Self-production of "crow's feet"

If cutters on your walk-behind tractor are outdated, or you have a desire to improve your equipment, for example, to reduce or increase the width and depth of processing, then you can make the part yourself. Often, such an idea can significantly increase the level of quality of land cultivation, as well as significantly speed up work.

If cutters on your walk-behind tractor are outdated, or you have a desire to improve your equipment, for example, to reduce or increase the width and depth of processing, then you can make the part yourself. Often, such an idea can significantly increase the level of quality of land cultivation, as well as significantly speed up work.

These parts are characterized by a simple design, so they can be made on your own.

The simplest option is to study and analyze the design of industrial-type cutters, and then make some adjustments to it.

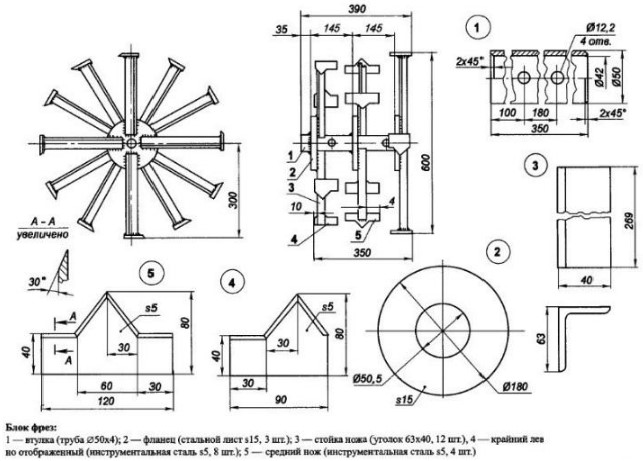

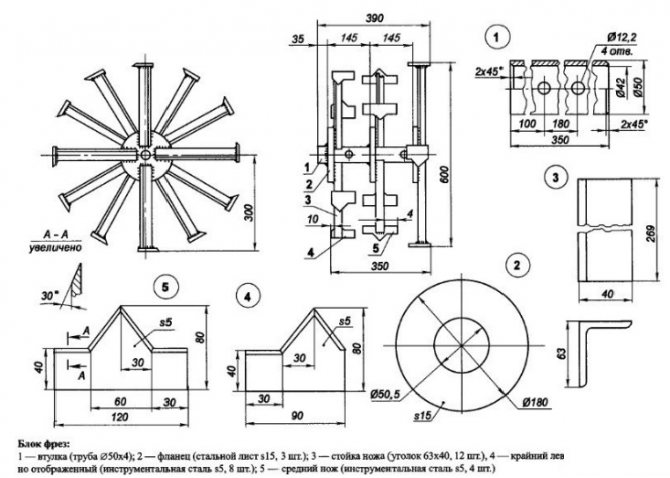

You need to pay attention to the fact that for self-assembly of cutters you will have to use individual drawings. So, homemade nozzles of this type consist of the following parts:

So, homemade nozzles of this type consist of the following parts:

- Sleeve. It can be made from a thick tube with a diameter of 50 mm.

- The flange is made from heavy plate steel. It can be made round, but it is much easier to make a square flange.

- Rack for a blade. Here you can use the steel corner. Some craftsmen use car springs for the manufacture of this element.

- Medium blade.

- Leftmost blade.

Blades are best made from tool steel alloys. Some craftsmen use car springs for this purpose.

Blades are best made from tool steel alloys. Some craftsmen use car springs for this purpose.

Using welding, the blades are mounted on racks that are attached to the flanges. The flanges are attached directly to the sleeve. Some people opt for bolted fasteners, but such designs are not very reliable.

The disadvantage of the crow's feet attachment is that this element is severely damaged during operation. As a result, the cultivator's engine is subjected to additional stress, and the performer becomes very tired. In order to minimize this, wheels must be placed on the axle on both sides, which will act as some kind of limiters.

In this situation, only the topmost soil layer will be cultivated. This option is convenient for cultivating soddy and strong overgrown land. After the first pass, the sod begins to collapse. Further, the wheels are dismantled, and additional processing is performed to one or another depth.

If homemade "crow's feet" are made competently, then their quality will not be inferior to industrial counterparts.

