Manufacturers of tracked equipment for the Neva walk-behind tractor

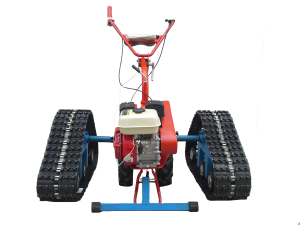

At the moment, there are a large number of different tracks for walk-behind tractors on the market. They are all similar in design, but may differ in track dimensions, number of rollers, quality of materials and operating principle.

Domestic snowmobile modules include:

- Lynx;

- Ant;

- Buran.

From foreign models, the products of the manufacturer Talon are in demand, and its models: Talon 380, Talon WT and others.

All these models are simple and reliable to operate. But for long-term and correct use, a few simple rules should be followed:

- Check the track tension periodically. When weakening it, it is necessary to tighten it immediately.

- All gears and rollers must be lubricated regularly for smooth running.

- Before each ride, visually inspect the condition of the tracked module.

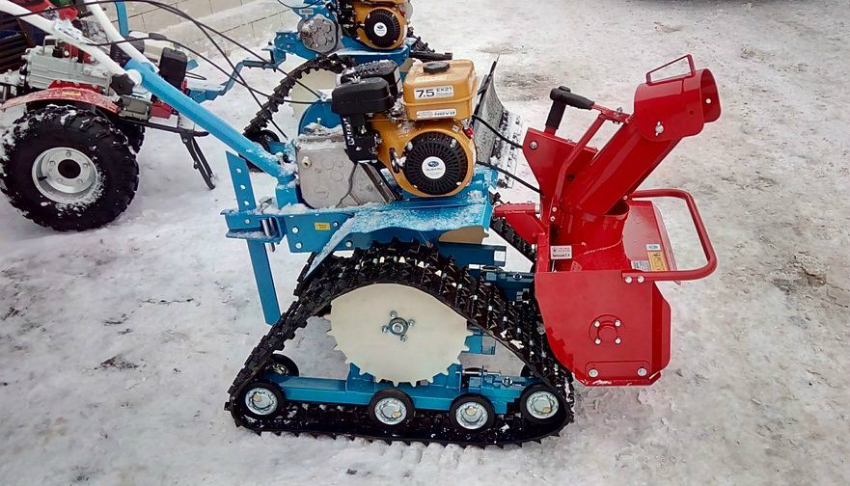

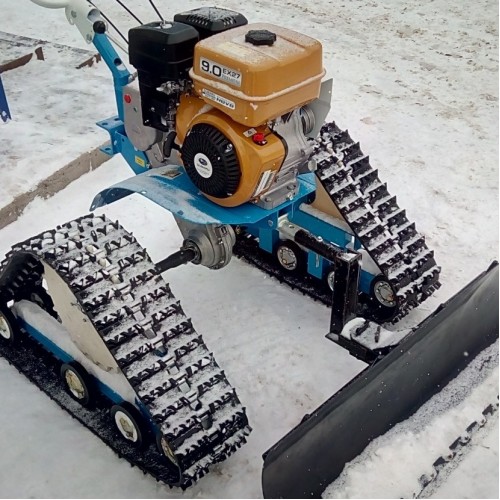

The track module is perfect for use on any surface, including asphalt:

About manufacturers and features of devices

Before choosing a specific brand, it must be clearly stated: the set-top box is always supplied pre-assembled at the factory. This eliminates bugs and problems caused by self-assembly.

The differences between the individual models concern:

-

the size of the tape with caterpillars;

-

characteristics of materials;

-

the number of clips;

-

start-up methods.

Among Russian firms, Muravei, Lynx and Buran have proven themselves to be excellent; from foreign suppliers Talon should be preferred.

You can put rubber tracks on the Neva walk-behind tractor for about 28,000 rubles.

If you mount the driver's seats, you can bring the structure closer to the tracked mini tractor. If the design is deprived of the ability to add a driver's seat, it will cost a little less.

