Grinding and polishing

In a separate group, it is necessary to make a huge number of nozzles intended for polishing, cleaning, surface grinding. With their help, you can not only remove paint or unevenness from metal or wood, but even remove a few millimeters of the material, increase its strength characteristics and much more! Let's take a look at some of them.

- Grinding attachment for a drill. Designed to remove rust on metal, eliminate visible product defects, sharpen steel cut and many other functions. Grinding drill bits are rods that hold abrasive bits. When the chuck rotates, it accelerates to the same speed and is used as a grinding wheel. The abrasive can have different grain sizes.

- Drill attachment for grinding wood. A similar object, as for metal processing, only instead of an abrasive, a polyurethane, rubber, mineral (etc.) circle is installed, with which you can make the surface extremely smooth and without chips, needles.

- Drill attachment for polishing. This is a specific tool, the base of which is made of rubber and foam rubber, an emery wheel can be attached to them. This design ensures maximum processing quality. Nothing worse than a polishing machine. The only drawback is that the drill turns out to be much heavier, so it will be a little uncomfortable to hold it.

- Grinding "sun". Another unusual nozzle. It is a circle from which strips of sandpaper emerge like rays. When the chuck rotates, the paper petals accelerate to high speed and grind any metal in a few seconds! The attachment is short-lived, enough for a couple of hours of work, but very effective!

We've covered the most useful attachments. Now the choice is yours: use these devices or buy expensive devices.

Material of manufacture and shape of nozzles

The design and material of drill bits depends on the type of technological operations in which they are used. For cleaning and roughing surfaces, various types of brush attachments are used, and for preliminary grinding - flat or petal based on coarse-grained abrasive paper. For fine grinding and polishing, fine-grained abrasives or non-woven materials are used. In the latter case, they are often used with grinding and polishing pastes and aerosols. When grinding requires the removal of a thick layer of material, including unevenly, cutters of various types from hard abrasives based on aluminum and silicon compounds are used.

Disc and fan nozzles

Flap circles are also used as attachments for drills. They consist of many identical strips of sanding paper, fixed at one end to the axis of rotation, resulting in a dense circular brush of abrasive lamellae. For external similarity, such nozzles are called fan-shaped in everyday life.

End caps

Abrasive end nozzles for drills are one of the varieties of cones - a locksmith tool that is used for manual grooving of profile surfaces, expanding holes and removing excess metal in hard-to-reach places. Such a roller cutter is a cylindrical shank, at the front end of which an abrasive head is pressed. And the name "face" is associated with the fact that processing with such a tool is most often performed in the perpendicular direction. Socket heads are available with a wide variety of heads: round, conical, cylindrical, parabolic, etc.Therefore, you can always choose a cutter, the geometry of which most closely matches the profile being processed. The material of the abrasive heads is various grades of high hardness emery stone. In a fixed drill, cylindrical cutters can be used to sharpen locksmith tools.

The most common tips and their descriptions

There are several hundred different attachments and they all differ in some way from one another. It is simply impossible to cover the entire range of products, so let's start with the most "popular" models that can replace your expensive tools. With their help, you can perform basic construction and finishing work, process many surfaces and materials.

We do not take into account the drill and the "shovel", only additional accessories. Let's take a closer look

- Crowns. Unique attachments for making holes in wood. An irreplaceable thing in the manufacture of furniture. They have different diameters and heights. As a result of the work, you get perfectly smooth holes in any wood. The cost of such crowns is from 40 to 700 rubles per piece (depending on the manufacturer, steel grade, height and other parameters).

- Screwdriver bit. There is nothing easier than making a regular screwdriver out of an electric drill. It is enough to buy inexpensive cruciform and straight tips and you have 2 types of screwdrivers at once. More precisely - 3 types, since there is also a percussion (punching function on a drill).

- Metal brush circle. Used for metal work (mainly), it is a metal bristle that is located around the shaft, and he, in turn, is attached to the chuck. This shape is made to maximize the balance of the nozzle. When you turn on the device, the brush has a very high speed and removes all rust and irregularities in seconds!

- Corolla. For mixing building mixtures, a specific nozzle in the form of a long screw and a large holder is used, which is inserted into the tool holder. With the help of such a thing, you can mix excellent tile adhesive, bricklaying mortar and whatever you want in a few minutes. Yes, at least mix the paint with a solvent! The quality of the mixture is much better than in the case of manual preparation of the mixture.

These attachments are known to almost every builder and have gained immense popularity not only in the construction industry, but also when performing many household tasks.

Choosing the cost of the device and the manufacturer

The list of well-known manufacturers who are responsible to the consumer for all their products is as follows: Bosch, Bort, Stayer, Gardenlux, Makita, FIT, Dremel, Prorab, Sturm, DeWalt, Vityaz. As for the difference in prices, there is a wide variation. Simple, low-functional devices are purchased for an amount equivalent to 15–20 dollars, and for devices with high power with a varied number of processes, you will have to pay about 1 thousand dollars.

