Types of cutters for agricultural work

Cultivator cutters serve many different functions. With their help, farmers have the opportunity to:

- Quickly destroy dense weeds;

- Cultivate the soil;

- Mix soil layers with fertilizers;

- Level the surface of the ground.

The cutters show themselves especially efficiently on clayey, waterlogged and stiff soils. Cutters are also often used for plowing virgin lands in pastures and meadows.

There are several types of cutters. Depending on the form, there are on sale:

- Accessories with saber-shaped knives - they are in the greatest demand among buyers and allow you to perform a wide range of works. The main advantage lies in the shape of the blades and the material - the cutters are made of steel and can be removed at any time. The vegetation practically does not wrap on them, which allows you to plow the soil many times faster;

- Cultivator cutters of the "crow's feet" type are a new solution in the equipment market. This type of equipment is often used for plowing hard soils. It cannot be disassembled, which makes it more durable than the first type. Among the downsides is the frequent winding of weeds on the blades, which is why most farmers use these cutters to work on "clean" soil. Often "crow's feet" are used for plowing before planting potatoes, as well as for treating the soil in order to prevent the appearance of Colorado beetles and other pests.

You can buy additional cutters of the required width today at any gardening equipment store. However, at a reasonable price, most often it is possible to buy Chinese products that are not particularly durable. Because of this, it makes sense to try and make the cutters yourself.

Milling cutters for a motor-cultivator are not distinguished by a complex design. Before you start creating items yourself, you need to carefully study the store options. This will make it possible to take into account all the design features of the equipment and make an effective inventory.

Before work, you need to make a drawing or use a ready-made scheme. It will need to indicate the material of each of the parts, the sequence and method of attachment.

After that, you need to prepare all the materials. If curly elements are used in the design, then it is better to order them immediately from the master.

When creating a cutter, special attention must be paid to the correct assembly. Try to avoid any deviations associated with the design, because any mistake can significantly reduce the efficiency of the cutters.

Moreover, improperly assembled inventory will pull the cultivator to the right or left.

An important factor is the position of the teeth. They must be installed in exactly the same position as in the design of store products.

Experts advise against making cutters larger than 50 cm in diameter. Equipment of this size is capable of sinking 26 cm into the ground, covering a strip 1 meter wide. This is more than enough for quality plowing.

Cutters in the shape of a saber are considered safer and are not able to harm the operator if he falls on a structure. The knives on them have a transverse arrangement and consistently plunge into the soil, without jerking.

To extend the life of homemade cutters, you must adhere to the rules for using inventory. When starting the cultivator engine, all knives must be positioned above the soil surface. After switching the engine from idle, the blades should be slowly lowered and plowing the soil should be started.

Not knowing whether to sharpen homemade cutters, many beginners make a lot of mistakes. It must be remembered that the more often the sharpening is performed, the better the result of the soil treatment will be, and the longer the knives will not succumb to corrosion.

