Views

A jack is a device that allows you to lift the maximum permissible weight to a certain height. There can be several types of such devices. Let's review several similar products.

Hydraulic

This is the most common type of rolling jack and is found more often than others. It works by pumping oil from the expansion tank to the slave cylinder using a hand pump. Oil trapped in the cylinder begins to squeeze it out. The extension length depends on the amount of oil supplied. Thanks to the safety valve, with overpressure in the cylinder, the oil will not squeeze out the sealing collars, but will go back to the expansion tank.

Jacks of this type are very popular due to their reliability and unpretentiousness. However, they need timely maintenance and proper storage. It is undesirable to keep these devices in rooms with high humidity. This can cause corrosion on the working surface of the stem, which in the future will lead to rapid wear of the sealing lip, then oil will start to leak. The jack must be stored horizontally so that it has support on all wheels.

Professional

They are also called "low profile". These jacks allow the lowest vehicles to be lifted to a maximum permissible height of up to 503 mm. It is equipped with more massive and durable wheels, since it is meant to be used on a daily basis. Some models are equipped with a dedicated jack lifting pedal. It allows for better regulation of the process in order to avoid sudden jerks of the machine. Otherwise, this is an ordinary rolling jack. The service interval for these models is very large.

Pneumatic

To operate this type of jacks, additional equipment is required in the form of a compressor and high pressure hoses. In addition, the working area of the product is limited by the length of the hoses. Such lifting mechanisms significantly save working space, and for lifting or lowering, you need to regulate the amount of compressed air using an air valve. To lift the car, it is necessary to open the air supply valve and close it in time, and in order to lower the load, it is necessary to relieve the pressure by slightly opening another valve. If the garage is small and has an air compressor, then such a product will significantly save working space.

Depending on the model, this type of trolley jack has a long handle that allows the device to roll under the middle of the machine and lift it up front or rear. Thus, each type of work has its own type of pneumatic jacks. Such products have the most important advantage - the speed of lifting and lowering.

Other

There are mobile varieties. This small jack will be able to satisfy all the requirements of motorists, whose cars have low ground clearance. The pick-up heights of the compact models range from 90 to 100 mm. Like any rolling jack, it is equipped with a hydraulic pump and cylinder. The carrying capacity of such products does not exceed 4 tons, most often there are models for 2 and 2.5 tons.

How to make the right choice?

When choosing, it must be borne in mind that rolling jacks are of different varieties and have different technical characteristics.

Types of rolling jacks

- Trolley hydraulic jack. The lifting mechanism in it is driven by the created oil pressure in the piston. It is used both for personal purposes and for car workshops for lifting passenger cars weighing up to 4 tons.A type of sliding hydraulic jack is a scissor jack: elongated, double-plunger.

Hydraulic rolling jack MEGAPOWER M-83503. Carrying capacity 3.5 ton, lifting height 145-500 mm (price about 5 thousand rubles)

Hydraulic rolling jack device

The main difference between the rolling jack and the others is the horizontal arrangement. The wheels mounted on the body make it easy to transport the device over the surface without lifting it. On one side there is a drive lever, on the other side there is a lifting platform combined with a hydraulic cylinder. The pressure in the hydraulic cylinder is created by pumping up the pump located in the casing, which starts pumping after pressing the drive lever. When lifting the support platform, its position changes, it approaches the lever.

REMAX trolley jack with raised platform. Carrying capacity 3 tons, pick-up height 133 mm, lift height 465 mm (price about 5 thousand rubles)

In order for the support to be reliable when lifting, you need to roll up the jack under the car at the same time as pumping up.

Specifications and model overview

- Carrying capacity. A 2t trolley jack and a 3 t trolley jack can respectively lift weight up to 2 and up to 3 tons, there are also 5 tons: common use - service stations, dealerships and car repair shops. The lifting capacity of the pneumohydraulic models is respectively higher than 5 tons to 10 tons. Used for the maintenance and repair of buses, special equipment and trucks. Some models of pneumatic hydraulic jacks can lift loads over 20 tons, for example TORIN SJQ0100 - lifting capacity 22 tons.

- Pickup height. The smaller this parameter, the more versatile the use of the jack. To service a sports car, a pickup height of no more than 65 mm is required. Sports cars have the lowest clearance (ground clearance), Niva (VAZ-2121) has 220 mm, Volkswagen Touareg II has 300 mm, and Hummer H1 has 410 mm.

