Design, features of the rotary tiller

Different models of cutters work on the same principle. The shaft with the cutting plates rotates, as a result, the plates raise the top layer of fertile soil, the same happens when a person digs the soil with an ordinary shovel. The design of the rotary tiller allows you to accelerate several times and make this process mechanized.

To set the shaft in motion, the diesel engine of the minitractor operates, which transmits the mechanical force to a special gearbox mounted on the cutter body. By means of the gearbox, the shaft with the knives begins to rotate, and thanks to the adjustment of the power of the gearbox, a person accelerates or slows down the rotation of the shaft.

The support wheels adjust the depth to which the cutter blades will go deep into the ground. And the frame of this device is necessary to connect the equipment to the mini tractor. Thanks to a protective metal cover, which is located on top of the knives and the shaft, the working mechanisms are protected from dirt, dust and other contaminants.

Do-it-yourself milling cutter for a mini tractor

Since the tiller is a simple design, you can make it yourself at home.

To assemble this device, you will need the following tools:

- welding;

- drill;

- Angle Grinder;

- spanners;

- bolts and nuts.

The first step is to produce a metal frame. To make it, you need either an iron pipe or a metal channel, the diameter of the pipe should be at least 40 mm, and the thickness of the channel should be 5 millimeters or more.

The selected material is cut into 4 pieces, the resulting parts are welded to each other using a welding machine. The width of the resulting frame can be from 50 to 150 cm, depending on the power of a small tractor.

During the creation of the metal frame, provisions are made for the places where the support wheels will be installed. They must be mounted in such a way that it is possible to adjust the distance of the cutter frame to the ground.

After fixing the frame and installing the wheels, the shaft is fixed to the frame at a distance of 30-50 centimeters from the ground, depending on the length of the milling knives.

To transmit tractive effort, a metal shaft is connected through a gearbox to the tractor power take-off shaft. The shaft must be fixed to the welded frame through bearings and bushings.

Knives are made from strips of metal, the thickness of which is 10-12 millimeters. Experts recommend using only high-strength tool steel for the manufacture of metal knives, because it is they who will experience the main load. Depending on the width of the shaft, use a suitable number of knives.

For example, for a device with a width of 120 cm, four elements are taken, on which three legs are installed. It is imperative that each leg at the end bends at an angle of 70-90 degrees, these bends will loosen the soil. The knives are fixed to the shaft through threaded connections. All structural elements that will rub against each other must be lubricated with oil or grease.

We offer you to watch an interesting video on how a do-it-yourself milling cutter for a mini tractor is made:

What rotary tillers are

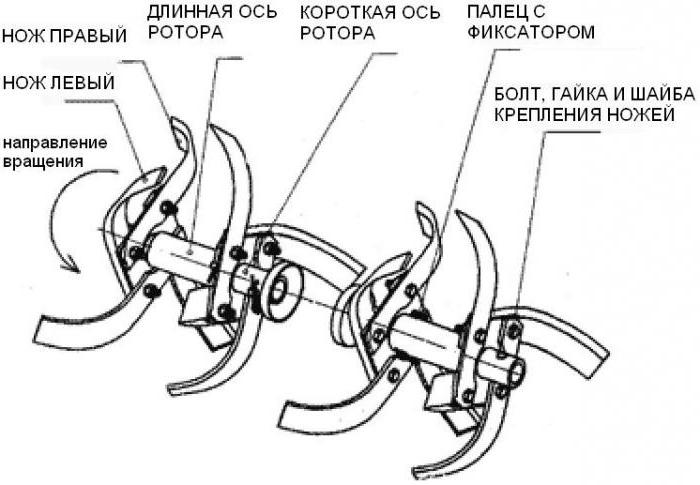

Mills, despite the similarity of the principle of operation, may differ in a number of parameters. The number of knives and their shape vary considerably. The more complex shape of the cutting parts, as a rule, increases the efficiency of the entire unit, especially in the fallow areas.Knife cutters can be divided into two types.

Most often, cutters with saber knives are on sale. Such a device is the most versatile. The cutter can easily work even on stony ground. These knives, in turn, are divided into three groups depending on the shape and, accordingly, the application.

- Simple (standard) - used on light soil, not contaminated with weeds.

- Crescent - used when working with denser soil.

- Chisel - have a large mass and are suitable for working on heavy or stony soil.

