Clamps manufacturers

One of the important criteria for choosing tools is the reputation of the manufacturer. We've selected the brands you can trust:

- Gross is a manufacturer that is part of the Russian concern "World of Instrument". Offers high-tech products made at a professional level. The company's catalog contains a large selection of carpentry, metalwork, measuring or other tools.

- Bison is a company that appeared only in 2005, but has already established itself thanks to high-quality reliable goods. The brand's equipment can be entrusted with the most difficult tasks.

- Kraftool is a German manufacturer of professional construction tools for various tasks. The company's products are famous for their ergonomics, stylish design and durability.

- Fit or Finch Industrial Tools is a Canadian company that manufactures hand and power tools for professional or home use. The brand was born in 1996, today it is one of the largest players in the world market.

- Stanley is a brand known since 1843. The American manufacturer quickly gained recognition for its high quality products. This logo sells reliable handheld or electric construction devices made from durable materials that are distinguished by sophisticated ergonomics and high performance.

- Cobalt is a Russian brand that makes assembly and locksmith equipment. The company follows three basic principles: reliability, ergonomics, optimal price.

- Matrix is a German manufacturer with an assortment of more than 3,000 items. Everything from fasteners to locksmith equipment or automotive tools can be found here.

- Sparta - manufactures accessories for home or car repairs. They are known for their low prices and are in demand among budget-conscious buyers who rarely resort to construction work.

- Santool is a handheld construction tool company since 2004. The main advantage of her products is a reasonable combination of price and quality. The brand's products are intended for personal use, but are also in demand in small workshops.

- Sibrtech is a brand that makes a simple, reliable, inexpensive tool. The title combines 2 words - Siberia and Technology. Laconic design and the absence of unnecessary bells and whistles are the main differences between the brand's products. Sibrtech products are designed to help with home or car repairs.

Selection Tips

Experienced and novice craftsmen often argue about which clamp is better to buy. In fact, the selection criteria for this tool have long been defined.

You just need to pay attention to the following points.

- Clamping force. The most powerful industrial models are capable of delivering indicators of 1 ton, but such a reinforced structure is not needed in everyday life. The simplest models have much more modest performance. On average, their clamping force is 20-100 kg. This is enough for most operations, even when working with machines in a home workshop.

- Fixation method. It determines how exactly the change in the distance from the movable element to the edge of the part will be carried out. When performing work on weight or at height, it is better to choose quick-clamping clamps that allow the master to perform this operation with one hand. Screw models are suitable for use in the workshop, but not very convenient to use without a workbench and other fixtures.

- Mass. It all depends on the purpose of the clamp.Those designed to work with milling machines can weigh up to 5 kg. It is better to choose household models in the range of up to 1 kg.

- Materials used. The most durable clamps with a reinforced body are made from cast iron and other ferrous metals. They are quite massive, focused on holding heavy parts. Household models are most often made from combined materials. The combination of synthetic materials, polymers and aluminum casting has proven itself well. The finished product weighs less, is not afraid of corrosion in case of rare use.

- Functionality. Not all clamps are created equal. Some of them have both clamping capacity and the ability to be used as a spacer. To do this, they are equipped with pivoting jaws that can be guided inward or outward of the housing.

- Corrosion protection. This moment is relevant only for products made of ferrous metals. To maintain a smooth ride for a long time, they are painted with powder formulations, and then periodically oiled and blackened. Galvanized clamps are effortless to maintain. As long as their coating is intact, corrosion does not threaten the instrument.

- Additional accessories. They are optional, but they greatly facilitate the use of the product. For example, models with rubber pads on the jaws allow you to work with fragile or soft parts, softening the impact at the point of contact. The included T-handle is also useful, allowing you to adjust the force when clamping the part.

All these points are important for choosing the right clamp, especially if the master is new to his craft. Experienced locksmiths and carpenters in practice comprehend the features of such a tool and no longer make mistakes when replacing it.

How to make a carpentry clamp with your own hands

The specified tool can be purchased at any specialized store. But if you wish, you can assemble a homemade clamp, with the required dimensions.

Professionals are often inclined to collect these devices on their own. In this case, it turns out to design a tool that will cope with individual needs, when performing certain tasks by the master.

Corner structures

This type of tool is used to hold individual elements of similar or different dimensions. The carpentry clamp will allow you to connect them to each other in the position that is required.

In practice, in most cases, angle-type fixtures are used when welding metal structures. They ensure their connection and retention strictly at right angles.

To assemble the device yourself, you need to prepare:

Diagram of a corner carpentry clamp

- Steel corner 40 mm.

- Pre-threaded hardened studs.

- Nut.

- Taps.

- 40 mm steel plates.

- Drill.

- Rods.

- Welding device.

It is necessary to weld the prepared corners to the steel plates, strictly observing the right angle. At the next stage, worm nodes are fixed on each side.

Here it is important to correctly determine the size of the working gap so that it corresponds to future workpieces.