- Lifting height. To raise the car when removing the wheels, a jack model with a lifting height of 300-350 mm is sufficient. For the maintenance and repair of cars in car repair shops, models of rolling jacks are needed for cars with a lifting height of more than 400 mm.

Jacks from brands such as MATRIX, WINNTEC and Ombra are popular among motorists who love reliability.

Comparative characteristics and prices of rolling jacks of the brands MATRIX, WINNTEC, Ombra

Characteristics of MATRIX jacks, brand - Germany, manufacturer China

Characteristics, add. devices

Characteristics of jacks brand WINNTEC system TURBO LIFTER., Manufacturer Netherlands

Characteristics, add. Devices

Rolling garage jack Ombra, brand Russia, manufacturer China / Taiwan

Characteristics, add. Devices

It is more convenient to use a jack with a rotary handle - we can recommend the MATRIX 510345 jack:

- Carrying capacity - 3 tons;

- Pick-up height - 130 mm;

- Lift height - 410 mm;

- Handle - rotary;

- Price from 3500-4000 rubles.

It should be noted that jacks with a swing handle are needed mainly for professional repairmen. In many cases, a rotary knob is not necessary.

Many positive reviews can be found on the Powerzone 380044 jack:

- Carrying capacity - 3 tons;

- Pick-up height - 100 mm;

- Lift height - 463 mm;

- The handle is not rotatable;

- Price from 5000-6000 rubles.

Tuck up three-ton jack Powerzone 380044

Important! The hydraulic trolley jack is designed to raise a load, but is not designed to hold it. When buying a jack, buy safety stands

Set of safety stands "Zubr" 285-420 mm (price about 1200 rubles)

How does a hydraulic jack work

The hydraulic jack is an easily transportable device that has the highest lifting capacity compared to other similar mechanisms. Also among his fellows it is distinguished by longevity.

Appearance

Operating principle

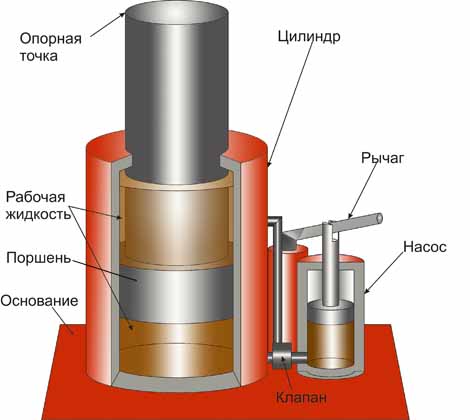

Several details are outwardly visible:

- Cylinder - it contains a piston and two sections with a working fluid.

- A pump that pumps liquid. It is connected to the cylinder by valves.

- Lever arm.

- Anchor point.

The pump pumps liquid from the first reservoir in the front plane of the cylinder to another, which is located in the rear plane.According to the principle of communicating vessels in the section from which the liquid was removed, an increased pressure is created. It pushes the piston out, and it lifts the load.

The mechanism is very simple, as is the design, due to the small number of parts. It is worth considering the function of additional elements:

- The base is what the pump is mounted on. The base should have a large area to compensate for the mechanical pressure when lifting the load.

- Reserve tank - connected to the cylinder, it houses the lever system and the pump.

- Piston - Rises due to oil intake.

- Plunger - Limits the piston lift height.

Jack details

The jack is located below the object to be lifted and does not need ropes, ropes, fasteners and other auxiliary parts. But you won't be able to hold the object on weight for a long time - the device serves exclusively for lifting.

What is the difference between the models

The main distinguishing feature of jacks is their carrying capacity, lifting and lifting heights. With a focus on them, device models change. For example, the lift height depends on the distance between the base and the anchor point. There are also features in the lifting principle.

Another quality is durability. Car enthusiasts for home use once a year and repair services need different mechanisms.

Important!

Before starting to repair a hydraulic jack, you need to know the model and features of its operation.

Roll-up type

The entire mechanism is located on a frame that is attached to the wheels. The compact and mobile rolling type can be used even in hard-to-reach places. The system of levers and pistons is located horizontally, due to this, the device can be easily placed under any load (for example, a car) and raised at any angle. Additional details in the rolling model:

- 2 wheels,

- suction and discharge pump,

- lifting platform,

- frame instead of base,

- lever - it must be pressed in order for the pump to work, which will transfer the hydraulic oil through the valves to the cylinder.