Correctly (depending on the characteristics of the soil) selected blades will extend the life of the unit. Another variant of the shape of the knives is the so-called crow's feet. This shape of the knives allows the processing of weed-infested soil, destroying unwanted vegetation. Such a cutter can "lift" virgin soil. However, unlike the previous type, such a milling cutter experiences heavy loads and often needs to be repaired. By purchasing this, in fact, a very efficient unit, you need to buy spare parts in advance, first of all the knives themselves, as well as bearings that take on most of the load.

The vertical rototiller looks quite exotic. Its general design differs little from conventional horizontal machines, but the force is transmitted through the gearbox not to one common horizontal drum with knives, but to a number of separately rotating vertical nozzles. The device is effective for surface loosening of the soil, and it also destroys weeds well, but it cannot provide deep tillage.

Homemade milling cutter for a mini tractor with your own hands from the Volga bridge

Using the bridge from the Volga car, a soil milling cutter is made for a small tractor, for example, a T-40. The width of the milling unit is 180 cm. First, a frame is made of metal corners or squares, the size of the frame is 180x60 centimeters, the base of the milling cutter will be installed on this frame.

The frame is welded on a flat plane so that there are no distortions, after which the washer and bearing are removed from the Volga bridge

The bridge is cut with a grinder to the length of the frame, it is important to cut at a right angle

The bridge is installed on top of the frame, and the cutting part of the cutter with knives is mounted at the bottom of the frame, the knives are fixed on a metal axle pipe, which is installed through the bearings and fixed with a plate to the frame.

Homemade cutters

Despite the relative availability of industrial rotary tillers, homemade units are far from rare in the Russian open spaces. Deciding on such technical creativity is pushed not only by economy. Sometimes the master tries to create not just the cheapest, but also the most convenient mechanism for him. Taking on such a difficult task requires certain technical skills, and if they are not there, it is better to give up right away, rather than go through a series of dangerous failures. The rototiller is an active agricultural mechanism and the quality of its units is a guarantee of safety, which must not be forgotten in any case.

If, nevertheless, the decision to start self-manufacturing is adamant, it is better to take care in advance of preparing as many units as possible (shaft, gearbox, gears, etc.) from mechanisms that are suitable in function and size. Real craftsmen also prefer to make knives of a home-made machine on their own. A good result can be obtained by taking a spring from a car as a starting material.

How to do homemade milling cutter for mini-tractor, see the next video.

We purchase a Chinese rotary tiller for a tractor

Almost always, a positive decision to buy a 1GN-180 rotary tiller is made on the basis of its low price, and already additional incentives when choosing are:

- the normal quality of this attachment;

- general unpretentiousness;

- ease of maintenance of the entire mechanism;

Indeed, these benefits actually exist and are verified by our fields.

However, it is still worth paying attention to important technical aspects, make sure that the rotary tiller is manufactured in the PRC, compare the differences between Chinese rotary tillers and European, Japanese and domestic manufacturers!

1) Are completed with a long driveshaft in a "case";

2) Spline connection with PTO of Chinese mini tractors;

3) The dimension of the rotor blades is less in length / thickness;

4) Are shipped disassembled;

5) The reducer of the 1GN-180 cutter does not have lateral displacement;

Of course, we know how to adapt such a soil tiller with T-40 tractors or MTZ-82 tractors.

Types of cutters for soil processing

Despite their versatility, all tractor milling cutters available on the market are divided according to their purpose.

For this factor, the equipment can be of the following types:

- cutters for continuous soil cultivation - these include garden, swamp and field devices used to uproot stumps and plow the soil before planting forest crops;

- specialized cutters designed for digging and cleaning trenches;

- inter-row cutters - these tools are used for plowing the soil between the rows during the period of active growth of the cultivated crops:

- combined rotary tillers - these devices include milling-seeding and milling-row-crop complexes.

All of the listed types of cutters show the highest productivity in certain areas of operation. Their structures are designed to withstand the highest loads in the most difficult weather conditions.

Description

This type of attachment is quite common in the domestic agricultural market. Mostly, these are Russian and Belarusian units made in accordance with domestic quality standards.

FR-00010

I would like to start the description of the model range with FR-00010, manufactured at the Minsk Tractor Plant. It is clear that it is intended for MTZ mini tractors, but it can also be aggregated with other models that have a similar attachment system for attachments, for example Uralets, Kubota, Bulat 120, Yanmar, Belarus 132n, Scout.

FR-00010

This device can be used not only on light soils, but also on rather heavy soil areas. It is permitted to use this cutter on slopes with a slope not exceeding ten degrees.

