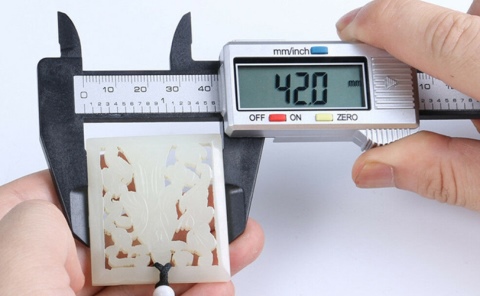

What is a caliper and what is it for?

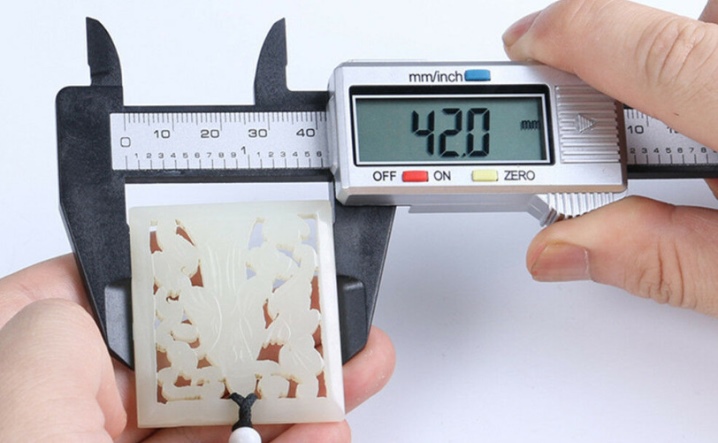

A vernier caliper is a measuring tool withslider, which can be shifted by measuring the size of the desired item. This tool measures thickness and diameter by gripping objects. You can accurately measure the outer and inner diameters of objects that are difficult to measure with conventional rulers. This tool can measure dimensions ˂ 1mm. Moreover, when used correctly, you can also calculate the size difference and measure the depth of an object.

Many believe that calipers are only used by professionals, whether used in laboratories, manufacturing, construction or field research. In fact, there are many ordinary people who use calipers in the manufacture of plastic parts for prefabricated models, measuring various diameters, both internal and external. The reason is that calipers are easier to use and more accurate than conventional rulers.

There are many affordable calipers available.

Checking the caliper

The work and accuracy of the caliper indicators depends directly on its technical condition. To check the characteristics, high-tech methods are used in a special laboratory. It is impossible to check at home or at the time of purchase, therefore, when purchasing a device, it is enough to look at the passport and calibration data.

During operation, you need to use the instructions and follow the basic requirements of the manufacturer, thanks to these rules, you will get high accuracy of indicators. During measurements, the vernier caliper may fall, bump or be subjected to other influences, so from time to time you need to do:

- external examination - a visual assessment of the caliper, its geometry, cleanliness of mechanisms and the need for additional lubrication of the grooves is carried out. All parts should be easy to read, move, and small problems need to be fixed;

- checking the zero value - is carried out by moving the frame to the very beginning at the stop. At this time, you need to ensure that the two scales are zero. The tenth division of the vernier shows a value of 19 mm;

- assessment of the quality of measurements on different surfaces. It is necessary to move the lips, distribute them against the light, evaluate their fit. Light should not penetrate, and if there are gaps, then the defect must be eliminated.

To get accurate values during measurements, you need to understand the basic rules. No device can independently measure a surface or part. With the help of a caliper, the digital value is displayed, and all the manipulations are carried out by a person moving the frame.

Which company is better to choose a caliper

When buying any meter, its accuracy is very important. After all, it is from the measurements that the manufacture of some parts according to the measurements will largely depend. If the measurements turn out to be incorrect, then you will get useless parts. The accuracy of the device can only be guaranteed by a responsible manufacturer. According to research, expert estimates, the following companies have become such:

- Norgau is a Russian manufacturer of high-precision devices and instruments, which has been on the market for over 20 years. In addition to Russian factories, Norgau has two subsidiaries in the EU countries. The products of this company are distinguished by their reliability and high accuracy.

- Matrix is a tool manufacturing company with a ten-year history, with a product range of more than 3000 items. These are measuring tools, cutting, carpentry, locksmith tools, equipment for construction, finishing works, for cars, as well as fasteners.

- Shan is a measuring technology company that has been awarded multiple international quality marks. The Shan brand in its modern form appeared in 2013 as a result of agreements between CJSC TD “Calibron” and Guilin Measuring & Cutting Tool.

