Introduction to shredders

When I was in the tenth grade, and it was 2000, the school, together with the state farm, in the village of Miltyushi, Cherepanovsky district, Novosibirsk region, sent us in the spring to burn straw. We walked through huge fields and set fire to straw, students from the 8th to 11th grades took part in this lesson, and this is more than 200 people. In addition, the state farm also burned straw on its own.

It turns out that the issue of disposal of agricultural waste, such as seed husks, sunflower stalks, hay, grass, peat, reeds and even branches, has long been resolved abroad. This whole line has the right moisture content and is simply granulated into pellets. Further, the pellets go both to the bedding of the animals and to obtain heat in special automatic boilers. Oh, by the way, in China for a long time they have been making from all this waste not only pellets, but even chipboard, for example, I have an article about making wood-based panels from reeds.

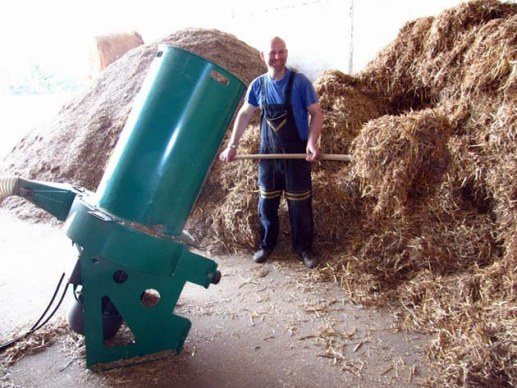

The hay grinder can be used for other agricultural waste as well. It processes bales, bales and bulk material into fine chopped particles. At the beginning of the article, you can see a picture with a fraction from weed waste. There are vertical and horizontal shredders.

Diy chopper for a walk-behind tractor: a set of preliminary works

Before you choose the design of a garden chip cutter and start assembling it, you need to decide on the goals of its creation:

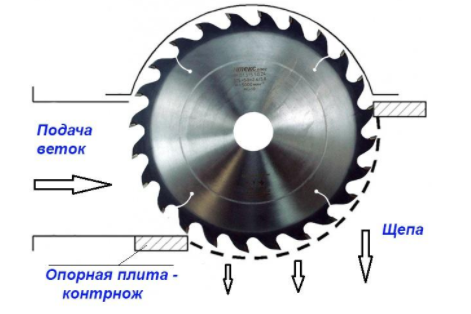

- To obtain sawdust, which can be added to the soil as compost or adapted for fuel briquettes, it is easiest to stop at a disc crusher for a walk-behind tractor;

- For the purpose of rough crushing of branches into a coarse fraction - shredders acting as a jointer;

After that:

- A traction unit is selected - motoblocks with a capacity of at least 5-6 hp are compatible with a chopper attachment. The most reliable designs are obtained on the basis of motor-blocks "Neva", "Kaskad", "Celina";

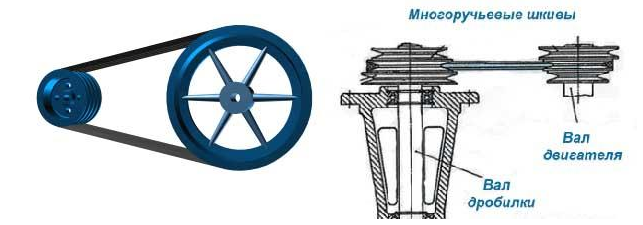

- They adapt the V-belt transmission - so that the cutting headset cuts without problems and does not wear out the engine, it should account for half of the declared torque of the device. For example, for a walk-behind tractor with 3 thousand rpm, the speed of rotation of the knives will be 1.5 thousand revolutions. At the same time, the length of the belts is being adjusted: for the leader it will be 10 cm, and for the slave - 10 cm;

- They modify the pulleys - it is more effective if the pulley has 3-4 strands. This will allow "maneuvering" between revolutions and speeds of work only due to the transfer of the belt, expanding the scope of the crusher.

Material and technical base:

- discs for circulars with victorious solders;

- gasoline drive from a home walk-behind tractor;

- belt;

- pulley;

- bearings;

- M20 bolts together with fasteners;

- pipes;

- steel;

- electric welding and grinder.

By what parameters to choose a wood shredder

When choosing a shredder, a person should first of all pay attention to the following:

- funnel diameter;

- functionality of the attachment;

- type of crushing system;

- the engine is gasoline or electric;

- equipment weight;

- the power of the wood shredder;

- a way of processing garden waste.