Roll-up type

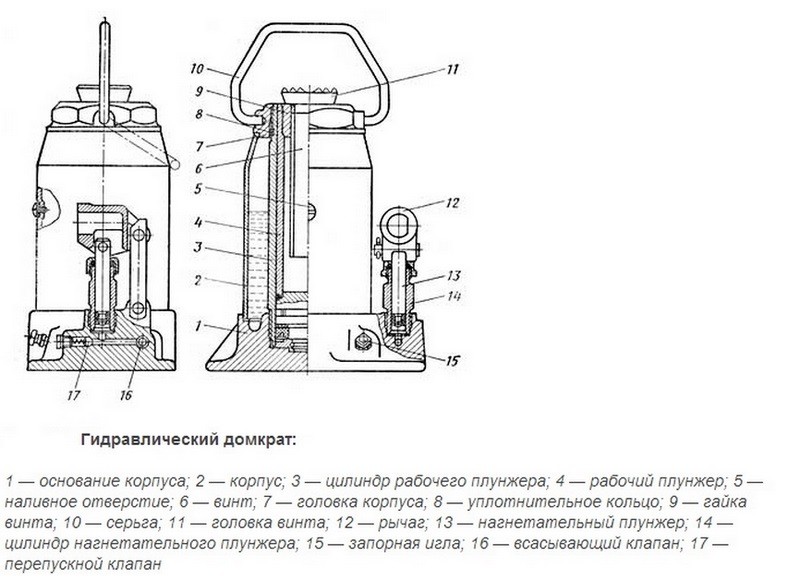

Bottle type

A simple version with a vertical cylinder. A distinctive feature is small size with a high carrying capacity - from 2 to 50 tons. The pickup height in bottle jacks usually starts at 15 cm and ends at 30 cm. The height is adjusted with a screw located at the top of the stem. The bottle type is designed in such a way as to exclude slipping during operation. For this, the support part is corrugated.

Each jack comes with a handle that makes it easier to use the mechanism. Those units that can withstand loads of 30 tons have an additional second handle. The doubled length increases the weight that the bottle jack can lift.

Bottle type

There are other types:

- Pneumatic - a cushion is installed, connected to a compressed air source, for example, a stationary compressor. It is used when the gap between the object and the surface is small. It can also be used with unstable support - for example, in swampy areas, on sand, snow. Such a jack can withstand a load of up to 6 tons.

- Screw - compact, standard car jack. Carrying capacity - up to 15 tons.

- Rack - has a maximum lifting height. A fastening mechanism moves along the rail, which snaps into place and rises like a ladder along with the load. Withstands 20 tons.

Jacks differ in the drive, which can be manual or electric.

A jack handle is a mechanical lever that is used to pump fluid. Electric drive means that the mechanism has an automatic built-in pump. Repairing the electrical version requires special equipment, while the bottle and rolling mechanical types can be repaired on their own.

If you are buying an industrial product, pay attention to the following points:

Can an inflatable jack work efficiently from a car compressor? It is clear that sooner or later, you will raise the car to a given height. But by this time, the compressor may fail from overheating.

If your garage does not have a compressed air blower, or if you need a pneumatic lift for travel, you need to find a compromise between chamber volume and lift height. A large air cushion will lift the car by half a meter, but it needs to be filled with something, and as quickly as possible.

For a passenger car or small crossover, a compact pneumatic jack with a lifting height of 400 mm is sufficient. Such a lift has a lifting height of only 65 mm (it can be brought under the lever even with a flat tire), and the lifting height reaches 30 cm with a lifting capacity of 2 tons.

Compact cushions (diameter 250 mm) do not require a lot of air. The powerful car compressor will lift the car in 10 minutes. And if a pneumatic jack is needed to work in a service, especially at tire service stations, you can not be shy about the size.

At a minimum, such a station has a compressor with a large receiver (you need to pump up the customers' wheels with something). An important point is ease of use. For operational work, the lift must be equipped with a trolley with a long handle. The lift control system is easily accessible - the operator must perform a minimum of unnecessary movements:

- I drove up, opened the valve, fixed the height.

- He opened the valve, lowered the car, rolled the jack.

A typical pneumatic lift for a workshop looks like this: Characteristics - sufficient to work with cars and SUVs of all sizes. Carrying capacity 3.5 tons. In the presence of a powerful compressor (220 or 380 volts) with a large receiver, it takes a few seconds to rise to the maximum height.

Important! The pneumatic jack is, in principle, not equipped with a safety device against a sudden fall.

That is, in the event of a sudden air leak, the heavy vehicle will fall. This could result in personal injury. If there is a need to work under the bottom of the car, be sure to use stops or trestles after lifting with a jack.

