How to install

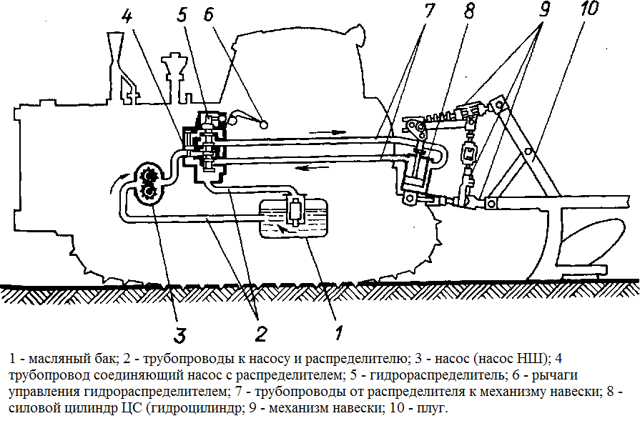

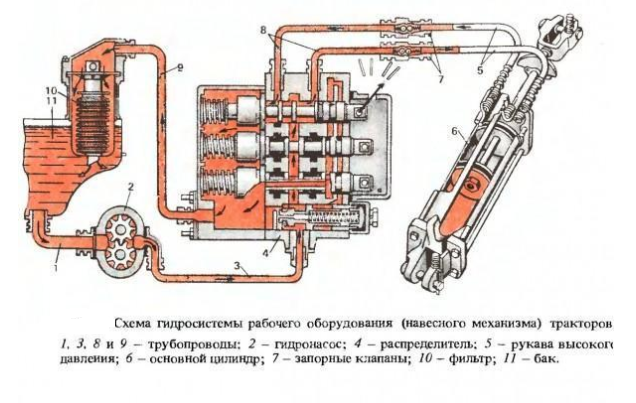

When all the components are purchased, it remains to assemble the mini-tractor, in the process of which all the elements are connected. To do this, the engine must be connected to the purchased hydraulic pump. Further from it, the tubes are connected to a distributor, after which they are directly connected to equipment in the form of pistons, motors, as well as a hydraulic tank connected to a pump. In this case, between the tank and the pump, it is required to put filters necessary for cleaning the oil.

Upon completion of the installation, a check of all systems should be carried out. If problems are identified in the work, all hoses are examined for integrity, as well as the tightness of the connections. When all is well, the unit is tested during a test drive. At this time, the steering hydraulics function is corrected, as well as movement, in the presence of deviations. A floating steering system should be excluded.

How to make hydraulics

The use of such a mechanism on a mini tractor allows you to get a number of advantages.

But the most important thing is that it ensures the stable functioning of additional elements.

Self-assembly of such a structure is very simple, it is important to have a sufficient level of technical knowledge, as well as to strictly adhere to the scheme or drawings. To collect such a device, you need to prepare a number of tools and parts.

The very sequence of work in this case is as follows:

- First, drawings of the future structure are created.

- All required parts are being purchased.

- They are being installed, as well as the installation of the hydraulics itself.

- After that, the parts are calibrated, and the performance of the structure is checked together with the transmission.

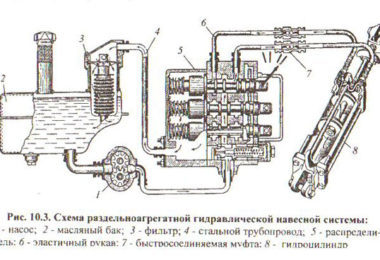

According to its scheme, do-it-yourself hydraulics for a mini-tractor consists of the following elements:

- Hydraulic tank where oil is poured.

- Power point.

- Hydraulic pump as well as distributor.

- Connecting hoses.

- Special hydraulic motors as well as pistons.

Sometimes, to supplement, various filters are mounted that change pressure indicators and other data. This prevents possible contamination of the pump as well as the power plant from contamination.

In the process of drawing up a diagram of a future design, it is important to consider:

The hydraulic pump must be placed under the tank

This allows the oil to flow under gravity, which reduces hydraulic problems during start-up.

For the correct functioning of the mechanism for a long time, it is important to first calculate the power of all the combined elements in the unit. It is taking these data into account that the hydraulic pump itself should be selected.

When the power of one is not enough, an additional installation of an auxiliary element is required. The latter will start working when the maximum loads in the system are reached.

