Classification and comparative points

This issue should also be given attention, because it reveals the main differences between hydraulic and other similar devices.

Bottle devices

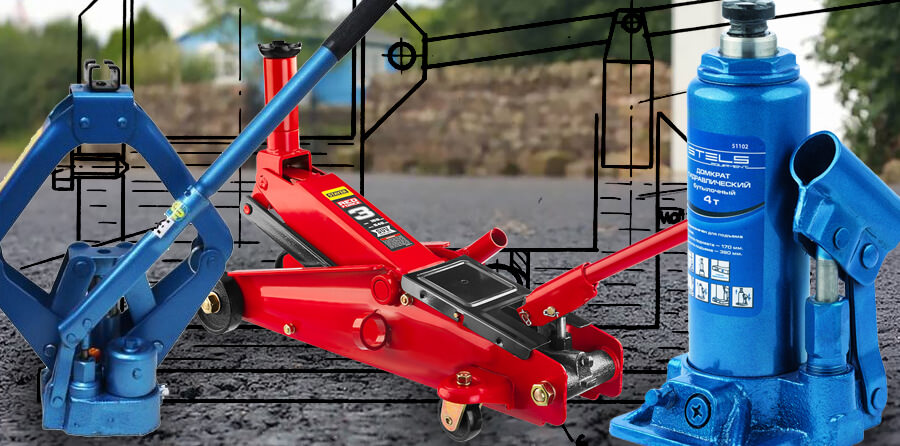

Jacks of this type have a fairly simple design. We can say that it is the most primitive among all devices found today. Hydraulic bottle jacks are actively used in many areas of human activity, which can be explained by their high carrying capacity. With their help, you can lift loads weighing from 2 to 100 tons.

Vertical versions have high strength characteristics and provide the ability to use a wide support to perform certain operations. They are most widely used in the service of trucks, where they are used to lift trucks or buses.

Sliding mechanisms

This group of lifting mechanisms is also one of the most demanded. Most often they are used in the automotive industry. In the design of these devices, the axis of the cylinder is not placed in a vertical plane, but is connected directly to the jack lever. These devices are necessarily equipped with wheels that allow them to be moved on any surface.

This group of lifting mechanisms is also one of the most demanded. Most often they are used in the automotive industry. In the design of these devices, the axis of the cylinder is not placed in a vertical plane, but is connected directly to the jack lever. These devices are necessarily equipped with wheels that allow them to be moved on any surface.

Hoisting mechanisms of this type are distinguished by high load-carrying capacities. They are also very easy to use. They work on the same principle as all other jacks. By its design sliding hydraulic jacks almost do not differ from bottle counterparts.

Hydraulic hybrids

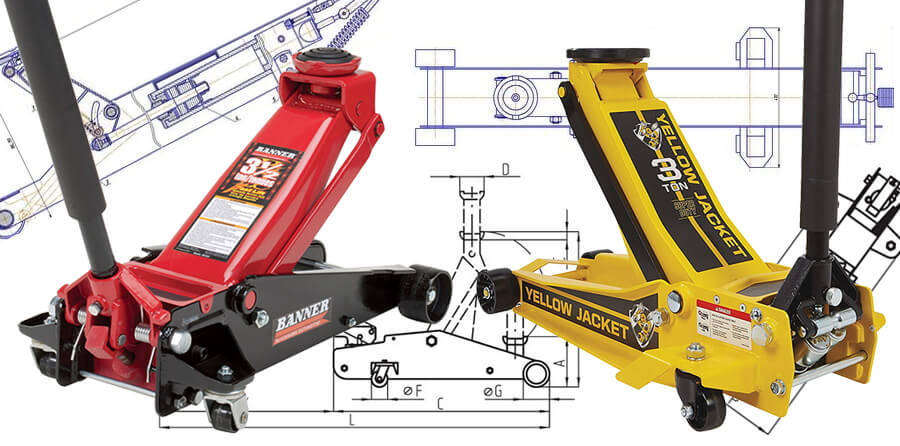

These versions of jacks are most widely used in the field of car service, where they are used to carry out repair work of varying degrees of complexity and with a wide variety of vehicles. Of the features of these devices, the presence of two work sites should be highlighted. They are useful when you need to raise a passenger car, and then some gazelle.

This is a great choice for professionals. Such models combine the capabilities of a bottle jack and a rolling jack. Due to the fact that their capabilities could be embodied in one multifunctional device, buyers have the opportunity to purchase an irreplaceable assistant and save a lot on this. These devices are as easy to use as the rest: you can use a hand lever or a foot pedal to operate them.

Hook Jacks

Most often, these mechanisms are resorted to in cases where a small pick-up force is required. They are great for lifting any kind of equipment. They can also be used in the process of assembling complex mechanisms, where a small pickup height is required.