So, independent production of "crow's feet" has the following advantages:

- you will have the opportunity to save money;

- you will make a part specifically for your cultivator;

- a properly assembled homemade cutter is in no way inferior to factory products.

How to work

After the cutters are installed, we start the walk-behind tractor. At first speed, right on the cutters, we drive up to the beginning of the section. If there is only one speed for moving forward, then we do it at the lowest engine speeds. To operate a motor-cultivator with a cutter, select the speed as high as possible. We turn on the second speed and, setting the engine speed to maximum, engage the clutch.

With the opener, set the desired cultivation depth. To begin with, we put it on the second division from the top. The shorter the part of the opener facing the surface, the finer the finish. With its help, we create a load and slow down the forward movement of equipment. Unable to move forward, the cultivator buries itself with cutters deep. The coulter is the same anchor. When the strip has passed from the beginning of the section to the end, then if the section is small, you can turn on the back one and return.

If the site is large, then it is more convenient to move in a circle. If it is possible to turn the steering wheel to the side, it is advisable to turn it. Then the operator will walk on hard ground and not trample on the already worked soil.

It so happens that the soil is heavy and the cultivator is light. Then you need to attach additional weight in the area of the cutters. Pick up the load in separate "pancakes", 6-7 kg each.

Cultivation is carried out with a slight overlap of the treated area. The second run is done so that one of the cutters is already on half of the processed strip. We focus on the groove that the opener leaves behind. Thus, the entire soil will be cultivated twice. So we will achieve uniform soil processing throughout the entire site.

When we cultivate row spacings, we install guide protective discs on the edges of the assembly. They will prevent plant roots from being cut and will not allow the unit to deviate from the specified path.

The purpose of the walk-behind tractor is to facilitate soil cultivation, so you need to know how to assemble cutters on it. The most laborious processes in the cultivation of horticultural and vegetable garden crops are associated with the need to prepare an area for planting plants. It is necessary to loosen the soil in order to further prepare the beds for planting seedlings or sowing seeds. Because of this, the assembly of the milling cutter of the walk-behind tractor is carried out immediately after the purchase of a mechanical assistant for the garden and vegetable garden.

For loosening, soil mills are used. The designs of the active working tool for crushing the soil are quite diverse. Some provide not only crushing lumps, they can also choose the rhizomes of perennial weeds. Therefore, homemade craftsmen invent and create rotary working bodies for walk-behind tractors, capable of fighting weeds.

Types and design features of cutters

Milling cutters on motor-cultivators differ in design and factory form, as well as in the number and basic arrangement of standard knives. They are attached to the rear of the agricultural unit and directly depend on the operation of the power take-off shaft. When the travel speed is increased, the cultivator cutters show the highest efficiency and maximum productivity on the site.

The design of the cutters consists of a specific set of lamellar sharpened tillage knives, which are fixedly attached to the blades at different angles. The blades, in turn, are fixed on the moving axis by welding or with fasteners.

During the movement of the cultivator, the knives alternately and without sudden movements go deeper into the ground. Due to the smooth operation of the organs, the transmission of the agricultural unit lends itself to minimal loads, even if the cultivator is used for processing clay and stony soils.

Modern motor cultivators are equipped with two types of cutting bodies:

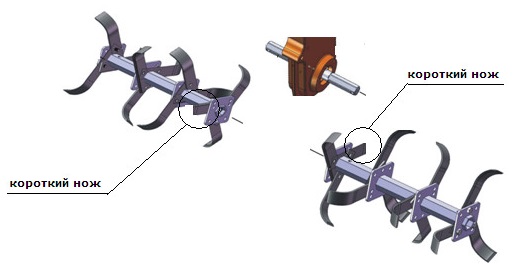

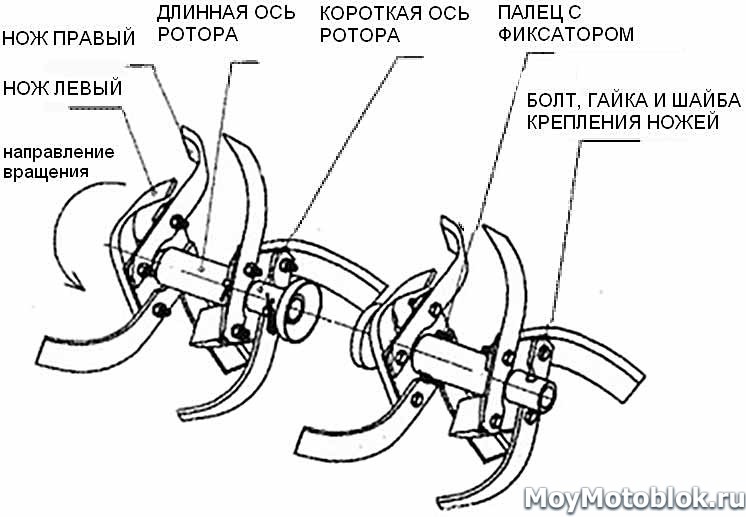

saber-shaped, or active - these devices are most often included in the equipment of branded cultivators. They are distinguished by a collapsible factory design, which simplifies their operation, maintenance, transportation and repair. When installing saber cutters, instead of wheels, blocks are mounted on the axle, the device of which includes 4 working mechanisms fixed with bolts, nuts and washers at an angle of 90⁰. The number of blocks can be different - 2, 3 or more. The width of the structure and the number of knives are also different - it depends on the weight and power of the agricultural machinery;

"Crow's feet" is a relatively new type of equipment for a motor cultivator. Its effectiveness on the site is ensured by a special shape. The device of the factory working bodies is non-separable, all-welded. The cutting bodies of the structure resemble the shape of triangles that are attached to the ends of the factory rack. These cultivator cutters are manufactured from mild steel. They stand out for their self-sharpening function, which greatly simplifies their operation in the garden.

Each of the types of devices is used in specific operating conditions. The rototiller saber milling cutter works best in areas with heavy clay or stony soil. Crow's feet show a higher efficiency in the garden with soft, loose soil.

About the elements

They are needed when cultivating the soil. Therefore, the quality of processing and the complexity of the procedure itself depend on the model: load on the motor, ease of control and labor intensity.

How to assemble the cutters?

As a rule, the milling cutter is included with the walk-behind tractor. But that may not be enough. Sometimes an increase in the depth or width of processing is required, so the device can be supplemented with other products. This solution also allows you to improve the process of moving the walk-behind tractor. In addition, this will increase the service life of the mechanism.

If the soil is clayey, then it is better to use two pairs of tiller-cultivators. And even if the soil is light and has already been worked before, additional elements will not become a hindrance.

Depth adjustment is possible due to the adjustable coulter. It is a durable element located vertically in the hitch of the walk-behind tractor. And the final loosening depth is influenced by the diameter of the cultivator cutter.

Types of cutters

The device consists of four bent knives - "petals", fixed on the shaft. Most of them are directional type: when assembling, the direction of movement must be taken into account. The knives are usually bent in both directions, except for those located at the edges of the shaft. There are models in which all the "petals" are bent only towards the gearbox: this prevents damage to plants when loosening. However, in this case, the working width is reduced.

Elements are made from stamped steel - for the lightest apparatus, and from steel strip, often forged. The last option is the most durable. As a rule, the cutter is a separate part, but there are models in which two rotary tillers are fixed on the same shaft.

Installation

Two types of knives are used.

Sharpened - the "petal" enters the ground more easily and does not adhere to the soil. Accordingly, the load on the engine is reduced and the fuel consumption is reduced. On the other hand, sharp blades cut the roots of the weeds, some of them remain in the ground and germinate again

Sharpened cutters should be used with great care.

With a semicircular edge - safer, but when loosening, they experience more resistance, more often they get stuck. Such an element removes weeds more efficiently, since it does not cut, but winds up the root and pulls it out of the soil.

The cultivator cutter diameter determines the maximum plowing depth. The relative is set by the opener.

