Nozzles

Drill mixer attachments are usually standard lengths of 400mm or 600mm and diameters ranging from 100mm to 160mm. If required, special extensions for 400 mm nozzles can be found on the market.

The type of attachment used depends on the properties of the solutions and mixtures with which the instrument will work. Heavy solutions precipitate quickly and must be stirred regularly to lift the sediment from the bottom. With light solutions, the situation is exactly the opposite - the raised components must be lowered down during mixing. Different mixer attachments are used for different purposes.

- A nozzle in the form of a right-hand spiral (with turns twisted to the right) is intended for mixing heavy mixtures of serious viscosity: tile adhesives, plasters, sealants, facade putty, epoxy resin, cement mortar. The nozzle of this design produces mixing from the bottom up.

- The left-hand spiral nozzle mixes from top to bottom. Such nozzles are recommended for working with light solutions and liquid mixtures - paints and varnishes, wallpaper glue, bitumen.

- The screw head has two opposite screws. Such a stirrer is good for working with varnishes and paints. Its upper blades press the mixture down to prevent splashing of the solution. And the lower ones are pushed up.

- The crosshead has four arms made of metal rods. Such a mixer is intended for materials in which the ingress of air during mixing is undesirable. For example, gypsum putties, sealants, some types of adhesives. The special design of the nozzle makes it possible to mix in one plane, without air entrapment.

It is interesting: How to choose a frame pool for a summer residence: we consider it in detail

How to choose a construction mixer?

Despite the fact that there are still hand-held devices on sale, they are gradually becoming a thing of the past, and they are being replaced by electric models, which are equipped with various nozzles depending on the density and type of mixture. The main indicator of the tool is the ability to mix a certain mass or volume of the solution in one cycle. This parameter is directly affected by the power of the product, which is measured in kilowatts. For home use, there are household tools, their power in most cases does not exceed 1 kW. For use in industrial construction, devices with a power of 2 kW and above will be most suitable. Such products easily work even with significant masses of high-density concrete - in one batch, you can get up to 200 liters of the finished mixture.

Be sure to pay attention to the weight of the product, since in any case you will have to hold it with your hands. The minimum weight is 2 kg, semi-professional designs will have a mass of about 7-10 kg, and already products belonging to the professional series will be even heavier - 10-15 kg

It is desirable that the products be equipped with an engine speed control system. This feature allows you to maintain a constant mode of operation regardless of the density of the mixture.

The torque of the equipment indicates which internal forces are generated directly in the stirred solution. The higher this factor is, the more dense the mixture will be able to process the selected tool. In the field of domestic use, it will be possible to prepare a plaster solution, stir the paint, obtain a high-quality putty mixture, a primer and other compositions that are of medium or low density.

It is also important to pay attention to the number of revolutions of the device.Regardless of the purpose, this figure fluctuates around 750-850 rpm. This will be quite enough to work with solutions of different densities.

It is desirable that the products be equipped with a soft start system. This technology prevents the mixture from splashing at start-up, reduces peak loads during start-up, which significantly extends the tool life.

This will be quite enough to work with solutions of different densities. It is desirable that the products be equipped with a soft start system. This technology prevents the mixture from splashing at start-up, reduces the peak loads during the start, which significantly extends the tool's service life.

When choosing models for inclusion in our rating, we took into account all the previously considered points, and also took into account the ratio of price and quality of products, and also turned to user reviews. We tried to include not too expensive devices in the review so that most of our readers can afford them.

Now is the time to move on to analyzing the specific characteristics of certain models.

Variety of drill mixer models

Now in hardware stores you can find a huge number of different models of drill-mixers and they all deserve attention. But in order to figure out which tool is needed for certain conditions and requirements, you need to familiarize yourself with the main models and manufacturers.

Fiolent tool

The drill mixer of this brand belongs to domestic production. Such a model as "Fiolent MD1-11E" is especially in demand. She has a high power, which is 1100 W and a large weight - about 4.7 kg. Such a device is capable of mixing viscous substances. The number of revolutions of the Fiolent drill mixer is 600 rpm.

Drill mixer "Interskol"

There are several models from this manufacturer that are used for mixing various substances. For example, the Interskol D16 / 1050 R drill mixer

Its weight is 3 kg 800 grams, while the power of the device is calculated at 1050 watts.

This tool is great for mixing building mixtures or drilling. If you insert a wood drill into it, you can get a hole up to 1 meter deep.

