Installation and connection of the power plant

If the gas generator was not originally designed to operate in difficult conditions in an open area, then its installation must be carried out in a dry heated room - especially for devices used as a backup source of electricity.

Of course, manufacturers can indicate that a gas generator is capable of working for a long time and confidently in the temperature range from –30 to +50 and at the same time not bend the heart. But here, at least, one must take into account the factor of thermal expansion of bodies and the likelihood of condensation. This means that if the gas generator is in an unheated basement, then its temperature will be equal to the ambient temperature.

When it is necessary to start it up, the windings heat up, and when the generator is turned off, they cool down. Condensation collects on them, which over time can reach current-carrying contacts and provoke a short circuit. With elevated temperatures, the situation is no better - no manufacturer will specify how long the gas generator will work in this mode, but the device will obviously need to be repaired much earlier.

The problem of exhaust gas removal and elimination of noise from the operation of the gas generator must be solved in each case individually. Here you need to decide where to stretch the corrugated hose (so that the exhaust does not enter the house), and what would be better - to make sound insulation or place the gas generator in a separate room.

The connection diagram to the home electrical circuit completely depends on the capabilities of the outlets or terminals installed on the generator. If the generator is powerful and has several outlets, then they are connected in parallel. Switching to power supply from a central power supply or a generator is carried out either manually or by means of automation, which monitors the presence of voltage on the line and gives the command to start / stop the gas generator engine and connect from the desired source.

This is all the information that can help you decide on your own which gas generator to choose for your home, workshop or trips out of town. This task is very easy to calculate if the generator is simply needed as an autonomous source of electricity for not too long operation of one or several devices. When a gas generator is purchased as a backup for the entire house or a production workshop, the complexity of the calculations will increase and if there are doubts about the correct choice of the device, it is always better to consult with specialists, especially since the information provided will allow you to ask them the right questions.

Maintenance

Timely maintenance of the generator set significantly affects its resource. The most frequent attention is demanded by the engine, as its most complex unit. The engine oil change and air filter service are required at the manufacturer's specified operating hour intervals. On powerful generators equipped with more sophisticated engines, the oil and fuel filters are also changed. Gasoline and diesel engines (gas - much less often) require replacement of spark plugs.

Timely maintenance of the generator set significantly affects its resource. The most frequent attention is demanded by the engine, as its most complex unit. The engine oil change and air filter service are required at the manufacturer's specified operating hour intervals. On powerful generators equipped with more sophisticated engines, the oil and fuel filters are also changed. Gasoline and diesel engines (gas - much less often) require replacement of spark plugs.

If the generator is used occasionally, do not store it filled up - oxidizing and decomposing over time can lead to clogging of carburetor deposits on benogenerators and paraffin deposition on diesel engines, which can completely cut off the flow of fuel. Also old fuel will make it difficult to start.

The generator itself is an almost eternal unit, only from time to time it is necessary to clean the brush unit of the synchronous generator from dust and change the brushes themselves, and sometimes the bearing bearings of the rotor.

Common misconceptions

The most common misconception, which is strongly supported by manufacturers of inverter generators, is the supposedly bad shape of the output voltage.

First, the voltage from the stator of the generator without connecting any kind of semiconductor converters, on the contrary, has an ideal sinusoid. This is due to the very principle of operation of electrical machines. Suffice it to recall that most power plants, hydraulic, thermal, nuclear, that is, based on the conversion of mechanical energy into electrical energy, operate on exactly the same principle as a home power plant. But semiconductor elements have a non-linear characteristic, and obtaining a strict sinusoid using semiconductor converters, including inverters, requires great technical tricks.

Secondly, most modern consumers use built-in switching power supplies, which do not care about the shape and frequency of the voltage (within reasonable limits), since the first thing that the power supply circuit contains is a rectifier and a filter. Consumers such as irons, electric kettles and electric stoves do not really care what voltage is applied to the input. The only devices for which the frequency and shape of the supply voltage are important are asynchronous motors and transformers.

The second common misconception is associated with the complexity of the design of inverter generators. Here we can say that this applies mainly only to products of little-known manufacturers who offer cheap equipment. Leading companies have worked out the circuit solutions of inverters to perfection, they use only high-quality components and perfect assembly lines. The electronic circuit of the control and monitoring unit of inverter devices is protected from moisture and dust, therefore good devices fail extremely rarely and, subject to the recommended requirements, can serve for a long time.