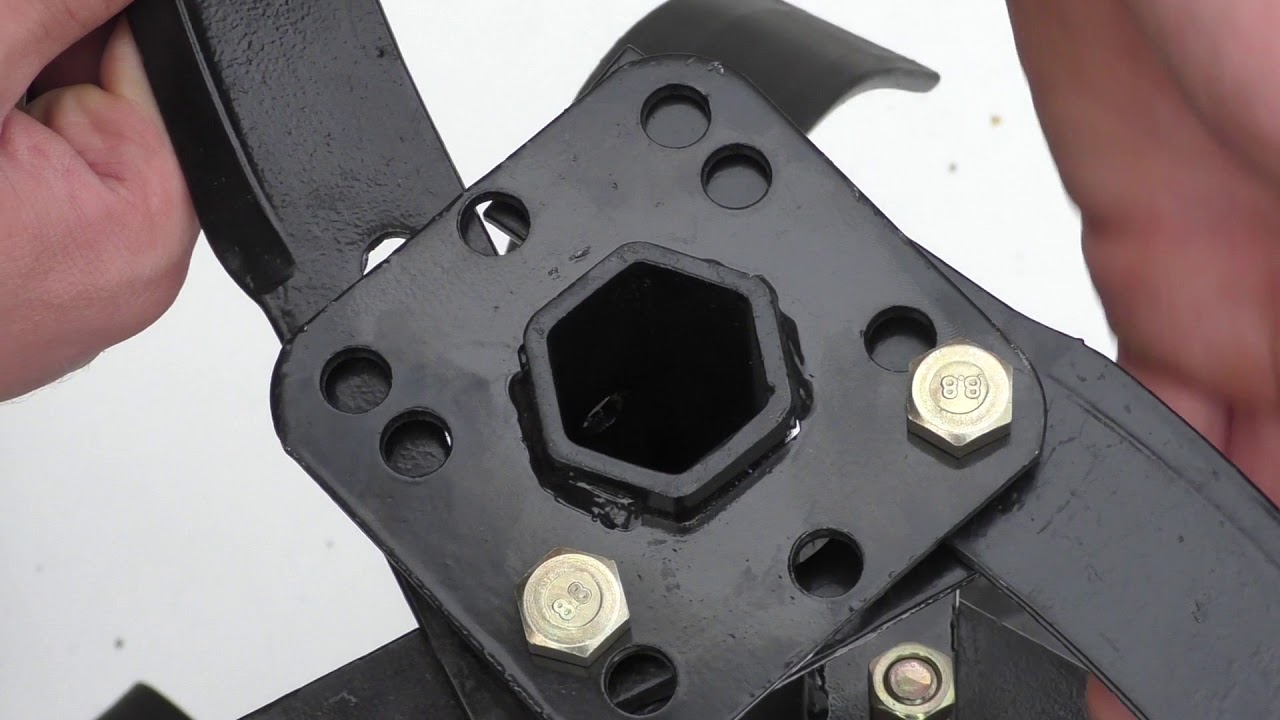

The "petals" are connected in two ways:

- rivets - the element cannot be disassembled. This difficulty is not so much during storage as during transportation;

- bolted - dismountable part. The photo shows a sample.

For the connection, welding is not used - this reduces the strength of the product.

Useful Tips

In order to optimize the load and increase the service life of the cultivator, the loosening width is selected by changing the number of mounted soil cutters.

The adjustable opener allows you to adjust the blade depth. He does all the work, you do not need to put any effort on the walk-behind tractor. The steering handle is slightly pressed to the ground, the coulter enters the soil more strongly and slows down the movement of the technique, thereby increasing the depth of cultivation.

In order for the gearbox not to rest against the untreated ground, the equipment is shaken a little.

When working with the cultivator, the user must keep his back straight and his hands at waist level. This position of the body contributes to a longer operation of the unit and will not harm health.

If the blades become dull after prolonged use, they must be sharpened with a grinder.Self-sharpening knives are chosen for ease of maintenance. The type of soil has a great influence on the cutting edges. Knives wear faster in wet or heavy ground.

For more comfortable work and high-quality soil cultivation, the rotational speed of the cutter for the console walk-behind tractor should reach 275 rpm, the cultivator - 140 rpm.

If mechanized equipment does not work well with the soil cutter, it is necessary to find out the cause of the malfunction and eliminate it in a timely manner. If it is impossible to carry out repairs, they turn to specialists for help.

How to assemble correctly

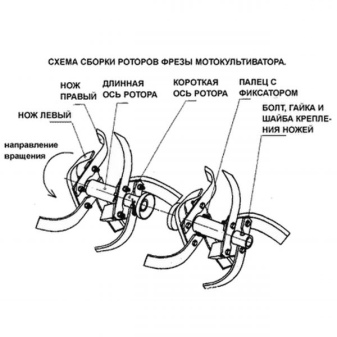

The quality and speed of tillage depends on the correct installation of the cutting elements. Before assembling the milling cutters of the motor-cultivator, you must carefully inspect the elements included in the kit. On them we will see the stamped letters L and R. This means "left" and "right". In order not to get confused, let us divide them into 2 identical groups. The hubs on which the knives are attached can be based on a round tube or hexagon. It depends on which shaft the cultivator has.

