Advantages and disadvantages of using a wood splitter

Before making any unit with your own hands, you should ask yourself whether it is necessary on the farm. Buying or making a device yourself will require a lot of financial costs and efforts, you need to weigh all the advantages and disadvantages. The advantages of the device include.

- Physical activity on a person. The operator of the machine only makes loading, controls the process, the main physical work is performed by the wood splitter mechanism.

- A device that includes an electric drive will cope with the assigned tasks faster than doing the work manually.

- Convenient use preserves health and physical strength.

- Ease of operation, lack of use of physical force make it possible to use the mechanism for all types of people.

Using the wood splitter

There are noticeably fewer drawbacks during operation, but still they are present, as with every device.

- Complex construction of some models. For a more even log, the end result is a hydraulic log splitter. Making such a mechanism at home with your own hands is expensive and will take enough time.

- The high cost of finished structures. Buying a ready-made wood splitter will save time for manufacturing, but the cost of some models is so high that it does not justify itself during the process of use.

It is necessary to understand that for a small area, the purchase of equipment is not advisable. Having a clear purpose and the constant sale of firewood, you should think about buying or making a wood splitter with your own hands.

Screw (cone-shaped) machine

A common model for harvesting firewood in small volumes is a machine with a cone splitter, into which a thread can be additionally cut, the propeller is an electric or gas engine. Such an apparatus splits the lumps due to the rotating cone that breaks the wood, and the mechanical pressure exerted on the workpiece by a person.

A common model for harvesting firewood in small volumes is a machine with a cone splitter, into which a thread can be additionally cut, the propeller is an electric or gas engine. Such an apparatus splits the lumps due to the rotating cone that breaks the wood, and the mechanical pressure exerted on the workpiece by a person.

You can buy the cutting part or grind it yourself if you have the skills of a turner. Remember that the presence of a thread will make it easier for you to work with a wood splitter, so it is advisable to cut it (we recommend the left thread). The depth of the thread is 2-3 mm, the pitch is 6-7 mm. The nose at the cone should be sharp. The seat on the gearbox must be at least 70 mm deep.

The engine should have a power of 1.5-2 kW, voltage - from 380 V. The number of revolutions 250-500 per minute, a speed below 250 rpm will greatly slow down the process of harvesting firewood, and above 500 rpm - there is a danger of pulling logs out of the hands ... If you have an engine with a given number of revolutions, you can put a "carrot" on the crankshaft. If the revolutions are off scale, you will have to mount a reduction gear or make a belt or chain drive to reduce the speed.

The bed is the table on which the blocks will be placed. It is made either from sheet steel or from thick wooden boards, the legs for it should be metal 40 cm long.

The distance from the table to the cleaver is 8-20 cm, if you increase it, there is a danger of overturning a chock of a small diameter. The installation of the log is vertical, otherwise the tree will get stuck between the "carrot" and the table and, most likely, will bend the shaft. The workpieces should not be longer than 0.5 m and not exceed 0.6 m in diameter. For this wood splitter, do not take tree species with intertwined fibers (birch, oak, etc.).For safe operation, put the cowl over the motor and the chain (belt).

Do-it-yourself hydraulic wood splitter

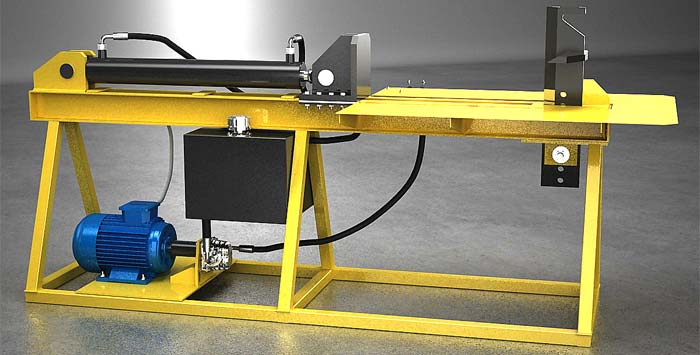

This is not the simplest and cheapest, but quite powerful and very productive device, almost eliminating manual labor when chopping firewood. You only need to install the logs on the platform and collect the finished firewood in a woodpile.