To ensure continuous and trouble-free operation of the unit, sensors must be installed that measure the pressure level in the system, as well as filters designed to clean the oil.

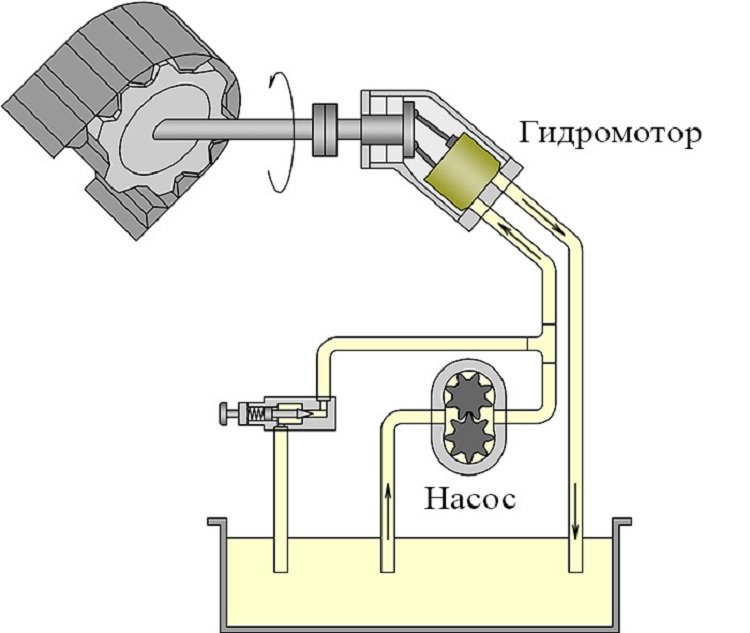

In order for the fluid to fulfill its role in the system, it is important that it is constantly in motion. A similar function is performed by a hydraulic pump that distills oil throughout the entire system.

The power plant connected to it transmits torque, thereby activating the fluid exchange mechanism. The pump itself is connected to the distributor.Based on the position in which the lever is located, the oil returns to the tank or it goes in the other direction to the hydraulic motor or pistons.

As a result, due to the high density of such a liquid, it allows for heavy traction movements. In the form of an engine for such a unit, various options are used, from electric to diesel.

An important condition is the need to provide sufficient power for the operation of the hydraulic pump for the mini tractor.

Selection and purchase of parts

The need for such a system is due to the simplification of the functioning of the pistons, as well as the easier movement of the unit. To avoid problems during soil cultivation, a hydraulic system is used, because the mini tractor itself has insignificant traction properties. As a result, it is required to purchase the necessary elements, refine the design, and then assemble the device. You can buy structural elements individually or already in a complex

It is important that each group of pistons has its own lever. For small units, 3 levers are sufficient:

- For braking.

- For frame control.

- For starting hydraulic motors.

In advanced models, valves are used, equipped with additional functionality. However, the price for such options is significantly higher than classic products. The selection of the purchased hydraulic pump is carried out based on the following parameters:

- The pressure level required to start the power plant. If this is insufficient, the hydraulic motor simply will not start working.

- Pumping speed, measured in l / min. Determines how fast the pistons and motors will function.

How to install hydraulics on a mini tractor?

The hydraulics are installed on the mini-tractor in order to move the unit and maintain the operation of the pistons. To eliminate possible complications when plowing the soil, it is required to use hydraulic motors. After all the parts for work are purchased, you can connect the hydraulics to the mini tractor.

This procedure is performed in this order:

- The first step is to install hydraulic valves. A separate lever must be allocated for each piston group. In most cases, 2-3 levers are enough, the first of which is necessary for braking, the second for controlling the power frame, and the third for starting the hydraulic motors. For excavators and other mini tractors with buckets, hydraulic valves with extended functionality should be used. Their prices are much higher than conventional mechanisms;

- The hydraulic pump must be selected with several important characteristics in mind. The first of these is the pressure required to start the hydraulic motor. If the pressure is too low, the motor will not start. The second important characteristic is the volume of the pumped oil. The more oil the pump pumps per minute of operation, the higher the speed of the hydraulic motors and pistons will be. The selected pump should be installed under the oil tank;