Installing the cutter

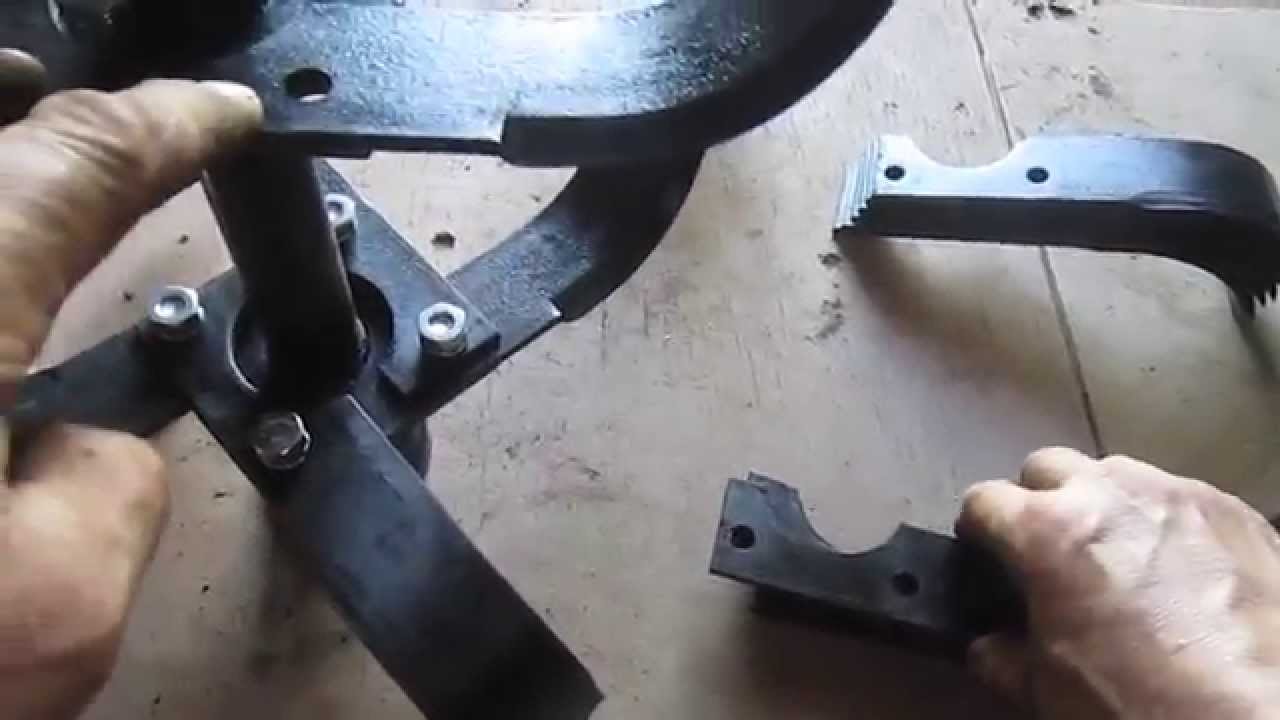

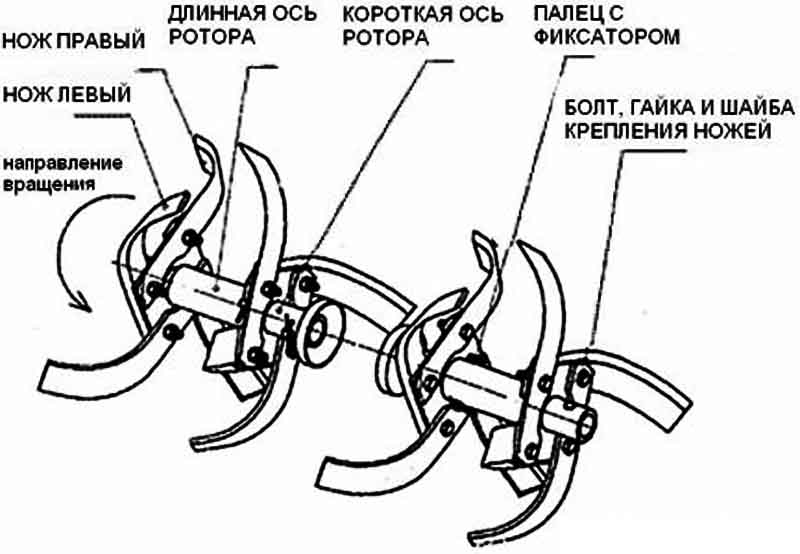

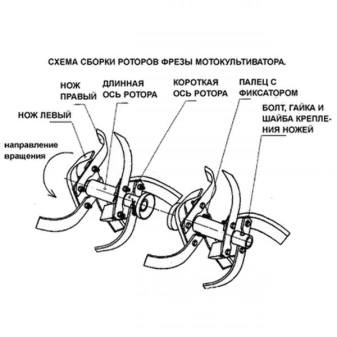

The process of installing a cutter on a walk-behind tractor is quite simple, but before starting work, you should carefully study the manufacturer's instructions and understand the installation features. The standard cutter design includes a rotor axle, a pin equipped with a special lock, several knives and fasteners. The installation of this equipment should be done in such a way that the cutter rotates counterclockwise. Tillers are self-sharpening tools that greatly simplify the process of using them. In other words, it will not be necessary to constantly disassemble the structure in order to sharpen the knives.

It should be noted that during the installation of the cutter, problems may arise, therefore experts do not advise to carry out the installation on their own - it is best to get an assistant in advance. The installation of a saber cutter deserves special attention. The fact is that it is not a monolithic structure, so first you have to properly assemble the product. The main thing is to establish the correct direction of rotation, since without this the device will not perform its tasks.