- Griff is a manufacturer of measuring, abrasive, metal-cutting, locksmith, construction equipment. The assortment of the company consists of about a thousand items. The Griff factory has strict quality control.

- Stayer is a company that produces both power tools for construction, finishing works and hand tools for repair, production, measurements. All products have Russian and international quality certificates.

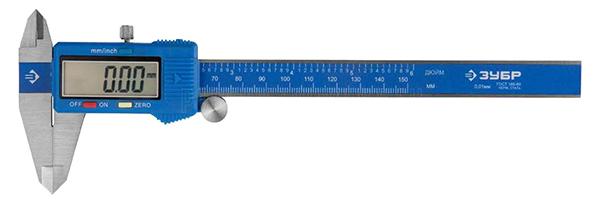

- Zubr is a Russian company that produces measuring instruments, fittings, plumbing accessories, household equipment, tools for construction, repair work.

- Topex is a popular European manufacturer of construction tools and instruments for precise measurements. The company was founded in Poland in 1990. Since then, they have managed to conquer the markets of Europe and the CIS countries.

Measurement rules

For measurements of external parts, it is necessary to firmly set the surface of the instrument on the part, placing it perpendicularly, and for accuracy, use the projections of the jaws. If the part is very long, then it should be placed parallel to the axis of the measuring device. For internal measurement, the caliper jaws should be positioned perpendicularly inside the part.

Depth measurement is carried out in the same way.

- Make the correct angle for the end of the rod in the original plane.

- Pull out the frame, pressing it against the part.

- Tighten the retaining screw.

- Write data.

For home use of a caliper, it is sufficient to use an accuracy class of 0.1 mm. Correct and careful use of the tool will ensure long-term and correct operation of the device. If this accuracy is not enough, then electronic devices will be an excellent alternative, their class is 0.01 mm.

A vernier caliper is a highly accurate measuring product, so it must be protected from dirt, water and other factors that can render the instrument inoperative. Manufacturers recommend using a soft, slightly damp cloth and wiping equipment prior to any use. After that, wipe the device dry, from time to time lubricate the moving parts with watch oil. Knowing the design and operation features, you can choose the right caliper, based on information about the best manufacturers.

Principle of operation

The principle of operation of any caliper is based on the coincidence of the required scale marks on the stationary and retractable parts. But a digital device has its own characteristics. It uses a capacitive matrix with an encoder. Simply put, a pair of simple capacitors operates in the circuit, connected one through the other, and the top plate of each of them is a common terminal. To create a capacitive combination, several capacitor plates are used.

Such a system has a sensitive response to sensor movement. The rotating part in this system is the slider. The fixed part is placed in a steel ruler. The digital block with a slider is fixed on the moving part of the caliper. When moving apart the jaws of the caliper, not only the movable part is shifted, but the slider rotates, pulling it in the right direction.

A long-term memory chip, or ROM, contains a microprogram that is loaded into the processor each time the digital module is turned on and organizes its operation. It interprets the data received from the caliper sensor through the ADC into readings and displays them on the display.

What to look for when buying a caliper:

Calipers are often equipped with other features that may help you.

Therefore, pay attention to them before buying a device.

Slider fixing screw for recording measurements

Sometimes you will find it difficult to read the measurement results while holding objects. At such times, it will be easier to free the object from the run, so that the measurement results are easier to read. With the fixing screw slider it will be easier for you to holdslider in movement, even if it is disconnected from the object. Functionretention on digital calipers also acts as locking screws on analog anddials.

Adjust the slider with one hand using the thumb roller

Sometimes you find it difficult to measure an object because you have to move slider with two hands. To do this, look for a device with the function thumb roller. Roller finger Is the screw for slow adjustmentslider ... You can easily customizeslider with one hand without letting go of the object with the other hand.

Consider your product quality and budget

To ensure that you select products with the highest accuracy, we recommend choosing a brand with a reliable reputation.

One of the famous brands is a brand from Japan: Mitutoyo. Mitutoyo is often referred to as the best caliper manufacturer in the world. This brand has slider, which is easy to move. Their products are often used by professionals in their respective fields. Naturally, the price of such a device will be more expensive than devices from other manufacturers. If you have a corresponding budget We recommend that you consider this brand first.

Many users also say that other brands have ample room for everyday non-professional measurement. Therefore, choose the product that best suits your use.