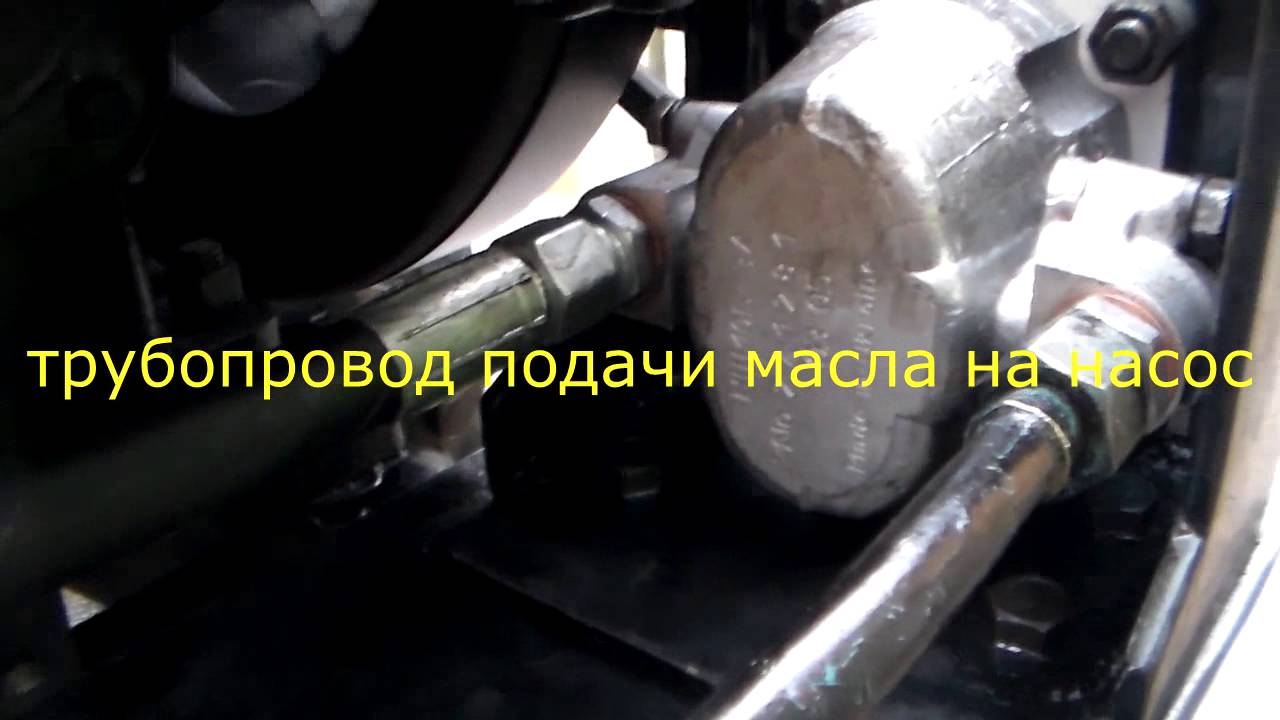

- After that, a hydraulic pump must be connected to the standard engine of the minitractor, the pipes from which must be connected to the distributor. From it, oil pipes should be drawn to the motors and pistons, as well as the hydraulic tank;

- The filter element will need to be installed between the hydraulic tank and the pump. A video will tell you in more detail about connecting the elements of the hydraulic system.

»As soon as the installation of hydraulics on the mini-tractor is completed, you will need to check the operation of the assembled structure. If a sufficiently high pressure is not generated inside the system, then you need to make sure that the pipes and hoses are tight. After that, you can start testing the hydraulics directly while driving on a minitractor.

>

Manual hydraulic valve

The hydraulic drive is better suited for the tracked all-terrain vehicle, but can also be used on. Rotation by means of a hydraulic cylinder is used on vehicles with a frame of two halves interconnected by a cardan-type hinge. For control, the front half is deflected, the hubs of the front and rear wheels are rigidly mounted on the axles.

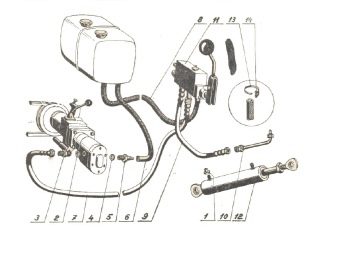

The hydraulic circuit uses:

- a lever mounted on a hydraulic distribution unit (it is possible to use a steering hydraulic distributor with the installation of a classic steering wheel);

- pump (type NSh-10);

- a reservoir for storing a stock of oil (required for a number of valve models);

- hydraulic cylinder;

- flexible lines for supplying fluid from the pump to the distributor;

- rubber pipes connecting the valve and the slave cylinder.

