Tool recommendations

If you want the tool to serve you for a long time, you must not only know how to choose a manual riveter, but also be careful when using it. Otherwise, it will quickly break in your hands, even if it is an expensive professional tool from a well-known brand.

Price is one of the important factors to consider when choosing this device

But besides him, other characteristics are of no small importance:

Rivet material. For joining aluminum parts, you can buy any of the tools available in stores. If you have to fix steel parts, then we advise you to opt for more powerful rivets.

Ease of use. If you plan to use fasteners of different diameters and from different materials to connect, then it makes sense to purchase a two-handed model

When choosing a tool, we advise you to pay attention to its head. It is desirable that it be rotary

Then you can easily make the connection in difficult areas. Before buying, it does not hurt to find out if a set of replaceable nozzles is included in the package.

This is especially worth worrying about for those who are going to use different fasteners for connection.

An important characteristic to consider when choosing a riveter is the presence of a waste container. It will be especially indispensable for those craftsmen who are going to erect a fence on the territory or lay a roof.

Rating of the best models

We have selected different cordless riveters for you. When compiling the rating, we were guided by their quality, reviews of real buyers and characteristics. Since people have different needs, we took tools with different performance characteristics, which are in different price categories. Thus, you can choose the most suitable option.

Time-Proof 500

The first in our rating was the Time-Proof 500 electric riveter. This is an inexpensive riveting riveter. In terms of its characteristics, it is at an average level - in many ways it is inferior to expensive models, but at the same time it surpasses cheap counterparts. Its characteristics are ideal for home use. Moreover, sometimes you can use it for more complex tasks, but in this case, the tool will work to its limit. It is suitable for rare use, but the tool may not cope with frequent serious work. The price is $ 200.

| The weight | 2.5KG |

| Power | 400 watts |

| Traction force | 8000 N |

| Riveting speed | 2 seconds / rivet |

| Material thickness range | 3 to 5 mm |

MILWAUKEE M12 BPRT-0

This cordless riveter is in the budget price range. It is good for its versatility (suitable for working with different surfaces of different thicknesses). In addition, it has a well thought-out design, which makes it easy to use. For example, it comes with a built-in LED that will illuminate the work surface in the dark.

| The weight | 1,8 kg |

| Voltage | 12 in |

| Traction force | 9000 N |

| Riveting speed | 2 seconds / riveting |

| Material thickness range | 2.4 - 4.8 mm |

METABO NP 18 LTX BL 5.0

Electric riveter from a well-known German manufacturer. It is not cheap, but the price is offset by its European quality and characteristics. It has high power, a very capacious battery and comfortable ergonomics. You can work with one hand, while the hand does not get tired even after several dozen rivets in a row. Suitable for daily professional use.The price is $ 750.

| The weight | 2 Kg |

| Voltage | 18 in |

| Traction force | 10,000 N |

| Riveting speed | 2 seconds / riveting |

| Material thickness range | 2.4 - 5.0 mm |

MESSER ERA-M4-10

The first riveter in the list to be used for threaded riveting. A specific tool that is designed to solve non-everyday tasks: riveting of thick metals, sheet steel. Supports rivets in sizes M4 - M10. Due to the specificity of the threaded connections, Messer operates at high power. Because of this, you can use it from the network. The price is $ 400.

| The weight | 1.65 kg |

| Voltage | 220 V |

| Traction force | 750 kgf |

| Riveting speed | 2 seconds / riveting |

| Material thickness range | M4 - M10 (thread) |

Toptul KPRA0306E

Universal cordless riveter. Designed to work with both thin and thick materials. High-capacity battery that fully charges in one hour. Suitable for both home use and craftsmen. The price is $ 550.

| The weight | 2 Kg |

| Voltage | 18 in |

| Traction force | 8,000 N |

| Riveting speed | 2 seconds / riveting |

| Material thickness range | 3.2 - 6.4 mm |

TOPTUL KPNA0510E

Electric riveter for threaded connections. According to its characteristics, it almost completely repeats the previous one (the manufacturer is the same - TOPTUL). The only significant difference is the type of rivets it works with. The price is $ 900.

| The weight | 2 Kg |

| Voltage | 18 in |

| Traction force | 8,000 N |

| Riveting speed | Adjustable |

| Material thickness range | M5 - M10 |

How to use it correctly?

In order to easily rivet any metal parts, you need to study the rules for using the riveter. About what kind of adjustment is required for a hand tool, how to put hardware when working with it, you should learn in more detail before starting to use the tool.

Threaded nut rivet

This tool takes some effort to work with. The procedure in this case will be as follows.