Comparative characteristics

First of all, when choosing a caliper, you will need to decide on its dimensions and on the details that will be measured. For small surfaces not exceeding 13 cm, it is recommended to use a tool up to 150 mm. This is the most common model, it is convenient and easy to use and store.

For parts 20-30 cm, it is better to use a large caliper, but the control is quite complicated, especially if the part is on the machine. When determining the size of the tool, its accuracy and measuring step are also important. When turning, it is necessary to select inventory of increased accuracy, class 0.01 mm, with possible errors up to 0.02 mm.

For working with wood, lower accuracy is suitable, since the raw material is soft, it can expand from moisture. For carpentry work, models will be cheaper, their choice is much wider.

Additional functions are an important part of electronic calipers. Modern models help to measure in mm and inches, but fractional data does not show everything. Other functions include:

- the ability to connect to a computer - models of this type will help simplify the calculations of a large number of parts when you need to draw up a specific measurement report. Connection can be wired and wireless; after synchronization, a report is generated in electronic form;

- automatic shutdown or inclusion of the device allows to increase the battery life.

The last factor that is taken into account when choosing is the material of the product. The service life and protective characteristics depend on this parameter. It is recommended to buy a stainless steel caliper, which does not corrode and is not afraid of stress. For turning work, it is better to take equipment that is protected from oil. Outdoor work provides models with protection against dust, moisture, class IP54 and above.

Vernier caliper ШЦК-I

This type of calipers is equipped with a circular scale, which is made in the form of a rotary indicator with a graduation of 0.02 mm. ShTsK-I are convenient for frequent comparative measurements, the indicator arrow is convenient for quick reading of the results, the possibility of jumps is excluded, which is sometimes the case with digital analogs. It is very convenient to use this type of caliper to control the same typical dimensions of parts.

Best Calipers 150mm Length

Measuring devices of this length are well suited for external and internal measurements in the production or repair of small devices, parts. They are also perfect as a household assistant, which is useful to have in every apartment. It is in this category that the largest number of models is presented. There are also the simplest manual calipers, and there are also high-precision electronic calipers 150 mm. Four out of 30-40 models became leaders.

Calibron ШЦЦ-I 0-150 0.01

Electronic caliper with a depth gauge Calibron ШЦЦ-l 0-150 0.001 is perfect for measuring objects with ledges and holes. Internal and external measurements can be taken. The device belongs to the first class of accuracy and is included in the State Register. Packed in a case. The jaws for internal measurements are 16.5 mm long, for external ones - 40 mm. The display is powered by CR2032 batteries.

Dignity

- High class of loyalty;

- High-quality assembly;

- The convenience of use;

- Nice case for storage and transportation.

disadvantages

Not the lowest price.

Despite the fact that this device is quite expensive, it justifies its price. The user characterizes it as durable and comfortable. For this, many are willing to pay the appropriate price. The Calibron digital caliper is bought once and for a long time.

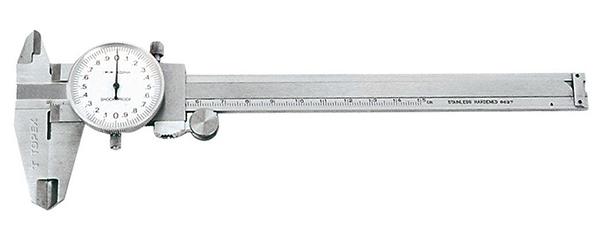

Topex 31C627

The Topex 31C627 mechanical vernier caliper is a first class precision instrument. The maximum length of the measuring scale is 150 mm. A vernier scale is applied to the movable frame, which helps to make measurements as accurately as possible and minimize errors. The material of the measuring device is stainless steel. This allows you to safely use the Topex 31C627 when working with hard objects.

Dignity

- Accuracy of readings;

- Ease of use;

- Durable material from which the device is made;

- Clear scale.

disadvantages

Very high cost of the device.

People who have purchased this meter talk about its pleasant and convenient use.

Bison 34463-150

This model is designed for indoor and outdoor measurements, as well as depth measurements. To improve the accuracy of data acquisition, the device is equipped with a digital readout display. The device is made of stainless steel in accordance with GOST. This ensures the durability of the measuring device.

Dignity

- Strong materials;

- Reliable build;

- High measurement accuracy;

- Bright, easy-to-read metric scale;

- High quality transport case.

disadvantages

High price.