When installing the pump, take into account the design feature - the absence of bearings. Because of this, the device cannot withstand radial loads.

The drive is carried out directly from the motor shaft or via an intermediate shaft mounted on a pair of ball bearings. The installation of the pump increases the starting forces, since it is necessary to turn the shaft of the additional mechanism.

The operation of the distributor is based on the principle of passing or stopping liquid by valves. Tilting the lever or turning the steering wheel moves the spool valve forward or backward. The spool opens the channels, and the working fluid is supplied under pressure to one or another chamber of the slave cylinder. This ensures the operation of the hydraulic cylinder in two directions. The flow rate is changed by adjusting the valve. The distributor can be equipped with additional sections, in this case the device is suitable for controlling additional hydraulics of a mini tractor.

How can you make hydraulics on a walk-behind tractor

Consider the advantages of a walk-behind tractor with a hydraulic drive:

- simplified management;

- the ability to connect attachments with a hydraulic drive: seeders, mowers, harvesting devices;

- improvement of the braking system.

Homemade hydraulics for a walk-behind tractor will help to perform braking by reducing oil intake. When the load sharing handles are in the inoperative position, the wheels can be completely locked.

To make hydraulics on a motor-cultivator, you need an oil pump with a high level of consumption of the working medium and medium pressure. This pump will act on hydraulic motors.

They are installed on the steel frame of the walk-behind tractor, which must be made from a rectangular pipe. The hydraulic motors should be installed as close to the drive axle as possible to drive the rear wheels.

To determine in which direction the rotation will occur, you need a distributor. For this, you can use used parts and components of the tractor "Belarus".

The oil is supplied by means of a spool. In the middle of the device, a special swing sleeve for the front axle is mounted. This design will avoid the need for a cardan shaft.

Thus, the front wheels will change the way they work. When turning the cultivator, the track width changes, the front axle is responsible for this in the system. For this reason, it is made independently.

As axle shafts with pivots in the cultivator on the right and left, swivel columns are mounted. Then you need to synchronize the installation of the rims and disks. Their relative position should be offset.

After installation and connection, it is necessary to check the operation of the entire structure. If any parts do not function well, then you need to check all connections for leaks. Then, after eliminating all the flaws, they turn on and check the operability of the walk-behind tractor with a hydraulic control system again.The steering and travel hydraulics should also be adjusted.

Hand-made hydraulics for a motor-cultivator will reduce the efforts to cultivate the land and optimize all agricultural processes.

Making a device such as hydraulics on a mini tractor with your own hands is a good solution to save money and get more performance from the device. Mounting and creating a new system is not something particularly difficult, and for those who like to do something with their own hands, this will be a great reason to dream up and make their own version of hydraulics.

Prophylaxis

To ensure efficient operation of the hydraulic system of the tractor, it is necessary to follow the rules of operation and timely maintenance.

When working with equipment equipped with hydraulics, you should regularly check its components for faults. Small-scale breakdowns will inevitably lead to the failure of the rest of the system. If you find one, you must immediately apply all available means to eliminate it:

do not exceed the prescribed load on the hydraulic pump, hydraulic cylinders, oil hoses and other components;

avoid excessively high pressure indicators, if necessary, release it in a timely manner or select a suitable control valve;

to maintain the stable operation of the hydraulic mechanism, it is important to change / add fluid to the system in a timely manner: an insufficient amount of it will lead to a decrease in operating efficiency and a rapid failure of the unit;

all maintenance and repair work of the system should be performed with the tractor engine off (to “cold”) after the pressure has been released.