Collecting such an element with your own hands for a walk-behind tractor is quite easy, because this is a task that is quickly mastered, but first it is better to study the functions that the unit will have to perform. Before starting the homemade assembly of the saber cutter, you need to carefully understand the drawing, and after installation, it is imperative to check the unit for operability. Usually, the first time it is not possible to fine-tune the equipment, so you have to make some adjustments to its operation.

Thus, cutters represent one of the most important elements for ensuring the efficiency of the walk-behind tractor. You can buy them at almost any specialty store. A large selection allows each person to choose the best option depending on the model and other features of their walk-behind tractor. The process of installing cutters is also quite simple and requires only care and an assistant.

For information on how to make do-it-yourself cutters for a walk-behind tractor, see the next video.

Which cutters are better for a walk-behind tractor: saber or "crow's feet"

Choosing the option of a rotary tiller for your unit, one should proceed from the characteristics of the soil. Of course, saber knives can easily cope with the cultivation of previously cultivated soils. When it comes to cultivating virgin lands or lands densely overgrown with grass, the basic mill cutters sometimes do not cope very well with the load due to the insufficient quality of materials and assembly (bolted and welded joints). The processing of heavy soil with such cutters is a rather heavy load on both the walk-behind tractor and its operator. Purchased or home-made cutters with knives made of high-quality metal cope with their task much easier.

As for the version of the "crow's feet" cutter, you can install the desired number of sections on the walk-behind tractor, adjusting its performance to the needs of your own farm and the power of the unit. This type of equipment handles hard soils and vegetation debris more easily and provides easier control of the device during operation. Many users mark this particular design as optimal from the point of view of practicality and reliability.

Useful Tips

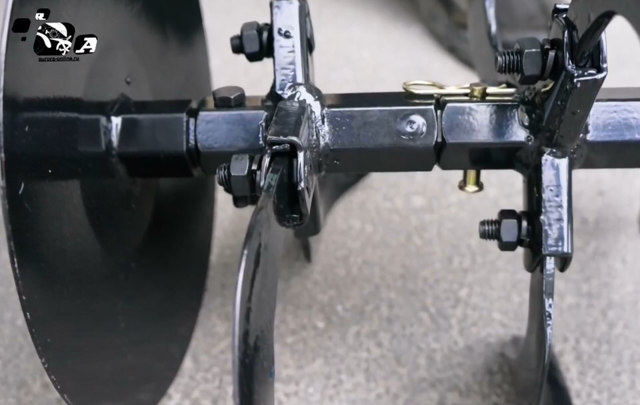

In order to optimize the load and increase the service life of the cultivator, the loosening width is selected by changing the number of mounted soil cutters.

The adjustable opener allows you to adjust the blade depth.He does all the work, you do not need to put any effort on the walk-behind tractor. The steering handle is slightly pressed to the ground, the coulter enters the soil more strongly and slows down the movement of the technique, thereby increasing the depth of cultivation.

In order for the gearbox not to rest against the untreated ground, the equipment is shaken a little.

When working with the cultivator, the user must keep his back straight and his hands at waist level. This position of the body contributes to a longer operation of the unit and will not harm health.

If the blades become dull after prolonged use, they must be sharpened with a grinder. Self-sharpening knives are chosen for ease of maintenance. The type of soil has a great influence on the cutting edges. Knives wear faster in wet or heavy ground.

For more comfortable work and high-quality soil cultivation, the rotational speed of the cutter for the console walk-behind tractor should reach 275 rpm, the cultivator - 140 rpm.

If mechanized equipment does not work well with the soil cutter, it is necessary to find out the cause of the malfunction and eliminate it in a timely manner. If it is impossible to carry out repairs, they turn to specialists for help.

The need and rules for sharpening during operation

When the walk-behind tractor is in operation, the working surface of the knife will inevitably wear out. To restore the cutting ability of the tool, it must be sharpened periodically. The timing of the procedure is purely individual. The wear rate of the knife depends on the following points:

- intensity of use of the walk-behind tractor;

- the hardness of the cultivated soil;

- the presence of plant roots or stones in the ground;

- the strength of the material of the knives.

Agricultural machinery manufacturers supply cutters with sharp blades. Therefore, when buying a walk-behind tractor, it makes no sense to sharpen the knives. However, the procedure cannot be avoided with intensive operation of the unit. To restore the sharpness of the knife, you will need an angle grinder (angle grinder or "grinder"), a sharpening or diamond wheel with a diameter of 12.5 cm. You can use a grinding machine, however, the dimensions of the cutter and the curvature of the blades will not give a good result. If the knives are small, they can be sharpened with fine-grained emery paper.