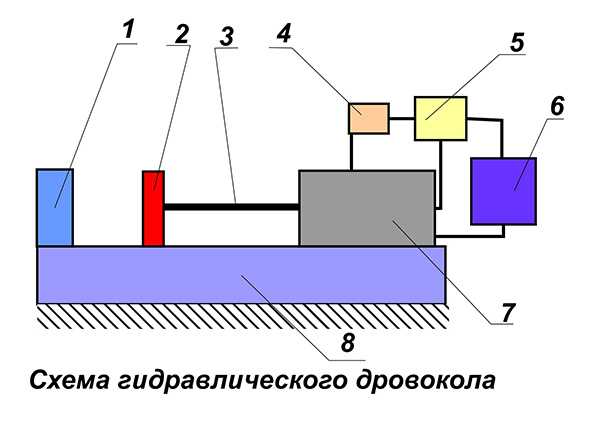

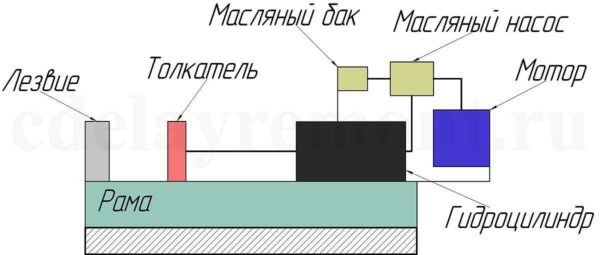

In this scheme, completely ready-made units are used - an oil tank and a pump, a motor, a hydraulic cylinder, a blade. Only the frame with the pusher is made independently.

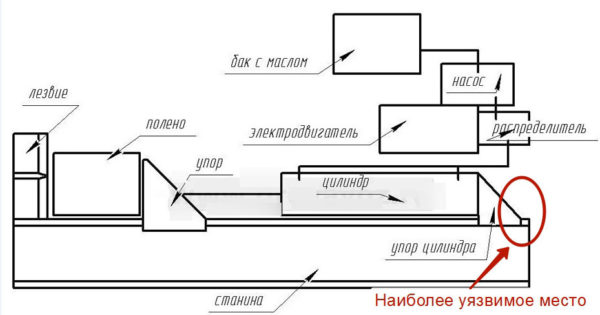

In a more detailed diagram, you can clearly see where the weakest point of the product is - where the cylinder stop is located

It is here that a poorly welded stop together with the cylinder is most likely to rip off the bed, therefore, the seams in this place should be treated with maximum attention.

This is what the finished model might look like.

As you can see from the photo, the knife in this case is made of a spring, sharpened at an angle of about 60 degrees. The pusher is welded from metal plates 5 ... 10 mm thick, the frame is assembled from a corner and a channel. You will have to choose the necessary metal rolling on your own, based on the available reserves.

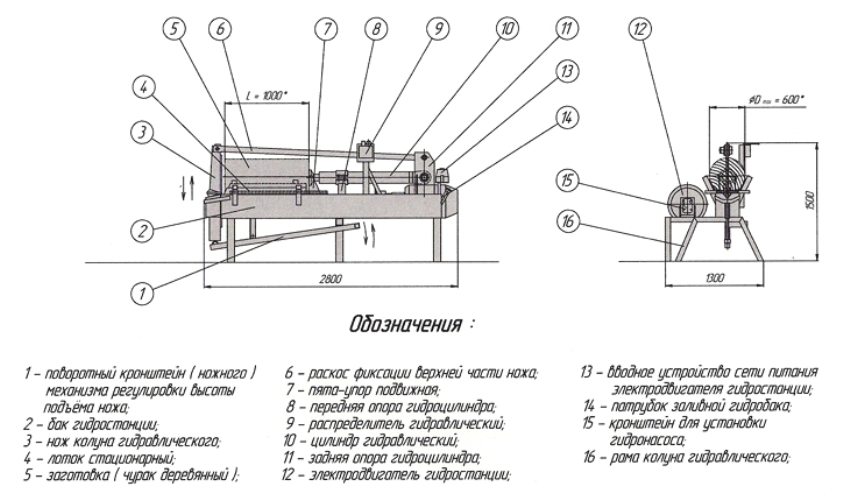

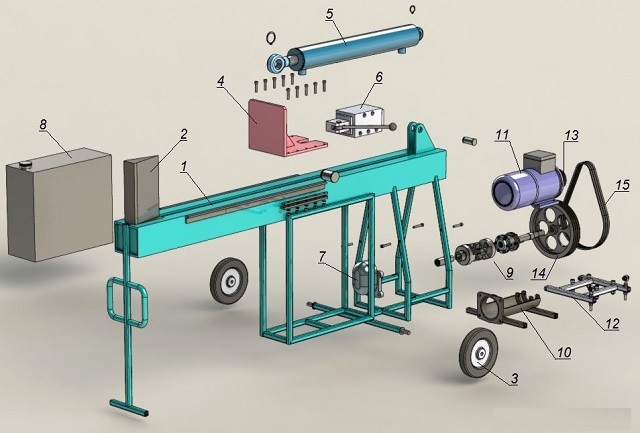

The main parts and assemblies of the device are presented on the assembly diagram.