Table of common faults in hydraulic systems and how to fix them:

|

Malfunctions and their causes |

Remedy |

|

Fault: low lifting and pushing force of hydraulic cylinders or its complete absence. Reason: the oil level in the system has dropped. |

Add oil. |

|

Oil with unsuitable characteristics has been used. |

Change the oil to a suitable one. |

|

Oil filter or hydraulic cylinder dirty. |

Replace or wash the filter element. |

|

Air in the system. |

Purge the system - remove air, identify the point of its entry and eliminate it. |

|

Fluid leaking from worn oil seals. |

Replace oil seals with new ones. |

|

The work of the relief valve, pressure is broken - jamming occurs in the open position. |

Flush / purge the valve. Replace if necessary. |

|

Malfunction in the valves of the directional control valve. |

Replace valves or their parts, if necessary replace the entire block. |

|

Leaks at the docking points of the system. |

Check for leaks, found to be eliminated by crimping, tightening, installing clamps, replacing. |

|

Defective piston or hydraulic cylinder seals. |

Check hydraulic cylinder for pressure leaks. Replace oil seals, piston. If necessary, change the unit as a whole. |

How to install hydraulics on a mini-tractor with your own hands, see the next video.

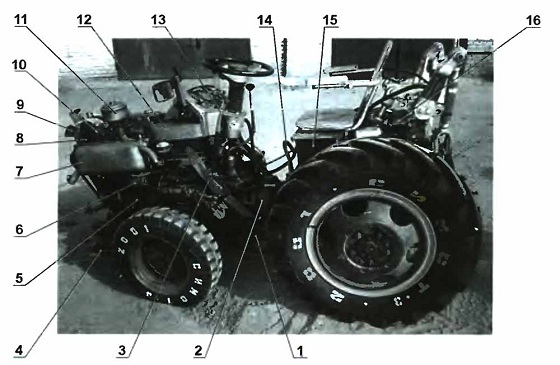

Mini tractor hydraulics device - design and principle of operation

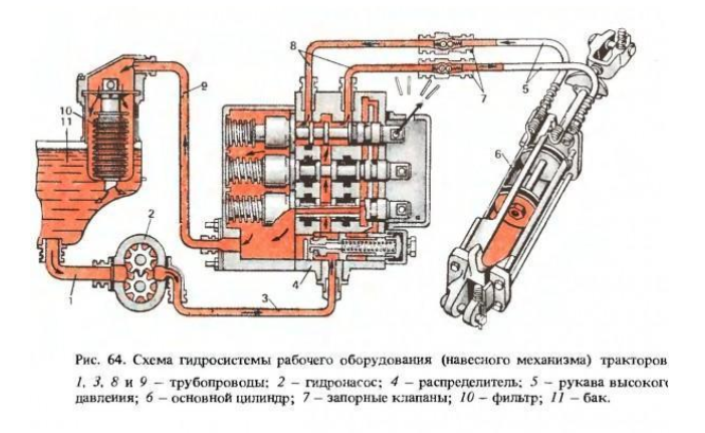

The hydraulics of a modern mini-tractor is a whole complex of elements and mechanisms that transform the energy of the engine of the unit and transmit it to the executive links. This principle of operation provides the farmer with the ability to control trailed, mounted and semi-mounted implements, as well as adjust the operation of the devices used by changing the depth of the track, lifting the frame and other settings.

Oil circulates inside the hydraulic system of the minitractor - the main working fluid, the function of which is to convert energy and transfer it to the executive links.

Other elements that are required for the stable operation of the mini tractor hydraulics include:

- a pump with a drive and a switching mechanism - this unit is necessary to create and maintain the optimal pressure inside the system for its operation;

- oil filling tank - this container must be of such dimensions that a sufficient amount of working fluid is placed in it;

- filter element - required for continuous oil purification and protection against breakdowns of rubbing hydraulics mechanisms;

- pipeline system - the oil circulates through the pipes from the reservoir to the executive links and vice versa;

- hydraulic distributor - plays the role of an element that directs oil to the final working link. The second function of the valve is to switch the entire hydraulic system to idle. In case of excess loads on the system, the valve reduces the operating pressure in the pipeline;

- hydraulic cylinder - this element receives oil from the distributor. It is necessary for raising and lowering the attachment used;

- hydraulic motor - this mechanism is connected to the wheels of the minitractor;

- valves, shut-off couplings, bends, hoses and coolers are consumables that most often need to be replaced.

The design of the mini tractor hydraulics is quite complex

In this regard, before assembling a homemade hydraulic system, it is extremely important to study the diagrams in detail and take into account all the subtleties of manufacturing the device.