Sharpen the working edges at an angle of 45 °. Remove the metal layer from the side of the factory sharpening. In this case, do not get too carried away: it is enough to grind off 1-2 mm. Over the season, it may be necessary to restore the cutter's cutting ability several times, and excessive metal removal reduces the strength of the knife. In some cases, the frequency of sharpening increases - it all depends on the intensity of exploitation and the type of cultivated soil.

When using the cutter in wet ground, the surface of the blades must be thoroughly cleaned. When rubbing against the ground, the metal surface is cleaned of the oxide film and becomes chemically active. This process is accompanied by increased corrosion, which entails the formation of pockmarks, chips, microcracks. To prevent such phenomena, the blades should be treated with special inhibitors or automotive oil.

2 Varieties of milling cutters for a walk-behind tractor - active, crow's feet

Milling cutters for walk-behind tractors can be of two varieties, these are:

- Houndstooth knives

- Active (saber).

Active knives are maximally adapted for all types of work performed. Their saber shape is considered the most popular, and it is quite simple to assemble them correctly with your own hands.

The effectiveness of active cutters was confirmed by the results of their use over the course of decades, and in most cases, cultivators are equipped with active (saber) cutters.

For the manufacture of such attachments, high quality carbon steel with a high degree of strength is used.

Active knives are characterized by a collapsible design, assembly and installation of products takes several minutes.

The steel used to create active milling cutters is completely incompatible with welding, and to improve the mechanical strength of products during production, the so-called thermal hardening is used. To enhance strength, the finished product is treated with high-frequency current.

Active saber cutter

Relatively recently, "crow's feet" cutters began to be used for motoblocks. This modification is recommended for the treatment of difficult and hard soil types.

It is this type of suspended equipment that is used in difficult conditions of unevenness and rocky soils.

The design of such knives is solid, which directly increases the strength characteristics of the products. The cutters are produced with standard technical characteristics:

- width - 40 cm;

- length - 37 cm;

- height - 38 cm;

- weight - 16 kg;

- permissible working speed of the cultivator - 2-5 km / h.

Such a tool also has its drawbacks - ordinary carbon steel does not have high strength characteristics. The knife should be inspected regularly, especially when working on clay soils.

2.1 Features of the assembly of milling cutters of a motor-cultivator

Before the assembly of the blades begins, it is recommended to prepare a drawing of the future device in advance and acquire the necessary tools and materials.

If in the process of creation you need curly components, then it makes sense to order them from the master of blacksmithing.

Other structural elements are manufactured independently. The assembly must be done correctly, focusing on the existing drawing.