- A hole with a diameter of 3 to 14 mm (M3-M14) is drilled in the steel workpiece. Reference point - riveting diameter.

- Insert the threaded rod into the riveting head.

- Screw the boss onto it. The action continues until the stop appears.

- Install the prepared hardware into the hole in the parts to be joined.

- Reduce the levers to generate the required effort.

- Unscrew the tool from the riveted joint.

"Harmonic"

This type of tool requires, when working, to provide sufficient free space for folding its elements. In addition, the length of the straightened lever part reaches 80 cm. This one should also be taken into account when preparing the workplace. The head in accordion rivets is always straight. In this case, you need to install the hardware as follows.

- Fasten the rivet in the head. Installation is carried out inside with a hairpin.

- Unclench the handle all the way.

- Insert the rivet into the prepared hole.

- Compress the mechanism, gradually increasing the pressure due to body weight.

- Remove the pin from the head.

The big advantage is that all manipulations are done with one hand. This makes it easier to position the rivets in the hole, allowing less fatigue with a large volume of tasks.

Exhaust

The principle of operation here is similar to that used in accordion riveters. Only the lever of the tool is located differently and requires the application of force from 2 sides. The cartridge is selected based on the size of the stud. The tool, when compressed, flattens the boss installed in the hole, riveting of the material occurs. The inner pin is pulled out.

The following video explains how to use the riveter.

Description and working principle

The device of all types of rivets is similar, only the drive of the tool (electric, pneumatic or mechanical) can be different. The manual riveter is no exception. The main principle of the tool is the connection of structural elements using a hollow rivet by crushing one end of it.

According to GOST, rivets are of several standard types, differing in diameter and length.

For a high-quality connection, the combination of the length and diameter of the consumable is important, of course, the larger the diameter, the thicker the sleeve wall and, accordingly, the more reliable the connection. Length is just as important, it determines how thick materials can be joined.

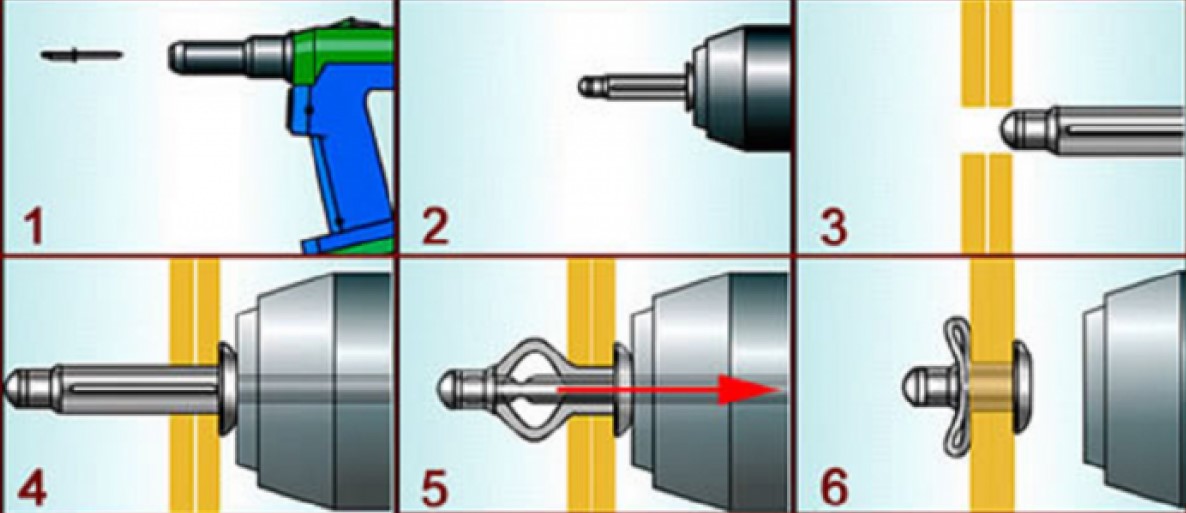

The manual riveter works as follows: through a rivet inserted into the hole using a system of levers, pressing the handles, we pull a steel pin with a thickening at the end. This expands the hollow rivet tube and holds the material together. The remainder of the pin breaks off.

Sometimes, with a large rivet length and diameter, a sufficiently large force is required; for this, the manual riveter is equipped with long handles and a system of levers that allow to distribute the force. If the material of the tool itself is not strong enough, loads can lead to wear, and repair is not always possible. Since different companies produce far from the same riveting tools, finding suitable spare parts can be more expensive than purchasing a new tool.