Diamond devices

Lifting mechanisms of this type are most in demand among motorists who need a device to lift their vehicle. These mechanisms are highly reliable. In their design, they look exactly like rhombus screw jacks. Every motorist will be happy to have such an assistant in the garage. In the design of these devices, the functions of the supporting elements are performed by four levers.

Device, features of the use of a bottle-type jack

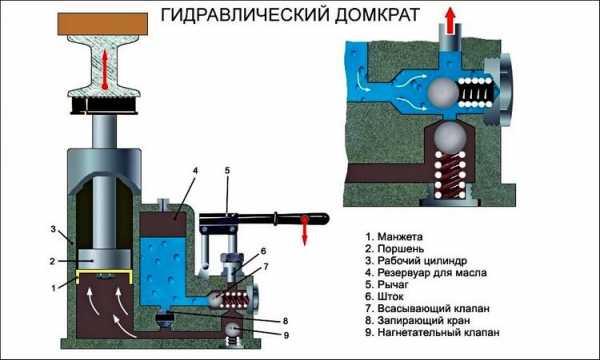

The illustration shows the components of the hydraulic lift.

The entire structure fits inside the reservoir with the working fluid.The lifting rod in the down position is completely recessed in the body. The lever handle is removable and does not take up much space in the transport position. Therefore, this type of jack easily fits in the trunk of a car.

A device capable of lifting a solid SUV (force of 5 tons) - measures (taking into account the unfastened handle) no more than a 0.7 liter bottle of wine. One person can handle such a jack.

- Easy to operate and maintain;

- High efficiency - up to 80%;

- Low effort on the working handle;

- Smooth operation due to the use of liquid;

- Possibility to control the lifting height with high precision;

- High reliability due to the absence of rotating and rubbing parts with effort;

- Lifetime - apart from O-rings, there is nothing to wear in the bottle jack;

- A good indicator of safety in work - in the event of a breakdown, a sharp fall of the lifted object or throwing a part of the tool towards the side is excluded;

- Wide range of applications, not limited to the operation only in cars.

- The jack body height is practically equal to the lifting height. This is typical for single-rod designs; telescopic (multi-rod) options are free from this drawback. This feature is partially compensated for by the extension screw, which is unscrewed from the stem. Due to this drawback, the initial lifting height starts from 20-25 cm. This limits the dimensions of the device;

- Slowness. One cycle of operation of the injection pump provides a lift to an insignificant height. The higher the lifting capacity, the more movements of the handle must be made to lift;

- Inability to accurately control the height of the lowering of the load;

- Work only in an upright position. In a tilted or horizontal state, air will enter the hydraulic system, and it will have to be pumped;

- Large mass of the device, taking into account the working fluid;

- The high cost of the product.

To work with low initial heights (for example, cars with a low landing), a rolling jack is used. It works according to a lever scheme, and a hydraulic cylinder is used as a driving force, as in a conventional bottle jack.

Flip-flop

Donut Shooter. ÐÐ ° нÐμй ÑÑÑÐ ° новР»ÐμÐ½Ñ Ð¸ ÑовмÐμÑÐμÐ½Ñ Ð'вÐμ конÑÑÑÑкÑии: поÑÑнÐμвой нР° ÑÐ¾Ñ (Ñ ÑÑÑнÑм ÑÑÑÐ ° жнÑм пÑивоÐ'ом) и гиÐ'ÑÐ ° вР"Donut." Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose Good luck.

Saucer, saucer, sartorial, sartorial, sartorial ± locl ll lll1. Burglar (2Ñ) bark bark Good luck. Burgundy borealis

Bumpy line ÐомкÑÐ ° Ñ Ð¿Ð¾Ð'кР° Ñной (3Ñ) впоР»Ð½Ðμ поÐ'ойÐ'ÐμÑ Ð'л Ñ Ð¿Ð¾Ð »Ð½Ð¾ÑÐμнной ÑÐ ° Ð ± оÑÑ Ð½ÐμÐ ± ол ÑÑой мР° ÑÑÐμÑÑкой в ÑÐμÑÑÐμ LOT.

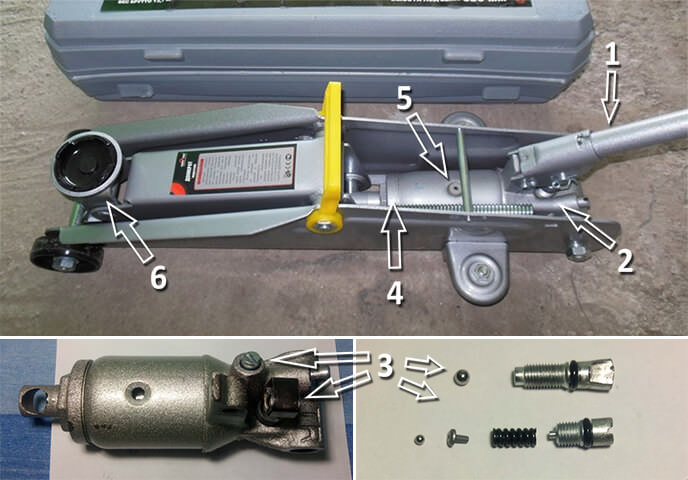

Jack repair and maintenance

The weak point of any hydraulic device is working cylinders, sealing elements and bypass valves. The bottle jack cannot be stored and used in a horizontal or upside-down position due to the potential for fluid leakage.