More attention should be paid to the knife system. It can be milling or disc

If the grind is not electric, it will be quiet and easy to clean. The only drawback is dependence on power surges. The gasoline engine is capable of handling almost any kind of waste, as it is more powerful.

In this video, you will learn about the pros and cons of a chipper:

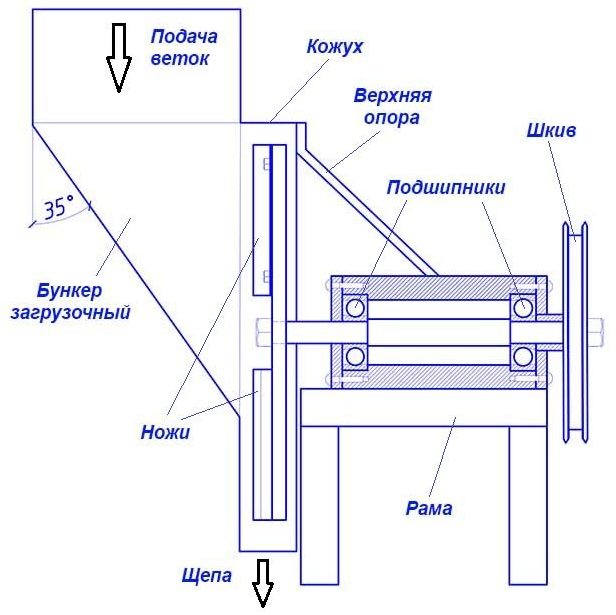

Straw chopper design

The homely owner, who has a land plot, and in addition, there are different animals, he knows very well why such a machine is needed. We will only add another area of application to the list: chopping hay and straw can be used to make fuel briquettes at home. If someone has conceived such a thing, then you cannot do without a straw chopper, try manually chopping or chopping such an amount of straw.

Craftsmen at home have adapted to making various artisanal straw choppers from old pumps and vacuum cleaners. Their principle of operation is the same as that of knives mounted on a rod rotated by an electric drill. The bunker is an ordinary old bucket, in which grass or straw is placed, after which rotating knives are lowered there and thus chopping occurs. Descriptions of such devices are easy to find on the Internet.

Only these mechanized cutting tools are too unproductive and impractical, and will fit only to prepare feed for a dozen rabbits. For briquette production or other purposes where a lot of raw materials need to be processed, you will need a reliable homemade straw chopper with sufficient power and performance. This is exactly what we will make.

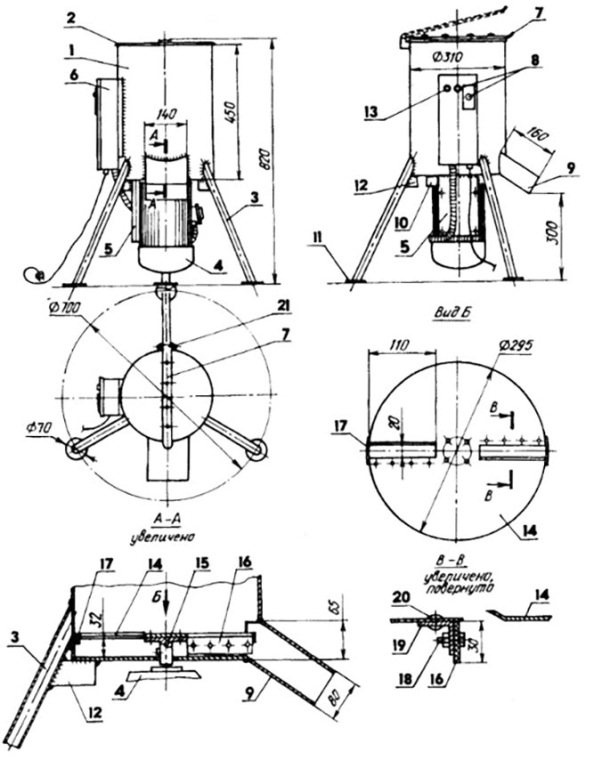

The heart of any straw chopper is the working unit, which is a metal hopper with sharp knives rotating inside. The latter are rigidly fixed on a steel disk, and the latter is on the axis of the electric motor. The hopper has a cylindrical shape and is raised high for safety reasons so that you cannot accidentally touch the knives with your hands when loading straw. At the bottom of the hopper there is a branch pipe for ejection of chopped straw, for convenience it is made inclined.