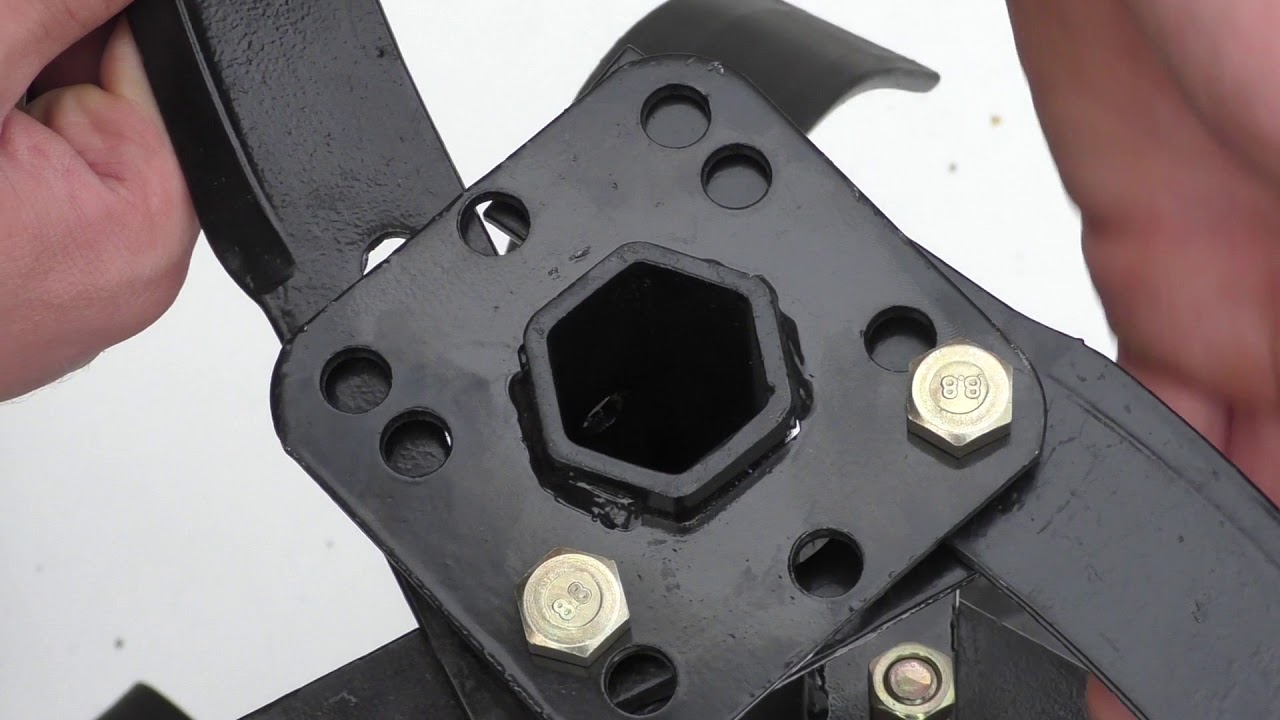

If the assembly does not occur correctly, then during operation the walk-behind tractor may deviate from the line of movement, which will complicate the cultivation of the land. The cutter blades are inserted into special slots and fastened with bolts.

Fastening the cutter to the walk-behind tractor

In this case, it is important to correctly place the cutting edge of the petal. It should be placed in the direction of travel and with a sharp end plunged into the soil

The additional section is attached to the main section using pins, and the limiting metal disc is connected to the frame using bolts.

It is recommended to select the number of blades based on the power of the unit. To assemble the cutting blades, you can use either one or several axes.

When assembling a 4-blade cutter, follow the sequence of the right and left blades on the mounting plate.

2.3 We make do-it-yourself cutters for a walk-behind tractor

For self-manufacture of a milling cutter for a motor cultivator, the following parts and tools are required:

- metal tube with a diameter of 42 mm;

- welding machine;

- angle grinder (grinder);

Do-it-yourself assembly of the unit allows you to accurately adjust its dimensions to the characteristics of a particular land plot.

Used vehicle spring plates can be used to create good soil openers.

During the manufacturing process, the blades should be adjusted to size and bent at the required angle in one direction. Using a welding machine, you need to attach the cutting elements to a pre-prepared tube.

During assembly, you can sharpen the cutting edge in the direction of the planned rotation of the unit. Further, the ready-to-use structure is connected to the unit's coupling unit, and during a test run, the necessary adjustments are made.

Homemade cutter

The "crow's feet" construction is assembled from metal elements with a diameter not exceeding 500 mm.

Due to these dimensional restrictions, the tool will be able to enter the ground to a depth of 250 mm.

During operation, it is worth paying attention to the fact that the knives pierce the ground consistently. In this case, jerks and blows should be avoided.

How to make homemade cutters with your own hands

If the cutters are worn out or there is a need to modernize the cultivator, for example, to increase or decrease the depth and width of cultivation, you can do them yourself.

In many cases, such an improvement allows you to improve the quality of soil cultivation, to get the job done faster.

The design of these parts is simple, so you can make them yourself.

The easiest way to design homemade "crow's feet" cutters for a walk-behind tractor with your own hands is to study the device of industrial cutters and make your own changes.

It should be noted that when the "crow's feet" cutter is made by hand, drawings for different types of motoblocks are developed individually.

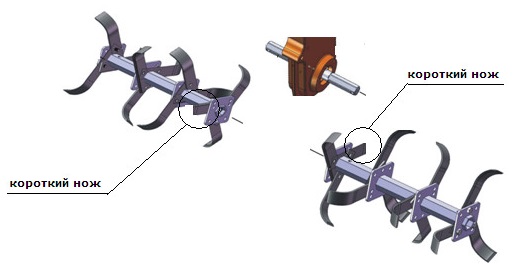

The illustration shows a classic version of a 4-row industrial cutter.

