How is the carburetor adjustment of the walk-behind tractor

What to look for during a motor failure? If a carburetor malfunction occurs, the first step is to check the fullness of the fuel tank and the oil level. If there is enough fuel and oil, then proceed to inspect the spark plug

To do this, unscrew it and check the spark with the ignition. Next, the flow of gasoline to the carburetor is tested. For this purpose, remove the hose from the fitting and monitor the flow of fuel. If no fuel appears, then most likely the filter mesh will need to be cleaned. For this, the fuel cock is unscrewed and all parts are rinsed with gasoline. The same is done with the carburetor jet.

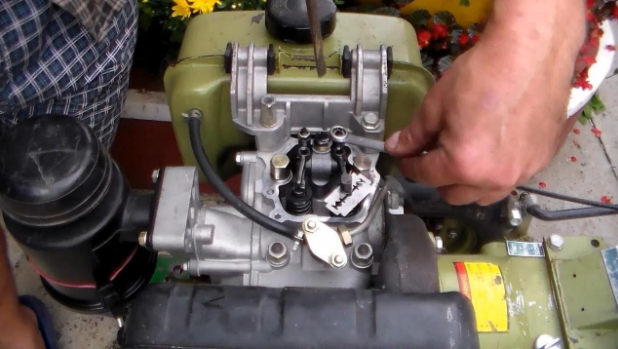

Carburetor cleaning is done as follows. To clean the device, you must first remove it. To easily remove the carburetor, you need to carefully inspect the body of the device and unscrew all the parts on which it rests.

So, remove the carburetor and pour gasoline out of it. We carefully separate all parts of the device (jet, float) for further purging and cleaning. This manipulation is performed with a special cleaner.

After cleaning, we thoroughly dry all the parts and feel free to start assembling. After assembly, adjust the carburetor for the walk-behind tractor.

We install the cleaned device using a standard gasket and fasten it with nuts. Don't forget about the air filter, the speed regulator and the gas supply hose.

Setting up the carburetor of the walk-behind tractor is to adjust it. In order to independently adjust the carburetor, you need to do the following steps:

- The screws for idle and full throttle must be tightened as far as they will go.

- Unscrew the low and full throttle screws one and a half turns (set the throttle valve in such a position that a gap of the appropriate size is formed between the base and the air duct).

- Start the engine and wait until it warms up.

- With the engine running, set the control lever to minimum speed.

- Achieve smooth engine operation. To do this, you need to make the minimum idle speed using the throttle screw.

- Set idle speed to maximum with idle screw.

- Set idle speed to minimum with throttle screw.

- Repeat steps 6 and 7 until the engine starts to run continuously.

- Set the engine control lever to gas.

- If an interruption occurs, unscrew the screw that regulates the quality of the mixture, no more than 2.5 turns.

I would like to note that the adjustment of the carburetor on the Neva walk-behind tractor is done clearly according to the above instructions. The K-45 device installed on the Neva walk-behind tractor is single-chamber and horizontal. The float chamber is located in the central part. The throttle valve is flat.

The Neva walk-behind tractor uses the DM-1K engine, which is produced at the Krasny Oktyabr Neva plant. The manufacturer categorically does not use Chinese-made engines. This also applies to the production of a motor-cultivator.

Adjusting the fuel system of the walk-behind tractor

If the fuel is not supplied to the cylinder, then, first of all, it is necessary to check if there is enough fuel in the tank. You also need to check whether it goes to the carburetor. For this, a hose is removed from the inlet connection of the device. If we are talking about a K45 carburetor, press on its quench so that the fuel starts to pour out through the drain hole.

If fuel does not enter the carburetor, then you need to turn off the fuel supply valve, completely disassemble it and remove accumulations of dirt from the mechanical filter.To achieve maximum cleanliness, all components must be treated with gasoline. The fuel cock is assembled and returned to its original location.

If fuel enters the carburetor, but is not supplied to the cylinders, it is necessary to check the correct operation of the fuel valve, as well as the presence of dirt on the jets.

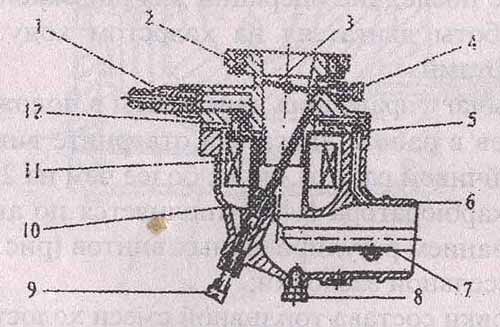

To deal with the carburetor of a gasoline walk-behind tractor of the KMB-5 type, you need to remove it from the engine and pour out the fuel from the float chamber. Through the fitting (see figure), with the help of which the gasoline is supplied, it is necessary to supply the air mixture, having previously installed the carburetor in the operating position. The passage of air should go unhindered, and when the carburetor is turned over, it should completely stop. These features indicate the full performance of the part.

Rice. 2. Carburetor KMB-5

Details in the figure: 1 - fuel supply connection; 2 - upper body; 3 - throttle valve; 4 - idle needle; 5 - jet; 6 - lower body; 7 - air damper; 8 - screw fixing the tie; 9 - maximum gas needle; 10 - spraying element; 11 - float; 12 - fuel supply valve.

The fuel level inside the float chamber can be adjusted using the float tab. Ideally, it should range from 3 to 3.5 centimeters.

To purge the nozzles, it is necessary to unscrew the full and low gas screws. Cleaning the carburetor parts begins by loosening the screws holding the upper housing. The lower body is removed, the fuel supply valve is flushed with gasoline, and the dirt from the nozzles is blown out by a pump. It is necessary to check if the float is intact. It is absolutely impossible to use rags in the cleaning process.

After completing the cleaning, the housings are connected. It is necessary to check that the spray tube is clearly inserted into the hole located on the upper body. Open the throttle valve and check how well the assembly is done. The screws that secure the upper case are tightly tightened. After the assembly process is completely completed, the carburetor should be adjusted. This will significantly improve the performance of the walk-behind tractor with attachments, since for correct operation, ideal adjustment of all its parts is required.

Views

The operation of the walk-behind tractor is provided by the engine, inside of which no ignition can occur without the required amount of oxygen, which is why it is required to correctly adjust the operation of the carburetor.

In the design of such equipment, units of two types are used:

- rotary;

- plunger.

Each of them has its own advantages and disadvantages, the use of one or another carburetor is due to the type of work performed and other characteristics of the equipment.

For the first time, carburetors of this type were used in aircraft construction and the automotive industry. Over time, the design has undergone some changes and has become more perfect.

In the center of such a carburetor, there is a cylinder in which there is a transverse hole. As it rotates, this hole opens and closes, so that air flows through the unit.

The cylinder not only makes a rotational action, but also gradually approaches one side, it is similar to unscrewing a screw. When operating at low speed, this carburetor is less sensitive, the hole opens only slightly, turbulence is created, as a result of which the fuel does not flow in the required amount.

In walk-behind tractors, this is used as an advantage, since instant acceleration is not required when the engine is running. Plunger carburetors have many of the same elements that are installed on the rotary model. The only difference is that they cost differently here, hence the ability to increase engine power faster.

There is no hole in the central section, so the cylinder is almost solid.In order to allow air to pass through, the cylinder moves, and at low speed, it retreats into the carburetor, thus blocking most of the air flow, thereby reducing the number of revolutions.

Breakdowns and repairs

The Agro unit differs from other models of the heavy class in its long service life and reliable operation.

The operation of the walk-behind tractor is affected by the operating conditions, competent running-in after purchasing the factory unit, timely maintenance and care.

If the unit is within the warranty period, then all repair work must be carried out by the manufacturer of the unit. The owner has no right to open the seals and repair it. If the malfunctions of the walk-behind tractor are minor, then you can independently adjust its operation.

Possible breakdowns and damage are presented in the Agros walk-behind tractor repair manual and have a general view. Among them are the following:

- problems with starting and malfunctioning of the motor;

- the undercarriage does not work;

- malfunctions in the gearbox (gearbox);

- clutch failures;

- the lubrication and cooling system is broken.

If the engine does not start, the reasons and remedies are as follows:

- There is no fuel in the fuel tank. Fill the tank with fuel.

- The hole in the fuel tank cap is clogged. Open the tank cap, clean the hole and reinstall.

- Fuel is leaking from the carburetor. It is necessary to adjust the carburetor of the walk-behind tractor.

- Clogged fuel system. Drain fuel from the fuel tank, flush with gasoline and blow out the carburetor jets, inspect the spark plug.

- Clogged filter. Replace or clean the filter.

If the engine works with noise, knocking or jerking, it is necessary to adjust the valves on the Agro walk-behind tractor using special probes.

If the idle speed is unstable, the gear cover clearance may be too large, so it is necessary to adjust the clearance to 0.2-0.5 mm.

A drop in the power of the walk-behind tractor is possible in such cases:

- clogging of the carburetor, gas hose, air filter;

- breakage of the crankcase cuff;

- carbon deposits in the combustion chamber.

Elimination methods include inspection, cleaning all parts, blowing the hose.

If the starter of the Agro walk-behind tractor fails or the fuse blows out, the best way out is to replace unusable parts.

Faults in the gear chain are manifested as a result of its jamming. The clutch can be damaged if the chain breaks, so change it.

The following malfunctions and breakdowns are possible in the gearbox:

- broken kinematics inside the gearbox;

- spontaneous gear shifting or their complete absence;

- oil leaks on the shift shaft.

It is better to repair the box in special workshops. The checkpoint is a complex unit, you cannot do without knowledge of mechanics.

Ignition system

In the problem of "why there is no spark", the reasons for the breakdown lie in the details, such as:

- candle;

- magneto;

- cap;

- high voltage wire.

If there is no spark or sparks weakly, it is necessary to adjust the intermediate gap and check the condition of the electrodes. The clearance rate is 0.8 mm.

If there are changes in the clearance between the intake and exhaust valves on the engine, they are clamped or relaxed to an acceptable value.

A low compression ratio was detected in the cylinder. All worn parts are removed and replaced.

Cleaning the muffler will also help get rid of the spark problem.

Replacing the engine

If the engine for the Agro walk-behind tractor breaks down and needs to be replaced, use an adapter kit. Instead of a native motor, imported ones with a cylindrical shaft with a diameter of 25 mm are well suited:

- Weima - with a capacity of 13 liters. with.;

- Subaru EX 27 - 9 HP with.;

- Honda 9 - 13 HP with.;

- Lifan 9 - 13 HP with.

Replacing the engine is as follows:

- remove the motor from the cultivator and dismantle the clutch mechanism;

- remove the driving cup under the conical shaft, change it to a machined one under the cylindrical one;

- a clutch of a walk-behind tractor is placed on an imported engine and connected to the transmission.

Spare parts

Spare parts can wear out with continuous use of the machine. Most often, replacement of parts of the clutch mechanism and bearings is required.There are no problems with the choice of parts for Agro. They can be purchased both from the official dealers of the company, and in free sale.

Types and methods of carburetor adjustment

As you know, the walk-behind tractor, like many other units of this type, works with the help of an engine. Due to the fact that the engine cannot ignite without supplying oxygen, it becomes necessary to use a carburetor. Two types of carburetors are used for the walk-behind tractor. One of them is rotary, the other is plunger. Naturally, each of these types has its own advantages and disadvantages, the choice depends on the walk-behind tractor, its performance and the type of work performed.

There are times when there are abnormalities in the operation of the carburetor (the process is unstable). In such a situation, the carburetor needs adjustment. How to adjust the carburetor on the walk-behind tractor? It is quite possible to do it yourself, following a certain sequence of actions.

- First, you need to turn the screws (full and low throttle) until they stop. Then turn them one and a half turns.

- Start the engine, give it time to start and warm up.

- Do not shut off the engine and place the engine control lever in the lowest speed mode.

- Next, set the minimum number of revolutions when the device is running stably.

- Then run idle to maximum.

- Shift idle to minimum. Repeat this step, alternating with the previous one, until the engine runs smoothly.

- Move the control lever to the throttle position.

Following such instructions, you can independently adjust the carburetor of the walk-behind tractor.

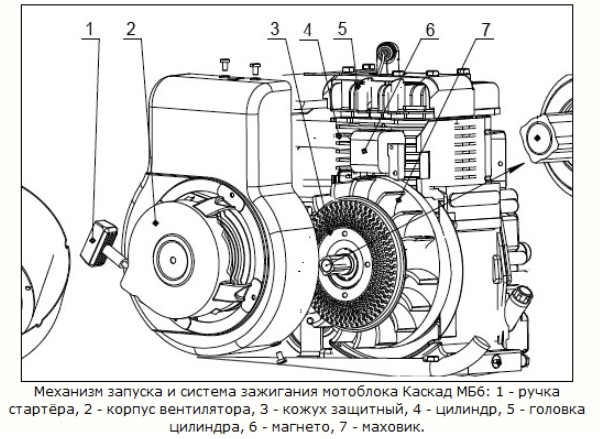

Walk-behind tractor ignition system

Ignition adjustment

The ignition coil for the Neva walk-behind tractor is regulated as follows:

- Take a piece of paper and fold it 4 times;

- Unscrew the bolts that hold the module;

- Place a piece of paper under them and tighten the bolts in place;

- Turn the handwheel in manual mode;

- Check for spark.

Video review of adjusting the ignition of the engine of the walk-behind tractor

One of the main factors in the proper operation of the ignition system is the gap between the starter and the flywheel. It should be between 0.1 and 0.15 mm.

To adjust it on the Neva walk-behind tractor, it is necessary to remove the housing and unscrew the stator bolts. Then put the dipstick and set the required clearance, screw the bolts back and check the clearance over the entire surface of the flywheel.

Generator, malfunctions, elimination

The generator is an important component of the entire mechanism. It is designed to charge the battery and work the headlights

When choosing a generator, you need to pay attention to its power. It must exceed the capacity of all connected devices to ensure smooth operation.

For the Neva walk-behind tractor, it is possible to use an old car generator.

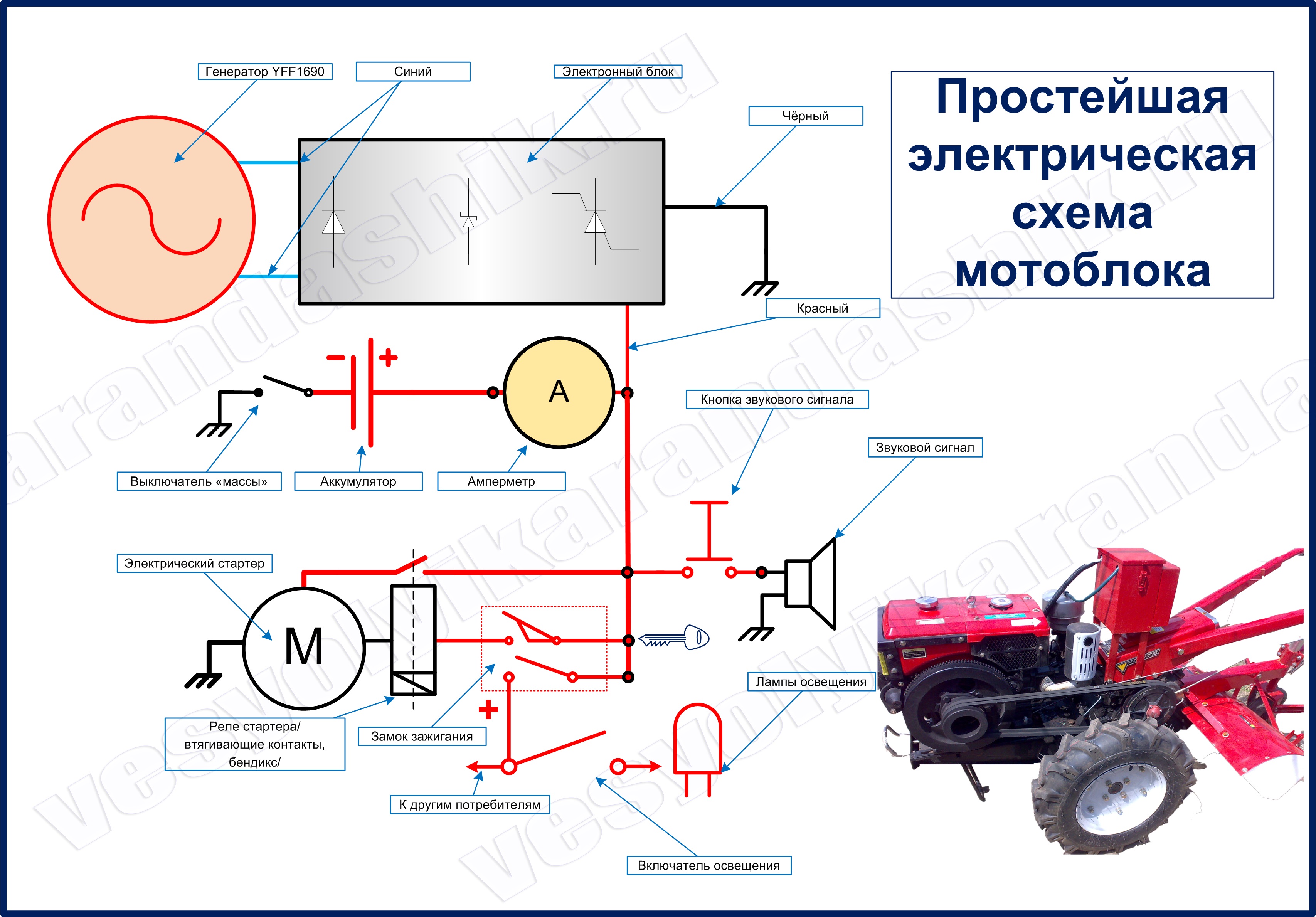

Important! During its installation, you must follow the diagram below. Otherwise, the generator could be ignited.

Electric diagram of the walk-behind tractor

There are 4 wires in the generator. Two of which are blue. It is thanks to them that the converter is connected. Red, connects to the headlights, and gives voltage to them.

Electric starter

Many people strive to improve the performance of their walk-behind tractor. During the winter seasons, it does not start well due to the fact that the recoil starter does not crank. In solving this problem, a special electric starter was invented for the Neva walk-behind tractor. This is an autonomous device that, when the ignition is turned on, starts to rotate and gives a spark.

An electric starter is a complex design, and it is not realistic to make it at home. Any other car electric starter that may have been left over from the old car can be used.

Candles

We have already figured out what candles are for and how to change them. Let's take a look at the brands that are required for each specific type of Neva engine:

| Engine model | Spark plug on the engine | Possible candle replacement |

| DM-1K (ZAO Krasny Oktyabr-Neva) | BRISK NR17C | BOSCH WR8AC |

| I / C 6.0 (Briggs & Stratton) | CHAMPION RC12YC | NGK BKR5E |

| Vanguard 6.0 (Briggs & Stratton) mod 117 | CHAMPION RC12YC | NGK BCPR5ES BRISK DR17YC |

| HONDA GX200 | 98079-55876 (NGK BPR6ES) |

DENSO W20EPR-U BRISK LR15YC CHAMPION RN9YCC BOSCH WR7DC ENGELS A17DVRM |

| EX17 (Robin SUBARU) | 065-01401-50 (NGK BR6HS) |

BRISC NR15C BOSCH WR7AC CHAMPION RL82CC |

| HONDA GC160 | 98079-56846 (NGK BPR6ES) |

DENSO W20EPR-U BRISK LR15YC CHAMPION RN9YCC BOSCH WR7DC ENGELS A17DVRM |

| I / C 8.0 (Briggs & Stratton) | CHAMPION RC12YC | |

| EY15 (Robin SUBARU) | 065-01401-50 (NHSP LDE6C) |

NGK B6HS NGK BR6HS CHAMPION L86C CHAMPION RL86C |

| Honda GX120 | 98079-55876 (NGK BPR6ES) |

DENSO W20EPR-U BRISK LR15YC CHAMPION RN9YCC BOSCH WR7DC ENGELS A17DVRM |

Headlights

Headlight with an electric starter on the Neva MB-2 walk-behind tractor

As standard, Neva walk-behind tractors are not equipped with a headlight. However, this option is presented as optional. Since it is almost impossible to carry out work in the evening without a headlight.

If desired, you can install the headlights yourself from a car, scooter, tractor, etc. To do this, by welding, make a special box for the headlight and put it there. And connect the wires from it to the generator. But not directly, but through a switch, which should be in the middle and be responsible for turning the headlights on and off.

Features of the device

The walk-behind tractor is a rather powerful unit with great strength, but at the same time of medium size, equipped with multifunctional equipment. Most of the equipment is produced with a gasoline, diesel or electric engine. The latter, by the way, are extremely rare. For the added fuel to ignite, the carburetor is required. The manufacturer represents the following types:

- rotary - the simplest in structure, they are mainly equipped with small-sized engines of 12-15 cubic inches;

- plunger - in this case, the design is complicated, therefore it is used to assemble powerful motoblocks.

Carburetion is carried out using the main parts:

- main piston;

- connecting part - fitting;

- fuel tank;

- high / low turn needle;

- Venuri tube.

So, the process begins with a piston moving upward, as a result of which a vacuum is created. The carburetor absorbs air, and it subsequently moves through the Venuri tube. The movement of fuel (from the tank) is directed towards the engine, this is done using a connecting fitting, acting due to the created vacuum. The liquid bends around the main needle, flows through the inlet socket, entering the Venuri tube. By pressing the throttle lever, the fuel is released by the low speed needle. Further, the first needle is responsible for the flow of gasoline.

Among domestic craftsmen and agricultural workers, equipment of Russian brands "Neva", "Oka", "Agro", "Utra" is especially popular. It is distinguished by its optimal configuration, high-quality, powerful carburetor. Especially Russian buyers appreciate the Neva K-45 motoblocks for their reliability and durability. The KMB-5 model is an older unit, so before buying, consult with a specialist who will provide a product that meets your needs.