The bunker rests on a tripod of such a height that an electric motor can be placed underneath, attached to its bottom by means of a plate. The detailed drawing of the straw chopper is shown in the picture:

1 - bunker; 2 - cover; 3 - tripod support; 4 - electric motor; 5 - engine mounting plate; 6 - control panel; 7 - amplifying band; 8 - control buttons; 9 - outlet branch pipe; 10 - engine mounting bracket; 11 - support thrust bearing; 12 - kerchief; 13 - lamp - indicator; 14 - disc with knives; 15 - faceplate; 16 - rubber gasket; 17 - jumper; 18 - bolt М5 (8 pcs.); 19 - scraper; 21 - lid hinges.

The operation of the apparatus is simple. By turning on the electric motor with the button and opening the lid, straw is loaded into the hopper. A finished cut flies out of the side pipe; to catch it, it is worth adapting some kind of container. A plastic barrel with a hole cut in the side will do, so that the straw will not fly in all directions.

Tools and materials

The size of the knives to be installed will depend on the size of the final cut.

To carry out such work, you need from the tools:

- a standard plumbing kit that every good owner has;

- good grinder;

- drill;

- welding machine.

But the materials will be listed as approximate, since in each case different options can be used:

- an electric motor with a speed not exceeding 2000 per minute, so that the device does not pose a danger to others during operation;

- sheet metal with a thickness of 2 to 3 mm, which will go to create all the main elements of the bunker;

- to create a bracket, you need metal 5 mm thick;

- pipe with a diameter of 25 mm for support;

- to create amplification, a strip with dimensions of 25 by 3 mm is required;

- 10mm steel plate.

Read an article on varieties of garden shredders here.

And this informative article is about forage grinders.

Popular factory models

When you don't want to make your own hay mills for your home, you can choose ready-made devices available in stores. The following options are considered the most common models:

- M15.The unit is equipped with sharp knives made of high-strength steel, as well as a reliable electric motor that produces 3 kW of power. In addition, the device has a convenient hopper where raw materials are fed. All in all, using the M15, you can process straw, hay, as well as thin branches. The drum rotation speed is 1500 revolutions, and the weight of such a unit is almost 130 kg.

- KR02. The device is very compact but has high performance. Due to the presence of a power of 1.54 kW, the model is capable of processing about 250 kg of material every hour. You can run from a 220V network.

- K-500. The unit, with a capacity of 2 kW, allows processing about 300 kg of raw materials in one hour. Due to this, the device is suitable for use on a farm where there is a significant amount of livestock.

General technical characteristics of grinding technology

A chopper for branches and other garden debris for a walk-behind tractor is usually called a special attachment, that is, a nozzle for garden equipment. This component is used to process branches of young growth, shrubs or fruit trees. It is also well suited for shredding brushwood collected separately from the forest. When the shredder finishes working, finely crushed shavings are formed. It can be stored in a compost pit to produce humus or used as mulch.

In the first case, a person receives fertilizer for his garden. The diameter of the shredded branches is usually about 50 millimeters. One of the main advantages of shredders is that they can fit different types of walk-behind tractors and cultivators.

The main thing to pay attention to is the presence of a drive with a belt from the motor to the gear pulley

Hay chopper device

The simplest hay and straw chopper is made from a conventional vacuum cleaner. An ordinary plastic or aluminum bucket serves as a working chamber, where raw materials are placed, and then a knife is lowered, mounted on a rotating shaft. Such a device can be made in a few minutes, but it has one significant drawback: low performance and impracticality. If the number of poultry or livestock is large, a more reliable hay crusher will be needed.

The working unit is the most important part of the straw chopper. It consists of a steel bunker with knives inside. The knives are attached to the motor axis with a special axis. Usually the hopper is made in the form of a cylinder, and for greater safety, the walls are left high. Can be made with short walls, but then equip the device with a lid.

The main components of the straw chopper:

- Working chamber with lid,

- Support,

- Motor,

- Gain bar,

- Knives or cutting disc,

- Receiver of raw materials.

