Operating tips

To extend the life of the jack, it is recommended to adhere to the following rules:

- It is advisable to change the oil of the lifting mechanism twice a year. If the jack is operated daily, it is recommended to replace it at least once a month with mandatory flushing.

- Any oil can be used for replacement. But for the winter season, it is recommended to fill in only synthetic oils.

- To prevent oil from thickening in winter, the tool should be stored in a warm and dry place.

- If lifting work is carried out in winter, it should be remembered that with prolonged use of the tool in severe frost, it may fail. Therefore, it is desirable to work with him as a last resort and for a limited time.

The best "repair" of the lifting mechanism is prevention to prevent the occurrence of malfunctions, that is, constant maintenance and timely replacement of the working fluid with pumping. After all, to eliminate any breakdown, you will have to use your time, and sometimes some funds. Therefore, all operating instructions for the hydraulic lifting tools must be followed to ensure that they will last for quite a long time.

Hydraulic low jacks with pneumatic hydraulic drive

These jacks can be divided into a separate category, primarily based on the use of compressed air supplied to the working fluid as a moving component. Air is supplied using a pneumatic hydraulic booster. To ensure that the maximum air pressure is not exceeded, a built-in safety valve is used in the design. The maximum stroke is limited by the overflow valve. The compressor and the low-grip hook-on jack are connected to each other by a special pneumatic hose.

The use of a low-lift hydraulic jack has a number of features

The use of a low-lift hydraulic jack has a number of features

How to choose a quality tool

Preference for bottle jacks should be given to well-known manufacturers of lifting devices. There are models of Russian and Chinese brands on the market - Matrix, Zubr, BelAk, Forse, Airline, OMBRA, Avtoprofi. The following models have become the most popular in the ranking of hydraulic tools.

- "Zubr Expert". The jack is made in China, and the design follows the well-known domestic model of the classic layout. Lifting capacity 5 tons, initial lifting height - 210 mm, maximum, taking into account the insert - more than 400 mm. Differs in high quality workmanship and the lowest price in its class.

- "Autoprofi DG-08". Another mechanism from the Middle Kingdom. It has a significant margin of safety and is one of the heaviest - almost 13 kg. Equipped with an overload relief valve. Working stroke from 200 to 400 mm.

Car jack "Avtoprofi"

Matrix Master article 507203 (8 tons). Supplied in packaging and weighs only 6 kg. The pick-up height is 230 mm, and the limiting height, taking into account the retractable rod, is 400 mm. This model is suitable for both garage work and truck drivers. The Matrix company controls the quality of all supplied products and guarantees a long service life.

In any case, the choice of a bottle jack occurs for the specific operating conditions of the vehicle. The average price for them is from 900 rubles, for the smallest, up to 4000 rubles for a powerful 20-ton.

How to choose?

The choice of each type of jack has, of course, its own nuances.However, there are general rules, taking into account which you can choose the most suitable model of the lifting device in each case.

In this case, special attention should be paid to the following key criteria

- Lifting capacity is the main characteristic of any jack. As a rule, this parameter is indicated on the device case and in the technical documentation, which is necessarily included in the delivery set. When choosing a specific lift model, it is strongly recommended to take potential loads into account. Exceeding the indicators specified by the manufacturer can lead at least to the failure of the lift itself. In addition, more serious negative consequences are possible.

- Pickup height. Most often, this parameter is most relevant for motorists, since it is determined by the vehicle's clearance. This performance indicator most often ranges from 6 to 25 cm. As practice shows, it is easier to choose the right model for owners of SUVs with increased ground clearance.

- Working height, or maximum lifting height. The indicator of most of the models on the market varies in the range from 30 to 50 cm. There are even car jacks with a working height of up to a meter or more.

- In some cases, there is such a thing as "working stroke". This term is usually understood as the difference between the minimum pickup height and the maximum lift height. Naturally, the wider the given range, the better.

In addition to everything already listed, when choosing a model of a lifting device, the type of drive should be taken into account. In this case, we are talking about the following main options.

- Mechanical drive based on the force applied to the jack handle. Such models are distinguished by maximum simplicity of design, and, consequently, relatively low cost.

- A hydraulic circuit that drives the loaded plunger of the mechanism due to the pressure of the working fluid created in the cylinder. By the way, as in the situation with the previous type of device, the key element is also the handle, which acts as a lever for the hydraulic pump.

- Pneumatic drive that provides lifting and lowering of the load using compressed air. The principle of operation is as simple as possible and is based on filling the working chamber with any gas. Due to the maximum ease of use and minimum labor costs, such models are correspondingly popular.

An equally important criterion is the jack brand. Naturally, experienced professionals and users strongly recommend making a choice in favor of original products of well-known brands. Such an approach to the selection of equipment allows you to count on the maximum correspondence of real performance indicators to the technical characteristics declared by the manufacturer.