Despite the weakened functionality, such propellers work quietly in winter conditions. They confidently overcome both off-road sections and snow strips. A big problem is the relative high cost of structures. Often they struggle with it, trying to make caterpillars with their own hands.

How to make a tracked module for a walk-behind tractor with your own hands?

The cost of materials for making a caterpillar with your own hands is much lower than buying ready-made equipment. Therefore, you can try to assemble it yourself.

Here are the most common options for such models:

Manufacturing from car tires.

In this case, they all turn out to be of a fixed width. Often they have to be manually adjusted to the correct size. This is a time consuming procedure. However, the end result is a solid model.

Grousers with belts

This is a very simple option when several grousers are connected with one tape. This design is easy to manufacture, but not reliable enough. Because the connecting tape often breaks.

Steel plate chains

This is a very cheap version of tracks, and anyone can make them. After all, consumables are almost always at hand.

Conveyor belt and bush chain with rollers

This is the most popular option. It can be applied at any time of the year. This type of tracked module is very easy to manufacture, but the connections are not very reliable.

The option should be chosen based on what functions the tracked module will perform, and what is the power of your walk-behind tractor.

For small powers, simple structures can be used, they can withstand standard loads. But for more powerful units, you should use more durable models.

Popular factory models

This agrotechnical equipment is produced by both domestic and foreign manufacturers. Let's list some models:

Track attachment Talon 380

Specifications:

- track height - 300 mm;

- track width - 190 mm;

- total length - 1035 mm;

- total width - 680 mm;

- track track - 300 mm.

Track module Talon WT for walk-behind tractor

Specifications:

- The nature of the engagement - pin

- Number of steps - 62

- Track weight - 34 kg

- Dimensions:

- Length - 154 ″ (3886 mm)

- Width - 20 ″ (500 mm)

- Pitch - 2.86 "(73 mm)

- Grouser Height - 1.25 "(32mm)

Tracked drive "Lynx-500"

Tracked drive "Lynx-500"

Specifications:

- Length: 3937mm.

- Width: 500mm.

- Grouser height 22.5mm.

- Manufacturer Composite.

Motoblock tracked attachment "Buran"

Motoblock tracked attachment "Buran"

Specifications:

- Length: 3686 mm.

- Width: 380 mm.

- Grouser height: 17.5 mm.

- Manufacturer Composite.

Attachment "Ant" to the walk-behind tractor

Attachment "Ant" to the walk-behind tractor

Specifications:

- The nature of the engagement - pin

- Number of steps - 44

- Track weight - 7.7 kg

- Length - 2222 mm

- Width - 220 mm

- Pitch - 50.5 mm

CAM track attachments

CAM tracked attachments are aggregated with almost all motoblocks of domestic and foreign manufacturers.

Specifications:

| Parameter | Meaning |

|---|---|

| Manufacturer | "SAM" Nizhny Novgorod |

| Manufacturer country | Russia |

| Applicability | Chassis |

| Compatibility | Motoblocks |

| Suitable for | MB Favorite, Skif |

| Working speed | 15-18 km / h |

| Length | 1000 mm |

| Height | 340 mm. |

| Width | 600 mm. |

| The weight | 37 kg. |

Specifications:

| Front attachment weight without propeller: | 37 kg. |

| Movement speed: | 15-18 km / h |

| Fuel consumption: | 1.5-2 liters per hour |

| Towed weight: | 200 kg. |

| Complete assembly time: | 10 minutes |

| Turning radius: | 2 meters |

Specifications:

| Parameter | Meaning |

|---|---|

| Manufacturer | "SAM" Nizhny Novgorod |

| Manufacturer country | Russia |

| Applicability | Chassis |

| Compatibility | Motoblocks |

| Suitable for | Agate, Salute, Tarpan, Omich. |

| Working speed | 15-18 km / h |

| Length | 1000 mm. |

| Height | 340 mm. |

| Width | 600 mm. |

| The weight | 37 kg. |

Specifications:

| Track length | 2222 mm |

| Caterpillar manufacturer | OOO NPO Kompozit, Kursk |

| Track width | 220 mm |

| Carrying capacity: | 200 Kg |

| Maximum fuel consumption: | 1.5 - 2 l / h |

| Dimensions: | 1000 * 600 * 340mm |

| The weight: | 37 kg |

Specifications:

| Front attachment weight without propeller: | 37 kg. |

| Dimensions without mover: | 1000x600x340 mm. |

| Movement speed: | 15-18 km / h |

| Fuel consumption: | 1.5-2 liters per hour |

| Towed weight: | 200 kg. |

| Complete assembly time: | 10 minutes |

| Turning radius: | 2 meters |

| Dimensions in packing: | 75x400x200 + 2 tracks |

Specifications:

| Build time | 10 minutes. |

| Speed | 15-18 km / h |

| Carrying capacity of the towed sleigh | 200 kg. |

| Turning radius | 2 meters. |

| Track width | 220 mm. |

| The weight | 37 kg. |

We offer a table of correspondence between CAM track attachments and motoblock brands:

| Modification of the attachment | List of compatible motoblocks or cultivators |

| SP-MB-1 | OKA, KASKAD, LUCH, FORZA, |

| SP-MB-2 | NEVA |

| SP-MB-SP-PN | PATRIOT, DOCOTA, NEVADA |

| SP-MB-S | SALUT, AGATE |

| SP-MB-U | URGA |

| SP-MB-F | FAVORIT, SKIF |

| SP-MB-Ts | TSELINA |

What materials are required

Converting the wheel modules into tracks requires a powerful engine. It must have an axis block. Power is important, since the walk-behind tractor will be driven by machinery on difficult roads. Without improvement, getting good maneuverability is unrealistic. Basic building materials that are required:

- Motoblock machine with gearbox, 4-stroke motor, axle unit option.

- Several additional wheels to put on the caterpillar.

- The track attachments themselves.

Depending on the building material used, two good diameter tires and a conveyor belt may come in handy. If you include a platform here, you get a compact tractor.

On a note! An additional platform will allow the vehicle to be used as an all-terrain vehicle when moving on a snow-covered track.

When choosing building materials to make tracks on a walk-behind tractor with your own hands, it is important to take into account that it should not be heavy. The motoblock machine is not equipped with a powerful engine, it simply cannot cope with a heavy load and will break. Tracked modules are made from:

Tracked modules are made from:

- Motorcycle tires.

- Chains.

- Tubes.

- Belts.

- A conveyor belt in symbiosis with a bushing-roller chain.

Usually, attachments for a walk-behind tractor are made from car tires - these elements can be converted without problems. It is correct to take tires of large trucks, taking into account the existing tread pattern, shape, because the pattern will improve grip. Tractor tires or elements from other large machines are perfect.

The tread pattern can provide full contact with both wet ground, and with an icy road, with a snow-covered track. In addition to materials for the tracked module, to create a full-fledged device, a walk-behind tractor with a gearbox is required, as well as several car wheels. If necessary, fix the trolley and, if you want, even on runners to carry significant weights through the snowdrifts.

Tips for use and after

When using tracked modules for a walk-behind tractor, you should fully check, carefully look at how high-quality the chain tension is, and also systematically treat the elements whose friction occurs when the walk-behind tractor is moved with machine oil. In addition, each time before use, it is necessary to check whether breaks have appeared on the chain.

After operation, it is also necessary to check the equipment and tracks, carry out an inspection in order to timely find damage or broken load carriers.

Using a motoblock structure, it is important not to allow arrivals to the rhizomes of age-old trees and rocky embankments, as well as stumps, otherwise the caterpillars will burst

Note! In order for the caterpillar base to the motor cultivator to serve as long as possible, it is important to guarantee the module comprehensive comprehensive care.