A do-it-yourself hay cutter is assembled at home from materials available to everyone. And its production does not require any special technical skills. To make a hay chopper with your own hands, you need to have a locksmith's kit, a welding machine, a drill and a grinder. Of the materials required:

- Motor (an electric motor from a washing machine is suitable),

- A sheet of metal, with a thickness of about two millimeters,

- A sheet of metal, about three millimeters thick,

- Steel sheet, ten millimeters thick,

- Pipe cut (do not use a diameter of more than 25 mm),

- A strip of metal, 3 mm wide, 25 mm long.

Manufacturing

Instead of knives, you can use a circular saw or a powerful food processor. A barrel or pipe cut with a diameter of at least thirty centimeters is well suited for the role of the device body.

Before making a straw chopper with your own hands, it is advisable to find clear and detailed drawings of the device on the Internet. They will allow you to avoid errors in the location of parts and fastening. Manufacturing begins with marking and cutting out a workpiece from a pipe cut. An additional bottom is attached to the resulting container by welding, and already a holder for the motor is attached to it.Several holes are pre-made in the steel sheet to simplify the process of mounting the motor. A DIY straw chopper made from a pipe will turn out to be stronger if you weld metal kerchiefs to the sides. A container for an already crushed product is attached below. Only then is the engine installed. It is attached to a steel sheet, and cutting knives or discs are placed on the axle and securely fixed.

The last moment: an electric cable and a toggle switch are mounted, as well as a cover and an indicator lamp. The device is now ready for use.

Garden shredders made in Russia

On the market of shredders intended for use in the country, there is a group of devices manufactured in Russia. In the rating of domestic shredders, two companies are in the lead.

- Equipment under the ZUBR brand has been produced by Zubr OVK for 20 years. This is a reliable technology with excellent ergonomics and high quality. Garden chippers are notable for their low price, simple operation, and convenience. The manufacturer provides a five-year warranty for all its equipment, while providing a wide service area.

- Another well-known Russian manufacturer is the full-cycle enterprise "StankoLes-Trade", which produces equipment under the brand name "Drovosek". Their shredders are inexpensive and reliable. The company gives a 12-month warranty on its equipment, and service is carried out in the workshops with whom they have signed contracts.

Top Models

For all the simplicity of the design, the Bison do their job well, no matter what unit they choose. The plastic housing makes it lightweight and the drawer makes it easy to collect the resulting substrate. Large wheels allow easy movement on the ground or on grass. The device has a bimetallic plate that protects the engine from overheating, as well as protection against starting when the box is open or if it is incorrectly installed. All BISONs are powered by electricity, which implies their use only in the presence of alternating current sources.

- Modification ZIE-40-2500. Unit equipped with wheels and a 50 l container. The motor with a 2500 W gearbox allows for the processing of rather large waste. This model is equipped with an alloy steel turbo knife, providing a high cutting speed of knotted material. The device copes with medium and large branches up to 40 mm in diameter.

- ZIE-44-2800 is a more versatile model, it can be used as a chopper for leaves, cut grass, branches, tree bark. The device is equipped with a turbo shaft rotating at low speed, which easily grinds the plant material. The maximum branch diameter is 44 mm. The apparatus is equipped with a 2800 W motor, as well as a receiving container with a volume of 60 liters.

Shredders of the Lumberjack brand are designed only for working with wood, they are more powerful, but also more expensive.

A modification that runs on gasoline should be highlighted:

MP300 is a device designed for chopping shrubs and wood waste into chips, the size of which can be varied by the arrangement of the knives. The device is equipped with a petrol engine with a capacity of 6.5 horsepower. The knife mechanism consists of two knives made of 6XC steel.

Dealing with the technique, you need to build on the conditions of its use and the material that will be crushed. For a garden plot, it is better to take universal electrical models. They help to dispose of a wide variety of waste products, as well as provide valuable organic fertilizer in the form of compost from recycled grass.

About the Bosch garden shredder - how it works, the best models

Makita UD2500 - parameters and description of the chipper for the garden

Vacuum cleaners for cleaning leaves in the garden - description, varieties

A nozzle for chopping branches on a walk-behind tractor - what is it, characteristics

How to make a garden shredder from a washing machine

All about wood shredders - description, characteristics

Step-by-step production of a straw chopper with your own hands

The shredder is manufactured using the following materials:

• electric motor; • a disk for a circular saw; • metal sheet 2-3 mm thick; • corner; • bolts, nuts, washers.