Specifications:

- digging depth - up to 120 mm;

- width of the processed strip - from 440 to 610 mm;

- unit length - 65.5 cm;

- unit width - 68 cm;

- unit height - 47.5 cm;

- total weight - 47 kg;

- productivity on light soil - 0.18 hectares per hour;

- productivity on heavy soil - 0.12 hectares per hour;

- the maximum speed is 3 km / h.

This cutter for a mini tractor, the price of which will be about 24 thousand rubles, is intended for preliminary preparation of the land plot for its further use.

For more information about the work of the cutter FR-00010, see the video:

FNM-1

FNM-1 is also produced in Belarus, as the previous model. It is used on a wide variety of soil types, but it is not allowed to be used on excessively inclined surfaces (up to ten degrees).

Specifications:

- digging depth - up to 80 mm;

- width of the processed strip - from 440 to 600 mm;

- unit length - 66 cm;

- unit width - 74 cm;

- unit height - 45 cm;

- total weight - 50 kg;

- productivity on light soil - 0.198 hectares per hour;

- productivity on heavy soil - 0.132 hectares per hour;

- the maximum speed is 3 km / h.

1 GQN-125

1 GQN-125 is a fairly powerful model, so it has certain requirements for a mini tractor, or rather, for its power. Nominally, it should be between 24 and 30 hp.It can be used on a wide variety of areas of land, from light to heavy soils.

GQN 125

Specifications:

- digging depth - up to 200 mm;

- width of the processed strip - up to 1250 mm;

- unit length - 90 cm;

- unit width - 100 cm;

- unit height - 135 cm;

- total weight - 220 kg;

- the maximum speed is 4 km / h.

The cost of this cutter is about 32 thousand rubles. In addition, this is not the only representative of this line. In addition to him, there are quite a few models that differ in the width of the strip that they process. In this case, the serial number will be identical to the given width.

How to do it yourself

Of course, buying a ready-made milling cutter is the simplest and most understandable action that fully justifies itself. However, many are wondering - how to make a milling cutter for a mini tractor with your own hands? The reason for this interest is, as always, the price of the finished device.

The starting price starts at 12 thousand rubles for a soil milling cutter, which prompts people to think similarly.

In principle, this idea is quite easy to implement, because the cutter device is not so complicated. To do this, we need a fairly standard set of tools:

- Bulgarian;

- welding machine;

- electric drill;

- bolts and nuts;

- spanners.

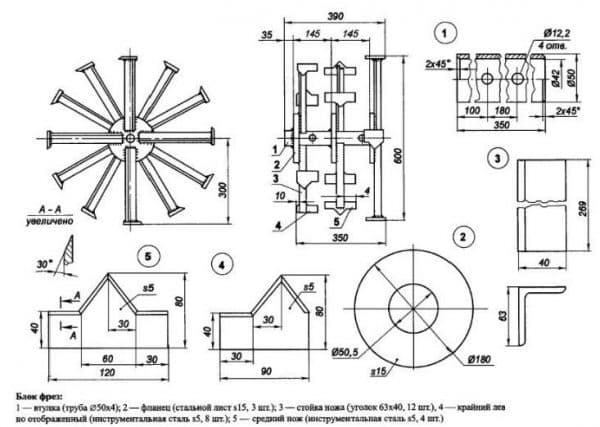

After making sure that you have everything you need in stock, you can proceed with preliminary preparation. A do-it-yourself milling cutter for a mini-tractor, the drawings of which are presented below, are a fairly typical design, so you do not need to invent a bicycle by inventing something new.

You just need to follow the technical advice and parameters necessary to build a quality device.

Drawing 1

So, let's consider a detailed algorithm of our actions:

It all starts, of course, with the manufacture of the device's support frame. For these purposes, we need a metal pipe with a diameter of about 4 cm, or channels.

Frame

- We cut the existing material into four parts, which must then be welded to each other. Remember that the width of the frame will directly depend on the power of the engine used in the minitractor. Therefore, if it is not powerful enough, it is better not to make a very large structure.

- It is necessary to provide for the installation of wheels in advance, with the help of which the depth of immersion of the shaft knives will be adjusted.

- Next, you need to fix the main shaft to the frame, which will rotate. As a shaft, you can use an ordinary metal pipe, the diameter of which must be at least 5 cm.

- The cutter shaft is connected through a PK-1.6 gearbox, which is aggregated with a power take-off shaft mounted on a minitractor. The main shaft is fastened to the frame using bushings with support bearings.