There are models equipped with fall protection mechanisms - pneumatic scissor jacks. The design includes a protective stop. A separate technology is soft pneumatic jacks without support pads. In fact, it is just a cylindrical pillow made of durable material. Power is enough to lift a heavy SUV. Since the volume is large enough, it takes too long to inflate the pillow with a portable compressor. The design provides for an operational set of volume, gases from the exhaust pipe. And then the pressure is increased by the car compressor. Of course, such a pneumatic jack cannot be considered as a full-fledged tool for repair work. Rather like an off-road emergency kit.

How to choose a pneumatic jack - video tips

Preparation method

Homemade hydraulic jack must withstand a sufficiently high pressure, be stable during operation.

Do-it-yourself rolling jack during assembly

The whole process of manufacturing a structure can be divided into several main stages:

- The first assembly is represented by a support platform, which must be manufactured using the most durable materials. High structural strength is achieved by creating several stiffeners from the channel.

- Greater stability of the base is achieved by using a 10 mm thick steel plate that is welded to the base.

- The next step is to create a stop and uprights from a profiled thick rectangular or square pipe.To calculate the required length, the maximum stroke is taken into account, to which the height of the lifting mechanism itself and the support platform is added.

- The rolling structure is created by installing the support platform on the wheels. They also need to be highly durable and withstand high loads.

- For the use of a rolling jack, a folding handle is created. It is also made from a pipe or a corner, and to adjust the angle, the handle is attached with a curtain.

It is quite difficult to make a hydraulic cylinder on your own. This is due to the fact that all elements have exact dimensions, the inner surface is ground to a mirror surface.

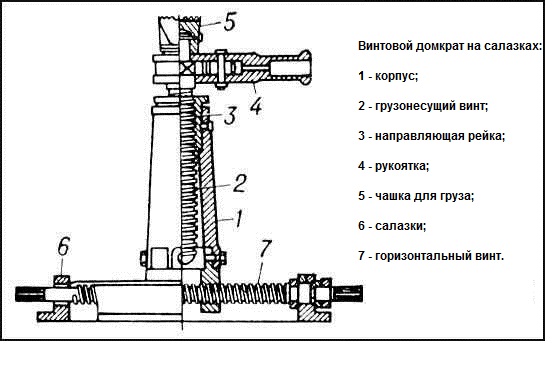

When considering how to make a jack with your own hands, it is worth considering the possibility of creating a screw structure. It is less practical to use than hydraulic, but at the same time it serves for a long period. The features for creating a homemade design are the following:

- To create a homemade design, you will need a channel and a rubber gasket, a threaded screw and axles holding the lower and upper arms.

- At the preparatory stage, holes are drilled for fastening the main elements, after which the rolling jack is assembled.

- The shoulders are connected and fixed to each other on the base.

- The threaded screw is threaded into the shaft and the load capacity of the structure is checked.

Using a rolling jack to repair a car

A homemade rolling jack is much cheaper than the purchased version, while it will last for a long period. The pneumatic model is designed for lifting large-sized equipment, screw for passenger vehicles.

Bottle type screw jack

Screw models of jacks, which have long been loved by motorists, receive a lot of positive feedback on their account. The fact is that this type of instrument has a number of advantages over other varieties.

For example:

- small dimensions;

- efficiency of use;

- durability;

- stability;

- simplicity and reliability.

It is very easy to fit in the trunk as it does not require a lot of space. Plus, it can be stored in any position, unlike the hydraulic type. This jack belongs to mechanical samples, therefore, in the event of a breakdown, it can be repaired by yourself.

Screw bottle jack

Another plus of such a unit is its price. In relation to other varieties of such tools, this type is cheaper, therefore it is more popular with car drivers. But still the price varies, and it depends on the manufacturer and the material from which the product is made.

At screw bottle jacks there are also disadvantages:

- small carrying capacity;

- low lifting height;

- insignificant support area;

- the need to constantly monitor the threaded connection.

Note!

The unit of this type has a lifting capacity from 1 to 32 tons.

What are they?

There are various types of screw jacks with a worm gear, but the main task of each tool remains the same - lifting and fixing the load in a certain position during the repair. The presence of a screw helps to lift the car without additional devices in the form of ropes or chains.

Most often, in the conditions of Russian roads, a vertical lever-screw jack is used. Vehicle weight can be up to one ton.