Important! For convenience, an additional handle is included with the drill mixer

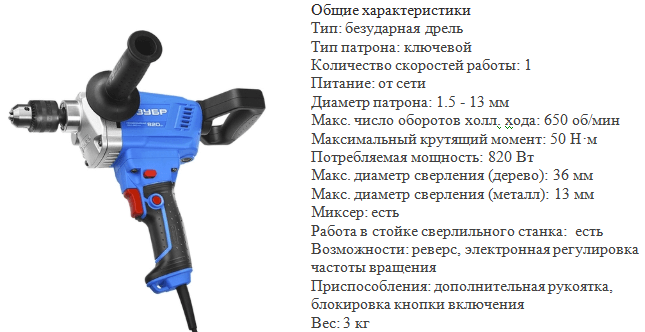

Drill mixer "Zubr"

This brand is in great demand on the Russian market. A huge variety of power tools are now produced under it. The Zubr 3DM-1200R drill-mixer model has a high power of 1200 W and a heavy weight of 4.5 kg, which allows you to mix even very viscous compositions. The frequency of rotation of the nozzle of such a device reaches 850 rpm. For greater comfort when working, in addition to the drill mixer, 2 attachments are included.

Drill mixer of the Japanese manufacturer "Makita"

Such devices have long been known not only in our country and every year they are gaining more and more popularity due to their quality characteristics and reliability.

If the drill mixer is needed only for domestic use during the repair, and it will not mix a lot of material, then you should take a closer look at the Makita 6013BR model. It is easy to use due to its low weight, which is only 2.8. The power of this model is slightly less than that of the ones presented above and is 620 W, but this is enough for periodic use for repair purposes. Moreover, when comparing with other analogues, it can be revealed that this model of a drill-mixer with less energy consumption, has the same performance.

Which manufacturers should you trust

The low-speed drill, supplied under the Zubr brand, is made in China. But, contrary to the popular stereotype, the products of this brand are quite convenient and comfortable to work with. Reviews indicate that she:

- professionally designed;

- suitable for a wide range of tasks (you just need to choose the right model);

- is relatively inexpensive.

Drills from Makita are also a good choice even for novice builders and repairmen. The Japanese corporation has managed to create excellent tools that have been in use for a very long time. Therefore, they are also appreciated by professionals.

A striking example is modification 6014 BR. With a power of 0.85 kW, it:

- develops a torque of 550 Newton meters;

- compatible with attachments up to 1.6 cm;

- relatively light (weight 2.5 kg).

Quite good reviews from consumers are received for the products of the Russian company Interskol, including the D-16 / 1050R model. All drills come in a decent base package. There are also many attachments and auxiliary handles. The already mentioned model is compatible with attachments up to 1.6 cm inclusive. Its mass is 3.8 kg, and the power consumption is 1.05 kW.

You should definitely take a closer look at the products of the Chinese concern Sturm. The company offers both cheap and expensive modifications. They are lighter and smaller than competitors' products. This is not reflected in practical characteristics. So, for the most popular version - ID20131:

- power reaches 1.1 kW;

- the torque can be 800 Newton meters;

- weight is 3.5 kg.

Rebir IE-1206ER-A is also a good option. The designers have taken care of full protection from dust, which allows you to work even in adverse conditions. The ergonomics of the handle are appreciated by consumers. A feature of the gearbox and intermediate shield is a long period of operation. After finishing work, it is easy to remove the drill thanks to the switch to reverse.

Choosing a drill mixer

When buying a mixer-drill, you need to be very careful and know some of the technical characteristics that these devices differ in order to choose the most suitable

First of all, attention is paid to the following characteristics of the drill-mixer:

Important! Since the dimensions of the drill-mixer are large, it does not have a special case in the delivery set

Product weight, which can range between 2.7 and 4.5 kg.

Power ranging from 620 to 1050 watts.

The number of revolutions per 1 minute is from 0 to 1050 revolutions.

Torque, which is 70 Newtons per meter.

The diameter of the spindle neck of the drill-mixer should be 43 mm, as required by the European quality standard.

It will not be superfluous to have some additional functions of the drill mixer. These are, for example, a smooth start and automatic shutdown of the device, protection against overload during operation, good insulation of the case with the presence of a plastic dielectric, the ability to adjust the rotation speed of the drill, the handle for easier and more convenient use, the presence of additional components in the set.

Important! Since the dimensions of the mixer drill are large, it does not have a special case in the delivery set

Why a rotary hammer is not a mixer

Rotary hammers or drills are really used as a construction mixer, and manufacturers delight their customers with hex beaters or SDS + fit. In fact, for any kind of long-term work, neither the first nor the second will work.

An important role is played by the number of revolutions per minute: for a perforator or drill, this indicator is close to 3000, which is 6 times higher than the optimal indicator for high-quality and uniform mixing of solutions.

Adjusting the speed will not solve the problem, because with low rotation power is lost, therefore, the motor will be overloaded. In addition, it is rather difficult to "catch" the desired position with the rheostat button. On perforators with a vertical engine, there is a step adjustment, it is easier to set a suitable speed with it, but this solution is suitable only for light solutions: paints, plasters.

Conventional drills have similar technical features, but they are complicated by a lower power rating and a small gearbox.Conclusion: light or medium mortars can be mixed with a drill or perforator, but only once and in small volumes.

Comparison of the presented products

Below is a comparative table of the main technical parameters of each of the presented device. It will help you choose the best quality and most versatile device for your home and industrial environments.

| Model | Dimensions (mm) | Power, W) | Weight, kg) | Price, rub) |

| Scheppach PM1200 | 560х390х700 | 1200 | 4.9 | 4 500 – 8 000 |

| Vitals-Master Professional Em 1612-2BR | 981x460x775 | 1600 | 8 | 7 000 – 8 900 |

| Fiolent MD1-11E | 540x380x780 | 1100 | 4.7 | 4 000 – 6 500 |

| AGP AM 5000 NC | 940x580x780 | 1500 | 32 | 24 000 – 25 900 |

| Rebir EM1-950E-2 | 560x400x600 | 1300 | 4.3 | 6 500 – 7 900 |

| Stark HM-1350 PRO | 550x390x590 | 1050 | 3.5 | 2 900 – 4 000 |

| Eibenstock EHR20 / 2S | 600x420x615 | 1150 | 4.2 | 7 000 – 9 800 |

Models

The range of autonomous tools of the company includes 4 models, characterized by battery operation, two operating speeds (up to 320 and up to 920 rpm) and the presence of such convenient options as a backlight, a charge indicator and a magnet for screws:

- AUM3N-12-2 with operating voltage 12 V and weight 1.5 kg;

- AUM5N-18T-2 with a voltage of 18 V and a mass of 1.9 kg;

- AUM5N-18-2, variant of the previous model with the possibility of installing a drill with a diameter of 13 mm;

- AUM4N-14.4-2 with voltage 15 V and weight 1.7 kg.

The active model range of percussion tools includes 3 items, which are characterized by a speed of up to 2800 rpm, the presence of a frequency regulator, a reverse mode, the possibility of fixing in a working state and an additional handle with a stop-depth gauge:

- TRU-670 / 13ER with a power of 670 W and a mass of 2.1 kg;

- TRU-770 / 13ER with a power of 770 W and a mass of 2.2 kg;

- TRU-870 / 13ER with a power of 870 W and a mass of 2.3 kg.

The 950 W (TRU5Z-13 / 950ER) and 1.1 kW (TRU4-13ER-2) hammer drill options were discontinued but are still available in select online stores.

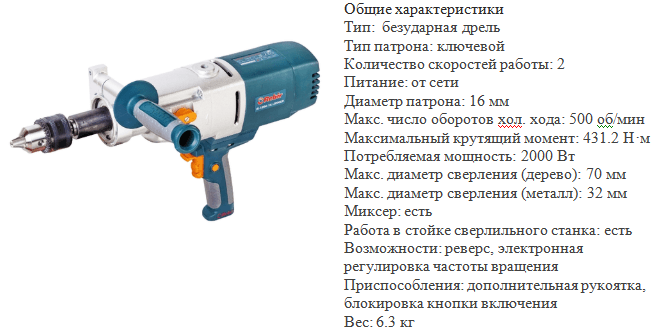

The range of the company's network products is very wide and includes:

- UM-510 / 10ER with reversible power of 500 W;

- UM2-16 / 1200ER with a reversing function with a power of 1.2 kW;

- IE-1305A-16 / 1450ER 1.4 kW;

- IE-1205-16 / 1450ER with a power of 1.4 kW at a speed increased to 1000 rpm;

- IE-1205-16 / 1700ER with a power of 1.7 kW;

- IE-1023M-16/1700 with a power of 1.7 kW with an increased speed of 1000 rpm and an additional vertical handle;

- IE-1206-1-16 / 2000ER with a power of 2 kW.

How to determine the appropriate modification

To date, manufacturers offer three versions of the mixer:

- drill mixer;

- two-hand mixer with one whisk;

- two-hand mixer with two whisks.

The mixer drill is a low-speed hammerless drill with a metal gearbox, which has an unusual design. Reduced (powerful and slow) speed allows you to regularly use it as a construction mixer. The power of such a tool varies from 500 to 2000 W, depending on the reliability and manufacturer. The device has a non-standard design for a drill, there are two comfortable handles for a secure grip and a large chuck up to 16 mm.

Relatively speaking, a drill mixer is chosen for the home, it will cope with light or medium-sized solutions. Models with power from 1 kW can also be used in construction for mixing viscous foundation mixtures. In addition, low-speed drills do an excellent job not only with normal drill work, but also with drilling large holes. For example, when you need to drill a wooden blockhouse, they are used.

Two-handed versions of mixers are divided into versions with one whisk or two. The difference between them is obvious: two whisks will quickly and efficiently mix any, even very viscous, mixture. The power of such models starts from 1 kW, if the indicator is less, the tool is not worth buying.

The first thing to do before buying is to assess the scale of future work. There is no point in overpaying for an unused potential or a second whisk if the tool is needed for light, one-time work. This rule applies and vice versa, a weak drill mixer will not always cope with pouring the foundation.

This is interesting: Lighting of the working area in the kitchen: explaining in general terms