How to make hydraulics on a Neva walk-behind tractor

When converting a heavy Neva MB-23 walk-behind tractor into a mini-tractor, equipping it with a hydraulic system will significantly increase productivity and facilitate control.

In the video below, the master shows the option of making hydraulics with his own hands.

What materials and devices will be required for this:

- hydraulic valve Р80-3 / 1-22 or Р80-3 / 1-222 (the unit can be purchased at disassembly of the MTZ tractor), to the levers of which the shift knob is attached through the transition rods;

- hydraulic pump NSh-10, which can also be removed from an old tractor;

- an oil tank with a filler neck, welded from steel sheet according to individual dimensions, the volume of which should be about 3 liters;

- oil filter (a part from a VAZ 2106 "Zhiguli" car is suitable);

- drive for connecting NSh-10, made of separate parts independently (bearings, splined shaft, single or double-grooved pulley, belt, flange, fasteners and a steel platform 3-5 mm thick for installing the unit on the body of the walk-behind tractor);

- 2 hydraulic cylinders T-40 for connecting the front and rear hitch (they can also be found at the tractor disassembly, or you can buy new ones in the agricultural equipment store);

- system connection hoses.

The connection is carried out in the same way as the above method.

Is hydraulics installed on your agricultural machinery?

From general to specific

Read

When every millimeter counts. Photo fact

There are two most common methods for creating a mini excavator with your own hands: you can install attachments on a small tractor or build an autonomous self-made mini excavator that can move independently or with the help of other transport. The second option is more time consuming. It is necessary to make the frame yourself, install at least the rear axle (you can use it from the old car), the engine. If you feel technically savvy, you can combine engine parts or use Chinese motors from different manufacturers. Just keep in mind that in the case of assembling parts from different machines, you will have to constantly adjust these parts and make improvements to them.

How to do it?

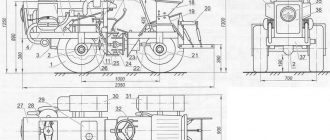

The work on creating your own hydraulic system for a mini-tractor begins with the design of the future structure and calculations aimed at optimizing the ratio of expended resources and efficiency.The power of the tractor must correspond to its intended purpose, and the technical characteristics of the hydraulic system units are proportional to the loads applied to them.

Insufficient power of the oil pump or low coefficient of permissible load on the hydraulic cylinders can lead to rapid failure of the entire system or individual components. An overestimated level of these indicators will increase the consumption of fuel and other resources, and create an imbalance in the system. To compensate for the difference in technical characteristics and equalize the balance, additional names are installed: the second pump, hydraulic cylinder and others.

In the drawing, it is necessary to reflect the design of the supporting frame, which will include a place for a pump, a distributor, pistons and other additional elements, as well as a hydraulic circuit connection diagram. At the same time, its configuration should be optimized so that the distance from the engine output shaft to the nearest point of transmission of the power of the hydraulic system is minimal.

The pump is installed as close to the drive shaft as possible. The reservoir with the working oil is located above it, which provides a free flow of fluid to the pump blades and reduces the leakage coefficient of useful mechanical energy. A filter is installed between the fluid reservoir and the pump. Its presence extends the smooth operation of the entire system.

By means of reinforced hoses, the pump is connected to a hydraulic valve, which is equipped with control elements. There may be several of them, depending on the functionality of the hydraulics. Since in order to maintain pressure in the system, the oil must continuously circulate through it, the distributor regulates the direction of its movement and supply to the cylinders, and also cuts off the flow at the moment of idle operation. The distributor controls are special levers supplied by the manufacturer with it.

After mounting the distributor, the hydraulic cylinders are installed on the working part of the frame. These elements can be represented by special piston units designed for use in the hydraulic system. In other cases, they can be made independently from oil-type automotive shock absorbers.

Attachments are installed on the tractor in conjunction with hydraulic cylinders - moving parts of the system that transmit mechanical force to it. The design of the fastening mechanisms is determined by the type of equipment, its actual configuration and the nature of the targeted work performed with its help.

The assembled hydraulic system must be equipped with technical assemblies and isolation means that require their mandatory installation. Among them are:

- drain unit in the hydraulic tank;

- pressure relief valve in the tank;

- pressure sensor;

- shut-off valve;

- drain from the pump and hydraulic valve;

- fine filter elements at the inlet to the hydraulic cylinders;

- sealing rings, washers, gaskets, nuts, clamps.

