Advantages and disadvantages

Wood splitters work faster and better than simple axes. At the same time, the risk of injury is much less. Preparing firewood for every 5 or 7 days for a house with an area of 200 sq. m. will take no more than 3 hours at a time. Those who do the same work with an ax are forced to spend up to 4 hours daily.

Thanks to a wide range of models, you can choose a wood splitter for any need. Using them is no more difficult than using an ax. Even the professional versions require almost no special knowledge. The tool can be used equally effectively both indoors and outdoors.

But it must be borne in mind that:

some modifications of wood splitters consume a lot of current or fuel;

device performance is rigidly tied to energy consumption;

not every device is capable of separating strong wood of great thickness into parts;

sometimes impractical devices are encountered.

Guarantee obligation

With the correct operation of the micromotor and careful handling of it, the manufacturer guarantees the correct operation of the Typhoon engine in accordance with the parameters given in these operating instructions.

Warranty time ~ 4 hours within 1 year from the date of purchase.

During the warranty period, the manufacturer performs free repair or replacement of the micromotor and its individual parts.

No compensation for defects caused by the fault of the manufacturer

The micromotor is manufactured in accordance with the technical description TO 89-43-196-87, tested and approved by the Quality Department.

Our guys used the typhoon on air combat models with a specially cast propeller. When using fuel with 10% Nitra, the engine produced 25,000 rpm, but after 4-5 flights, the lower connecting rod head was destroyed. After the second engine was damaged, they stopped using fuel with nitra. On standard 80/20 fuel, the motor produced 20,000 rpm and worked stably.

Typhoon-2.5 is a specialized model aircraft engine for F2D cordon air combat models.

F2B Cordless Models | Control line stunt | Aerobatics

How to choose?

A close look at the wood splitter market reveals that it is full of many different models. The selection of the correct version can be quite difficult. But there are elementary recommendations that can significantly simplify the process. So, when you need to cook quite a bit of firewood (for a fireplace, for a small, periodically heated bath), you can use the simplest manual devices.

When it is planned to operate the wood splitter indoors, gasoline models will definitely not work. Comparatively low-noise electrical devices that do not generate exhaust gases are a different matter. Their additional advantages are compactness and comparative ease of use.

Importantly, electrical devices do not consume lubricating oils. And the payment for electricity ultimately turns out to be less than for fuel and lubricants

However, almost all powerful professional wood splitters are equipped with internal combustion engines. In addition, the lack of connection to power supply significantly increases the mobility of the device. Wood splitting machines installed in industrial plants are always evaluated according to the rate of movement of the pistons. For home devices, this indicator is almost irrelevant. The few professional piercing systems that are equipped with an electric drive only work when connected to a 380 V network.

Horizontal wood splitters are considered safer than vertical ones, but they are characterized by low efficiency.When choosing a device, one should take into account the dimensions and length of the logs to be split. The amount of splitting force determines how large workpieces can be cut. In the case of workpieces of the same size, a more powerful device will be able to cope with harder wood. As for the working mechanism, the conical type of wood splitter is considered the simplest solution.

It must be clearly understood that such a device cannot cope with pieces larger than 30-40 cm. For any mass harvesting of firewood, only mechanisms with a hydraulic transmission system are suitable. The simplest manual wood splitters on a spring are better than the usual ones because of the softer stroke. Even quite effective strikes do not interfere with this. Regardless of other features, it is necessary to take into account the height of the wood splitter - whether it will be convenient to use.

For information on how to make a wood splitter with your own hands, see the next video.

Navigation¶

-

2020/04/17 12:44 Obsidian refreshed the page AIGS GraFiS. 2020/01/19 16:59 Obsidian has updated the Air Compressibility Ratio page. 2019/08/17 15:24 Obsidian has updated the Barrel A. 2019/08/17 15:24 Obsidian has updated the Barrel B. 2019/07/18 10:44 Aleksey has updated the page Linear Burn Rate. 2019/04/10 14:10 Obsidian has updated the page Siberian Fire and Rescue Academy (Siberian Fire and Rescue Academy). 2019/01/23 15:56 Obsidian has updated the Online GDZS Calculator page. 2019/01/23 09:32 Obsidian has updated the AIHS GraFiS page. 2018/12/04 11:01 Obsidian has updated the Fire extinguishing agent delivery devices page. 2018/11/11 16:12 Obsidian has updated the Path Traveled by Fire page. 2018/11/11 16:08 Obsidian has updated the Online GDZS Calculator page. 2018/11/04 20:15 Obsidian has updated the Online GDZS Calculator page. 2018/09/03 11:21 Obsidian has updated the Pumping and hose systems page. 2018/08/27 09:34 Obsidian has updated the page Fighting fires in buildings with hinged ventilated facades. 2018/07/31 16:54 Obsidian has updated the page Calculations of parameters of work in RPE. 2018/07/31 15:00 Obsidian has updated the page Calculations of parameters of work in RPE. 2018/07/24 09:26 Obsidian has updated the page Calculations of parameters of work in RPE. 2018/07/17 14:46 Obsidian has updated the page Calculations of parameters of work in RPE. 2018/06/19 20:56 Tor has updated the page Combined fire extinguishing schedule of changes in fire area, required and actual consumption of extinguishing agents over time. 2018/05/18 16:40 Obsidian has updated the Firefighting Operations Headquarters page. - Random page

- New page

- All pages

- Categories

- Files

-

- Top 10 tankers in 2017

- History of fire trucks

- news

- 2015 news archive

- News-2016

- PSP standards

- 2015 results

- Results of work for 2016

- First Aid Fire Vehicles

- Firefighting tankers

Pages that have links to this article

-

- AL-30 (131) PM-506D

- AC-40 (131) model 137 (-137A)

