Tracked module for walk-behind tractor

A tracked module for a walk-behind tractor is an attachment that will make it possible to convert your equipment into a snowmobile or a motorized towing vehicle. Moreover, this can be done in a matter of minutes.

To make a caterpillar drive to a walk-behind tractor with your own hands, you may need a drawing.

Under the Krutets brand, caterpillar belts are produced, which, regardless of the power and weight of the cultivator, are suitable for walk-behind tractors of any manufacturer. They have a sturdy frame and can be used in any season. The attachment is installed on the walk-behind tractor using keys.

The well-known attachments for walk-behind tractors include domestic "Lynx", "Ant" and "Buran". Imported ones include: Talon 380, Talon WT, etc.

As for a self-made caterpillar, you need to remember that its high height increases the center of gravity of the unit. This threatens instability and rollover on bends and problem areas. For stability, you need to increase the additional axle.

If the wheelbase is narrow, then it needs to be widened. A bushing must be installed on the drive shaft. It can be purchased at any auto parts store.

It just can't handle a heavy load. Walk-behind tractors with water cooling are ideal. The motor does not overheat with this cooling.

Tracks for a walk-behind tractor allow fans of outdoor activities in winter - fishermen and hunters - to get to the desired place without hindrance. Such a machine can also transport various goods, hay or firewood.

Reviews of homemade caterpillars are positive. When self-manufacturing tracks, you cannot save on trifles and details, otherwise the walk-behind tractor will turn out to be unreliable. Or you need to purchase homemade consoles from craftsmen who have repeatedly been engaged in the manufacture of tracks for walk-behind tractors.

If you are not confident in your abilities, it is better to purchase a ready-made set-top box. Its only drawback is the high price.

Design features of the device

Making components for a home-made caterpillar for a walk-behind tractor with your own hands allows you to save money on the purchase of factory devices and the further operation of the equipment. If everything is done correctly, then self-made caterpillars for the walk-behind tractor increase the cross-country characteristics.

Compared to wheeled counterparts, tracked motoblocks are not so widespread. The explanation is simple. Wheel units from Texas, Patriot, Cayman, Viking, Forza are best suited for plowing land. This design is best suited for ground work.

Alteration of a wheeled walk-behind tractor is a work consisting in attaching one additional wheel on each side. It turns out a four-wheeled walk-behind tractor, on which you can put on tracks. They can be, in turn, purchased or homemade. Additional wheels can be detachable. This allows you to timely convert the unit into a standard walk-behind tractor, ideal for working in the garden.

For this, the wheels are fixed to the axle, which are already provided in the structure, by means of a rigid or flexible transmission. This solution is considered advisable, since the need for the installation of additional fasteners disappears. As for the device of these motoblocks, they fully correspond to the parameters of wheel modifications:

- Engine. It is powerful, four-stroke. It has a function for locking the axes.Due to this, the tracked walk-behind tractor can turn in place without making a full circle.

- Transmission. The standard kit includes a gearbox, clutch system and gearbox.

- Chassis. Caterpillars are used here. They replace the wheelbase. If the alteration is made, then one kata is added to the existing pair of wheels on each side. They put on a homemade caterpillar.

- Control bodies. Located on the control handle. Includes emergency stop mechanisms and all sorts of clutch levers.

Before starting your own production, you need to evaluate the offers in stores specializing in the sale of such equipment. Particular attention is paid to the price of certain types of tracks for well-known manufacturers of motoblocks. Let's say a caterpillar for a Neva walk-behind tractor costs about 28,000 rubles. This is a fully functional snowmobile attachment. Separately, you can buy a seat for drivers, thanks to which the walk-behind tractor acquires the features of a tracked mini-tractor, albeit with not such impressive performance characteristics. The technical parameters are as follows:

- develops a speed of the order of - 18 km per hour;

- total weight of the console - 37 kg;

- width - 60 cm;

- length - 100 cm;

- height - 34 cm.

Accommodates one driver and one passenger on board. In addition, on sale you can find an attachment for a walk-behind tractor on tracks, which is designed for the Salute and Agat models. Its cost ranges from 25 to 27 thousand rubles. This design does not provide for the attachment of a driver's seat. Because of this, some restrictions are imposed on the functional features of this device. But for driving on off-road and snow such transport is quite suitable.

Their feature is the ability to control not only with two hands, walking behind the walk-behind tractor, but also while sitting in a folding sleigh. The latter will have to be purchased separately. Considering that the average cost of a set-top box is about 30 thousand rubles, not counting the price of a folding sleigh, we can say that making the tracks yourself saves a lot of money.

What are the different types of tracked systems?