- Knives for a mini tractor cutter are made of metal plates, the thickness of which should be about 1.2 cm.Depending on the width of the shaft, the number of cutting elements will also be different. For example, if the width of the shaft is at least 120 cm, then four knives can be installed on it.

- Moreover, each knife consists of three cutting elements, the ends of which are slightly bent. The fastening of these elements to the shaft is carried out using bolts and other fasteners.

- In principle, your homemade milling cutter for a mini tractor is assembled by your own hands. As a finishing touch, you need to lubricate all parts that will be subject to friction with grease.

Blade types

The plate knife is located on a rotating shaft and is the basis of the design of the device; high quality steel is used for its manufacture. There are several types of knives to suit different tasks and environments:

the most durable option is the chisel, it can be used on rocky, dense and difficult areas;

sickle-shaped ones are versatile in application, the only limitation is that they cannot be operated on soil with stony deposits;

The standard knives are suitable for both heavy and light soil, it is important that it is free from a lot of stones and clogging.

The principle of operation and types of cultivators with a cutter

The increased interest in tools with a rotary tiller is due to the ability to obtain high quality soil cultivation in one pass of the working body of the unit. Cultivators of this type are especially popular when processing small land plots for planting vegetables. The work of the machine consists in the dynamic loosening of the soil by rotating an active organ equipped with ripper knives.

Tillers device

The supporting structure is a rectangular frame made of a metal bar with a hinged three-point device for the rear hitch of the tractor. On the left and right sides of the frame, vertical struts are attached, in the lower supports of which an active member rotates on bearings. The cutter itself is a tubular shaft with knives hinged on it. The cultivator is driven by an independent tractor PTO. The torque to the cutter is distributed by a reducer as part of the cultivator through chain or gear drives. The rear baffle bar as part of the structure allows to increase the degree of crumbling of soil clods. Its position regulates the degree of soil crushing. To prevent breakdowns of the mechanism in the event of unacceptable loads, a safety clutch is installed in the structure of the drive. Depth adjustment is carried out by setting the level position of the support wheels or shoes. For good penetration, some models are equipped with one or two powerful duckfoot shares, attached by their stands to the front bar of the cultivator frame.

Gear side transmission of the tiller

Tiller chain drive

Benefits of the cutter

The active rotary cutter of the cultivator, together with ideal loosening, ensures leveling of the surface, effective moisture retention in the soil, crumbling of the root system of weeds and crop residues of the previous crop.

- Milling frees you from multi-operational preparation of areas for planting or sowing, that is, they replace continuous cultivation and harrowing in one pass.

- Such complex processing reduces the time for soil preparation, which allows sowing or planting in tight agricultural terms.

- In some cases, on well-groomed areas, with light physical composition of the soil, spring milling frees plowing from preliminary autumn.

- During processing, the cutter perfectly copes with the incorporation of organic fertilizers pre-distributed on the surface of the treated area.

Varieties of cultivators with a cutter

In addition to structural differences in the method of driving the device, the fundamental is the design of the cutter and the shape of the knives, which determine the nature of processing with the fulfillment of agrotechnical requirements and the ability to work in special conditions.

By the nature of soil cultivation, active organs are subdivided into:

- Vertical milling cutters - loosening with straight knives occurs in a vertical plane without turning the soil

- Horizontal milling cutters - soil crushing occurs with curved blades (L-shaped) with a partial revolution

- Combined milling cutters with knives of various shapes that perform loosening, partial mixing of the soil, chopping up weeds and crop residues

By purpose, cutters are subdivided:

- Lightweight general-purpose implements for continuous cultivation on plowed areas to prepare for sowing or planting with a working depth of up to 15 cm,

- Heavy milling cutters designed for basic and pre-sowing soil cultivation, for plowing turf and virgin lands with a depth of up to 30 cm

- Cutters for preparation for planting of certain types of crops with the possibility of installing bed formers and hillers

- Cultivators with rotary tillers are capable, in addition to loosening the soil, crushing roots and tall crop residues

- Cultivators with a cutter for continuous cultivation of stony soils in mountainous areas

- Equipment with cutters for inter-row loosening of row crops

How to make a homemade bridge cutter

The bridge from any passenger car is taken as a basis.

All unnecessary elements that will not be used in the cutter device are cut off from the bridge. The bridge is installed on a metal frame, which is manually welded from metal pipes or channels, the frame should be positioned on two wheels so that the bridge is at a height of 30-70 centimeters from the ground.

To fix the milling shaft, it is necessary to make metal homemade cheeks from iron, the metal thickness is used from 8 to 12 millimeters.