The main signs of failure:

- Low oil level in the slave cylinder.Because of this, the stem will not be able to rise to the desired height. Eliminate the malfunction by adding oil and pumping.

- Oil leakage from under the seals. This causes the liquid level to drop and air enters the system, which reduces performance. Replacing the gaskets from the repair kit helps.

- Sags under load. Weak grip. Sign of air ingress or leaks in the system. It is necessary to find and fix the leak by repair or replace worn parts.

If these or other malfunctions are found, it must be disassembled in order to be repaired.

The procedure is as follows:

- Drain the oil.

- Unscrew the piston of the working cylinder and the plunger.

- Remove the bypass valve.

- The wear of gaskets and working surfaces, the condition of rubber goods are visually assessed.

Important!

Seizures and scratches on the cylinder mirror are not allowed.

The assembly is carried out in the reverse order, after having cleaned the parts from dirt and old oil. After that, the jack should be pumped so that it starts working normally. To do this, oil is poured into a cylinder with an extended stem through a special hole. It also serves as a liquid level. The stem is then vigorously pushed in several times to expel air bubbles from the slave cylinder. They make 10-15 lifts with a small load until the jack starts to hold the load. Any type of hydraulic jack can be repaired.

It can be concluded that it is impossible to do without a jack when repairing a car. The bottle jack is popular with car enthusiasts

The most important thing is to choose the right model and make timely repairs to the device.

Principle of operation

The principle of operation of such a mechanism is quite simple. For a correct understanding, consider all its main elements:

- oil piston pump;

- lever arm;

- valve;

- working hydraulic cylinder;

- expansion tank with oil.

The principle of operation of the jack is that during the operation of the pump, which is set in motion by pumping in manual mode, oil from the reservoir is supplied to the working hydraulic cylinder, thereby squeezing the rod out of it.

Accordingly, the more oil is pumped into the hydraulic cylinder, the further the rod will move out of it. Thanks to this extension, the platform is lifted, which is rigidly connected to the rod.

During the process of pumping oil, the lifting mechanism must be located directly under the machine so that its lifting platform rests on a special place on the body. As soon as the required height is reached, you need to stop pumping oil, and the jack will remain at this height. After lifting the load, it is advisable to remove the handle with which you were swinging so as not to accidentally press it and add oil to the cylinder - this can be dangerous to life and health.

After completing all work, the machine must be lowered again. This is very easy to do. It is necessary to find a bypass valve on the mechanism and slightly open it so that the oil can flow back into the expansion tank, and the jack is lowered. To prevent the loaded tool from falling too abruptly, open the bypass valve gradually and gradually.

In order to avoid mistakes and to work correctly with the described device, before using it, you must familiarize yourself with the instructions that always come with the device itself. In addition, the product must be looked after and prevented in time. By observing all the recommendations described in the operating manual, your jack will serve for a very long time.

The device and principle of operation of a hydraulic jack

Principle operation of any hydraulic jack based on Pascal's law, known from school. All hydraulic jacks are designed as two communicating vessels. They are filled with special hydraulic oil.In the process of pumping this oil from one vessel to another through a special valve, excess pressure is created in the second vessel. Thanks to this pressure, the process of movement of the jack piston takes place, This piston plays the role of a lift.

To return the jack piston to its original state, the so-called bleed valve opens. Through it, the hydraulic oil is returned to the original container. A pneumatic jack is built on a similar principle. The main feature of such jacks is the use of air pressure for lifting and lowering operations. It is created by a separate compressor.

The jack control depends on the selected pump model. The control process can be carried out either manually, by a hydraulic system, or by a pneumatic system.

A detailed hydraulic jack diagram includes the following elements:

- Cylindrical body. It houses the hydraulic oil. He is one of the communicating vessels.

- Piston. It moves in the housing due to oil pressure. This pressure is generated by the control system.

- Distributor. With its help, the pressure is redistributed in the required direction.

- Hydraulic oil filter. Thanks to it, dirt and various particles are removed from the oil composition. In addition, it prevents the formation of highly viscous areas.

- Discharge valve. With its help, the required pressure is maintained in the working area of the jack. This helps to raise the required load to a given height and keep it at that height.

- To return the piston to its original position, a special pressure relief valve is provided.

- External pump. With its help, oil is pumped into the cylinder and the required pressure is maintained. In modern jacks, three types of pumps are usually used: gear, vane, piston.

The detailed diagram below allows you to understand the structure and principle of operation of the hydraulic jack. With its help, you can evaluate the technical characteristics and expertly identify possible malfunctions.