planting an ax on a hatchet, the latter must be picked up and purchased. In terms of material, professional carpenters and lumberjacks recommend well-dried birch. This material is quite common, and also has properties that create convenience when working with the tool. Harder woods work well for decorative options, but not for workers. The most convenient form of the ax, which gives the least return to the hands, has long been determined. Ideally, the CD axis (fig. 1) intersects with the gripping center P or there is a slight backward and upward offset. In the other two cases, the impact has to make unnatural movements to compensate for the recoil.

Types of ax blades.

Fitting the ax to the eyelet means cutting it to the required shape. For this, some kind of woodworking tool will come in handy, for example, another ax, a sharp knife, and the like. And here there is one point that must be taken into account.

The axis of the ax blade and the longitudinal axis of the ax must be in the same plane. Simply put, the blade needs to be aligned with the ax.

A few words about the eyelet. It can be either straight or conical in a certain part of the ax. The conical shape of the lug is considered more suitable for good attachment. Before cutting the hatchet, you need to carefully adjust the shape.

It was the turn of the cuts on the upper end of the ax. Their number is determined by the selected wedging method, of which there are many. It can be only one longitudinal groove, it can be two or three lateral, one longitudinal.

Many professionals consider one longitudinal and four lateral. This can be seen in photo 1, but these are not all options.You can select both a slight offset of the cuts and a split rip cut. Many people decide this question based on their own ideas about the mechanical properties of such compounds.

Figure 2. Diagram of an ax attachment on a hatchet.

Pay particular attention to the depth and width of the cuts. The depth should be such that the resulting groove is completely hidden in the eyelet

Otherwise, the handle may split when wedging or working. The kerf must correspond to the thickness of the wedges. The wedge should not enter the cut too easily, then there will be no point in it, but it should not enter too tightly, then it will not be possible to drive it inside.

Wooden or metal wedges (fig. 2) can be purchased or made by yourself. Both methods work equally well. They are inexpensive, but if there is nowhere to buy, you can simply cut them out of well-dried birch. The shape and dimensions must correspond to the parameters of the cuts. A metal wedge can be made from a fairly hard sheet, for example, from an unnecessary shovel. (fig. 2)

If the preparatory stage is passed correctly, then no special problems should arise.

Self-production of a wood splitter

Making a mechanical splitter for firewood with your own hands on a spring mechanism is an easy task, especially if a person has initial experience with welding. Although, on the other hand, bolted connections can also be used. In this case, you will need a grinder and a drill from the tools. It is not difficult to work with them, therefore, even without previous experience, it will not be difficult to make a wood splitter.

For self-production of a mechanical cleaver, this scheme will help

The design of the cleaver can be any, the main thing is its power, quality of production and stability. But before starting production, it is necessary to make the correct calculations and prepare drawings. In this case, a do-it-yourself firewood cleaver is easy to make even for a novice master, and the quality will be quite good.

It is important to calculate what the optimal lever length will be in relation to the weight on the blade. It is also important to adhere to the correct location of the spring and hinge, the distance between them

Try to choose higher quality materials for your cleaver that will serve you for many years

If the dimensions of the structure are calculated incorrectly, then the product will not fully fulfill its function. For example, the cleaver can be very weak, so it will take a lot of effort. The principle of operation is easy to understand. The further the spring is fixed from the hinge, the more power the cleaver will have, but the length of the lever should equally increase. You need to find the perfect spot where the spring will have sufficient strength and it won't be difficult to later lift the lever and tension the spring.

For the production of a simple lever log splitter, you can use the materials at hand:

- a shock-absorbing spring from a car (VAZ or similar);

- a ready-made cleaver blade or a steel blank for self-production;

- pipe, the diameter of which coincides with the diameter of the spring;

- steel pipes, profiles and other metal products for the manufacture of the frame.

Threaded cone wood splitter:

For the manufacture of hinges, it is not necessary to use a bearing mechanism. The design itself turns out to be quite massive, so an ordinary shaft and sleeve are enough. The same mechanisms are installed as hinges on the gate.

The manufacturing process is also simple. In each individual case, it is necessary to rely on the prepared calculations and drawings, and they may be different. All actions must be performed in the following sequence:

- measure and cut off the frame elements with a grinder;

- assemble the frame using welds or bolted joints;

- bowls are made and a spring is installed;

- at the last stage, the weight and the cleaver blade are attached.

If the structure does not come out very stable, then additional pipes are welded to the lower part to increase the supporting area.

The correct cleaver with your own hands:

The main thing is to adhere to the general recommendations for manufacturing and follow the drawing. For a simpler version, you can make a cleaver in the shape of an ax, but with an elongated handle and a heavy cutting part. Even the most primitive model will help the owner in preparing firewood for the winter.

Cleavers have been known since ancient times - this is a type of ax, characterized by an increased weight of the chopping part and a special sharpening of the blade. Their task is not to chop the log, but to split it. At the moment the tool's iron honor hits a tree, an ordinary ax sticks into it and gets stuck. The cleaver, having a greater mass and a blunt blade, splits the tree into two parts under the influence of the impact force. There are many cleaver configurations. They differ in shape, weight, sharpening angle, handle length and other design characteristics. At the moment, there are modifications of cleavers in electric, gasoline, semi-automatic, manual form, and even cleavers for bricks.

Attachment of the ax

Attaching the ax to the metal wedge can be done in several ways.

- Welding. Thanks to this method of fastening, it is possible to achieve high strength and reliability of the tool during operation.

- Manufacturing of ax elements as a single structure. Characterized by rigidity and strong recoil when working with such a tool.

- Bonding of structural elements of the ax in specially designated areas. Epoxy is used for bonding. And the handle is made of polymers. It is quite difficult to carry out such a procedure on your own, since a room with recirculation ventilation will be required during the manufacturing process.

- Putting a metal wedge on the tool handle with subsequent wedging. This method is considered optimal for the independent implementation of this procedure. With strict adherence to the recommendations, the tool is characterized by the strength of the attachment.

It is worth noting that the successful implementation of putting an ax on a hatchet depends on the availability of existing skills, knowledge and the required tools.

It is possible to carry out such a procedure on your own, but you need to objectively assess your abilities. Since in the case of an unreliable attachment of the metal wedge to the handle, the tool will loosen after what period of time of intensive work. Thus, the insertion will have to be done again.