In one case, the track module is designed as an axle. At the bottom it is supplemented with four rollers. And already with the help of the rollers, the required mechanical stress of the track is formed. On the left and right are a pair of gears. When they fall into the grooves of the tracks, they tighten them and allow the device to move.

The gears move horizontally due to a special frame. It is attached with bolts. One side of the shaft equipped with gears is complemented by a gear transmission. Through a special circuit, it transmits the effort to the tracked unit. V-shaped parts are built into the running belt, the sharp edge of which looks along the path of the walk-behind tractor.

There is also another version of the drive. It is not reflected on the device of the track itself. Only the wheels have been replaced with a large gear wheel attached to the axle. In the lower part, the frame is equipped with eight rollers. The purpose of using these rollers is to keep the belt taut and ensure smooth running.

How to make tracks for a walk-behind tractor with your own hands

Consider how to make tracks for a walk-behind tractor with your own hands. To assemble the caterpillar on your own, you can use a variety of materials that are easy to find. List of materials and tools that are needed to make a caterpillar:

- Bulgarian;

- drill;

- jigsaw;

- welding machine;

- bolts;

- nuts;

- keys;

- knives;

- screwdrivers;

- pliers;

- sanding belts;

- chains.

The crawler drive for the walk-behind tractor must evenly distribute the load on the ground during operation. Therefore, it must be strong and light at the same time.

The most affordable way is to use a roller chain with a conveyor belt. To obtain a track from the specified materials, the edges of the chain and tape must be stitched.

To do this, you can use a machine, or you can sew by hand. But this method is unreliable. A hinge similar to a piano strip is also suitable for connection.

Consider how to make homemade tracks for a walk-behind tractor from tires. There is another method of making homemade tracks for a machine that uses a tractor or car tire tread.

These caterpillars are easier to prepare and much more practical. This method has another advantage - there is no need to prepare the lugs separately.

Manufacturing method: first you need to pick up a tire and carefully cut a tread track out of it. If you do this by hand, you will need a well-sharpened knife. But, as practice has shown, it is better to use a jigsaw and a file with fine teeth.

To reduce friction, while working with the jigsaw, you need to wet it from time to time with water or a special soap solution.

The advantage of a tire track is that it is initially round and has a closed circle. The downside may be the limited width of the tire.

Consider a method of making a product from belts and chains. Tracks can also be made from standard V-belts. Connect them using lugs, which are attached to the belts with screws and rivets.

When making tracks from chains, they must be the same size. The chains are unclenched, closed in a ring and welded. Steel plates can be used to make lugs, which are used to fasten chains with bolts.

They have a circle diameter of 30 mm. For heavy motoblocks, such as MTZ or Agro, these tracks are not suitable.

Ready-made tracks for walk-behind tractors are very easy to install. They serve as attachments.

Tracked platform, types, modifications

This equipment is produced by both domestic companies and foreign manufacturers. As a result, there are many modifications that differ:

- by form;

- according to the installation principle;

- for use.

Module forms

Of the whole variety of models, two main forms can be distinguished:

- Rectangular axial;

- Triangular gear.

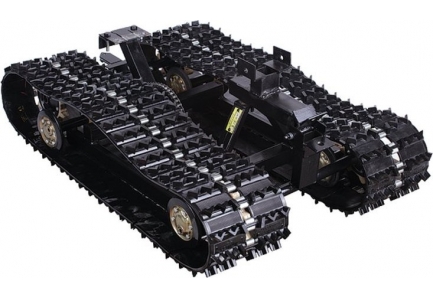

Axle attachments consist of:

- platforms;

- axles;

- four rollers;

- two gears;

- two caterpillars.

The platform is attached to the walk-behind tractor with bolted connections. Four rollers are attached to the bottom of the axle. The rollers apply the required track tension. Two gears located on both sides of the track, falling into the groove, set the platform in motion.

The triangular gear attachment consists of the following elements (for each track separately):

- large gears;

- rigid frame;

- eight rollers;

- caterpillar tape.

Crawler drive triangular

Large gears are mounted on an axle coming from the gearbox of the walk-behind tractor. The rollers are fixed at the bottom of the rigid frame, they are located in pairs on both edges of the track. This structure allows you to provide the required track tension when driving. Unlocking the differential allows the walk-behind tractor to perform various maneuvers - turns, turns, etc.

Having decided to buy (or make your own) a tracked drive for a walk-behind tractor, you must take into account the following characteristics of the attachment:

- The optimal speed of the walk-behind tractor on a caterpillar track. Powerful models can provide speeds from 18 to 20 km / h.

- Loading capacity of the attachment. In most cases, models with a carrying capacity of 200 kg are purchased, but each owner of the equipment has the right to choose and select this characteristic to suit his needs, taking into account the engine power of the walk-behind tractor.