- Air mechanical foam

- History of fire trucks

- Fire fighting equipment classification

- Foam ratio

- NCPN-40/100

- Fire extinguishing agents

- Foam

- PN-40UV

- Fire

- Fire-technical equipment

- Fire trucks

- Foaming agent solution

- Barrel A

- Barrel B

Pages referenced by this article

Site search

We collect the screw and hydraulic apparatus

A suitable engine with a speed of 500 rpm and an output of 1.5-2 kW will greatly simplify the design of the splitter. Such an electric motor is directly connected to the cone; there is no need to put a belt drive. If the unit with these characteristics could not be found, prepare the following set of materials:

- 2 single-strand pulleys of rated diameter, reducing the shaft rotation frequency to 500 rpm;

- V-belt;

- bearing blocks and driven shaft;

- helical splitting cone, made according to the drawing;

- shaped tubes or other rolled products for the manufacture of a table;

- an electric motor mounting plate made of 8-10 mm thick sheet;

- metal 2-3 mm on the countertop;

- fixing bolts with nuts.

A table must be welded from metal profiles, a sheet of metal must be fixed on top. The motor is mounted on a plate under the table top, the output shaft with a cone is at the top. The pulleys are either keyed or fixed with locking screws.Be sure to ground the unit when connecting the power cable.

An important point. When splitting firewood with a screw device, you must correctly move the block to the tool - strictly in an upright position. If you put it on its side, one piece of wood will get stuck between the cone and the table top.

On the stationary version, the oil station is located separately

The assembly of the hydraulic splitter is distinguished by the assembly of the equipment. Instead of an electric motor and a "carrot", you need to install a blade, a pusher plate and a working cylinder. Note that the rest of the components can be placed separately by leading the high-pressure hoses from the hydraulic station pump to the cylinder.

The process of manufacturing a hydraulic unit is shown in a very detailed and intelligible video clip:

How to make a wood splitter on a spring

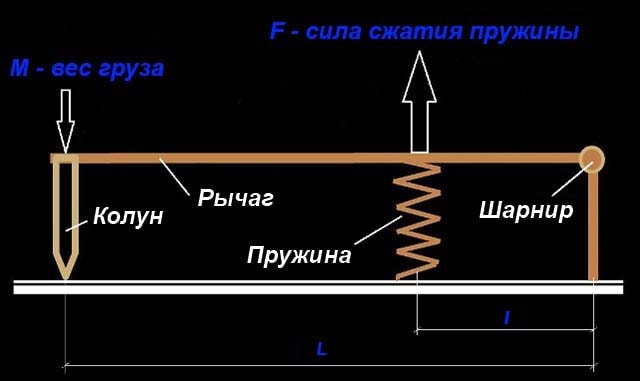

We already wrote above that the frame design is chosen arbitrarily, the main thing is stability. But before you make a lever, you need to calculate the basic dimensions according to the force distribution scheme. The challenge is to achieve the perfect balance between boom length, end weight and pivot-to-spring distance. The mechanics of this system is described by the equation:

- M is the mass of the counterweight at the end of the beam, kg;

- F is the spring force;

- l is the distance from the hinge to the spring, m;

- L is the total length of the lever, m.

If we neglect the calculation, then 2 scenarios are possible: you will have to make a lot of effort to swing the arrow or the cleaver will hit very weakly. The physical meaning: the farther the spring is from the hinge and the higher its stiffness, the longer the lever and the mass of the load will be required.

Design diagram of the arm length and weight of the load at the end

An example of determining the basic dimensions of a beam. We take a spring from a Zhiguli car, which compresses with an effort of about 200 kg (the weight of the car is 0.8 tons), and move it away from the rack by 30 cm. The rest of the indicators are calculated by the selection method - the length of the boom is taken as 2 m, then the weight of the load is 30 kg, including the weight of the cleaver and the lever. Checking: 30/200 = 0.3 / 2 = 0.15.

Use simple materials to assemble the lever log splitter:

- a spring from a small car (VAZ, "Tavria" and the like);

- a ready-made blade from a manual cleaver or a blank made of low-carbon steel 20 mm thick;

- a pipe along the diameter of the spring - for making cups;

- various rolled metal products for the frame - corners, round and profile pipes with a wall thickness of 3 mm.

The assembly process is quite simple and does not require a detailed description. Guided by the drawing, weld a stable frame, make cups and install a spring with a lever. Finally, attach a weight and a splitting blade to the beam.

If the structure turns out to be unstable, simply slide additional pipes onto the horizontal supports. For an overview of the finished cleaver with dimensions, see the video:

Design and principle of operation

You can put chocks no longer than 50 cm into the wood splitter. They will be split by a special screw, which is screwed into each log. The movement of the screw is provided by various types of motors. The transmission mechanism acts as a connecting link.

In household models, the work is done as follows:

- the machine is placed on a hard, level surface;

- raise the locking handle;

- move the emphasis so that it is exactly opposite the blade;

- put a log;

- lower the emphasis;

- press the pedal to split the log.

There is another design in which the motor is mounted on a bed. The gearbox connected to the motor turns the shaft. The working cone is fixed on the shaft in advance. In some versions, the screw is attached directly to the motor. This requires the use of a reduction gear; sometimes such models do not work satisfactorily.

The most powerful wood splitter options are equipped with hydraulic cylinders. They are capable of pushing either a log or knives (depending on what is the intention of the developers).