Basic tools and parts

If the question of installing a wood splitter for household needs has already arose, and you are reluctant to buy at market prices, you need to prepare materials and tools for self-production. In order to make a homemade mechanical wood splitter, you may need:

- Metal parts, pipe cuttings, channel bars.

- Bulgarian.

- Welding machine and the ability to use it.

- Skills of calculation and drawing up of schemes.

- Creativity.

At the same time, in order to manufacture any type of device, the circuit must be developed for each separately, depending on the availability of parts and conditions of use. Also, if you wish, you can watch training videos, of which there are plenty of them on the network today.

Why are foot operated wood splitting devices attractive?

Mechanisms for splitting firewood with a foot drive are ideal for home, seasonal logging. They can easily split medium diameter chocks and free your back from overload.

If we talk about mechanical models of wood splitters, then it is almost impossible to injure them. Such a tool is intuitively easy to use and suitable even for older people, in fact, even a teenager can handle it.

Spring-loaded leg cleavers can easily handle logs with a diameter of 20 - 25 cm

Spring-loaded leg cleavers can easily handle logs with a diameter of 20 - 25 cm

The device folds easily, does not take up much space, and is suitable for use in the country or in a private house. If necessary, it can simply be removed to the shed.

Log splitting feeders

Wood splitters, in which the principle of pushing through fixed knives is implemented, mechanize the main technological process: splitting logs into separate fragments. By the type of pusher drive, it is customary to determine:

Hydraulic, in them the pushers are connected with the rods of the hydraulic cylinders. The pump creates pressure in the oil, which is transmitted to the inside of the mechanism. These are the simplest designs, since the hydraulic drive devices do not have additional energy converters.

Inertial ones use rotating masses. The energy accumulated by the flywheels is converted into the forward movement of the pusher. The devices use special clutches, which are activated by the operator after placing a fragment of a log on the bed.

Rack and pinion gears use a rotary-to-linear converter using a gear and a rack with teeth. At the right moment, the gear turns until it meshes with the teeth of the actuator. The pusher moves the block onto the fixed knives. It splits into smaller pieces.

The crank mechanism receives torque from the gearbox. It is converted into translational movement of the pusher. Engagement (disengagement) is controlled by a permanently open clutch. At the right moment, the operator engages the clutch, the crank begins to rotate, forcing the connecting rod to move forward. The cycle ends with the return of the crank and connecting rod to their original position.

Detachable nut and lead screw. The motor is switched on, the rotation of the shaft is transmitted to the lead screw. At the right moment, the split nut is connected, the rotating shaft moves it, acting on the pusher. To return, the direction of rotation of the shaft is changed (a gear transmission of reverse rotation is used).

Homemade wood splitter - what and how to do

If you have the necessary materials, then it is easy to make a wood splitter with your own hands: drawings, photos, instructions are freely available on the Internet. To do this, you need:

- various metal scraps;

- Bulgarian;

- welding inverter;

- the ability to cook;

- the ability to draw up and calculate schemes;

- creative savvy.

Welding inverter

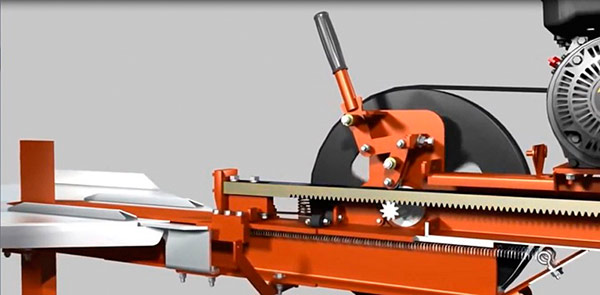

Rack wood splitter - scheme and manufacturing

The easiest way is to make a rack and pinion wood splitter with your own hands: drawings, photos, instructions for which are posted on the Internet. Its basis is a powerful steel frame, to which a wedge, a motor and a gearbox are attached. To make it, take an electric motor with a power of at least 2 kW and two pulleys with a diameter ratio of at least 1: 4. It is also possible to use gearboxes from various mechanisms with a gear ratio greater than 8: 1. If you do not have an electric motor, but have a gasoline engine from a saw or trimmer, you can plug it in. In this case, it will be necessary to further increase the gear ratio of the gearbox due to the too high speed of such a motor. Make a wood splitter knife from sheet steel at least 1 cm thick, sharpening it at an angle of 90 degrees. To work with thick logs, it is necessary to make a compound knife so that its thickness is at least 5 cm, and inside it, reinforce it with a steel blank of a suitable shape.