- The maximum permissible height of snow masses (if you plan to use the attachment and the walk-behind tractor as a snowmobile). The main limit is the engine height. Modern attachments allow you to comfortably move on snow up to 50 cm high.

- The permissible level of liquid mud, water also ranges from 45 to 50 cm.The reason is the same - the engine height.

In order to ensure the duration of operation and serviceability of all elements of the module, it is necessary to perform the following actions regularly (before and after each operation):

Inspect the track attachment before driving.

Check the tension on the rollers.

Check that the fasteners are secure.

Pay attention to the integrity of the tracks, the condition of the track.

Lubricate all moving and track assemblies regularly.

Installation

The uniqueness of the track attachments lies in the fact that their installation instead of the basic wheel drive in a matter of minutes turns an ordinary walk-behind tractor into an effective towing vehicle, all-terrain vehicle or a snowmobile. Such modernization is most relevant for equipment belonging to the category of small-sized agricultural units with a shaft with a diameter of 30 mm. The tracked module can be purchased ready-made or assembled independently. To implement the second option in the vastness of the World Wide Web, you can easily find drawings and video instructions for assembly and installation.

High-quality purchased and competently hand-made devices are characterized by increased strength and durability. Do not forget about the simplicity of installation, operation and maintenance. To install a purchased platform of any configuration and complexity, no special knowledge and technical means are required. Basic skills and a minimum set of tools will be enough. The installation of homemade units has a number of nuances. It should be borne in mind that a platform that is too high shifts the center of gravity of the entire machine, which in itself negatively affects its stability. As a result, the risk of the walk-behind tractor overturning on the off-road and when performing maneuvers is significantly increased. To increase stability during the installation of tracks, an additional axle must be placed higher.

In addition, the width of the axles must be taken into account. Experienced owners advise increasing the wheelbase if necessary. If a differential is not available, a pivoting jib can be used as an effective alternative. This triangular device will have a positive effect on the maneuverability of the tracked walk-behind tractor.

When choosing, purchasing, manufacturing and installing a tracked drive, it should be borne in mind that such an upgrade is not relevant for air-cooled models. This is due to excessive load on the power unit.

Requirements for converting equipment to caterpillar tracks

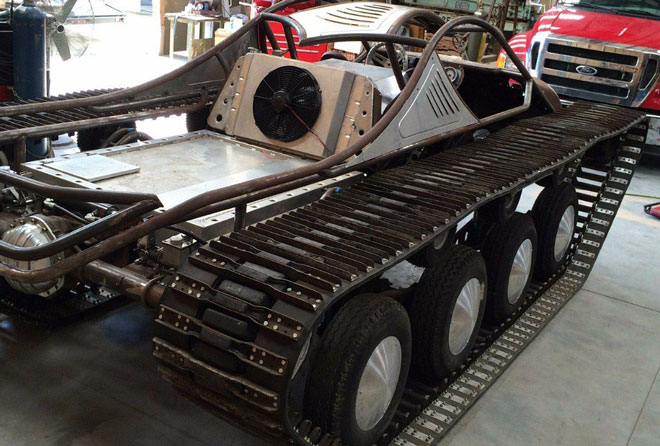

The figure shows the simplest homemade product - a cart with tracks made of tires.

Retrofitting of equipment at the main engine house is carried out exclusively for utilitarian considerations of pragmatic owners of wheeled vehicles or motor vehicles, who wished to improve the all-terrain qualities of their "assistants".

For all models of equipment designed for driving in the field, the market offers serial versions of industrial-made main engines.

However, all of this costs a lot of money, and tires are free or very cheap.

Regardless of the type of car or motor vehicle, the craftsmen take into account the following factors:

- To install the main engine mechanisms, it is necessary to equip special frame structures of increased strength and rigidity, capable of withstanding increased weight and dynamic loads.

- When using improvised means, many craftsmen use pneumatic wheels as tensioners, as well as a pair of driving and driven wheels. The tape is put on the flat wheels, which are then inflated, creating the required track tension.

- The owner of the equipment must clearly determine the purpose of the machine in order to select the optimal dimensions of the width and length of the track.

- Taking into account the increase in the weight and traction loads on the engine after the installation of the main engine, it is necessary to optimize the correspondence between the maximum engine power and the track width. Otherwise, the engine will quickly fail.

When choosing the ratio of engine power and belt width of a homemade tracked installation, you can be guided by the data of the price lists for all-terrain vehicles equipped with serial tracks.

Below we will consider the categories of machines that are most popular among craftsmen when converting to a caterpillar track.