As for the breakdowns of internal combustion engines, in most designs, long-run drives are used, which have high reliability and durability. Subject to the use of the required and high-quality fuels and lubricants, regular maintenance (replacement of filters, spark plugs), engine failure is unlikely.

As has been shown, the correct formulation of the requirements determines which device design is preferred. Both types have their own areas of application, advantages and disadvantages, but they can often be interchangeable, so it cannot be categorically stated which is better. Currently, until the prices of inverter devices fall to reasonable limits, most of the buyers are guided by the familiar devices that use a gasoline engine with an alternator and a simple control circuit.

Selection Tips

The variety of models on the market makes it difficult to choose the right device. Usually in the first place is the value of the permissible load power. The following data on the value of power can help in this:

- Departure for nature - up to 1 kW;

- Power supply of the most necessary household appliances in case of interruptions - 2-3 kW;

- Food for a small private house or apartment - 5 kW;

- Big house - 7 kW.

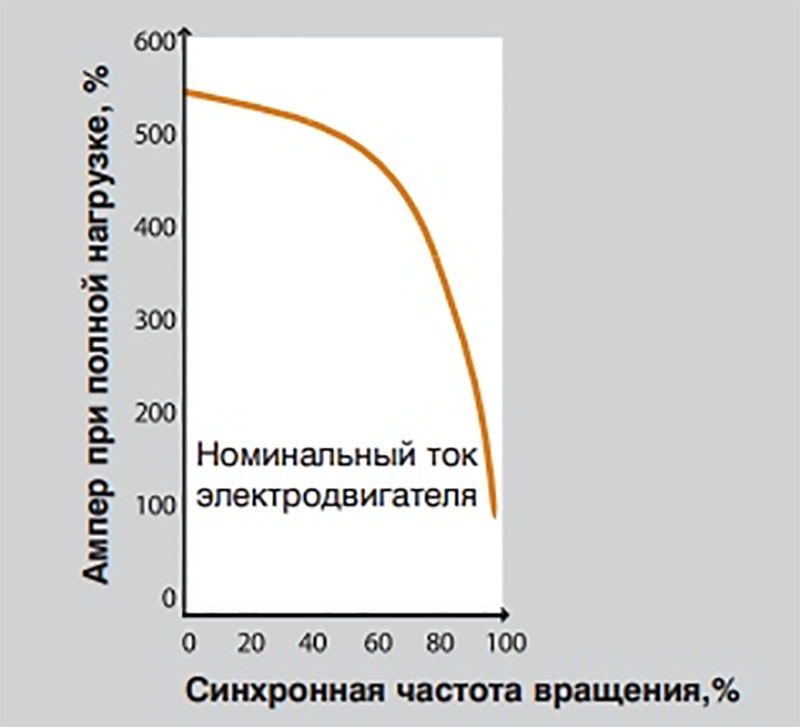

Note! In the case of using mini-power plants in construction, their power should be at least one and a half times higher than the power of the connected power tool. So, if a grinder with a power of 2 kW is used, then at the moment of start-up the consumption current exceeds the nominal 1.5-2 times

Therefore, the power of the generator must be at least 3 kW.

The dependence of the starting current on the speed

The dependence of the starting current on the speed

Which generator to choose, classic or inverter? An ordinary device is sufficient to power the vast majority of consumers. The choice in favor of an inverter should be made in the following cases:

- Frequent work with minimal load. The reason here is not only efficiency, but also a decrease in the reliability of the operation of a conventional device;

- The requirement for high efficiency;

- Minimum dimensions. Going out into nature with a large-sized power plant is difficult for obvious reasons.

A classic mini-power plant is more suitable if:

- Work is required for a powerful load (more than 5-7 kW);

- Continuous work with minimum load is not supposed;

- The dimensions of the device are not critical;

- The cost of the equipment is important.

Powerful inverter

Powerful inverter

A gasoline engine runs on high-octane gasoline, a diesel engine requires appropriate diesel fuel to operate. Sometimes you can find the design of a power plant that works using liquefied gas.

Review of popular models

The rating of the best inverter generators includes models recognized by the most relevant consumer audience. They are compact, have a power range of 1 to 2 kW, are reliable and safe to use. It is worth considering the most attractive offers in more detail.

"Bison ZIG-3500". Single-phase inverter electric generator with a power of 3 kW, with a manual start-up type. The model is equipped with a single-cylinder four-stroke motor, air cooling system, and belongs to a synchronous brushless design. This energy source can work up to 3 hours without interruption and is equipped with a soundproof enclosure. There are 2 220 V and 1 12 V sockets on the case.