For some novice specialists and amateurs, the cost of the device and brand recognition play a purely symbolic meaning, it is much more important if the device exactly matches the work for which it will be purchased. It is this requirement that allows us to buy high-quality devices at a low cost from our domestic manufacturers.

Design features

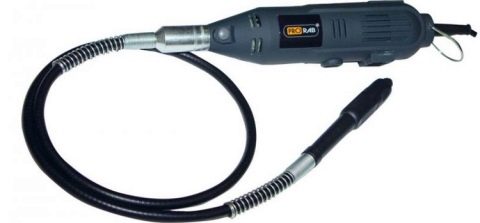

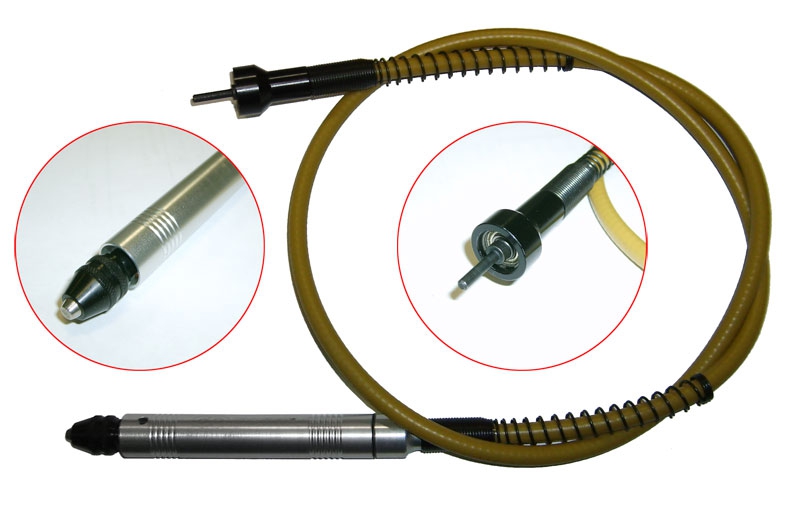

The main design feature and at the same time the main advantage in application is the ability to bend it anywhere in any direction. This is achieved by using the following components:

- flexible and durable steel braided cable that transmits torque;

- armor braid or coil-wound spring wire that acts as a flexible drive body.

The outside of the wire is covered with a corrugated plastic sheath, inside of which there is a grease. It reduces friction, prevents abrasion of the core cable and protects it from moisture and dust.

The design of the drill's flexible drive also includes bearings to which a cable is attached. They keep him spinning. At one end, the cable is fixed in the chuck, at the other end, a tool holder is provided on it.

Extension shaft with collet

Such a drive is designed for light and delicate work, you should not count on turning a sour bolt with it or turning a 130 mm self-tapping screw at full speed - you must remember that the torque transmitted by the flexible shaft is limited.

How to do the job with a flexible shaft engraver

Beginning of work

distracted by looking for a nozzle or flexible shaft

In order to prevent the chips from sticking to the tool, selected from the surface of the material, it is lubricated with paraffin. After 15-25 minutes of using the device, it is turned off to cool down (if the design does not provide for a heating system).

Engine speed change

It is necessary to change the speed of revolutions in case of switching to another operation or when changing the processed material. If a soft material such as plastic is in the work, then its drilling and grinding is carried out at a low speed so that the edges of the cut parts do not melt and smear the whole picture. To work with metal, you need the speed of the averages. A high number of engine revolutions will be needed when processing hard stone, otherwise the natural material simply does not lend itself to grinding or drilling.

Instrument care

Use a soft cloth for cleaning, you can use a soapy solution to moisten. It is not allowed to use various solvents, alcohol or aggressive detergents for cleaning.

They constantly check the working condition of the nozzles, if any are out of order, they must be replaced. Incorrect vibration resulting from working with a worn accessory can damage the tool.

The use of a flexible shaft engraver is a creative process, it is important to choose the right model of the device and take into account the characteristics. Then the engraver will serve without breakdowns for a long time.

What operations are performed using a flexible drive engraver

Special attachments help to turn an engraver with a flexible shaft installed on it into a truly universal device, including:

- grinding and polishing wheels, allowing to bring the surface of the workpiece to an impeccably smooth state;

- brushes used for cleaning the surface of the product and grinding it in hard-to-reach places;

- cutting wheels for cutting products and processing their torn edges;

- drills, with which the device turns into a miniature drill;

- cutters and, allowing you to process products in hard-to-reach places;

- pen-shaped nozzles, with which engraving work is performed.

To ensure the convenience of working with such a device equipped with a flexible drive shaft, you can purchase additional accessories - rubber pads on the handle, power button lock, etc.

All kinds of holders turn out to be very useful, in which, in addition to the shaft and the engraver, various attachments can be fixed.

Engravers, on which a flexible drive shaft is installed, also include a drill used in dentistry, a manicure machine, equipment for processing natural stone and applying inscriptions and drawings to the surface of products from it.

You can also use a flexible shaft for a drill or purchase a flexible shaft for a screwdriver. With this enhancement of familiar power tools screwdriver attachment or a drill can be successfully used to perform work even in the most inaccessible places.