Bison 34463-150 is in great demand among professionals. According to their reviews, they are completely satisfied with the accuracy of the device, its resistance to external influences, and the case. It is also convenient that after five minutes of inactivity the digital display turns itself off. This saves batteries.

Stayer Professional

Stayer has created a professional meter that is absolutely reliable and accurate. Range of application: internal, external and depth measurements. The accuracy of the result is 0.1 mm. The measurement results are instantly displayed on the digital display. The screen is large enough and easy to read.

Dignity

- Convenience of work on measurements;

- Excellent accuracy;

- Durable materials;

- Low price.

disadvantages

Not the most secure storage case.

This meter is perfect as a duty home option, while modern and with a digital screen. The price contributes to this. From those who regularly use the Stayer measuring device, as a rule, there are no complaints about its durability.

13 good tile cutters according to customer reviews

$ 11.5 Digital Vernier Caliper / Tools / iXBT Live

This model has a perfectly fitted steel body, due to which a high accuracy of readings is achieved, which does not float depending on the compression force.He also knows how to display fractional fractions of an inch, although the benefits of this for residents of the CIS countries are so-so.

Specifications

Range: 0.01mm to 150mm Resolution: 0.01mm / 0.0004 "Accuracy: ± 0.04mm / 0.0016" Battery: 1 x LR44 Battery (included) Total length: 234mm Material: Stainless steel

Unpacking and appearance.

Gray package

Polyethylene foam

OEM plastic box

Inside, the subject is wrapped in polyethylene, instructions, a bag of desiccant and two spare batteries.

Like these ones.

The bright print of the scale catches the eye, otherwise it is similar to other similar models.

Bar body without burrs, smooth, well polished.

The depth gauge ruler is also made of stainless steel.

Instead of a vernier, a digital module with a display and several controls is installed.

There is also a frame clamp screw and a micrometer feed shaft, if you can call it that.

Comparison with other models

I have previously purchased a couple of digital models. First with a carbon fiber body for $ 6

I thought it would be enough for my needs, but the jump of zero during the measurement and the periodic sliding of the battery compartment cover periodically made me want to smash it against the wall.

Then I came across a stainless steel model for $ 10, which also did not live up to expectations, and we can compare it with it.

Outwardly very similar, on the rods the postscript STAINLESS HARDENED

But let's take a closer look at the subject again

And this is an outrage. It's still hard to see the ends, they were not polished at all.

Internal measuring jaws, seemingly ordinary aluminum.

Model being reviewed.

The outer dimension sponges are similar, viewed from below by DANIU, probably it was necessary not to specify.

And here you can see the alignment of the jaws and the gap.

The second sample does not react at all and nowhere.

But the monitored model is really made of steel.

Comparison of indications.

DAINU shows the same thing. And what was the indignation for? Just think, polished badly.

Let's increase the pressure slightly. Minus 0.08mm. Interesting, isn't it? I haven't tried it yet)

Squeezed the second ... Minus 0.01mm, and the effort exerted even greater.

The key role is played not even by the soft material of the body, but by the tolerances due to which the frame moves relative to the rod. The contact pads may also be different, but I did not dig so deeply.

Measurement accuracy check

I calibrated the zero point once, during the tests it did not move.

I will use the thickness gauge calibration sheets. To begin with, 0.05 mm.

Further 0.1 mm, I try to apply the same force.

Then 0.25 mm. Shows 0.02mm less.

At 0.5mm, the error is 0.01mm

At 1 mm, the same is one hundredth of a millimeter.

But on a 2 mm plate, one hundredth was a plus. I do not remember what the declared error in the thickness of the plates was, but it was well within the declared error of the caliper ± 0.04 mm.

Outcomes

I think everyone understands that it is better not to save on the tool, but you also don’t want to overpay if you do not need high accuracy and reliability.

Nevertheless, the reviewed model has shown itself to be very good, so if you consider the price / quality ratio, I think it is worth every cent spent.

Although it is more pleasant to use it - the design is felt in the hand more solid, smoother, weighty (160 grams), the zero point does not "creep away" during use and the screen does not turn on from the slightest vibration as in the previous samples.

I bought here

I bought it for $ 12. Now the store has provided coupon 20DNC, which reduces the price from $ 15 to $ 11.49

Features of Electronic Calipers

The design features of electronic types almost do not differ from simple models, but the instrument is additionally equipped with electronic parts. Main parts:

- sponges measuring the external size;

- sponges for measuring internal dimensions;

- barbell;

- frame;

- battery;

- length measuring roller;

- reset button;

- on / off button;

- switch from inches to mm.

