Specifications

Gasoline engine models - Lifan 168F, 168F-2, 177F and 2V77F are excellent for motoblocks.

Model 168F belongs to the group of engines with a maximum power of 6 hp. with. and is a 1-cylinder, 4-stroke unit with forced cooling and a 25 ° crankshaft.

The technical characteristics of the engine for the walk-behind tractor are as follows:

- The volume of the cylinder is 163 cm³.

- The volume of the fuel tank is 3.6 liters.

- The cylinder diameter is 68 mm.

- The piston stroke is 45 mm.

- Shaft diameter - 19 mm.

- Power - 5.4 liters. s. (3.4 kW).

- Rotation frequency - 3600 rpm.

- Launch - manual.

- Overall dimensions - 312х365х334 mm.

- Weight - 15 kg.

The 168F-2 model is of particular interest to the users of walk-behind tractors, since it is a modification of the 168F motor, but has an increased resource and higher parameters, such as:

- power - 6.5 liters. with.;

- the volume of the cylinder is 196 cm³.

Bore and stroke are 68 and 54 mm, respectively.

From engine models with a capacity of 9 liters. with. the Lifan 177F is distinguished, which is a 1-cylinder 4-stroke gasoline engine with forced air cooling and a horizontal output shaft.

The main technical parameters of Lifan 177F are as follows:

- Power - 9 HP with. (5.7 kW).

- The volume of the cylinder is 270 cm³.

- The volume of the fuel tank is 6 liters.

- Diameter per piston stroke - 77x58 mm.

- Rotation frequency - 3600 rpm.

- Overall dimensions - 378x428x408 mm.

- Weight - 25 kg.

The Lifan 2V77F engine is a 2-piston V-shaped 4-stroke overhead valve gasoline engine with forced air cooling, a contactless transistor magneto ignition system and a mechanical speed governor. In terms of technical parameters, it is considered the best of all models of the heavy class. Its characteristics are as follows:

- Power - 17 hp. with. (12.5 kW).

- The volume of the cylinder is 614 cm³.

- The volume of the fuel tank is 27.5 liters.

- The cylinder diameter is 77 mm.

- The piston stroke is 66 mm.

- Rotation frequency - 3600 rpm.

- Starting system - electro, 12 V.

- Overall dimensions - 455x396x447 mm.

- Weight - 42 kg.

The service life of a professional engine is 3500 hours.

Fuel consumption

For the 168F and 168F-2 engines, the fuel consumption is 394 g / kWh.

Lifan 177F and 2V77F models can consume 374 g / kWh.

As a result, the estimated duration of work is 6-7 hours.

The manufacturer recommends using AI-92 gasoline as fuel (95).

Traction class

Light motoblocks of traction class 0.1 are units up to 5 liters. with. They are purchased for plots of up to 20 acres.

Medium motoblocks with a capacity of up to 9 liters. with. cultivate areas up to 1 hectare, and with heavy motoblocks 9-17 liters. with. traction class 0.2 treats fields up to 4 hectares.

Lifan 168F and 168F-2 engines are suitable for Celina, Neva, Salyut, Favorit, Agat, Kaskad, Oka vehicles.

The Lifan 177F engine can also be used for installation on medium vehicles.

The most powerful gasoline unit Lifan 2V78F-2 is designed to work in difficult conditions on mini tractors and heavy walk-behind tractors, such as Foreman, Sadko, Don, Profi, Plowman.