An approximate diagram of a rack and pinion wood splitter

The pinion gear should be 4–6 cm higher than the bed and be at a distance equal to double the length of the log from the knife. In addition, it is necessary to make a carriage that will ride on the bed. The height of the carriage must match the installation height of the rack and pinion gear. On the front (facing the knife) side of the carriage, install a cross plate that will act as a pusher. For this, use sheet steel with a thickness of at least 7 mm. Install any hinge on the carriage that will raise and lower the rack, and also make a spring mount to raise the rack above the gear. Install and secure the return spring, which will move the carriage towards the gearbox. Install a lever on the bed that will press the rack against the gear. With this lever you will control the work of the wood splitter - when the lever is pressed, the rack comes into contact with the gear and moves forward. If necessary, cut the rail with a grinder - it should be slightly shorter than the distance from the feed plate to the knife.

Wood splitter rail

Homemade installation

Hydraulic wood splitter - materials and drawings

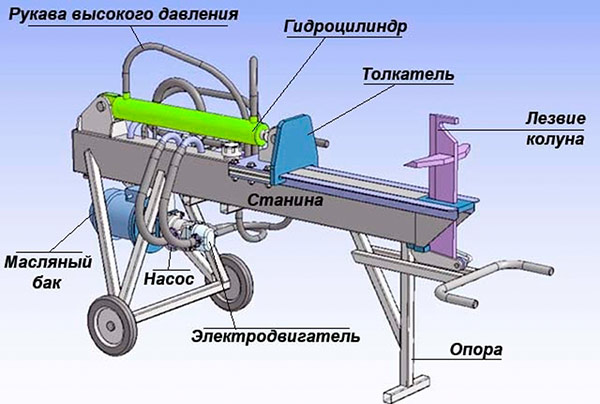

To make a hydraulic wood splitter with your own hands: drawings, photos, instructions for which you will find below, you will need:

- electric or gasoline engine with a capacity of over 2 kW;

- oil pump;

- oil tank;

- high pressure hydraulic hoses;

- control block;

- hydraulic cylinder;

- I-beam or U-shaped metal beam;

- metal corner with a shelf size of 30–40 mm;

- sheet metal 0.5–2 cm thick (it is advisable to stock up on pieces of different thicknesses).

An approximate diagram of a hydraulic wood splitter

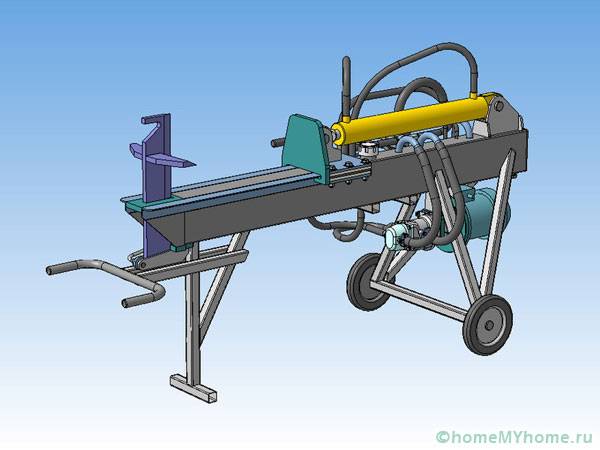

Make a frame from an I-beam or U-beam. The wider the beam, the more load the frame will withstand and the more difficult it will be to transport the wood splitter. Therefore, the optimal width of the beam is 10–15 cm. Fix the hydraulic cylinder above the beam at a height of 5–7 cm and install a pusher made of sheet metal with a thickness of 7–10 mm at the end of the rod. Make a body for the knife so that it can be moved around the bed.

Hydraulic cylinder installation

Assembled device view

Complex shaped knife

To lock the knife in different positions, do the following:

- drill holes with a diameter of 12 mm in 5 cm increments on the underside of the bed;

- drill 2 of the same holes with the same pitch in the knife body;

- from above, insert 2 bolts with a diameter of 10 mm into the knife body and weld them;

- having adjusted the length of the working space, fix the knives with metal washers and nuts.