On one side there is a small ledge with a hole for a cotter pin and a seat for the first link of knives. Let's take one of the semi-axes. It will be located on the left, in the direction of travel. We collect the first link, starting from the gearbox. Place the cutting edges so that they make a counterclockwise circle. We put the right and left knives in turn. In the presence of 4 elements, 2 knives lie on the bottom, 2 - on them, on top. Where there is a hole for a cotter pin on the half-shaft, the knife in front of the hole should lie higher. Otherwise, it will be difficult to install and remove the cotter pins.

We fasten the element so that the base plate is between it and the gearbox. Otherwise, the blade may catch on the gear case. When the first link is ready, the second is assembled.

We look at any of the screwed knives, on the next plate we find such a position so that the new knife looks in the same direction, but has been shifted a few degrees counterclockwise.

On the attachment plates, we place the cutters on the same side as the first link. This is necessary to maintain the same distance between them. A correctly assembled cutter, when viewed from the end, looks like a spiral. We collect the right cutter in the same way.

Varieties of cutters for a walk-behind tractor

Structurally, a soil milling cutter is a set of tillage knives located on a rotating axis. Such a module consists of two parts, which are installed on the drive shafts of the wheels on both sides of the power unit. Due to this arrangement, the walk-behind tractor is able to move independently during cultivation.

You can also distinguish the type of motoblocks with mounted cutters, the rotational movement of which is given by the power take-off shaft. The module is located behind the power unit and does not participate in the movement. Motoblocks such as MTZ, Neva, Prorab, Sich, Agro are just produced in various modifications, with or without a power take-off shaft.

Active (saber)

Knife blocks on such cutters consist of four cutting elements spaced 90˚ apart. There can be 2, 3 or more such blocks on one side of the drive. The number of knives and the width of the module depends on the weight of the walk-behind tractor and its power.

The knives are curved strips of tough alloy steel. For self-production in the presence of heat treatment with subsequent hardening, spring steel of the 50HGFA type has proven itself well. The bends of the knives have alternately different directions.

The design of the active cutter allows for cultivation in areas with stones and roots without the danger of breaking the knives. But it is advisable to use this type of equipment on light processed soils.

"Crow's Feet"

The cutting elements of such cutters are made in the form of a triangle made of strong steel, located at the end of the rack. This location was the reason for the emergence of such an extravagant name.

As in the case of active cutters, the width and number of knife blocks is determined by the weight and power of the cultivator. The number of cutting elements located around the circumference in the knife block is from 4 or more. An increase in the number of knives implies a better crushing of the soil, but the power of the power unit will also need increased power.

These types of cutters are designed for the processing of heavy types of soil and virgin lands. The presence of branched root systems in the soil leads to frequent plugging of the module.

Both types of tillage cutters have their own advantages and disadvantages. When choosing an option for self-production, it is necessary to take into account the structure of the soil, the required degree of soil crushing, the layout and power of the power unit, the complexity and manufacturing technique.

It's interesting: Should I buy a forza 105 walk-behind tractor - we learn all the nuances

Homemade milling cutters for a walk-behind tractor - the procedure for manufacturing equipment

The simple design of milling cutters for walk-behind tractors allows you to make such devices with your own hands. Below we will consider the correct procedure for the manufacture of different types of equipment. for plowing the soil.

How to assemble correctly cutters on a walk-behind tractor - manufacturing of saber-shaped equipment

Immediately before making saber-shaped rotor devices, we advise you to study the drawings that will tell you the correct procedure for assembling the equipment.