It is important to remember that large companies care about their reputation, and for them the corresponding risks are of great importance.

In parallel, it is worth paying attention to the quality of materials and workmanship. In a situation with branded jacks, this, as a rule, does not arise any problems.

As a result, a device is acquired that is extremely reliable and with a maximum service life. This, unfortunately, cannot be said with certainty about the models belonging to the “no name” category. Often, such mechanisms fail after the first attempts to use them.

Experienced professionals prefer not to take risks, since the use of an unreliable lift can lead to extremely negative and sometimes even tragic consequences. At the same time, for many, the financial side of the issue plays a decisive role. However, now, taking into account more than a wide range of products on the market of many companies, you can easily find the optimal combination of price and quality.

Along with all the above criteria, the dimensions and weight of the equipment often become the determining parameters. This is most relevant for car owners. Not every jack model can be freely placed in the trunk of a vehicle.

What kind of work does the bottle jack device allow?

Jack characteristics table.

The sphere of application of bottle jacks is the car service associated with the maintenance and repair of cars. The bottle-type jack is widely used in the railway industry, since it allows the repair of railway trains.

The hydraulic jack is used as a power unit for presses, pipe benders or pipe cutters. If, after inspecting the mechanism, it can be concluded that the device is working properly, then work should be started. In combination with a large carrying capacity, the compact size of the tool allows it to be used in garages and workshops. The device can be transported in the trunk of a car, which allows for the replacement of punctured wheels if necessary.

The bottle jack mechanism is reliable. Hydraulic jacks are used in the car repair process, which must be lifted and fixed at the desired height. For example, the mechanism allows you to remove a car wheel for its subsequent balancing using special equipment.

It is convenient to transport it, which is carried out exclusively in a vertical position, since oil in the horizontal position of the tool is capable of flowing out. In general, its service life is determined by the number of gaskets and oil seals in its device.

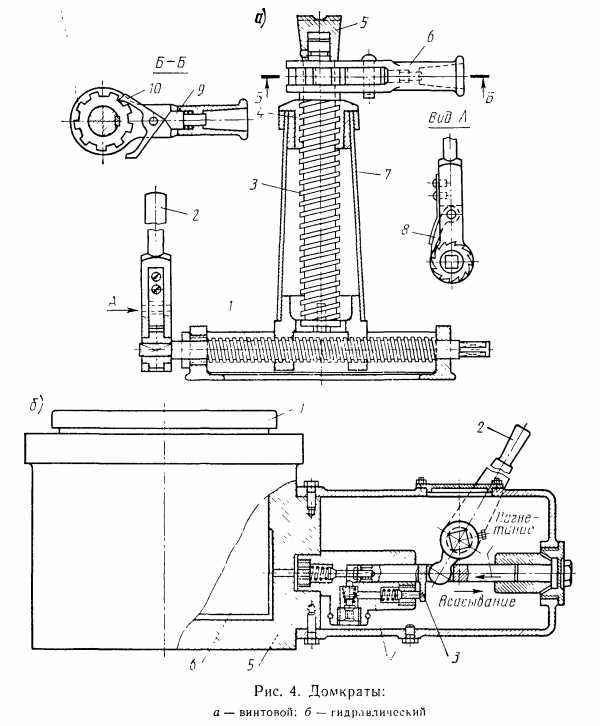

Bottle type hydraulic jack design and features

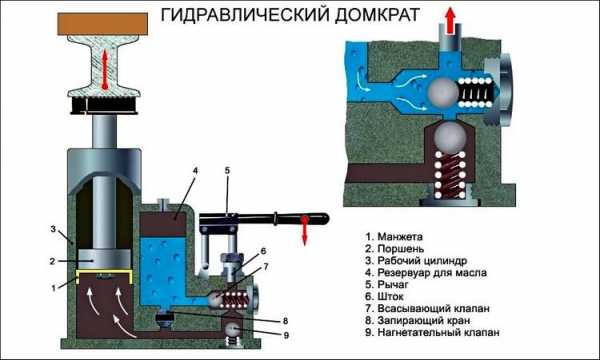

Bottle jack device.