Levers and a screw are the main ones in the design. The angle between the levers is changed using a special handle. Such tools are small-sized, have a small height and a working stroke. The structure is rigid, the support is wide. Their plus lies in simplicity and versatility when carrying out repair work.

Rack

This type of long stroke design can have multiple screws, which increases the lifting capacity. Additionally, the mechanism has a rigid body and thread, one screw is screwed into the other, which guarantees a certain lifting height. The only drawback of such structures is their weight and low lifting height (with one screw).

Telescopic

The type of jacks working due to the presence of a cylinder and a pivot point, which guarantees the fixation of the load in a given position. Sometimes in such models, a spacer mechanism is provided, which increases the performance. In the cylinder, a special piston occupies a key place, which provides a connection with the rest of the mechanism. If the design is hydraulic, then the presence of a pump with a liquid is also provided. The difference in liquid level is what gives the work efficiency.

In this case, the piston performs the function of pumping by means of valves. One of them is located near the cylinder and prevents oil from entering the key parts of the mechanism. The position of the liquid in the reservoir is maintained under pressure. The pressure when lowering the load decreases evenly, and the working fluid returns to the reservoir during operation.

Cable

The myth that jacks are only used to change wheels has long ceased to hold water. On the road, the tool is used precisely for this, but this is far from its only purpose. It all depends on the type of tool and design features.

The cable jack is designed for lifting drums. It is used as a pay-off device in the process of cable rewinding and laying. Using it, it is much easier to rewind or rewind the cable completely.

The jack axis is threaded through the central hole of the drum and is fixed between the bushings and the cones. The structure additionally receives protection in the form of frames and, only after that, it is the turn of work for the lifting mechanism. Lift in conventional models can be carried out up to 100 mm. The design of cable jacks can be screw, lever or hydraulic. It all depends on what kind of tool the user needs to work.

Industrial

Industrial jacks are lifting devices of a completely different class, designed for professional maintenance of a wide range of vehicles. Their designs can be with ratchet or screws, but the main thing that distinguishes them is their high technical characteristics.

For example, industrial type mechanical jacks have a lifting capacity of more than 20 tons. And the performance of hydraulic models of the same line can reach up to 200 tons. All this is combined with strength and a fixed lifting height. It is clear that this option is not suitable for a home workshop.

With electric drive

Despite their name, such jacks are quite capable of autonomous operation; they do not have to be constantly connected to the outlet. The on-board electrical system will also do, the jack will work even if the engine is out of order. The work algorithm is quite simple:

- the device connects to the network;

- the required height is created using the remote control;

- the jack lifts the load on its own.

Other

If we talk about other types of tools, then a mini plastic jack is more suitable for self-production, this is the option that is completed today for most Russian-made cars. Typically, these devices are classified as rack jacks and have a simple threaded screw design. There are two screws in the design. It is with their help that the car is lifted, and then the load is securely fixed. The ease of use of such a design is individual for everyone, many drivers find it easier and more accustomed to resort to using hydraulic models. But the mechanical model is easier to transport.

DIY repair

A hydraulic jack rarely breaks seriously, most often the problem is dirt, valves or lack of fluid. All of this is easy to repair, as well as fixing a more rare problem - a leak.

Broken valves

On a note.

If the jack is full, but still does not hold or lift the load, it is necessary to disassemble the device and check the valves.

Attention is drawn to how the valves fit into the seats. If the contact is loose, check the springs that may have weakened

The valves could get clogged, so remove the dirt with a damp piece of cloth, then dry thoroughly. If the contamination is strong, for example, due to oil, then flush with gasoline, kerosene. Then dry with compressed air.

Jack scheme

If the valves are deformed, then they must be replaced with new ones.

The springs are checked, in case of loosening they are replaced with more elastic ones. If it is not possible to replace, then a washer can be placed under them so as to increase density and strength.

Fluid leak

Occurs with mechanical damage and breakage of parts. It is required to completely disassemble the jack, along the way checking metal parts for corrosion, for example, the piston. Elements, in particular the stem, are checked for deformation. Damaged parts are replaced with new ones.

It is recommended to drain all oil and rinse the jack and parts with kerosene. Old cuffs and gaskets are replaced with new ones.

How to remove air or dirt

Air accumulation is inevitable during continuous operation. In the same way, dirt gets into the working cavity.

The jack works on the principle of communicating vessels, that is, when the liquid leaves, pressure remains. But the air in the system does not escape under pressure, but is deformed and creates a cushion, due to which lifting is impossible.

Air is eliminated when changing the oil. Dirt is removed with a sediment remover.

Disassembled jack