Specifications

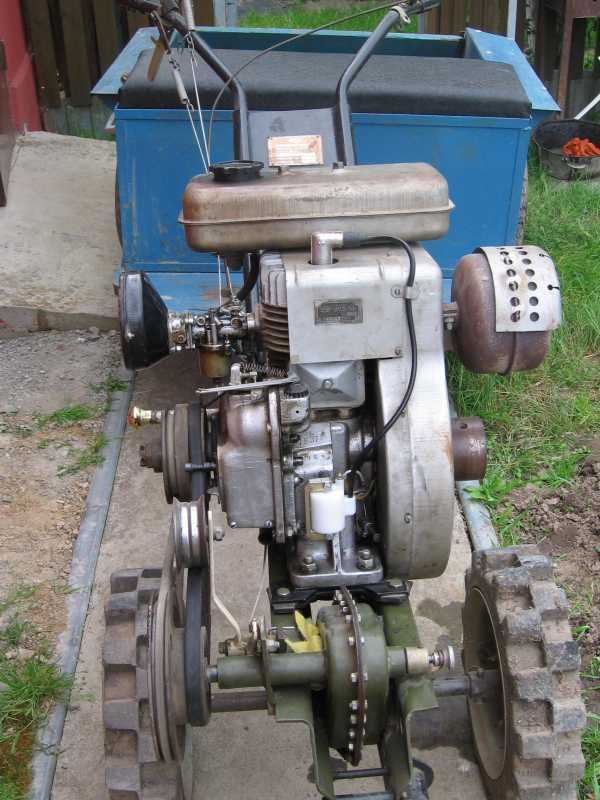

According to the instruction manual for the Ural walk-behind tractor, the product consists of a frame made of a steel profile. A power unit, a clutch mechanism and an additional 2-speed gearbox are installed on the frame. The power unit is mounted through rubber shock absorbers to reduce vibration on the controls.

2 wheels are used for movement. The walk-behind tractor uses solid rubber tires with a diameter of 430 mm and a width of 110 mm. Fixed track width - 540 mm. The walk-behind tractor is controlled by handles fixed to the frame. The handles are used to rotate, change engine speed and shift speeds. The steering can be adjusted to suit the height of the operator. A bar with holes is used for adjustment.

Walk-behind tractor dimensions:

- length - 1880 mm;

- width - 690 mm;

- height - 1280 mm.

A pin is installed on the front of the frame, which is used to install attachments. The pin is housed in a steel body bolted to the cross member. In the body of the pin there are 2 holes through which the attachments are fixed. On the rear cross member there is a bracket for attaching trailed implements.

The engine installed on the walk-behind tractor needs regular maintenance with partial or complete disassembly. After 250 hours of operation, lapping and valve adjustments are required. There are marks on the gears for setting the valve timing. The clearance between the tappets and valves is adjusted using a special screw located at the end of the tappet.

The manufacturer allows a variation in the length and height of products within 50 mm, in width - within 20 mm. The weight of the equipped device is 120 kg, the mass of the towed trailer is 350 kg. The maximum travel speed is 11.5 km / h. For the fastest possible movement, a combination of the highest gear in the engine and higher speed in the additional gearbox is used.

Installing the Lifan engine on the Ural walk-behind tractor

The factory equipment of Ural motoblocks assumes the presence of a domestic engine. In some cases, the power and performance of such a motor is not enough, so it becomes necessary to redo the equipment. It is quite simple to equip the Ural walk-behind tractor with a Lifan engine with your own hands, however, before starting work, you need to decide for what purpose the equipment is being created, choose a suitable engine.

Certain engines are suitable for motoblocks of different types and weights, therefore it is important that the parameters are combined. The heavier the walk-behind tractor itself, the more powerful the engine must be

For the Urals, models such as Lifan 170F (7 hp), 168F-2 (6.5 hp) are suitable. Their installation requires minimal rework.

The main feature that distinguishes Chinese engines from domestic ones is the direction of rotation of the shaft, for Lifan - to the left, on factory engines of the Urals - to the right. For this reason, the walk-behind tractor is configured to rotate the shaft to the right; to install a new engine, it is necessary to change the position of the chain reducer so that the pulley is on the opposite side, which allows it to rotate in the other direction.

After the gearbox is on the other side, the engine is installed in the standard way - the engine itself is bolted, the belts are thrown over the pulleys, and their position is adjusted.

Ural with ZiD engine

Small batches of engine blocks were equipped with a ZiD-4.5 power unit. The design of the motor is not much different from the UMP-5V. The crankshaft has a pulley and sprocket to drive the chain. The pulley is located on the flywheel side, the chain drive is located on the gear side. The chain drive is used to control stationary installations. The engine is lubricated by spraying, oil is supplied by a plunger pump from a sump containing 1.5 liters of fluid.