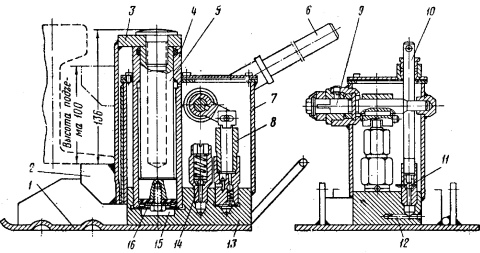

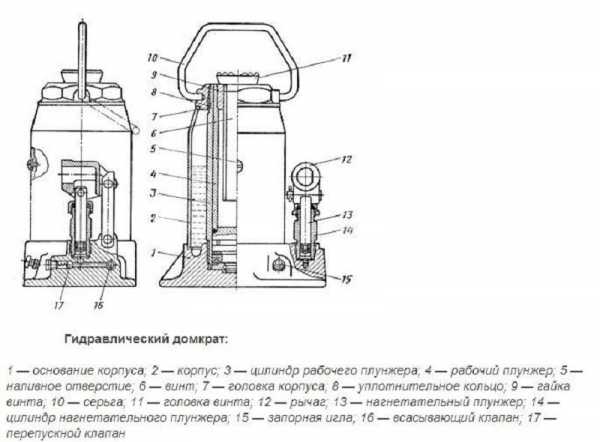

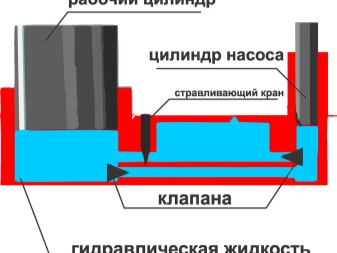

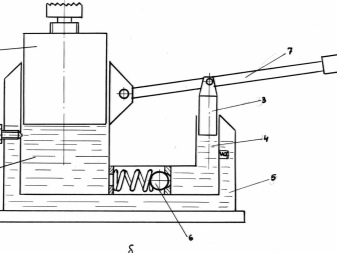

bottle type is shown in the figure. Each element that makes up the structure corresponds to a certain number, implying the presence in the mechanism:

- Handles.

- Pump.

- Valve.

- Reservoir.

- Cylinder.

- Stock.

- Screw.

The suction valve is located on the tank nozzle. This should prevent fluid from returning to the reservoir if the pump plunger is lowered. The position of the discharge valve refers to the cylinder nozzle, which prevents the hydraulic fluid from leaving the cylinder when the pump plunger is lifted.

The valve is opened with a special screw that allows pressure relief in the device. Then the load is lowered to the ground. In general, this design is time-tested.

The connection of the bottle jack to the pump or pumping station is carried out due to the presence of a coupling half, which is a quick disconnect. It eliminates fluid loss due to disconnection of the tool from the pressure source. The main structural elements are:

The bottle jack quick-release coupling eliminates fluid loss as a result of the tool being disconnected from the pressure source.

- Frame.

- Extendable plunger (piston).

- Working fluid (hydraulic oil).

The body serves as a guide cylinder for the plunger and at the same time a special reservoir for the working fluid. If the jack has a lifting capacity of up to 20 tons, then the location of its lifting foot is marked in the part of the screw that is screwed into the plunger. Therefore, the initial height of the mechanism can be increased by loosening the screw.

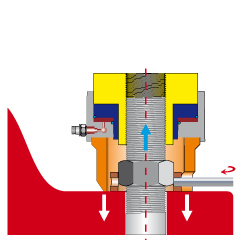

The plunger must pump oil from one common reservoir to another under the piston. When oil appears under the piston, it should move. The oil is no longer returned to the general reservoir due to the actuation of the valve. As the plunger operates, more and more oil flows into the reservoir under the piston from the common reservoir.

An integral part of a bottle jack is a liquid, which has the characteristic of an incompressible working material.This allows you to smoothly lower and raise the load, as well as fix it at a certain height, ensuring accuracy when braking.

Spindle oil allows you to smoothly lower and raise the load, as well as fix it at a certain height.

The speed of the lowering of the load can be controlled by the hole required for the outflow of a special liquid coming from the cylinder, which can have a different composition. It is possible to use antifreeze mixtures, which include the following components:

- Alcohol.

- Water.

- Technical glycerin.

- Spindle oil.

Spindle oil solidifies at temperatures below 35 ° C. When choosing a bottle jack, lift and pickup heights are taken into account, not just lifting capacity. The lifting capacity may be sufficient to lift the vehicle and the stroke will be low. This requires control over the level of hydraulic fluid, oil seals and their tightness.

Hydraulic Jacks Selection Options

Rolling jack

Rolling jack

After determining the optimal type, the correct hydraulic jack must be selected. To do this, you need to know its basic operational and technical characteristics. You can preliminarily familiarize yourself with them in the contents of the equipment passport.

The first step is to find out the maximum weight of the load that will need to be lifted.

It is important to correctly distribute the load on the surface of the working piston. Therefore, in some cases, you may need more than one jack.

An alternative option is to purchase a two-rod one with a better stability indicator.

Knowing the device of each model and the restrictions on use, you can decide in advance on their choice. After that, the analysis of the remaining parameters is started:

- lifting height;

- the minimum distance from the upper surface of the working cylinder to the base when folded;

- the composition of the working fluid. It is recommended to use oil with mineral additives. This expands the operating temperature range;

- effort on the drive;

- drive type - mechanical or electrical;

- dimensions

Some industrial and semi-professional jacks have the ability to install pumps to create pressure in the working piston. But bottle bottles do not have this function - a lever system is used to pump oil.