List of required tools:

• welding inverter; • grinder; • drill; • set of wrenches.

As a result, we have just such a practical straw chopper that will help you chop straw, grass for a compost pit, and perform the work necessary on the site.

How a straw chopper works, hay is shown in the video:

A hay cutter or straw chopper is an indispensable unit in a subsidiary farm. With its help, you can quickly and easily grind hay for poultry or young animals, as well as grind straw for warming beds or winter roads, making briquettes for heating. It is not difficult to make a hay chopper yourself, and the practicality and functionality of a home-made device will not be inferior to store counterparts.

Do-it-yourself disk wood chopper for a walk-behind tractor

Assembly progress:

- We make a shredder frame. For her we need: An equilateral corner with a width of 5-6.3 cm; Welded hollow billet from corners with a side of 3.5 cm; Pipe-profile 4 x 4 cm; Channel; Pipes with a cross section of 0.32-0.48 m. As a result, you should get the rack shown in the figure. For additional rigidity, it can be reinforced with crossbars, and for convenience - with a handle or wheels;

- We select the base site - a sheet of stainless steel with a thickness of 1 cm, the dimensions of which are selected based on the number of holes for installation and their spread over the plane;

- We adapt the tensioning mechanism of the belt drive: the holes for installing the motor from the walk-behind tractor are made so that it can be moved relative to the horizontal plane and bolted in several positions; we put the plate on the hinge. At this moment, the belt should be pulled from the propellant mass; on the opposite side, the plate is clamped with pins;

- We grind the shredder shaft, on which the cutting elements will be located. It can be based on any steel billet, which after turning will acquire a cylindrical shape. The landing size of the shaft is chosen arbitrarily for the bearings available at home (2 pcs.) - for example, from the rear axle shafts of the Zhiguli. For each of them, you will need a body with flange connections, which you can buy or adapt home-made;

- We carry out threads on the finished shaft for aggregation with cutting parts according to the proposed drawing;

- We purchase about 15-20 carbide-tipped circular saw blades (all of the same size);

- We pre-procure a set of gaskets to protect the rotating blades from displacement. Sheet steel is taken as such washers;

- We string the circular knives and spacers one by one, leaving 8-10 mm between the toothed blades. They can be positioned asynchronously for greater cutting capacity;

- We collect a loading bunker for a wood cutter on a walk-behind tractor. It should be a box with massive walls and a solid base. It can be retrofitted with a fixed knife to provide preliminary shredding of wood debris. Weld it at right angles to the cutting block;

- We equip a base for lateral installation of ball bearings on a shredder for a walk-behind tractor;

- We organize a bell - a feeding casing, which should protect the operator's hands from rotating parts;

- We assemble the chopper according to the scheme.

If desired, the shredder can be modified by reinforcing with an auxiliary shaft. It becomes a tightening mechanism that makes it easier to feed the branches. For this, a second shaft is machined, along which steel rectangles are welded. It is connected to the main gear of the wood chopper and its gear is lowered.

The resulting attachment to the walk-behind tractor has the following technical parameters:

- crushes 6 cm hard and 8 cm soft wood;

- interrupts the slab - waste after working on the sawmill;

- passes through itself 3-5 m3 of waste per hour (the indicator depends on the power of the walk-behind tractor).

The grass chopper for the walk-behind tractor should have a slightly different design due to the fact that large discs will only wind, and not chop it. Therefore, the knife block is replaced with a cutter or blades with a minimum diameter.

Manufacturing recommendations

The metal must be marked and cut out in accordance with the drawing. Cut pipes and corners to the required length and clean. The bottom is welded to the hopper, and a bracket for attaching the electric motor is welded to it. The steel plate is fastened vertically to the bracket, first you need to make holes in it that coincide with the mating part of the engine. For stiffening, gussets are welded to the side of the plate.

Supports are attached to the body at an angle; gussets are also welded to them, which play the role of stiffeners. When the hand-made straw chopper is already on the supports, a cut ejection branch pipe is attached to it. Then an electric motor is attached to the plate with bolts, and knives are mounted on its axis and securely fixed. Last of all, a cover is attached and the electrical part is installed.