This way you can adapt the splitter to different lengths of logs. Bring in a good hydraulics to connect the oil pump, oil tank, control unit and hydraulic cylinder in one chain.

The main types of wood splitters

Wood splitters, depending on the presence or absence of a drive, can be mechanical or manual.

Their device differs radically from each other.

In addition, these machines differ in the way they move:

- Stationary. They are often industrial machines that are heavy and large. The use of such wood splitters in a domestic environment is impractical.

- Mobile - devices equipped with wheels for transportation, or they are lightweight, which allows them to be moved. According to the method of laying logs, wood splitters are divided into horizontal and vertical.

Manual

The principle of operation of manual wood splitters is based on the simplest physical laws, without the use of any additional special devices.

The person himself acts as a source of energy.

Manual wood splitters are preferable in the home as they are not suitable for cutting really large volumes of combustion material.

In turn, they can be divided into several types:

Manual

Stand - the base on which the blades are fixed upward.

The workpiece is placed on the blades, and a blow is made from above with a sledgehammer.

Crowbar cleaver

It is a pipe with a cleaver at the end, inside which a heavy rod (scrap) moves freely.

The cleaver is placed on the workpiece, after which the rod drops sharply (hits the cleaver inside the pipe).

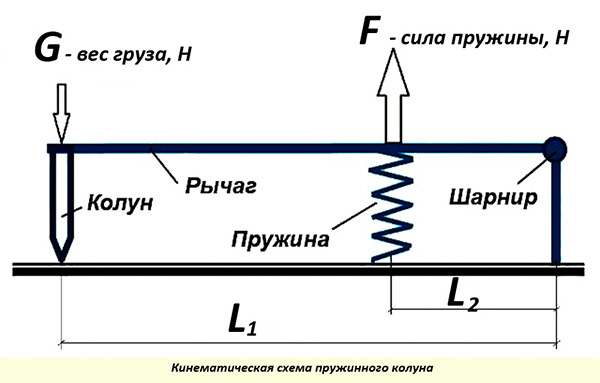

Spring loaded

It is a lever, on one side of which the blade is located, and the opposite side is movably fixed on the bed.

In this case, the junction is spring-loaded.

The principle of operation is a large leverage of strength.

Rack

The mechanism for feeding logs into the blades is made in the form of a rack with notches.

Mechanical

There are much more varieties of mechanical wood splitters than manual ones, since various types of motors can be used to feed the workpieces to the blades, as well as the feeding method itself.

In addition, blades are not the only ones capable of splitting wood well.

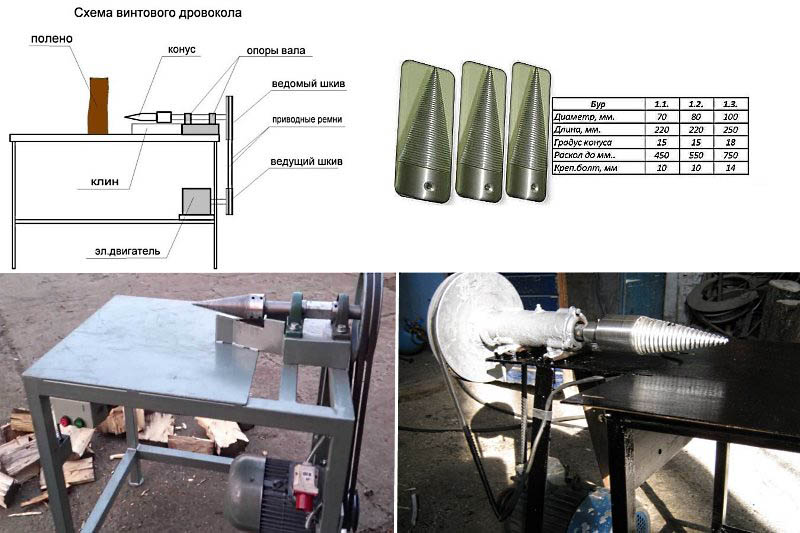

Mechanical wood splitters are a frame with a motor, on the shaft of which a tapered screw is located.

The principle of operation is to screw this screw into the wood, due to which the fibers of the material are easily exfoliated.