Here:

- bed;

- cleaver (knife);

- wheels (optional, if necessary, periodically move the machine);

- carriage pushing the chock onto the knife;

- hydraulic cylinder;

- hydraulic distributor with a lever, it drives the machine;

- hydraulic pump (NSh-32 models);

- tank for filling liquid (oil), volume 32 l;

- drive shaft of the hydraulic pump with cardan shaft;

- drive shaft cover;

- electric motor (model AIR80V2);

- turntable;

- driving pulley;

- driven pulley;

- drive belt.

This is how the bed might look in this model.

Carriage assembly.

Turning platform.

Transfer mechanism.

Assembled device.

This video describes how to make a homemade hydraulic wood splitter.

Product features

In the household, a wood splitter is always useful, you can either buy it ready-made or make it yourself using scrap materials. The ready-made options have been improved, there are a number of additional functions that allow you to chop a maximum of firewood in a short time.

There are many installations working in an automated format. This is good, because you can not waste time on work, but start the machine that will do everything by itself. Experts identify several features, behind which mechanisms can be categorized:

- By the way the logs are laid, the machines can be vertical and horizontal. Sheer structures are considered more powerful and durable, since they can process even a thick deck in a short period. If the log is crooked or has a lot of irregularities, then it is better to give preference to the horizontal mechanism.

- Maximum amount of stacked firewood. Depending on this criterion, the equipment can be divided into appliances for home use and for industrial scale.

- Drive types. For home use, a machine with a small power of an electric type is suitable.

In this video, we will consider a hydraulic log splitter:

The simplest do-it-yourself wood splitter

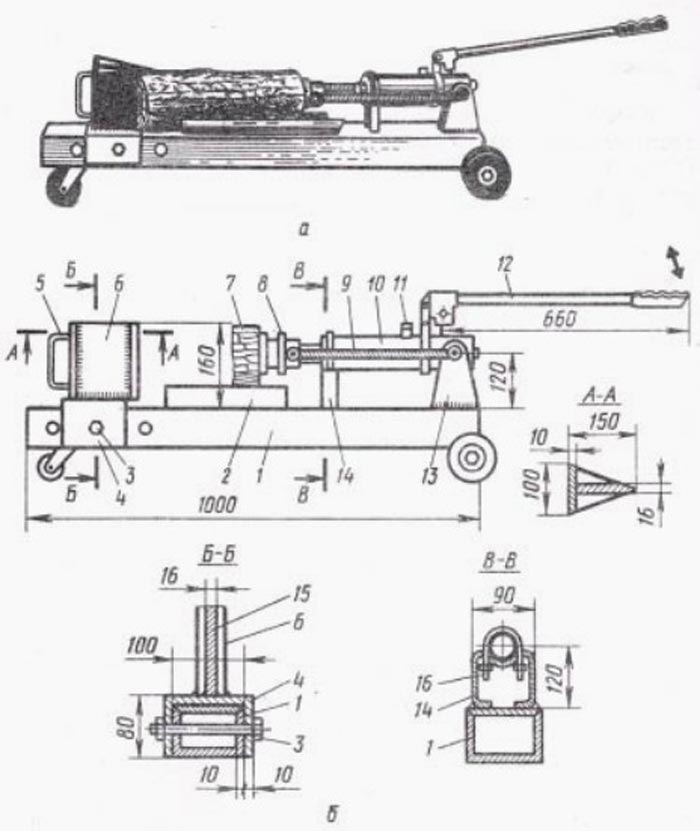

threaded metal cone

In the case when it is not possible to order or make a cone on a machine, this part can be made with your own hands using a grinder. At the same time, it is not necessary to strongly maintain clear dimensions. In this case, you just need to first put the grinder on the pulley of the electric motor, and evenly cut the metal, having achieved its free rotation.

The finished cone is put on a shaft with bearings of the required size, where at the end there is a flange with an asterisk from the motor scooter wheel. A threaded cone is attached to the shaft with a bolt or pin, this makes it possible to easily remove it from the shaft and unscrew it from the block when it is jammed.

The removed cone, which is jammed in the log, can be easily unscrewed from the tree using a gas wrench. If the cone is firmly fixed on the shaft, then, when it is jammed, it becomes necessary to remove the drive chain, because the motor shaft cannot always be turned in the other direction.

Manufacturing features

The way this wood chipper works is very simple. During rotation, the cone, like a self-tapping screw, is screwed into the log, splitting it. When working with a wood splitter, you need to be extremely careful and follow safety rules.

Varieties of wood splitters

Household appliances only have the function of splitting the log. Professional devices represent a very complex design, which produces wood supply, trimming at a given length, splitting and ejection of chopped firewood. Naturally, the price, performance, and power of these devices does not go in comparison with ordinary factory wood splitters, and even more so with their own hands.