It is not at all necessary to repeat the construction presented in the article. The main thing is to correctly make a working unit with knives, and you can adapt an electric drive to it in any convenient way. Just remember that the number of revolutions of the cutting shaft must be within 2000 rpm. And then, if the scope of the knives is not more than shown in the drawing. Otherwise, the machine will become a source of increased danger.

How to assemble a grass and hay chopper yourself

The rate of decomposition of the grass depends on the degree of its grinding. In the process, grinders are used, which are easy to make yourself.

Craftsmen have come up with a lot of options for making shredders. For example, they suggest using a drill in a craft. The craft uses the principle on which the food processor works. Inside the cylindrical body (an ordinary bucket is used), a knife is placed on the drill shaft. He, having a good sharpening, quickly rotating, dissects the stalks of grass.

For a homemade grinder, a drill with a power of 850 watts or more is suitable. A hacksaw blade is used to make a knife. When sharpened correctly, the grass will split rather than collect on the blade. A well-prepared knife always stays clean.

One-sided sharpening is arranged on the knife. Place it inside the body with a bevel down. When chopping with fresh grass, it is better to use a diamond-shaped knife with a sharpening strip narrowing towards the edge. On such a knife, the grass, due to centrifugal force, slides along the blade and is guaranteed to be cut. On a diamond blade, as a rule, grass winding is not observed.

According to the scheme described above, you can make a grass chopper from a Typhoon vacuum cleaner. The craft will look more presentable, and its performance will be more.

There are two holes in its body: the upper one, through which the grass is loaded; bottom - lateral, intended for the exit of the crushed mass.

The Typhoon model of the vacuum cleaner has a housing that is ideal for the described scheme of chopping grass. It has a top hole size that is most suitable for the process. But if there is no such unit, then you can use a bucket, an old pan, even a piece of pipe of sufficient diameter will do.

The engine for the craft is suitable from the washer. A hacksaw blade is used for knives. Racks are made from a profile pipe with a section of 15x15 mm. The only thing is to order a 4-centimeter sleeve to which the knives are attached.

The motor is located at the bottom of the container. Its output shaft is passed through its bottom and provided with a sleeve on which the knives are bolted. An outlet is made on the side of the container, from below.

Assembling a device based on a washing machine tank practically does not differ from assembling a grinder with a different capacity. The difference is that a small rectangular hole is cut out in the bottom of the tank before assembly. It is reinforced with metal corners.

After installing the engine, it is connected to the cable and the starting device. After that, the straw chopper is ready for use at home. Such, at first glance, simple units can significantly facilitate labor and save time on farming.

Owners of their own farms find it difficult to do without the help of small-scale mechanization. One of these assistants is a hay and straw chopper for private households. You can buy a ready-made unit, but such models are not cheap. For those who are well versed in technology, it will be more profitable to make it with their own hands.

Washing machine hay cutter

A simpler and less powerful DIY hay chopper can be made from a regular washing machine. In addition to the typewriter, you also need:

- Knives or cutting disc,

- Electric wire,

- Bucket,

- Metal corner,

- Fasteners,

- Locksmith set.

How to assemble the device

A small rectangular cutout is cut out at the bottom of the case, about 20 by 7 cm in size. Its perimeter is sheathed with metal plates for greater strength. A stand is made from the corner. The height of the stand depends on what you plan to use as a receiver for shredded raw materials. For buckets, the stand is made higher than for boxes.

To attach the motor, two small holes are made on the shaft, after which a threaded sleeve is installed on it. The engine is mounted on a shaft, and the entire structure is attached to the bottom of the tank with metal studs. After that, cutting discs or knives are put on the shaft.

It is very important to select the size of the discs so that they do not come into contact with the walls of the working chamber.

Before connecting the motor to the cable, you need to decide on the working and starting winding of the electric motor itself. This can be easily done using a special tester: the working winding has less resistance than the starting winding. The engine is connected as follows:

- One end of the start winding is connected to the start toggle switch,

- The other end is connected to the main wire and the working winding,

- The free end of the working winding is connected to the main wire and the wiring from the start switch.

- The hay chopper is ready.

Small farmers and villagers who own their own farms often have to use various mechanisms in their daily life to facilitate this or that work.

Such devices include a hay and straw grinder - a straw chopper.

Such devices can be easily purchased in specialized stores, choosing from a wide range. But it will be much cheaper to make a straw crusher with your own hands, due to its very simple internal structure. Before talking about manufacturing, you need to make out what it consists of.