Necessary:

- Monitor the level of regulation and chain tension.

- Externally, look so that when riding on a technical apparatus, the chain is solid.

- All contacting parts, mechanisms must be coated with machine oil.

Elementary care recommendations will help to reduce to zero the risks of failure of ready-made motoblocks and, in particular, a tracked unit. The motoblock machine on tracks will become a powerful assistant for the implementation of tasks.

Connecting tracks to a walk-behind tractor makes it possible to significantly change maneuverability and cross-country ability. This leads to an increase in the range of potential operations that the machine can handle. The tracks outperform traditional wheels in some positions. Regarding the reworking process, it is quite simple for itself, but you need to have experience, knowledge, prepare materials and tools, if you wish, attentive attitude to the work, the task set, everything will definitely work out.

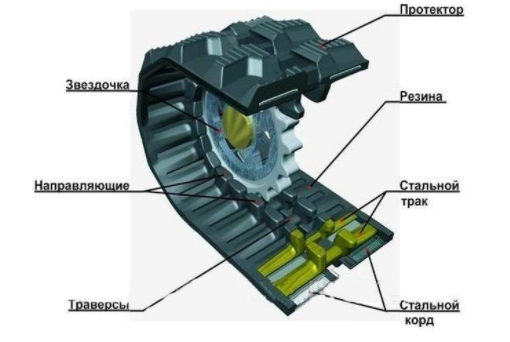

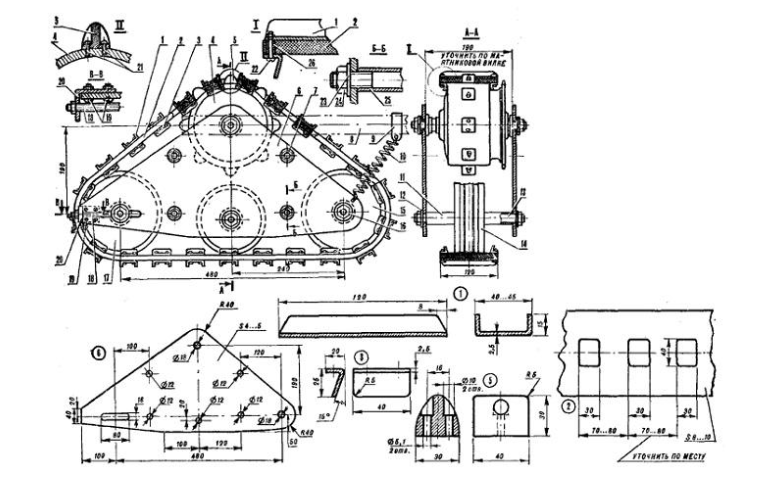

Track module device

At the moment, there are two options for manufacturing a tracked module. What are their designs and features?

First option

The track module is an axle. At the bottom, 4 rollers are connected to this axis. These rollers are used to create tension on the track.

Tracked module for motoblocks Neva

There are 2 gears on the left and right edges, which fall into the grooves of the tracks and serve to tension the tracks and bring the module into motion. The gears move in a horizontal plane using a special frame, which, after installation, is fastened with bolts.

On one side, a gear transmission is welded to the shaft with gears.

By means of a chain, the articulated transmission drives the entire track assembly.

The track has V-shaped inserts. These rates should be set with the V point in the direction of the walk-behind tractor.

Second option

This design has a slightly different appearance. Instead of wheels, a large gear is installed, which is attached to the axle, and at the bottom of the frame there are 8 rollers (two on each side of the belt). They keep the track taut and allow the Neva walk-behind tractor to move without interruption.

The track attachment is sold ready-made.This eliminates the need to assemble it on site. And you can exclude breakdowns associated with incorrect assembly.

It is sold disassembled, how such a tracked module for the Neva walk-behind tractor looks and works in general, look at the video: