General recommendations for selection

When purchasing an electric impact wrench, it is necessary to consider where and for what purpose it will be mainly used. In this sense, it is difficult to call it universal. But there are a number of criteria, knowledge of which will allow you to buy the optimal model.

The presence of a "drummer". It is not difficult to understand - with it the scope of application expands significantly. Even heavily rusted fasteners will easily give in without any "liquid key". And this is, first of all, saving time. Those who have come across such work will appreciate it.

The presence of a tightening torque regulator. Even an experienced master will not always be able to do this "by eye". For example, by changing the rotation speed. What can we say about the amateur. Especially if we are talking about small (and the most common) thread - M6 or 8. Tearing it off if the torque is incorrectly adjusted is a piece of cake. The article is devoted to just such - momentary - models, but the emphasis should be made. When choosing, this must be clarified, since it is difficult to distinguish externally electrical types of impact wrenches.

Configuration. In everyday life, you rarely have to use the angular model of the tool, so it is more expedient to purchase a straight ("pistol").

Material. There are few options - "iron" or plastic

Experts advise paying attention to the "insides" of the instrument. In a high-quality nutrunner, all working units must be metal

But the case is made of high-strength plastic. By the way, all well-known manufacturers (the same “Makita”, “Bosch”) complete their products in this way.

Additional "services" - at personal discretion. Here are just the most common ones:

Rubberized pads. The ease of use of the tool is obvious. With any effort, such a wrench will not break out of the hands

It is especially important if you have to work with gloves.

The number of places for installing an additional handle. There may be several

It also increases the usability of the tool, depending on the specifics of the work.

To choose the most suitable electric model wrench, there is enough information. All the features of the products available for sale, given the variety of assortment, cannot be noted. The only thing that should not be forgotten is that the “more expensive is better” principle does not apply to this e-tool. He is chosen to solve specific problems.

Specifications

Let's start with the most important characteristic of the device - the moment of force. The higher this indicator, the larger the nuts the tool can move.

Before purchasing a device, you need to find out for yourself what purposes it will be used for. If you decide to unscrew the small bolt with a powerful device, then it will simply break the thread. Therefore, experts recommend starting from the approximate diameter of the nut.

For nuts of size 12, a device with a torque of 100 Nm is suitable. The size 18 nuts unscrew the device well at 270 Nm, and the size 20 is tied with a torque of 600 Nm. It is the most powerful unit to date.

The type of chuck depends on the size of the nuts to be loosened and the torque of the tool. The quarter-inch hex chuck is usually installed in very weak fixtures. They work in tandem with flat or sacral bits (sizes 1-3) and nut (sizes up to 12). M12 heads are often found in mini hammer drills.

Less common types are 3/8 "and square (0.5") chucks. The latter is the most popular among the M8-M12 heads. The square variety is used in conjunction with very large nuts, which are found in the repair of trucks or during the assembly of large iron structures. Many manufacturers, in addition to the standard configuration, add several adapters as a bonus to less popular cartridges.

The performance of the tool can be indicated by the maximum number of rotations per second.This indicator is not very much in demand when working at home, but it is a very important point when installing in factories, where the tool is almost never turned off. All other buyers can ignore the RPM. You just need to know that it is closely related to the number of blows made by the device per second. And the higher this number, the easier it will be for you to work with the instrument. Since not in all cases the user needs a high rotational speed, it is advisable to make his choice in favor of those devices that have a pre-installed gearbox and have an adjustable speed mode.

Electric wrenches are subdivided into non-impact and percussion wrenches according to their variety. The impact function will not be useful in all cases. The bolts are often tightened quite tightly, so if a blow is triggered at the slightest pressure, the thread and nut will immediately become unusable. Therefore, the manufacturer provides a function to turn off shocks.

Please note that the rotational force of percussion instruments will always be higher than that of unstressed instruments, even if the power is equal to

Let's talk about powering the instrument. It can operate from 220V power lines, from the on-board power supply of a truck (24 V) or a car (12 V), as well as from an autonomous power supply. Most often, electric wrenches are very resource-demanding. You will not be able to work more than a quarter of an hour from one battery charge. There is no guarantee that replaceable batteries will give you at least half an hour of uninterrupted operation. And buying a third battery is too expensive.

If you do not plan to use the device for complex tasks, then purchase versions that work from the network. They do not need to be plugged into a 220V outlet. Power wrenches work great even on car power and can be transported in the trunk.

Best 12 Volt Electric Impact Wrench

A compact but powerful example of the BORT BSR-12 impact wrench powered by a 12-volt DC network. The model is not designed for serious loads, but due to its characteristics it is one of the best solutions for motorists. The device can be powered both from the terminals of the car battery, and from the cigarette lighter, and even from the 12-volt line computer power supply suitable power. The torque of 350 Nm is sufficient to loosen and tighten the wheel nuts of passenger cars.

At such a low price, it was not without flaws. We are talking about poor quality lubrication of units from the factory. For this reason, after purchase, it is recommended to disassemble the wrench and apply additional grease to the rotating parts in contact with each other. Another disadvantage is the length of the power wires. Sometimes it is not enough, so you should additionally build up one and a half to two meters.

Specifications

- Type - straight, shock, powered by 12 V.

- The torque is 350 Nm.

- Turnovers - 3.3 thousand rpm.

- Chuck: 1/2 ”type.

- The presence of a reverse - is.

- Weight - 1.4 kg.

Minuses

- the quality of the lubrication of the elements;

- short wires.

An electric impact wrench greatly facilitates the process of working with threaded fasteners. Powerful models designed for industrial operating conditions are completely indispensable if you need to unscrew or tighten, for example, a large diameter nut. When buying a tool you like, you should make sure that the shaft size matches the socket heads, and vice versa.

Wrench ZUBR ZGUE-350

Impact wrench DeWALT DCF899N

Wrench P.I.T. PIW1050-C

Cordless impact wrench Makita Dtd152z

Gasoline impact wrench Airtec MASTER 35 (England)

Wrench Bort BSR-900

Electric impact wrench 300Nm Bison ZGUE-350

Wrench Makita TW0350

Wrench Makita DTW251Z

Wrench Makita TD110DWAE

Wrench Makita DTW285Z

Wrench Bort BSR-550

Wrench Bort BSR-12X

Impact wrench Makita Tw0200 impact

Wrench Bort BSR-12LI

Screwdriver Makita TD0101

DeWALT DW292-QS Electric Impact Wrench (710.

Screwdriver Bort BSM-300I

Impact wrench RedVerg RD-IW18V

Wrench Makita TW060DZ

Screwdriver DeWALT DCF887N

Hammer Wrench GWT450 PREMIUM

Wrench Bort BSR-12

Wrench Metabo SSW 18 LTX 200 0

Wrench Makita TD110DZ

Cordless impact wrench BOSCH PDR 18 LI (without A.

Screwdriver Makita TD0101F

Wrench Makita DTW1001Z

Impact wrench DeWALT DCF887N (impact)

Impact wrench Makita 6906

Cordless impact wrench MAKITA DTW 181 Z with imp.

A person who is engaged in repair work sooner or later thinks about purchasing a wrench.

Such a tool is useful for work on the disassembly and assembly of threaded connections, as well as in cases where it is impossible to use a simple wrench - difficult to reach thread location, corrosion, poor metal quality or special non-standard nuts.

Industrial and household nut tightening devices increase the efficiency of repair work, as well as speed up the process of assembling and disassembling various items.

In order for such a useful device to become a faithful assistant during installation, one should responsibly approach its choice, take into account the features of its device and operating conditions.

In this article we will tell you how to choose a wrench, what points to pay attention to when buying, as well as the main advantages and disadvantages of popular models

Best angle wrench

In cramped working conditions, you cannot do without an angle electric wrench. One of the best models of this type of device is the Makita 6940 DW, which is able to function effectively in places with limited access.

In cramped working conditions, you cannot do without an angle electric wrench. One of the best models of this type of device is the Makita 6940 DW, which is able to function effectively in places with limited access.

The height of the device is 6 cm, the length is 37 cm, which allows it to be used for various purposes in everyday life and in professional workshops. The device is equipped with a torque limitation at a certain level, upon reaching which the engine stops working and eliminates the breakdown of threaded connections, and also significantly saves battery power.

This electric nutrunner is applicable for the maintenance of cars, as well as for use by specialists in the installation and repair work. Specifications:

- Maximum torque - 30 Nm;

- rotation frequency - 2000 rpm;

- diameter of screws M4-8, bolts M4-10;

- battery with a voltage of 9.6 V;

- the maximum number of beats per minute - 2700;

- spindle 1/4 inch;

- weight 1500 g.

Pros:

- Small dimensions;

- the shock principle of operation ensures fast and reliable fastening;

- can be transformed into a straight-type screwdriver or ratchet wrench with certain attachments;

- applicable to work with old screws deeply located in the processed plane;

- a responsive trigger that drives the engine;

- low noise level during operation;

- work can be done with one hand due to the acceptable diameter of the device and the location of the control system;

- ergonomic design,

- the presence of a case.

Minuses:

- Low battery capacity;

- low indicator of the level of maximum torque and speed.

A cordless wrench is a useful purchase for a person who installs and dismantles various structures, repairs buildings and various automotive and agricultural equipment.

The device for twisting and unscrewing threaded connections is useful both for a beginner in the repair business for domestic needs, and for an experienced specialist in professional activities. A high-quality device will reduce the share of manual labor in daily activities and significantly increase its efficiency.

Drive types

The wrench is a device for twisting and unscrewing threaded connections, the shape of which outwardly resembles a pistol with a handle and an elongated body with the main working units located inside.

The wrench is a device for twisting and unscrewing threaded connections, the shape of which outwardly resembles a pistol with a handle and an elongated body with the main working units located inside.

The device is indispensable for tightening - unscrewing a large number of nuts or servicing hard-to-reach connections.

The variety of types of these tools is great. They are classified according to various parameters, which determine the usefulness of the device and the ease of use in a particular case.

By the type of drive, the following types of tools are distinguished: electric, pneumatic wrenches and manual.

Electric - the principle of models of such a device is based on the rotation of twisting nozzles using an electric current.

These devices are distinguished by high power, speed of operation and absence of vibrations, while the power source can be a 220V network - this subspecies is called wired, or a built-in battery in a cordless nutrunner.

The battery is compact and portable, its use is possible in various conditions of high-rise or summer cottage, without access to electrical networks, however, as the battery discharges, the power of the device will weaken, which will need to be charged to continue functioning.

An electric wrench with adjustable tightening torque will allow you to quickly and efficiently service structures with complex and strong connections, unscrew or tighten numerous nuts and bolts.

Pneumatic impact wrenches require a compressor or a wall inlet to operate, since the nozzles rotate under the pressure of compressed air.

This type of device is quite powerful, has a large torque, and at the same time it is lightweight, compact and safe to operate.

Since wall inlets in our country are just beginning to appear, and a compressor for household needs is rarely bought, pneumatic impact wrenches are more often used by professional car mechanics or builders to perform work tasks than by amateur craftsmen in everyday life and minor repairs.

The principle of operation of manual impact wrenches is based on a rotational movement carried out by a person to operate the impact wrench.

When using a hand tool, the small forces applied are converted into increased rotation by means of a multiplier that converts torque.

This type of equipment is reliable, easy to operate, autonomous and mobile, lightweight and small in size.

This type of equipment is reliable, easy to operate, autonomous and mobile, lightweight and small in size.

Where to buy a good pneumatic impact wrench in Ukraine?

The Automechanika company will be able to make you a very good offer: it is in pneumatic wrenches that we have models of the highest quality, but at very competitive prices - the best in their class on the market:

- Air impact wrench ½ "of the highest quality from the famous manufacturer Hazet Germany: model 9012-1SPC with a force of 1000 Nm at an excellent price of 184 euros. We have been selling this wrench for more than 8 years: Convenient, simple and very reliable, officially recommended by VAG

- A very interesting new model of the V4800 impact wrench with a force of 1200 Nm at an excellent price of 125 euros. Manufacturer - Vigor Germany Hazet group.

- Powerful short air impact wrench ½ ”9012M from Hazet Germany with a force of 1100 Nm and a record light weight of 1.3 kg. This model is officially homologated by VW-Audi.

Be careful: choose wisely and profitably.

Contact us, we will always be glad to see you.

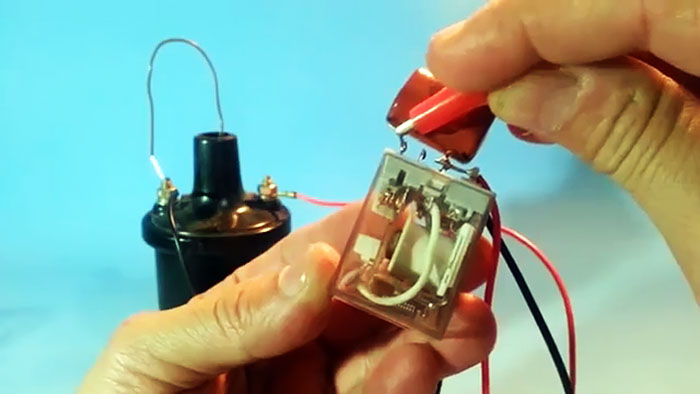

Types of mechanisms

According to the mechanism of action, instruments are divided into percussion and non-percussion.

According to the mechanism of action, instruments are divided into percussion and non-percussion.

Impact (impulse)

Impact devices are designed in such a way that, in addition to rotation, the device is capable of performing impact movements with a special striker. Impulse devices allow you to adjust the work of the torque, count the number of blows carried out.

At the beginning of thread tightening, the impact device produces long impacts, which turn into short impacts before the final tightening. The final blow is the strongest, its power is provided by a reliable bolted connection.

Unstressed

This type of equipment functions statically and has a high torque, which allows you to tighten and unscrew nuts in structures of varying complexity.

What's better

When choosing between an impact and a non-impact device, it should be remembered that the former are cheaper and will cope with small amounts of work with threaded connections in everyday life, the latter are much more expensive and are used to perform industrial tasks and professional repair work.

The additional function of the impulse device allows you to use the addition of the force of individual blows, control the force and torque, which significantly increases the efficiency and speed of work.

Strong impacts accelerate the rotation of the chuck, which is able to penetrate solid material and withstand its density.

Advantages and disadvantages of mechanisms

The manufacturer rarely describes a type of percussion mechanism (only in expensive models)

But this is the indicator that you should always pay attention to. Therefore, be sure to ask the seller for information about the "stuffing" of the tool

An experienced consultant will always inform you. Also, this information can be found on the manufacturer's website by reading reviews about the device.

All types of percussion mechanisms will be considered below.

The Pin Clutch and Rocking Dog feature a long nose cone-like system. None of these systems can be used for complex tasks.

general information

Outwardly, this tool is in many ways reminiscent of the familiar electric drill. And the device is almost identical - the same body and motor with a gearbox. The only difference is that if the drill chuck is clamped drill or small drill, then the wrench is equipped with a special working tip. And in terms of their functionality, they are somewhat different.

Unlike pneumatic, mechanical or hydraulic counterparts, such devices are considered universal, since they are equally well suited for tightening and loosening nuts. It is the models of electric wrenches that are recommended for use in everyday life. For example, for working with roofing material (the same professional metal).

It is worth paying special attention to motorists!

So the widely advertised pneumatics in terms of maintenance of the "iron horse" is of limited use. It is not suitable for changing wheels

The reason is that this type of impact wrench is only good for loosening the fasteners. But the reverse process, tightening the nuts, it is better to "entrust" another tool. Working with a pneumatic impact wrench, even an experienced craftsman, through inattention, will easily rip off the thread. And if not, then with its constriction, this will inevitably happen. It is only a matter of time and intensity of vehicle operation.

How to choose an electric impact wrench

The tooling market offers a wide range of electric impact wrenches, both household and professional grade, each with unique specifications and features. Based on them, you should select the device for specific tasks.

Nutrition

Each electric impact wrench belongs to one of the following categories by type of power supply:

- Networked - powered from a household network.