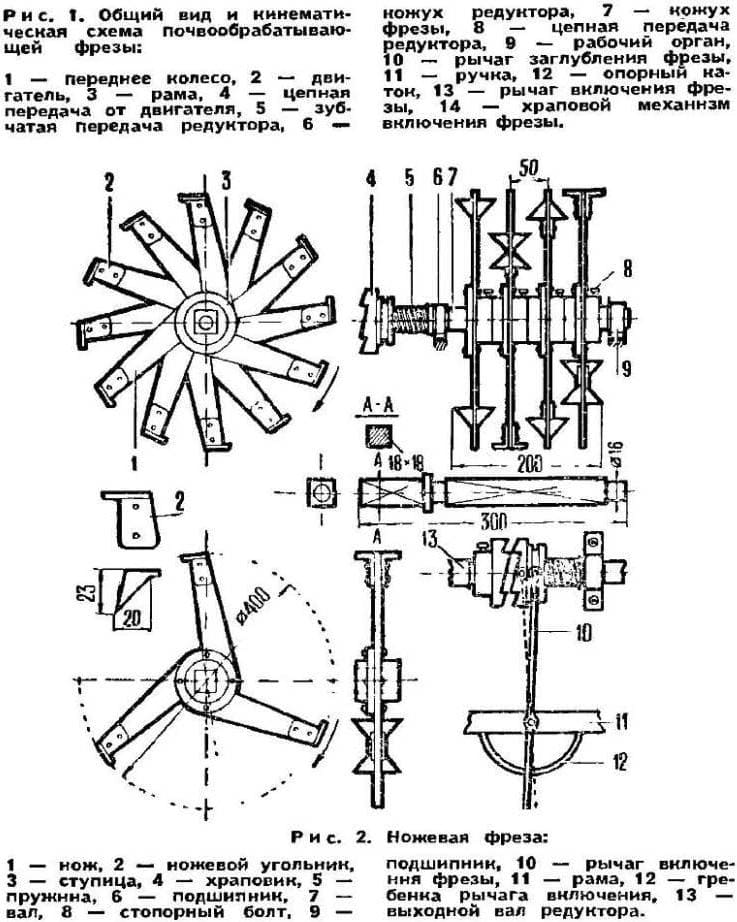

Any saber cutter for a walk-behind tractor consists of two interconnected blocks, each of which contains 12 cutters. The design of one separate unit includes 3 units, each of which is equipped with 4 cutting knives. The latter, in turn, are located in relation to 30 ° in relation to each other.

The assembly of saber-shaped devices is as follows:

The assembly of saber-shaped devices is as follows:

- First, make a stand using a 6.3 × 4 cm corner;

- Weld one of the ends of the rack to the flange so that later you can combine 4 cutting knives with each other;

- Connect all cutting elements of the cutter to each other by means of flanges and bolts with washers.

A rotary milling cutter manufactured in this way has high strength and stability, which will allow you to use it for processing soils of any density.

Manufacturing of cutters "crow's feet"

Immediately before assembling this type of fixture, you will need to carefully prepare for work. With tools and materials you will need:

- steel pipe, 4.2 cm in diameter;

- steel plates for making cutting knives;

- welding machine;

- grinder with a set of disks.

The active crow's feet cutter is assembled in the following order:

- For the manufacture of cutting elements, you can use the springs from the car. Cut them into equal pieces, and then weld them to a steel pipe that plays the role of a base;

- Sharpen the edges of the cutting elements and weld them to the base used;

- After assembling the equipment, start it and make the necessary settings. At the same time, keep in mind that after starting the walk-behind tractor, the equipment knives should hang in the air, and not touch the ground.

In order for the crow's feet cutter to last as long as possible, it must be slowly lowered to the ground. Otherwise, the equipment may break down.

Self-installation of cutters on a walk-behind tractor

Self-installation of equipment on a walk-behind tractor is performed in exactly the same way, both for saber cutters and for devices such as "crow's feet".

In any case, the procedure is as follows:

- Place the manufactured cutters on a special wooden "goat", about 0.5 m high;

- Gently tilt the walk-behind tractor at an angle of 45 °, and rest it on the opener;

- Place the "tragus" under the handlebar grip of the walk-behind tractor;

- Dismantle the standard wheels of the agricultural machine, and install homemade cutters instead;

- At the left and right outer ends of the cutters, securely fasten the discs for the cutters - they will significantly improve the movement of the walk-behind tractor with cutters and make it smoother and more stable.

After completing all the above steps, you can start processing the soil. During work, do not forget to monitor the reliability of the fastening of the plates, fixing the main and additional cutters on the walk-behind tractor.