The most common type of hand-held blind riveter, called "pistol", is quite simple. It has two handles. One is movable, transmitting force to the mechanism, the second is fixedly connected to the tool body. It is to it that the elements of the ratchet mechanism are attached, stretching and breaking off the rivet pin, into it, with the help of a thread, heads are installed under the corresponding diameter of the rivet pin.

Rating of the best manufacturers

Hand riveters are produced by almost all companies, one way or another related to the production of hand tools. Among them there are some kind of leaders, whose products are deservedly in high demand or have the greatest number of positive reviews. Let's start with one-handed models.

A relatively inexpensive representative of this class from the German company Stayer can be successfully used at the household level. Interchangeable heads allow the installation of 2.4mm, 3.2mm, 4mm and 8mm blind rivets. The more expensive version from the same manufacturer is equipped with a swivel head and can be used to work in a wide variety of conditions.

A similar tool POP PS-15 is produced in Great Britain, it is made of an aluminum-based alloy, which makes the tool one of the lightest in its class (no more than 600 g). The riveter is equipped with three removable heads for different diameters of consumables. Comfortable handles allow you to work for a long time. Experts recommend such a tool for professionals because of its exceptional reliability.

The Russian-Chinese manufacturer of tools "Zubr" also presents to the market a successful model "Zubr Master-31195". The model is equipped with a swivel head and four replaceable nozzles of different diameters. The aluminum alloy provides a weight of about 700 g. Comfortable handles allow you to work for a long time. Another model of this manufacturer "Zubr Universal 270 mm" has 8 attachments for different rivet diameters in the set. This greatly expands the range of its use.

The swivel head has an Italian armero zepper with the A320 / 104 marking. The diameter of the blind rivets varies from 3 to 5 mm. Light weight and durable alloy, according to experts, cannot compensate for the inconvenience of plastic handles. However, everything pays off with reliability and the ability to work in a variety of conditions.

The reliable one-hand riveter for threaded rivets is offered by the Russian manufacturer "Cobalt". The instrument under the name "Cobalt 243-561" has a low weight, a durable aluminum body, very comfortable handles. The diameter of the rivets is limited from 4 to 6 mm. The product range of this manufacturer also includes rivets for blind rivets, both one-handed and two-handed.

Popular two-handed models usually represent the same manufacturers. The two-handed riveter from the already mentioned Stayer company can be classified as a professional tool. The two-handed scheme allows you to work with it for several hours, having installed hundreds of rivets during this time.

Akin to the previous and no less popular German model Kraftool industrie 31182, it has long folding handles that allow significant force when installing a blind rivet. When folded, the tool fits into a compact case, in which removable nozzles for various rivet diameters are placed. Experts note the significant weight of this professional tool, about 3 kg. But this is also indicated as a guarantee of the highest reliability of this model.

Riveter threaded principle of its operation step by step instructions

The most reliable connection is provided by means of threaded devices. The principle of their operation is quite simple, but it causes some inconvenience - each rivet must be screwed onto the end of the tool before use. The instruction on how threaded devices work is as follows:

- Initially, it is necessary to drill a hole of the corresponding diameter in sheet steel - from 3 to 14 mm or M3-M14

- Install a threaded tip (rod) into the tool head of the corresponding diameter

- Screw the threaded boss onto the tip until it stops

- Install a rivet in the holes of the elements to be connected

- Rivet by acting on the levers (bring them together)

- Further, to disconnect the tool with the resulting connection, you will need to unscrew it

- After that, the connection is ready for use, and a bolt of the corresponding diameter can be screwed into it.

For clarity, a video is presented below, which shows what a threaded tool is and how it is used.

Species overview

In accordance with numerous reviews from ordinary users and experienced professionals, electric riveters have long become indispensable helpers. And in this case we are talking about performing installation work in everyday life and in the conditions of small workshops, as well as on an industrial scale.

Household

At home, both mains and battery rivets can be successfully used. However, the second option will often be much more convenient. For example, a tool that is not tied to the network will become indispensable when performing roofing work. The main distinguishing feature of household (amateur) riveter models is the maximum simplicity of the design, the main element of which is a rotating head. Their advantages include:

- ease of operation and the need for minimal effort;

- riveting speed;

- impressive safety margin of equipment;

- the ability to install rivets of different sizes.

Professional

Industrial models of electric rivets are a modern type of tool with a wide range of applications. Such devices allow the installation of various types of fasteners with a fairly wide range of diameters (as a rule, this parameter ranges from 2.4 to 6.4 mm). We are talking about such hardware products as blind rivets, threaded rivets, rivet nuts, and studs.