Basic materials required for the manufacture of a clamp

Experts advise, if you intend to work with structures of various sizes, it is worth collecting several carpentry clamps. The reason is that the fixation is the worse, the longer the crank has a stroke.

At the end of the stud, a stop is organized immediately after it itself is screwed into the working nut.

Moreover, the emphasis itself must be able to rotate along the hairpin.

A hole is made behind the knob. A metal rod will be placed here, which will take on the function of a lever.

This is the simplest design, which even an inexperienced master can independently assemble. But it will be very useful in practice.

Pipe

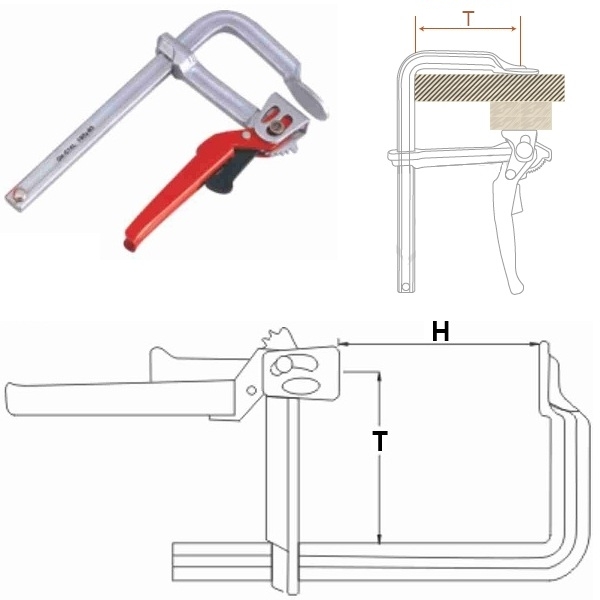

Pipe Clamp Assembly Diagram

The most difficult practical option for welding is the end connection of individual pipes. For its implementation and significant simplification, pipe clamps are used. They guarantee the correct connection of the individual sections.

It is not difficult to make the specified device on your own. You will need a couple of steel plates, and also a suitable corner. To ensure the desired fixation, threaded studs are provided in the device itself.

Despite its apparent simplicity, this device demonstrates high efficiency in practice.

Other options for joinery clamps

There are other types of joinery clamps. They are used depending on the specific production need within the framework of some manipulations.

If you gently quickly fix small elements, a device shaped like a caliper will do. To make it yourself, a sheet of plywood and a few bars are enough, along with additional elements - a stud and a nut.

A stop is attached to the main rail on one side. A recess is made in it, where the mechanism itself will be placed. When the bracket is in the required position, you need to fix the part by turning the knob on the hairpin.

Clamp of two wooden jaws

The simplest, but no less effective in practice version of the clamp is assembled from a nut equipped with a lock, steel studs, a pair of wooden blocks, thrust washers and nuts.

In order for the clamp to act as a full-fledged vice, it is worth initially making several sets with similar characteristics.

When performing individual manipulations, the constituent elements of the structure must be held on the table surface in order to facilitate their further processing.

To do this, a self-tightening clamp is suitable. Its bracket is made of wood or metal.

It is a simple device that is a lever. When you turn it, a quick clamp works, which is automatically triggered. To set the desired height, it is enough to move the pin placed on the workbench.

Typically, quick-release designs are assembled according to individual requirements for the desired manipulation.

Peculiarities

A clamp of this type is considered the best for long-term use in a carpentry workshop. This tool owes its long service life to a thick steel rail. It is she who ensures the durability of the tool. Due to the notches on the movable bar, the possibility of displacement is excluded during clamping.

The main advantages of this tool are:

- large thread pitch, which ensures long work without slipping;

- the design of the sliding part is very convenient for quick resizing;

- such a clamp is universal and can be used in any conditions and work.

No matter how good the tool is, it always has its drawbacks, namely:

- to clamp, you must use both hands:

- if the clamp is too tight, the guide can bend.

This product is mainly used for working with wood, which means that the last of the shortcomings in this case is not terrible, since it will not be possible to compress wood with such force without deforming it.

Clamps are also categorized

By clamping method

The classic tool has a screw mechanism that moves the moving part of the structure. The clamping force is regulated by the master himself. Therefore, the work is carried out in both hands. Quick-release devices are more convenient, since fastening and unclamping of parts is carried out with one hand.

By effort

The clamping mechanism is responsible for the reliability of fixation. In some models, the force value can vary from 20 kg to 1 ton.

By weight and materials of manufacture

Steel and cast iron clamps are of high quality and reliable. But it should be borne in mind that such devices are heavy.There are cast aluminum models and mechanisms made from synthetic raw materials. These models are lighter and more durable.

By functionality

There are tools with various options for adjusting the clamping angle, clamping force, jaw rotation, which greatly expands the capabilities of the device. Some clamps can be used as a spacer.