Before starting work, the entire system is configured.

The working diagram of the hydraulic equipment for a mini-tractor is shown in the diagram:

Hydraulics for a mini tractor is an indispensable element of an agricultural machine, the main function of which is to ensure the ability of the unit to work with different types of attachments. Almost every modern mini tractor is equipped with a hydraulic system, but there are still models on the market that do not have it in the configuration. In this case, you can assemble the hydraulic system yourself. Homemade hydraulics will significantly expand the functionality of the mini tractor, and will allow you to use it not only in the field, but also in the local area.

How to make hydraulics on a homemade tractor?

Despite the complexity of the device, the hydraulics for the tractor can be manufactured independently.To do this, the operator will need to be as careful as possible, since for the well-coordinated operation of the assembled mechanism, it is necessary to make accurate calculations and act strictly according to them.

A home-made mechanism gives the tractor driver important advantages:

- the ability to operate additional attachments, including a trailer;

- improving the braking performance of the tractor;

- increased handling both on a flat road and off-road;

- individual components and the general hydraulics device can be adjusted as it is convenient for the operation of a specific person.

All this will make the practical use of agricultural machinery with hydraulics not only convenient, but also more effective, regardless of the work performed.

It is important to adhere to the drawings for self-assembly of the hydraulic system on the tractor. They need to describe not only the dimensions and characteristics of the components, but also the sequence of their installation.

In the future, tractor hydraulics should be assembled in the following sequence:

- First you need to make a solid frame. All hydraulic elements will be attached to the supporting structure. In order for the frame to be subjected to minimum loads, the nodes used must be installed as close as possible to the axial center. This will improve balance and reduce vibration to the supporting structure;

- After that, you need to fix the hydraulic oil reservoir. If it is plastic, then it can be fixed with clamps. If the tank is metal, then it is better to weld it to the frame;

- Then you will need to install an oil pump. It should be located above the tank. Thus, the pump will have free access to the working fluid and will be able to ensure a stable start of the entire system;

- During the manufacture of a hydraulic system for a tractor, it is necessary to correctly calculate its performance. Thus, the manufacturer will understand whether a more efficient 2-section pump needs to be installed;

- After installing the pump, the filter elements must be fastened. There should be several of them - at the outlet from the oil reservoir and at the point where the fluid is supplied to the cylinders. The more filters, the more difficult it is to service the hydraulics. However, with an increase in their number, the service life of a homemade system will increase;

- At the end, pipes will need to be pulled between the hydraulic units. They must be made of a material that is resistant to oil components. It is best to choose tubes made of technical rubber. Fasten the pipes to the outlets and inlets using clamps. More details about the manufacture of hydraulics for a tractor for a tractor can be found in the video.

How to make a hydraulic system for a mini tractor with your own hands

Farmers who decide to make agricultural machinery on their own are interested in how to make hydraulics for a mini tractor. This question is due, among other things, to the significant high cost of ready-made equipment offered on the market. The popularity of such homemade products is also due to the fact that all the parts necessary for assembling the hydraulic system of the tractor are available to everyone. Also, the system diagram is published on the Internet in the public domain, which also makes the manufacture of equipment much easier.

DIY made hydraulics for a mini tractor gives the farmer three main advantages:

- Additional equipment can be used, including a trailer.

- Better braking system.

- The most convenient control.

- All elements are adjusted taking into account the needs of a specific person, who will subsequently operate the tractor and supervise the conduct of all work. This is what will make the tractor the most comfortable to drive.

Consider how to make hydraulics on a mini tractor with your own hands. A device such as hydraulics for a mini tractor involves drawing up a competent diagram and preparing all the necessary elements for assembly.One of the key elements is a powerful oil pump, with the help of which the hydraulic system on the mini tractor will be influenced.

In addition, you need to prepare in advance a distribution element that will help change the direction of rotation, several hoses, a tank and a special element for removing oil.

Assembly steps:

- The hydraulic pump must be positioned above the tank so that it has free access to the oil supply and ensures a quick start of the system.

- It is imperative to calculate the power of operation of all elements of the equipment, so that you can understand whether it is worth installing a hydraulic pump equipped with two sections. This will make the work uninterrupted, even if the loads are very heavy.

- Oil cleaning filters will make your hydraulic attachment system last longer.