The wood splitters can be vertical, horizontal and combined according to the feed device for splitting wood.

In horizontal apparatuses, the block is mounted on a horizontal gutter. Moreover, taking into account the design, either the pusher moves the log to the stabbing knife, or the knife moves along the guide towards the log.

In vertical wood splitters, the log is fed vertically, and a moving knife from above splits it. The mechanisms of this design are the most productive, they do not take up such a large area, but they also have their drawbacks. So, during the operation of vertical wood splitters, you need to support the split logs with your own hands, which requires strict adherence to safety precautions.

Combined devices combine the capabilities of the devices described above and are used only in woodworking factories.

Given the power source, wood splitters are divided into the following types:

- Tractor-driven machines. Such devices are connected to the tractor hydraulic system with a powerful take-off shaft. These are professional and powerful devices that are designed to work in large industrial enterprises, forestry farms and complexes.

- Wood splitters with diesel or gasoline engines. These are very powerful machines that are usually used in logging. However, they are also suitable for work in country houses.

- Combined devices. Some models have electric motors or internal combustion engines, and are also adapted to work from the tractor shaft.

- Wood splitters with electric motors. These are the simplest wood splitter designs. The electric motor activates the hydraulic pump. These units are easy to operate and maintain and can be installed in almost any room.

Wood splitters with electric motors require little maintenance and are best suited for home use. The only prerequisite for their operation is the availability of electricity.

Taking into account the design of the log splitting mechanism, wood splitters are divided into the following types:

- Cone or screw (we just told above how to make this wood splitter with our own hands). In these devices, the role of a knife is played by a threaded cone, it splits the log by screwing into it. With the help of this principle of operation, you can completely make a wood splitter with your own hands, because it is quite simple, and does not need to make additional mechanisms. But, for its productive work, a powerful electric motor is required.

- Hydraulically driven. At the heart of these devices is a hydraulic pump that drives the splitting knife, it, pressing with great force on the log, splits it.

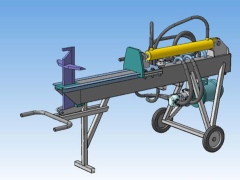

Also, industrial devices differ in the way of transportation. Most often, heavy and large devices are made in a stationary version. But in the design of light vehicles, wheels are provided, they make it easy to move them.

Hit or crush?

Splitting blocks is considered a dangerous production process: a blank that has turned out of the machine is capable of flattening a person, and flying chips pierce him through and through. It is impossible to completely exclude abnormal situations when splitting wild wood - in this respect, it is far from completely predictable material. As a consequence, some types of technical classification of devices for splitting raw wood must be kept in mind in order to make a log splitter safe enough in everyday life. Namely, it is a shock action or a push action:

- Mechanized impact splitters with intermediate energy storage are highly efficient, economical, almost completely relieve the operator of muscular efforts, but they are structurally complex and the most dangerous to work with. Cope with any block, incl. with butt ridges of elm and larch.

- The same, manual ones without a mechanical energy storage device are non-volatile, cheap, and structurally simple. They can be used in a push mode and thus split twisted and knotty blocks up to 25-30 cm in length. Less muscular effort is required, and the safety of work is higher than with manual splitting with a cleaver on the block. Are unproductive; suitable for irregular and occasional preparation of firewood.

- Pressure splitters driven by an internal combustion engine or an electric motor are quite expensive (see below). Also, the muscular effort of the operator is almost completely eliminated. The performance is sufficient for the regular supply of firewood at a house up to 200-300 sq. m in winter with frosts down to -40 and below. The highest possible security is achievable for this class of devices. Disadvantages are the complexity of the design and rather high energy consumption in the form of electricity or liquid fuel.

Why - not to beat

In mechanical impact wood splitters, a relatively weak engine spins the flywheel through a fluid coupling. Thus, the motor runs almost all the time at optimal rpm and consumes a minimum of fuel / electricity. Then, a crank with a pusher is engaged with a flywheel (hydraulic or frictional), which feeds the chura to the splitting knife. The impact force is colossal: more energy can be "pumped" into a flywheel with a diameter of 60-80 cm than in a 100 kg aerial bomb. Churak actually does not prick, but is cut with a knife despite any defects in the tree.

Abroad, where energy resources and high-quality straight-grained wood are expensive, household mechanical impact wood splitters are produced and in demand, see the photo at the beginning. There is no import of such devices in the Russian Federation, and industrial ones are finalizing their resource and analogues are not being developed to replace them. The reason is extremely dangerous. Modern composite super flywheels do not burst, but it is impossible to stop the push from the flywheel and thereby prevent the development of an emergency situation into a threatening and dangerous one. Therefore, further in the article, mechanical impact wood splitters with energy storage are not considered.