Professional models of power tools differ from their household “counterparts”, first of all, by their increased power. An equally important point is the main performance indicators, and, first of all, high productivity. It should also be remembered that such models are more weighty and overall. They also differ from amateur ones in cost.

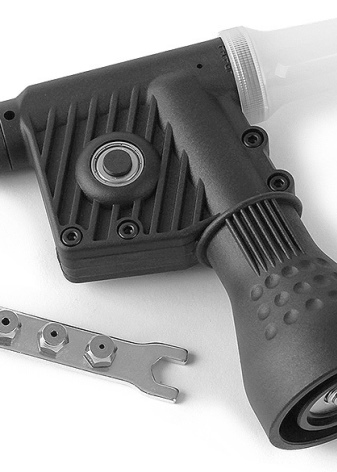

Packing

Above, we have already mentioned attachments for screwdrivers, the popularity of which continues to grow at a record pace. This device is easily and quickly installed in a standard power tool holder. After such modernization, it can be successfully used for:

- assembly of furniture;

- performing work in a car repair shop;

- installation of ventilation systems, air conditioners and other structures.

Naturally, this is far from a complete list of the possibilities of packed rivets.Such nozzles are versatile, since they can be installed in most cartridges. models of cordless and cordless screwdrivers and drills.

Removing rivets from clothing

This is done in two ways. One - with the help of side cutters, the other - with a knife and a pair of pliers. The choice of methods depends on whether your rivet is alpha (inner) or beta (outer). The corners and edges of the stitching are mostly riveted with alpha varieties, otherwise known as eyelets. Beta is used in cases of buttons that fasten clothes. One part there is alpha, and beta is riveted on it. Despite the fact that such rivets hold the material perfectly, they are afraid of mechanical stress.

How to rivet alpha rivets with a knife and two pliers?

- Carefully so as not to damage the fabric, insert a sharp knife blade under the edge of the wide part of the rivet on one side and bend it back so that you can grab the edge with pliers.

- Do the same for the opposite side of the rivet. Insert the knife blade and peel back the edge.

How to rivet a beta rivet on your clothes? It's even easier here. The procedure is as follows:

- Take the garment with the flared (folded) part of the rivet protruding from the inside of the pressure washer facing you.

- Take side cutters (preferably with those on the pliers), set them under the very bottom of the extended part and squeeze.

wikiHow works like a wiki, which means that many of our articles are written by multiple authors. Volunteer authors worked to edit and improve this article to create this article.

The number of sources used in this article: 5. You will find a list of them at the bottom of the page.

Rivets are a type of fastener that is used in everything from racing cars to yachts. The rivets are lightweight and quick and easy to install. A modern rivet consists of two parts, a punch and a head. A hole is drilled in the parts to be fastened, a rivet is inserted and the punch is pulled out with a special tool. The punch ball expands the tube, forming a closing head, thereby securing the part securely; the remainder of the rod is torn off. The diameter of the rivets varies from 1.4 to 6 mm, rivets are made from brass, aluminum, steel, copper and monel. The rivet joint is cheap and durable and can be used instead of welding, screws and bolts. However, such a connection may become loose, requiring removal and replacement of the rivet. This manual describes several ways to remove the rivet without damaging the mounting hole, quickly and professionally.

How to choose a quality device

Why is the question of how to choose a riveter still relevant? Indeed, despite the fact that the tool belongs to the category of hand tools, it has a fairly high cost. To save money, many buyers decide on a desperate step - they choose cheap models. As a result, the device breaks down very quickly, and it turns out that the money was wasted. You should also not buy expensive models, as it turns out that the tool will simply lie on the shelf in the garage most of the time. What to consider when choosing a manual riveter - there are such nuances:

Instrument body material - do not buy plastic models. No matter how colorfully they are described by manufacturers and sellers, such tools are a toy that is suitable only for children. You need to choose devices only from high-quality steel. Conscientious manufacturers indicate the type of steel used in the technical description

How much the tool weighs - a good threaded rivet has the appropriate weight, which allows it to be used to connect rivets with a diameter of 12-14 mm

Complete set - usually good and high-quality devices are sold complete with replaceable heads, as well as consumables

In addition, the devices are located in special plastic, metal or wooden cases, which simplifies not only their storage, but also transportation.

The manufacturer is very important, because today different manufacturers with an unknown reputation appear on the market. Trying your luck is not recommended, so choose riveters from manufacturers such as Kraftool, Matrix, Gross, JTC, Stayer and others.