Certain models include additional features, depending on the manufacturer and design features. In modern devices, you can find wireless options for data transmission, the ability to connect to a computer and other features, but the main parts are the same.

The principle of operation is to use a digital vernier, which has a matrix with codes. In fact, all electronic calipers appeared on the basis of the SCC model. Among the advantages of technology are:

- instant display of data on the dial. In the course of production activities, this is very convenient, since it speeds up work, at home it makes it easier for beginners to measure;

- several types of measurements allow the use of a vernier caliper in different areas, since mechanical types do not make it possible to immediately show the depth, external and internal parameters;

- the highest possible accuracy;

- small size of the device, which affects the weight and ease of use. Convenient to use in hard-to-reach places;

- additional functions.

The main disadvantage is dependence on a power source, since it will be impossible to use a caliper without it. Other disadvantages include:

- high cost of the device;

- high sensitivity to drops, shocks, vibrations, humidity;

- software crashes that lead to instrument malfunction.

Knowing some of the features of electronic types, you should highlight the best brands that are recommended for use in industry and at home.

Overview of simple models

There are 4 main types of mechanical models: ШЦ-1, 2, 3 and ШЦК. The simplest caliper is ШЦ-1. The model is very common, it has a vernier scale with an accuracy class of 0.1 mm, although other types of divisions can be found.

The ShTs-2 variant differs from the first with an additional frame, which includes a limiting screw and a mechanism for adjustments, in addition there are jaws. The lower part makes it possible to find out the external and internal dimensions using different surfaces. The difference in indicators is immediately visible on the case, which allows measurements with high accuracy. The upper lips are sharpened, used for two purposes:

- marking;

- measuring the depth of thin parts.

The ShTs-3 model is structurally similar to the ShTs-2, but there is an upper pair of jaws for measuring and marking. Such a device is quite long, so it allows you to measure large parts.

ShTsK-1 is a mechanical device that has a circular digital scale. This is the best vernier caliper of the simple types, as it gives the maximum measurement accuracy. To move the frame, a rack and pinion gear is used, which is driven by the handle wheel. There is a screw on the head to fix the position. The disadvantages include the need to constantly keep the device clean so that the rack and pinion mechanism does not fail.

ШЦЦ-1 is a simple device with a digital display. With the help of it, work on counting is much easier, the accuracy class is as high as possible, it is 0.01 mm. The display has buttons for control and selection of modes, there is an autonomous power source.

Calipers ШЦ-III, ШЦЦ-III

This type of calipers is designed for measuring large parts with high accuracy. The maximum dimension can be from 450 to 5000 mm. For ShTs-III, ShTsTs-III, the jaws are directed only downward, their length can be ordered from 100 to 300 mm, which allows you to measure parts in a wide range. The graduation is 0.01 mm for digital calipers and 0.02 mm for mechanical ones.

Let's briefly dwell on specialized calipers, which can hardly be found in a regular store:

- ШЦЦТ - pipe vernier caliper used to measure pipe diameters.

- ШЦЦВ - digital vernier caliper for measuring internal holes.

- ШЦЦН - analog for measuring external holes.

- ШЦЦУ - digital universal vernier caliper, which includes a special set of nozzles with which you can carry out hard-to-reach measurements: measurement of pipe walls, center-to-center distances, internal and external measurements.

- ШЦЦД - a vernier caliper for controlling the thickness of brake discs, as well as for measuring parts that have protrusions.

- ШЦЦП - tread caliper is used to measure the residual tread depth of car tires.

- ШЦЦМ - vernier caliper for measuring center-to-center distances.

Interesting: Disinfection of pool water

Features and purpose

A caliper allows you to more accurately determine the outer and inner diameters of gaps and holes, the length and depth of parts in various projections. A special purpose caliper also allows you to measure the distance in grooves, small-diameter holes, the distance in the part machined in a certain way, the distance between the axes, the thickness of the pipe walls, etc.

In its simplest form, the main part consists of a fixed base with a left-hand jaw. The right one moves together with a movable guide - a rod, and is rigidly connected to it. This pair of jaws is used for external measurements. The second pair has incisors turned 180 degrees and moves similarly to the first pair and serves to measure internal diameters and distances. There is a second scale on the bar, which helps to more accurately measure the desired distance. At the end of the ruler there is a depth gauge that allows you to read the distance for the depth of the holes. To fix the readings taken from the part or hole, so that the rod does not move, a holding screw with a handle is provided.