The chock is pushed onto the cone by means of a stop that is set in motion by hand force.

Cone wood splitters - structurally similar to ordinary mechanical options, however, the logs are manually mounted on the cone.

Another name for these devices is screw wood splitters. The cone itself is fixed directly on the axis of the electric motor.

Reduced wood splitters - in their design, a reduction gear is used to reduce the speed on the cone.

Allows the use of a high-speed motor.

Often, geared wood splitters are called machines, which are a frame, on one side of which the blades are fixed.

On the reverse side there is a motor with a special gearbox that converts the rotational movements of the shaft into reciprocating movements of the piston, which feeds the workpieces onto the blades.

Depending on the type of engine used, wood splitters are divided into:

Electric is the most common option.

The electric motor, which is powered by a household network, is not demanding in operation and maintenance, and has sufficient power for domestic use.

In addition, electric wood splitters are also environmentally friendly devices.

Among the disadvantages, only the low mobility of such machines can be noted.

Gasoline - options with a gasoline engine.

They are much more powerful than electric ones, they are not tied to a power source (fuel).

Suitable for both household work and for the preparation of firewood on an industrial scale.

Tractor-driven - either the tractor's hydraulic system or its power take-off shaft acts as an energy source.

Another type is hydraulic wood splitters.

Due to their power, they are able to split wood of any species, both dry and wet.

Due to their productivity, such production devices are often used in logging.

The simplest hydraulic option is a frame on which the blades are fixed on one side (they can be at different angles relative to each other in order to completely process the whole block in one pass) and on the other a pushing piston.

This piston can be connected to the tractor's hydraulic system, or to its own motor-hydraulic pump system.

Such devices are capable of delivering a pusher pressure of up to 12 tons.

Main characteristics

A wood splitter is a machine designed for splitting wooden blocks into logs suitable for laying in a stove.

Regardless of the design, each log splitter has a number of common characteristics, on the basis of which you can choose a device for specific tasks:

- Dimensions. Industrial machines are large in size, while household options are relatively compact. Dimensions directly affect the weight of the wood splitter.

- Engine power (for mechanical versions) - directly affects the performance of the wood splitter and fuel consumption.

- Splitting power. The parameter determines the maximum force that can be applied to split logs.

- Working length and diameter. These parameters determine the maximum longitudinal dimension and diameter of a piece of wood that can be split.

- The stroke of the piston and its speed of movement.

The first parameter is the distance the piston travels at a time.

There are wood splitter options with adjustable piston stroke.

This function is useful if you need to split small logs, as a shorter stroke will save fuel and time.

The speed of movement determines how much time will be spent on splitting the workpiece.

In order for the machine to withstand serious loads, good quality metal is used for the manufacture of its body and all working elements.

The material directly affects the life of the machine and its reliability.

Homemade Screw Cone Log Splitter

The screw log splitter (we mentioned it earlier) can be vertical and horizontal. It differs from the usual wood splitters in the shape of the saw tool. This is not a blade, but a cone. There are no special operating conditions for such a wood splitter. Such a system does not care if there are knots in the log. They are equally quick to cope with wood of different configuration and quality.

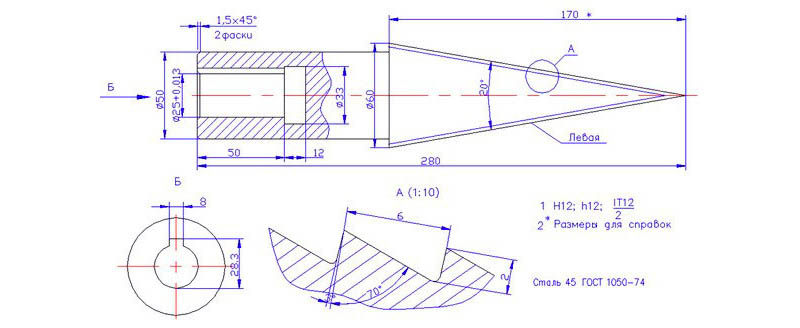

Diagram of a cone for a wood splitter

Diagram of a cone for a wood splitter Screw machine diagram

Screw machine diagram

Such devices are considered to be among the safest. In addition, such a mechanism does not require a powerful motor, which is definitely a plus. Power of 3 kW will be enough to ensure uninterrupted operation.