For the manufacture of the cutter shaft, a thick-walled pipe is taken, its diameter is about 50-60 millimeters. Several segments are welded to the milling shaft, from 5 to 10 pieces, to the ends of which knives, for example, "crow's feet", are welded.

On the shaft and on the bridge, 2 sprockets are installed on both sides, the number of teeth of which is from 18 to 28, two chains are put on the sprockets on both sides of the axle and the shaft, the chain pitch must correspond to the pitch of the teeth on the sprockets.

The cutter shaft is fixed to the bridge using a metal plate, about 10 mm thick. A protective metal casing is put on over the sprockets with chains. The chains must be coated with grease.

How to make a tiller with your own hands

The assembly of a cutter for a mini tractor begins with the assembly of parts, accessories and tools. From tools you will need wrenches, a welding machine, a grinder for cutting and processing metal. Assembly materials - sheet metal for the manufacture of cutting elements, a gearbox with gears for transmitting torque from the wheels to working elements, bolts and nuts, as well as electrodes for the welding machine. Add wheels and two shafts here - one for the cutters, the other for the wheels themselves.

Let's see how to make a milling cutter for a mini tractor with your own hands. We start directly with cutters - they are metal curved knives fixed with bolts and nuts on rectangular platforms. These pads are welded directly onto the main shaft. We are engaged in welding, we make holes in the sites and fasten the knives - two bolts for each knife. To prevent unauthorized unwinding, we use locknuts.

Another approach is to cut the padded knives from a single piece of metal. The design will turn out to be more durable, but less maintainable - the broken off knife will have to be welded back by electric welding. In addition, such complex cutting will require a gas welding or plasma cutter. The designs of cutters for soil cultivation for a mini tractor can be different. But it is better to make your choice in favor of the first option - with bolts and nuts, since here you can quickly replace a broken knife.

A pipe or channel with a diameter / width of 40 mm acts as a support frame for the cutter. Two shafts are attached to them - the main one and with wheels. Fastening is carried out using bushings equipped with bearings - both shafts must rotate freely on their axis. The shafts are connected to each other using a gear reducer.

Types of cutters

Tillage rotators, depending on the method of attachment to the tractor, are divided into mounted and trailed. The latter, in turn, come with their own motor or PTO drive.

Tillers are:

- For the preparation of land for growing vegetables and rice. In such cases, field milling cutters are used. They have standard blade or sickle knives that can easily enter waterlogged soil.

- For processing meadows and pastures.For this, a "swamp" rotator is installed. Its feature is angled plate blades.

- For row spacing. Row cultivation devices are suitable here. Their feature is the presence of a vertical axis of rotation. Used to remove weeds and compact the furrow bottom.

The blades are selected according to the type of soil:

- for soft soil with small stones, use classic lamellar nozzles;

- sickle-shaped knives are considered universal, which grind any type of soil;

- on rocky terrain or heavily clogged areas, work with chisel blades.

Depending on the purpose of use, the equipment is divided into groups:

- For continuous processing. These are garden, field and swamp cuttings that loosen the ground while removing dense weeds. Used for plowing forest land.

- Inter-row complexes for loosening planted fields.

- Specialized cutters for digging trenches.

- Universal sowing and row-crop complexes.

Ground cutting attachments by the principle of rotation blades on the shaft are divided into horizontal and vertical. The former are used for cultivating fields for farmland and for plowing virgin lands. The soil after them becomes more crumbly and soft, which contributes to the correct formation of root crops. Despite their popularity with farmers, horizontal cuts have disadvantages: the blades cut the roots of the weeds in a horizontal plane, which promotes their rapid growth.

Vertical milling cutters for a tractor do not mix soil layers, and therefore are suitable for cultivating the soil for plants with roots growing deeper. This allows you to increase the yield by 10-15%. Their disadvantage is limited use. For example, they are not suitable for fertilizing, for loosening the ground after the spinous parts of plants. Also, they are not recommended for use on clay and gray forest soils, which, after processing, are taken in large lumps.

Functions

A tractor equipped with a milling cutter that combines the properties of a cultivator and a plow allows you to quickly and with minimal time expenditures solve all the tasks associated with soil cultivation. This assistant is indispensable in areas planted with coarse-stemmed plants, and also characterized by floating, complex soil. The functionality of the cutters is not limited to this, they provide the application of all types of fertilizers, level the surface, mix the soil layers, remove weeds and at the same time grind the vegetation. Devices are indispensable in improving meadows and pastures, processing complex soil layers.