The rotation sensor of the roller rolling along the bar is located inside - it counts on it how far the moving part has moved, and is guided by the main scale.

The accuracy of the digital caliper is up to 0.01 mm, which brings it closer to an analog micrometer. A mechanical micrometer also has an accuracy of up to 10 microns, but in that the measuring range is limited to 2.5-10 cm, and for a caliper, this limiting distance is much greater - 15-130 cm. An electronic caliper is, in fact, the simplest microcomputer with a processor, ADC, RAM.

If a purely mechanical (analog) caliper does not have special requirements for error (“as much as I saw, I noted as much”), then in a digital one, according to GOST and international standards, the error should not be more than 10% of the graduation price.

The scope of application of the caliper is metalworking production, car industry and car service, repair of all kinds of equipment and products, construction.

Interesting: Retaining ring remover - design, types, characteristics

Advantages and disadvantages

Advantages of the digital caliper.

Increased accuracy and low error, which is extremely important for accurate measurements, where the slightest discrepancy in a certain part will immediately cause unstable operation in the entire mechanism or installation.

Simplified verification (or calibration) - when it is necessary to check the operation of several calipers at once.

The speed of perception and transmission of the received data. This is extremely important in production, where the conveyor has an inspector who determines the accuracy and accuracy of certain dimensions of the produced parts and identifies manufacturing defects.

The readings of the device are given instantly - the calculation on the scales is not required here.

Beginners do not need to learn how measurements are made - the sensor and the digital module will do everything for them.

The ability to switch from one type of measurement to another - on multi-profile parts that have different approaches to measuring a particular gap.

The ability to easily convert inches to centimeters and vice versa, as well as transfer data using the built-in interface for external communication with PCs and mobile devices.

Disadvantages of an electronic device.

- The presence of a battery - forgetting to replace it in time, you will be faced with the need to make measurements "the old fashioned way".

- Sensitivity to high humidity, shaking, shock and vibration, which can easily damage the electronic module.

- Software glitches due to strong nearby interference, static sensitivity. Hence, the inoperability of both individual functions and the entire device as a whole. The indication may disappear - most calipers do not have a backlight, and it is impossible to guess that the device is still serviceable and functional (when the display is off).

It is interesting: Shtangenreismas - purpose, verification, GOST

Types of caliper tools

Calipers are of different types, among the main ones there are:

- vernier;

- dial;

- electronic.

Not everyone understands which device is better to use, electronic or simple (mechanical). Modern people prefer electronic technology, but many remain faithful to the simple and reliable design.

Vernier devices are the simplest, include a bar-ruler with a scale of 1 mm. The vernier itself is a movable part with jaws, a ruler and an additional scale for counting tenths and hundredths of a millimeter.

The dial devices are similar to the first ones, but the moving part is equipped with a mechanical dial with an arrow that indicates the desired value. It is easier to use this, the eyes do not get tired, and the overall work time is reduced.

Electronic devices are of a modern type, they are equipped with a display and sensors, with the help of which the desired values are displayed. The advantages are high accuracy and ease of operation. The described types are often used in everyday life, but there are models with additional characteristics and a distinctive purpose:

- pipe - used to clarify the diameter of the pipes. Instead of jaws, a cylinder is installed, which adheres closely to the measured elements and helps to perfectly determine the dimensions;

- tread - used to determine the tread depth on tires, often used at service stations;

- for brake discs - it has protrusions on the jaws, with the help of which the tightness of adhesion to various parts is improved.

In addition to a caliper, you can find similar tools on sale, but their essence differs in terms of internal or external measurement:

- height gauge - used to determine the layout of the part, height. Structurally, it includes a barbell with a powerful base, a frame with a vernier and a mount with a sponge or markings rides along it;

- depth gauge - used to measure depth, structurally consists of legs on the sides and a bar;

- caliper - used to measure teeth of gear mechanisms and racks. Structurally, it includes 2 rods located perpendicularly, one has jaws.

By examining all the features, you can determine the best mechanical and electronic calipers for your home or industry.

Vernier caliper ШЦ-II

This series of tools is used to control external and internal dimensions. The measurement range is from 0 to 250-300 mm with a graduation of 0.02 and 0.05 mm. ShTs-II is used more often for marking work, for this reason they are equipped with special carbide nozzles that protect the tool jaws from rapid wear.