A belt drive is used to transfer torque from the engine to the transmission. The belt for the walk-behind tractor has a size of 11201711 mm. The walk-behind tractor uses a 2-speed gearbox, the device and control of which are similar to cars with the UMZ-5V engine. The reducer has 2 speeds, which reduce the rotation speed by 17 and 7 times, respectively. Gear shifting is done with a handle. Before starting the engine block, it is necessary to check the level and add the gear oil in the gearbox. The rated capacity of the crankcase is 1.5 liters.

The engine ignition system includes a magnetic circuit that ensures constant ignition timing. As wear occurs, the angle changes, resulting in unstable ignition. To adjust the ignition of the engine block, it is necessary to control the moment when the switch contacts open and the maximum gap between them.The check is performed by removing the flywheel by aligning the notch on the crankshaft with the notch on the base of the magnetic armature.

The power system includes a K16N or ZiD-12 carburetor and a fuel tank containing 8 liters of gasoline. Adjusting the carburetor walk-behind tractor allows you to ensure uniform engine operation and fuel consumption declared by the plant. Adjustment is made with the engine warm by turning the idle screw and throttle stop screw. This adjusts the minimum idle speed.

Operation and maintenance manual

With proper operation and maintenance of the equipment, it can work for a long period. The operating instructions are as follows:

- Assembly and installation of equipment, connection of all elements is carried out.

- Engines are supplied dry. This moment determines that you need to purchase a suitable lubricant and pour it into the structure. Some models operate with a fuel mixture that includes oil.

- The first start must be done carefully. For this, the idle mode is selected, the engine warms up for several minutes.

- After working for the first 20 minutes, it is recommended to drain the old oil, after which a new one is poured. This is due to the fact that at the time of grinding in the main elements, metal shavings can get into the lubricant.

- It is recommended to use a cultivator at 2/3 power for the first few hours. This will eliminate the likelihood of various malfunctions.

- At first, it is recommended to monitor the temperature of the engine, because there is a possibility of overheating.

- If the motor is unstable, you need to stop the walk-behind tractor, and then find the cause of the problem.

- After using the equipment, the surface should be cleaned from various contaminating elements. In addition, the state of all basic elements is checked, since further operation with malfunctions is not allowed.

Service provides for a timely oil change. In this case, it is necessary to periodically add lubricant to the gearbox.

Engines for the Ural walk-behind tractor: UMZ-5B

The carburetor engines of the Ulyanovsk Motor Plant UMZ-5 in the UMZ-5B and UMZ-5DU-B models, which were installed on the UMB-K "Ural" agricultural unit, are 4-stroke single-cylinder. They run on gasoline with a minimum octane number and have a forced air cooling system. They have a capacity of 4.5 liters. sec., the number of revolutions of the crankshaft per minute - 2000 (at rated power).

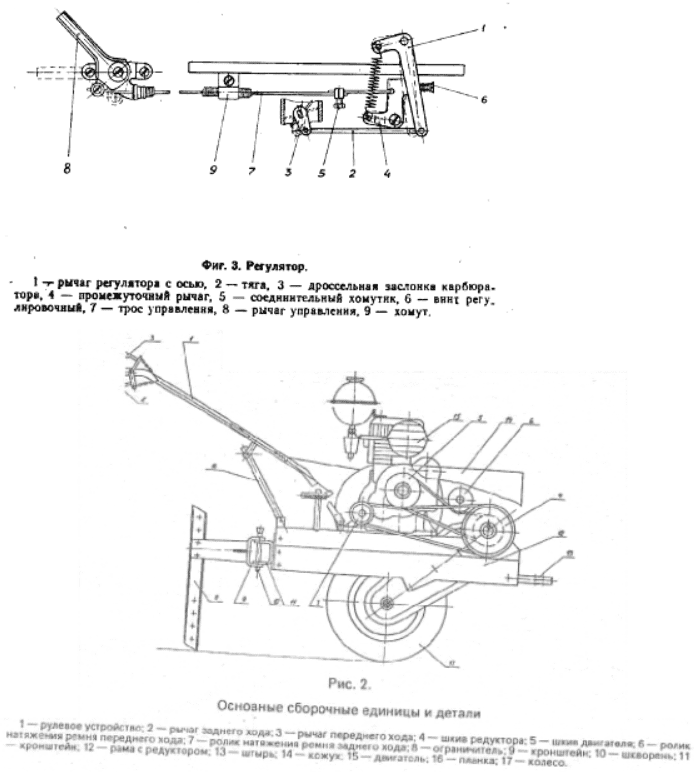

UMZ-5B has a 2-stage gear reducer, while in the UMZ-5DU-B device there is a single-stage gearbox - this is their main difference. The gearbox diagram is shown below.

Operation manual and repair manual for these Soviet-made motors include:

- recommendations for engine care (which oil to fill and how to change it, how to clean the fuel tank, how to change parts);

- the order of actions in the event of malfunctions;

- algorithm of actions for the correct setting of the internal combustion engine carburetor.

The correct operation of the entire system will depend on the correct adjustment of such an important part of the internal combustion engine as the carburetor.

- First, be sure to warm up the engine, and at minimum speed it is necessary to tighten the idle screw until it stops, and then unscrew it a little, by about 2.5 turns.

- Next, you need to close the throttle valve and, by rotating the stop screw, set a smaller opening angle at which the motor runs smoothly and without interruptions.

- It is necessary to "catch" the moment when the internal combustion engine reaches its maximum rpm by screwing in and out the idle screw.

- Now the screw that regulates the opening of the damper is again set so that the opening angle is minimal, provided that the motor runs smoothly.

- In the case of an increase in revolutions, points 3 and 4 must be continued until there is an increase in the engine speed.

How to install a Lifan engine on a walk-behind tractor

Each model and class of walk-behind tractor has its own engine. Consider these examples:

- Motoblock Ugra NMB-1N7 with Lifan engine corresponds to the 168F-2A version in terms of technical characteristics.

- Motobloku Salyut 100 - version 168F-2B.

- Ugra NMB-1N14 middle class - Lifan 177F engine with a power of 9 liters. with.

- Agat equipment with a Lifan engine can be equipped with the 168F-2 and Lifan 177F models.

- An eye with a Lifan 177F engine when aggregated with attachments will work better and more efficiently. Model 168F-2 with a capacity of 6.5 liters. with. also suitable for the Oka MB-1D1M10S walk-behind tractor with the Lifan engine

The engine can be installed on motoblocks Ural, Oka, Neva according to the following algorithm of actions:

- Remove the protective cover from the old engine, belts, pulley, while unscrewing the bolts.

- Remove the air-purifying filter to disconnect the throttle cable.

- Remove the engine from the walk-behind tractor frame.

- Install the motor. If necessary, a transition platform is installed.

- A pulley is attached to the shaft, the belt is pulled for better track performance, adjusting the position of the motor.

- Secure the transition platform and engine.

The user must take care of the mounting hardware when installing the motor.

Motoblock Cascade

When installing an imported Lifan engine on a domestic one, the following additional parts are needed:

- pulley;

- transition platform;

- adapter washer;

- throttle cable;

- crankshaft bolt;

- fasteners.

The mounting holes on the frame are not aligned. For this purpose, a transition site is being acquired.

The cascade is equipped with a domestic engine DM-68 with a capacity of 6 liters. with. When replacing the motor with Lifan, choose the 168F-2 model.

Motoblock Mole

When installing a Lifan engine on a one equipped with an old domestic engine, when replacing, it is necessary to have installation kits, which include such elements as:

- pulley;

- adapter washer;

- throttle cable;

- crankshaft bolt.

If there was an imported motor on the walk-behind tractor, then only the Lifan engine itself with an output shaft diameter of 20 mm was enough to install it.