- Rechargeable - powered by a built-in or removable rechargeable battery.

- 12-volt - powered by a 12-volt DC source, such as a car cigarette lighter or battery.

The tool of the first group surpasses the other two in power, but among the battery options there are also productive models, and their main advantage is independence from the network. 12-volt wrenches are also called automobile wrenches, since their main purpose is the installation and dismantling of fasteners for the wheels of cars.

Appointment

By purpose, the tool is divided into:

- Household - small lightweight wrenches, not designed for continuous long-term operation.

- Professional - designed specifically for continuous work in harsh conditions. As a rule, it is a powerful and productive tool.

- Specialized - designed for specific tasks. An example is rolling models for tire fitting of trucks and special equipment.

Power

The more powerful the motor of the electric nutrunner, the more complex fasteners it is able to cope with.For example, to remove the wheel of a car, you need a device with a power of about 350 watts. At the same time, for truck tire fitting or when assembling metal structures, a wrench will be required, the engine of which is capable of delivering more than 1 kW.

Torque

Perhaps this is one of the main indicators that should be guided by when choosing an electric nutrunner. Too high a torque can damage the fasteners, while too low will simply not tighten the nut or bolt to the rated torque. For household models, the parameter ranges from 100 to 300 Nm, while the production tool transmits more than 500 Nm of torque to the spindle.

Spindle speed

The parameter completely determines the performance of the nutrunner. The faster the spindle rotates, the faster the job is done. The tool for auto repair shops and manufacturing enterprises has a spindle rotation speed of 1.5-3.2 thousand revolutions per minute.

Impact mechanism

Its presence greatly simplifies the unscrewing of an overtightened or stuck fastener. In addition, the percussion mechanism allows for a better tightening of this very fastener. Between impact and non-impact models of impact wrenches, you should choose the first.

Additional functions

Each of the additions increases the cost of the tool, which means that when choosing, you should decide in advance whether each specific item is needed in the work. At the same time, additional options make work easier. Among the add-ons, the most popular are:

- electronic speed control system;

- electronic brake;

- illumination of the work area;

- torque control.

Also, wrenches are selected taking into account their design. In addition to the classic straight lines, there are corner models designed to work with fasteners in confined spaces.

Classification

By the principle of work

- Drums. The most effective tool modifications, since they can be used to dismantle heavily rusted structures.

- Pulse. They are also called static, rotational. The most used models with a large torque control limit.

By design features

- Corner. Impact wrenches of this type cannot be percussion; only static. The disadvantage is a small tightening torque (up to 150 Nm).

- Straight. Such models are equipped with percussion mechanisms. Their plus is in the increased tightening force (up to 4500 Nm). But the disadvantage is that such a tool will not work everywhere due to limited access.

By appointment

Categorization, as for any other power tool - professional, household and intermediate version (semi-) models. Operational practice shows that for household chores, household modification (but only with a network connection) is more than enough.

Nutrition

Cordless wrenches. The advantage of such models of electronic tools is only one - mobility. With its help, you can solve relatively simple everyday problems. That is, the scope is limited.

There are enough cons. First of all, for the reason that it is of little use for "serious" work. And it's not just the lack of capacity according to the passport. As the battery is discharged, it gradually decreases. Consequently, cordless impact wrenches are designed to perform individual, short-term technological operations, and, moreover, relatively uncomplicated. Trying to turn off a "stuck" part with such a model is a senseless exercise.

The price is relatively low - from 5 560 rubles. For example, a Ryobi nutrunner (series R18iD3-0).

Connected to the vehicle electrical system. Such models are mainly of interest to motorists who prefer to independently service their "iron horse", including changing tires.

The price is within 5 190 - 5 980 rubles.

Network electric / nutrunners. These models are highly efficient. Their efficiency can reach 70%.For comparison - the pneumatic analogs have a limit of 15%. Another important plus is the versatility of the application. This is especially appreciated in everyday life. The network impact wrench will equally well cope with any work both in the construction (repair) sphere, and in tire fitting.

The price of the model starts from 5 380 rubles. An example is the Swedish electric wrench “DWT” (series SS09-24).