Main elements:

- Sleeve. For its manufacture, you will need a pipe with a diameter of 50 mm and a wall thickness of at least 4 mm.

- Flange. It is made of steel sheet 5-15 mm thick. It can be in the shape of a circle, but it is easier to make it in the shape of a square.

- Rack of a knife. Material - steel corner with 63x40 mm shelves. Vehicle springs can be used. Often the rack is made of steel strip. This is the cheapest option, but also the most unreliable. During operation, the rack plays the role of a vertical plane cutter.

- Leftmost knife.

- Medium knife.

The knives are made from tool steel. Many craftsmen use car springs to make knives. Knife shapes can vary considerably. Their sharpening angle is usually 45 °. In the process of work, the knives become dull, so they need to be sharpened periodically.

Using a welding machine, the knives are welded to the posts, the posts to the flanges, and the flanges to the sleeve. This is how a non-separable structure is assembled. Some craftsmen prefer bolted connections. This design is less reliable, but makes it easy to remove and change the stands. The collapsible cutter is easier to clean of dirt and weeds wrapped around it.

One of the drawbacks of crow's feet is that they go deep during operation, which is not always necessary. There is an additional effort on the motor-block engine, the operator gets tired. To reduce the depth, wheels are installed on both sides of the axle, which act as limiters.

In this case, only the topsoil is cultivated. This method of processing is very convenient for heavily overgrown and soddy soils. After the first pass, the sod is destroyed. Then the wheels are removed, re-cultivation is carried out to the required depth.

The milling cutter is the main working "organ" of the cultivator. With its help, loosening, and weeding, and preparation of the soil for planting are carried out. For mechanical models, as well as devices of the ultra-light and light category, it acts as the only functional element. Trailed equipment is also used in medium and heavy units.

Varieties

The classification of cutters for a walk-behind tractor is based on several criteria. So, at the location, they can be lateral and hinged. The first ones are installed on the wheel drive shafts on both sides relative to the power unit. With this arrangement, the cutters play the role of wheels, driving the walk-behind tractor. The second method of placement involves installing them behind the walk-behind tractor and working from the power take-off shaft. This arrangement is most typical for most modern motoblocks, including such well-known brands as Celina, MTZ and Neva.

The second criterion for the classification of cutters is their design. On this basis, there are 2 types: saber (active) cutters and "Crow's feet".

Saber cutters

They are included in the basic complete set of the walk-behind tractor and are the most popular among farmers. The cutters have a collapsible design, which makes their installation, maintenance and transportation very convenient and simple.The active cutter is made in the form of a block that includes four cutting mechanisms located at right angles to each other. The knives are fastened using bolts, washers and nuts, and the number of blocks on each side of the drive can be 2-3 or more. Welding is not used in the manufacture of cutters. This is due to the special properties of high-carbon steel and its immunity to this method of joining.

The knives that make up the cutter are quite simple and are steel strips curved at the edges. Moreover, they are assembled into a block in such a way that bends in one direction alternate with bends in the other. Due to the shape of the knives, resembling a saber, active cutters are often called saber cutters. This design, combined with the high hardness and strength of the material, makes it possible to use this type of equipment when plowing virgin lands and heavy soils with a high content of stones and roots.

Hound's Feet Mounted Cutters

These cutters have a one-piece, non-separable design, due to which they are characterized by high strength and long service life. With their help, you can not only effectively work stony and clay soils, but also fight small weeds, and also deeply loosen the soil. Standard factory-assembled models have rather compact dimensions: 38 cm in length, 41 in width and 38 in height, while the weight of the structure is 16 kg.

This species owes its name to the peculiarities of the design of knives, which are presented in the form of pointed triangular plates located at the edges of steel rods, and vaguely resembling crow's feet in shape. The number of cutting elements can be different - from 4 pieces in factory models and up to 8-10 in homemade samples.

With an increase in the number of knives, the quality of soil cultivation increases markedly, however, and the load on the engine also becomes much greater.

Therefore, when making your own grip cutters, it is necessary to take this fact into account and not overdo it. The maximum speed at which a walk-behind tractor equipped with Hound's Feet cutters can move is 5 km / h, which corresponds to the average speed of an adult

In this regard, it is quite convenient and comfortable to operate such equipment. The material for the manufacture of cutters is low-carbon steel of medium density, which is why knives are often prone to breakage and deformation when working with problem soil.