Top 5 popular models

The most popular drills and drivers:

Bosch (GSR 1440-LI). High-quality and ergonomic tool from a branded manufacturer. Powered by a Ni-MH rechargeable battery (there are two in the set) in two modes with a maximum power of 1400 rpm. The screwdriver is sold with a case and charger.

Metabo PowerMaxx BS Basic. German quality and a power of 34 N / m with a small housing size allow you to work with a screwdriver in small spaces. Convenient quick-change chuck and dual-mode functionality (at 1400 rpm). Powered by rechargeable batteries (two Li-Ions included).

Makita 6271DWAE. Lightweight Japanese assembly tool. Accelerating power up to 1500 rpm, complete with double-sided bit, case, two Li-Ion blocks and charger. Two modes of operation and 16 speeds on the regulator.

SPECIAL BDA-18. Russian drill / screwdriver, also manufactured in the PRC. Attractive price, which is 1.5-2 times lower than that of foreign brands, is achieved due to the used "non-environmentally" Ni-Cd blocks (2 per set) and single-speed operation (up to 650 rpm) Comes with bits, charger and case.

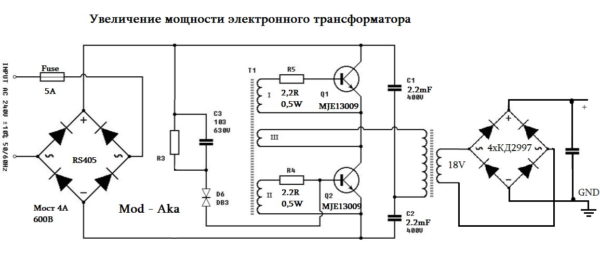

Power supply for a screwdriver - diagram and assembly procedure

Many are familiar with the situation: the screwdriver is alive and well, and the battery pack ordered to live a long time. There are many ways to rebuild the battery, but not everyone likes to mess with toxic elements.

How to use an electrical appliance

The answer is simple: connect external power supply... If you have a typical Chinese device with 14.4 volt batteries, you can use a car battery (convenient for working in a garage). Or you can pick up a transformer with an output of 15-17 volts, and assemble a full-fledged power supply unit.

The set of parts is the most inexpensive. Rectifier (diode bridge) and thermostat for overheating protection. The rest of the elements have a service task - indication of the input and output voltage. No Stabilizer Required - Your screwdriver's electric motor is not as demanding as the battery.

note

As you can see, bringing a cordless drill to life is not that difficult. The main thing is not to make a hasty decision: “throw away and buy a new electrical appliance”. If your screwdriver batteries are completely out of order, then you can convert it to a network power supply how to make such a power supply, see this video

If your screwdriver batteries are completely out of order, then you can convert it to a network one how to make such a power supply, see this video

Here you can download the PCB in lay format

This is how the diagram of the rework of the charger looks like.

Household and professional models of screwdrivers difficulties choices

Modern manufacturers - market leaders have long been producing high quality amateur models. However, their continuous operation time is up to half an hour, then you need to let the device cool down. They are designed for 20-30 hours of work per month. Their main difference from semi-professional models is less expensive materials and manufacturing technologies. This gives rise to their main differences from amateur ones:

- Longer continuous working time - up to 3-4 hours.

- More common resource - up to 100 hours per month.