The rate of pressure release is also taken into account. This is determined by the characteristics of the valve. It is recommended to purchase jacks with a two-way valve, which returns the plunger to its original position relatively quickly.

The video describes the design of various hydraulic jacks:

How does a hydraulic jack work

The hydraulic jack is an easily transportable device that has the highest lifting capacity compared to other similar mechanisms. Also among his fellows it is distinguished by longevity.

Appearance

Operating principle

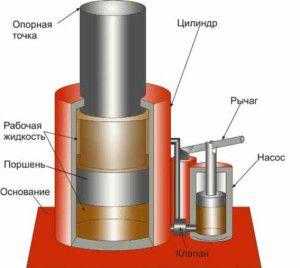

Several details are outwardly visible:

- Cylinder - it contains a piston and two sections with a working fluid.

- A pump that pumps liquid. It is connected to the cylinder by valves.

- Lever arm.

- Anchor point.

The mechanism is very simple, as is the design, due to the small number of parts. It is worth considering the function of additional elements:

- The base is what the pump is mounted on. The base should have a large area to compensate for the mechanical pressure when lifting the load.

- Reserve tank - connected to the cylinder, it houses the lever system and the pump.

- Piston - Rises due to oil intake.

- Plunger - Limits the piston lift height.

Jack details

Jack details

The jack is located below the object to be lifted and does not need ropes, ropes, fasteners and other auxiliary parts. But you won't be able to hold the object on weight for a long time - the device serves exclusively for lifting.

What is the difference between the models

The main distinguishing feature of jacks is their carrying capacity, lifting and lifting heights. With a focus on them, device models change. For example, the lift height depends on the distance between the base and the anchor point. There are also features in the lifting principle.

Another quality is durability. Car enthusiasts for home use once a year and repair services need different mechanisms.

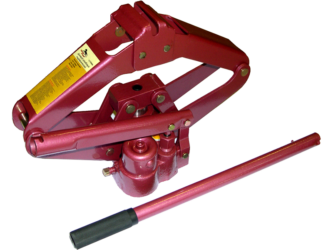

Roll-up type

The entire mechanism is located on a frame that is attached to the wheels. The compact and mobile rolling type can be used even in hard-to-reach places. The system of levers and pistons is located horizontally, due to this, the device can be easily placed under any load (for example, a car) and raised at any angle. Additional details in the rolling model:

- 2 wheels,

- suction and discharge pump,

- lifting platform,

- frame instead of base,

- lever - it must be pressed in order for the pump to work, which will transfer the hydraulic oil through the valves to the cylinder.

Roll-up type

Roll-up type

Bottle type

A simple version with a vertical cylinder. A distinctive feature is small size with a high carrying capacity - from 2 to 50 tons. The pickup height in bottle jacks usually starts at 15 cm and ends at 30 cm. The height is adjusted with a screw located at the top of the stem. The bottle type is designed in such a way as to exclude slipping during operation. For this, the support part is corrugated.

Each jack comes with a handle that makes it easier to use the mechanism. Those units that can withstand loads of 30 tons have an additional second handle. The doubled length increases the weight that the bottle jack can lift.

Bottle type

Bottle type

There are other types:

- Pneumatic - a cushion is installed, connected to a compressed air source, for example, a stationary compressor. It is used when the gap between the object and the surface is small. It can also be used with unstable support - for example, in swampy areas, on sand, snow. Such a jack can withstand a load of up to 6 tons.

- Screw - compact, standard car jack. Carrying capacity - up to 15 tons.

- Rack - has a maximum lifting height. A fastening mechanism moves along the rail, which snaps into place and rises like a ladder along with the load. Withstands 20 tons.

A jack handle is a mechanical lever that is used to pump fluid. Electric drive means that the mechanism has an automatic built-in pump. Repairing the electrical version requires special equipment, while the bottle and rolling mechanical types can be repaired on their own.

Principle of operation

To understand the action of a hydraulic jack, you must first pay attention to the fluid that works inside it. They use oils with a lower viscosity level.

They should not even contain trace amounts of water.

When the pump is running, a special fluid enters the reservoir with a large cylindrical groove. The walls of the container are tightly enclosed by a movable rod, which is part of the piston. According to physical laws, when a container is overfilled with oil, it begins to squeeze all adjacent parts of the device. The body and valve are designed to withstand enormous pressure. Therefore, the only option for the development of events is the displacement of the piston upward.

Separate hydraulic jacks are used to tension the reinforcement. But they can also be designed to solve a number of other tasks (depending on power and characteristics):

- raising cars and other vehicles;

- compression of very tight and powerful springs;

- connection of parts of a building structure at a height;

- repair work;

- other situations when you need to work with a heavy load, fixing it for a long time.