The cone splitter is not so sensitive to the diameter of the log

The most important thing here is to place it correctly under the cone, exactly in the center of the cut.

Why do we need firewood - improving the quality of fuel

There are quite a few energy sources in the modern world:

- Natural gas is available over large areas. It is enough to open the burner and light it, as a bluish light appears, which gives off a significant heat flux.

- Liquid fuel dispensed through the injectors burns with a bright red or yellowish flame. Even in heat engines, different types of liquid energy carriers are used.

- Coal and its products have a long combustion cycle. The reddish flame gives off heat for a long time not only by convection, a powerful flow of thermal radiation enters all surrounding objects.

- Firewood was the first available heat source. They remain relevant at the present time.

Stove heating is used in many homes. Baths and saunas, when advertising their services, indicate that they use firewood of certain types of trees as a source of heat. Outdoor cooking traditionally involves the use of wood in the technology of thermal processing of food.

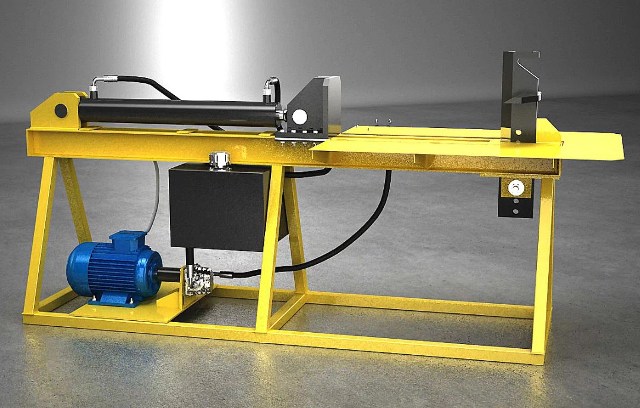

Hydraulic cleaver

Hydraulic cleavers are characterized by a large amount of work in a short time. This unit works thanks to a hydraulic pump and an engine. The cleaver itself in the device can be positioned as a stop or at the end of the stem

When assembling the unit, it is important to calculate some details:

- Installing the deck - you can chop the log vertically and horizontally.

- The length of the log to be processed.

- The force applied to work depends on the cylinder and the motor.

- Engine power - depends on the connection to the 220 or 380 V network.

- Purchase of a hydraulic cylinder.

- Purchase of an oil tank.

- Installing the oil pump.

- Installing the engine.

- Oil flow assembly.

- Metal corner 30-40 mm.

- Pieces of sheet metal.

The hydraulic splitter is more difficult to assemble, but it is more productive than the geared wood splitter. The hydraulics allow for a large amount of work. Can be used to sell ready-made firewood. Such a wood splitter in its principle is similar to a wood splitter with a jack, so it is not so difficult to assemble a water splitter, the main thing is to calculate the length of the processed decks.

Wood chopping with wedge devices

Wedges are the simplest tree felling devices. In them, the level of labor mechanization is minimal. The main task of the device is the oriented fixation of the block relative to the cutting edges. The blows are applied by the user himself, swinging a heavy hammer or sledgehammer.

In cleavers, the movement of the wedge ax is performed along a constant path. The treatment object is placed on a fixed platform. To maximize the impact force, the mass of the actuator is increased.

To soften the operation of the device, it is equipped with powerful springs. They soften the impact at the end point, preventing the wedge from touching the supports (prevent the wedge from dulling). Along the way, springs help the user lift the heavy knife for another blow.

In a stable position, the entire system is in a balanced state. The moment created by the weight of the weight G located on the arm L₁ is balanced by the force of the spring F on the arm L₂.

G L₁ = F L₂

It is most convenient to use springs from a car. For standard cars, the initial compression value is F = 8 kN (800 kg). Shoulder L₁ = 2.0 m. Taking the shoulder L₂ = 0.3 m, the weight of the load will be G = 300 kN (30 kg). The spring mechanism works quite softly, although the action of the wood splitter is based on blows to the chopped block of wood.

The person lifts the load from the level of the belt by 0.5 ... 0.6 m. Then the wedge is released. He falls and breaks the block. If complete destruction has not occurred, then you have to raise the cleaver and block. With subsequent impacts, the weight of the entire system acts, the impact is stronger. Even gnarled scraps break with repeated stress.