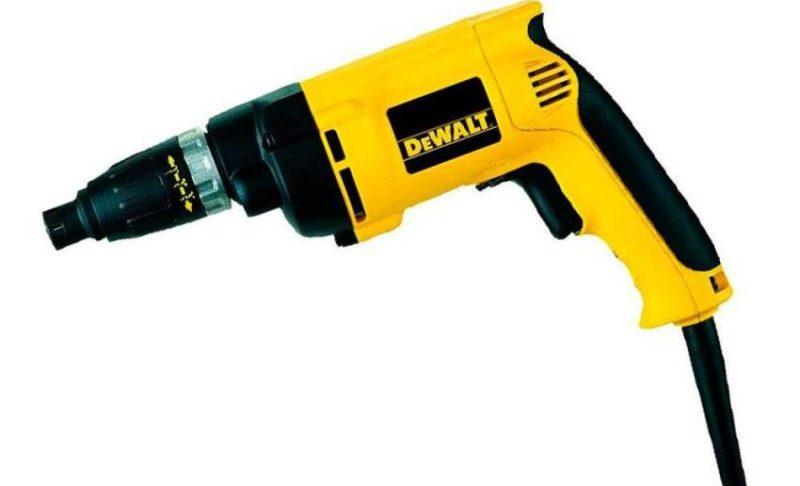

Professional network screwdrivers have even more resource, they can work without stopping for more than 8 hours.

Professional screwdriver

So if you do not plan 2-3 work shifts a day, then it is better to leave a professional device on the store shelf.

So, if for the house you need to hang a shelf - another, it is quite possible to get by with an amateur device, moreover, assembled at the Chinese branch of a well-known brand.

If a large repair or installation of a 200-meter fence is planned, it makes sense to choose among powerful semi-professional network screwdrivers. It will cost less than three Chinese bought consecutively and ingloriously broken from overload.

Where to start work

To convert a screwdriver for power from a 220 V electrical network, first of all, you will need to solder an electrical wire to the contacts of the charger. But since the wire has copper conductors, and the power supply has brass terminals, it will be very difficult to connect them. But in the world nothing is impossible, so we use acid as a connector. It is necessary to treat the terminals of the charger with acid, and then solder the wire to the contacts. The connection must be of high quality, since the contact and the functioning of the device itself depend on it.

At the next stage, the old battery is reworked. To do this, it must be disassembled and the entire inner part removed from it. Although the manufacturer does not recommend doing this, we will need a battery design.

When disassembling the battery, it is important to use protective equipment and not to throw the inner filling into the trash, but to dispose of it. A weight should be placed in the battery case, which will be the counterweight.

After the inside of the battery is removed, we proceed to the process of soldering the free contacts of the electrical cable to the battery terminals located in the inside of the case.

Important! During soldering, it is important to control the polarity, but if you do not observe it, then nothing terrible will happen, only the device will function in the other direction. But with the help of a switch, this situation can be easily solved.

The electric cable is inserted into the battery from the outside, making a special hole in the structure of the required diameter

After that, it is important to make sure that the cable is securely fixed in the structure of the battery case. To do this, you just need an insulating tape, with which you should wrap the cable from the inside and outside, thereby making a lock

After that, we insert the battery case into the screwdriver and use it for its intended purpose.

Views

Electric screwdrivers are usually divided into several types.

- Local power screwdrivers. As a rule, these are the simplest and most reliable devices. Power is supplied by simply plugging a wire into an outlet.

- Combined devices. These are more sophisticated tools that can be powered in parallel from both an outlet and a rechargeable battery. As a rule, their cost is higher, which is compensated by the convenience of their use.

-

Screwdrivers with motor brake:

- the electrical principle of the brake, as a rule, is based on the closure of the + and - of the motor, if you suddenly release the "Start" button;

- if the brake is mechanical, then its principle of operation is similar to that implemented in a regular bicycle.

- Drywall screwdrivers. They differ from ordinary network ones by the presence of a screw-in depth coupling, which is necessary when using hardware of considerable length.

- Impact screwdrivers. When working with stuck hardware, an impulse is used to enhance the impact, that is, the cartridge begins to rotate in jerks of greater power, intermittently.

These tools are also distinguished by the types of cartridges:

- tools with toothed (key) chucks, in which the nozzles are fixed with a special key, which takes a certain time, but such a fastening is considered highly reliable;

- screwdrivers equipped with keyless chucks are leaders in easy and quick change of nozzles, but when working with materials of increased hardness, the reliability of such a fastening leaves much to be desired.

The power of the used attachment also depends on the diameter of the chuck. Non-professional power tools are usually equipped with cartridges in the range of 0–20 mm.