Making a conclusion about what kind of hand-type riveters are, I must say that tie-down models are quite enough for home use. A threaded tool can also come in handy, but only if you plan to work with sheet steel. Proper storage and use will increase the service life of even a budget model of the tool.

The riveter can be called a master of splicing various blanks. For household use, a hand tool is suitable. In the article, you can familiarize yourself with how the device works and how to use it correctly.

How to work with a riveter and how to choose consumables

They work with a riveter like this:

- Parts that require connection are applied to each other and securely (sometimes with a magnet) fixed.

- Make a hole. Its diameter should be a couple of mm larger than the rivet size.

- A consumable is inserted into the resulting hole.

- A head is screwed onto the riveter, the diameter corresponding to the rod.

- They push the tool to the very side and squeeze the handles. If the rod does not come off the first time, the compression is repeated. Sometimes you need to do several approaches.

The metal for the rivet sleeve is selected depending on what material the parts that need fasteners are made of. Usually these are soft types: copper or aluminum. They are easily deformed and do not corrode. The pull rod is made of steel.

The size of the rivets for the tool must correspond to the thickness of the material. For strength, select the smallest possible diameter. In addition, when choosing a riveter in the store, be sure to check the correspondence of the set of heads to the diameter of the rivets.

Too long rivet body reduces the strength of the joint. It has been empirically proven that a length of 1-1.5 cm larger than the diameter is best suited. This is how the riveter makes a strong and beautiful connection. The total length of the rivet body can be completely different. Indeed, sometimes you need to connect fairly thick workpieces. The dimensions of the core do not particularly affect the process. The main thing here is its compatibility with the heads.

A hand or blind riveter is a very convenient and versatile tool. With its help, you can quickly and firmly connect parts at home without the help of professionals.

Choosing the type of drive

Before choosing a riveter, you need to figure out what they are. Let's start with the drive.

-

Manual (power). To install the rivet, you need to squeeze the handles. Sometimes you have to make a solid effort - for hardware with a diameter of 5 mm and more. The most reliable and inexpensive. This is a justified choice if the tool is bought for a one-time use - to mount the roofing material, to put a fence, to sew up the slopes.

- Electrical. Almost no effort - hold the tool and pull the trigger. More expensive, but also more productive models.

- From the network. Not too expensive, so you can buy for home use as well. But not every construction site has a source of electricity, and cords / extension cords are a hassle.

-

Rechargeable. With the same performance, they are more mobile, but weigh more (the battery itself also has weight), and are more expensive.

- Pneumatic and pneumohydraulic. The most reliable and productive tool. But it's worth buying for professional use only. After all, you also need a compressor.

Video review of the MILWAUKEE 2550-20 M12 RIVET TOOL cordless riveter.

Hand riveters are bought for household use. But even this “simple” tool is not easy to choose. First of all, the range of prices is surprising - from $ 5 to several hundred dollars. How to navigate here? We must say right away that it is definitely not worth taking too expensive for a single use, as well as too cheap. The rest must be understood.

What types of rivets are available

The riveting method does not lose its popularity, even despite the availability of different welding equipment. Not all materials can be welded by welding, so the use of rivets has always been and will always be relevant. Depending on the tool used, rivets, or they are also called bosses, are classified into the following types:

- Regular or classic - this is the simplest type of rivets, which are shaped like a fungus. Designed for riveting two or more sheets of steel without the use of specialized tools. The principle of operation of such rivets is that the connection is carried out by crushing the boss of the boss with a hammer

- Semi-tubular - they look like a half-hollow rod. The advantage of such equipment is that they do not require a lot of effort to connect, but they have low strength, which is their disadvantage. They are usually used where there is little mechanical stress.

- Exhaust - they are also called embedded, tear-off and traction. They are used in conjunction with pull-out rivets, and are often used not only for joining galvanized sheets, but also when installing corrugated board fences

- Piston - used to ensure the connection of two parts where there is little or no load. Usually used on clothing as a decorative material

- Threaded - they are also called nut. They are also designed to be used in conjunction with a specialized tool - the threaded rivet. This is the most reliable type of riveted connector

All types of rivets are used in various fields - mechanical engineering, auto repair, construction, fabrication of sheet steel structures, tinsmiths, etc. Depending on the type of riveter, it is necessary to select the appropriate boss. If you need to make a one-time connection using the riveting method, then you do not need to buy a special tool. For this, classic rivets are used.

When choosing, it must be borne in mind that rivets come in different diameters, which affects the quality of the connection. Tie rivets are available in the following standard sizes:

Threaded rivets are also available in different sizes:

The larger the size of the rivet, the higher its cost, and, accordingly, the stronger the connection.