Difference in the period of operation

Especially if the latter will be used for percussion work very often. Due to its pneumatics, much less vibration and more acceptable conditions for the functioning of most of its mechanisms are provided.

The tool is equipped with a safety clutch in order to protect against breakage for the situation when the drill can jam in the hole, for example, when the latter hits metal reinforcing bars.

What are the price differences between percussion instruments?

With uniform power (but not impact energy, which is much higher in a hammer drill), a hammer drill is almost 1.5-2 times more expensive than a drill.

What to prefer between the two types of instrument? It will not be possible to unequivocally answer the question of which of the tools described here is better. It will all come down to what goals the purchase of electrical equipment pursues. The rock drill is ideal for drilling and hammering in concrete enclosures.

It makes sense to buy it when the situation requires the execution of many holes.

When there is no such need, that is, the tool is needed for domestic needs (for making several holes, for hanging shelves or cabinets on the wall), it is better to give preference to a drill with an impact mode.

Features of working with a drill

The drill is the main tool of the home craftsman. Its main purpose is to drill holes. She may be:

- classic;

- rechargeable;

- screwdriver;

- mixer;

- corner;

- shock.

To drill a hole, the drill must have a speed control to enable low speed.

The classic drill is designed for drilling holes in some materials that are not particularly durable. Powered by an electrical network. Has an engine of sufficient power to perform woodworking.

A variation of this tool is the cordless drill. It is used in places where there are no sources of stationary power supply. Perfect fit when performing work on the street... Rechargeable, replaceable batteries provide power to the drill for a long time.

The drill driver can drill holes and drive screws and self-tapping screws. This tool is characterized by low engine power and small size. A great thing when assembling furniture and household appliances. Equipped with a reverse mechanism.

The drill mixer, in addition to its basic functions, can mix various solutions and mixtures. The scope of delivery includes a special mixing attachment.

The angle drill is used when working in places with limited space. The tool has a remarkable feature - the ability to drill at an angle of 90 °. The drill gearbox is L-shaped.

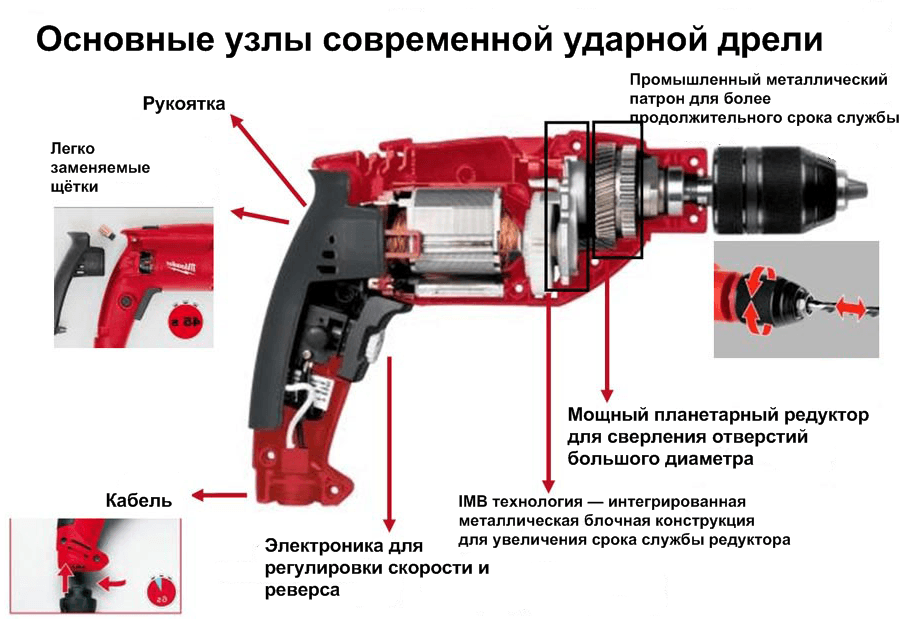

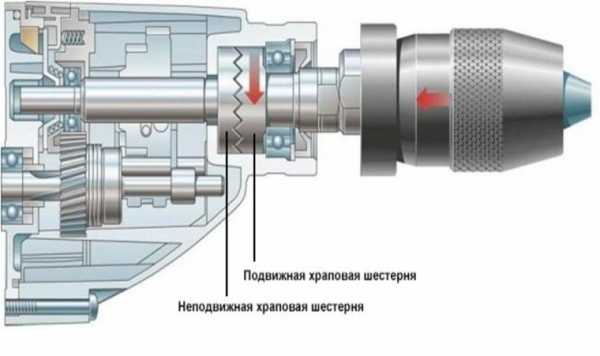

The hammer drill has an increased motor power. It is capable of punching concrete and brick due to the reciprocating motion of the working shaft, which resembles a hammer drill. A ratchet mechanism is located inside the housing, giving axial movement to the working shaft.

Drill chuck diagram.

All rotary hammers and drills are divided into professional and household. Household tools are cheaper and lighter. They require work breaks. Professional models can work daily and for many hours at a time. They are produced by highly skilled workers in factories in Europe. Credible manufacturing companies affix factory markings to the instrument case

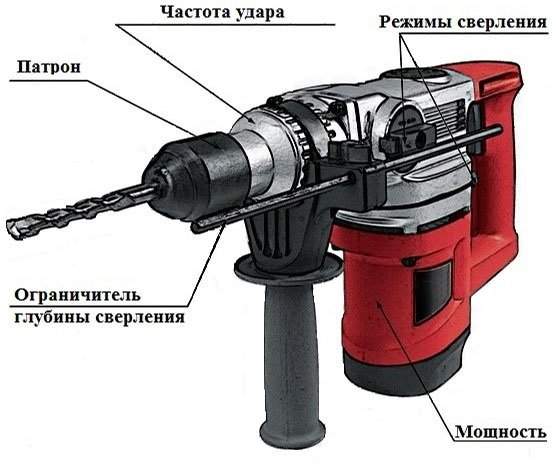

When choosing a tool, you need to pay attention to:

- engine power;

- rotational speed;

- speed regulator;

- maximum hole diameter.

The power of these units is 300-1500 watts. For processing plastic and wood, 500 watts are enough. To drill large holes, a power of 1000 watts or more is required.

The higher the number of revolutions, the greater the productivity of the tool. Household tools develop 2500-3000 rpm.

The torsional coupling allows you to adjust the number of revolutions of the working shaft for drilling and screwing in screws.

The maximum size of holes that the tool can make is indicated in the technical documentation. Exceeding this size can lead to damage to expensive equipment.

No. 6. Shaft rotation speed and its adjustment

Rotational speed drill shaft on idling can reach 3500 rpm, but such a frequency is not always necessary. The higher this parameter, the faster it will be possible to drill the hole and the smoother its walls will be. High revs are more necessary in order to grind and polish the surface, but they will also come in handy with impact work. In order to tighten the screw, 400-500 rpm will be enough.

The versatility of the tool is provided by a rotational speed switch. In the simplest models, a step switch is used, in the more advanced ones - an electronic one that clearly reacts to the force of pressing. If you press hard, we get the maximum speed.

A speed limiter and soft start will also be helpful. The latter allows you to smoothly accelerate the engine and provides a gradual increase in speed from minimum to required. This allows you to get rid of jerks at the start, overloads and drilling errors.

Perforator

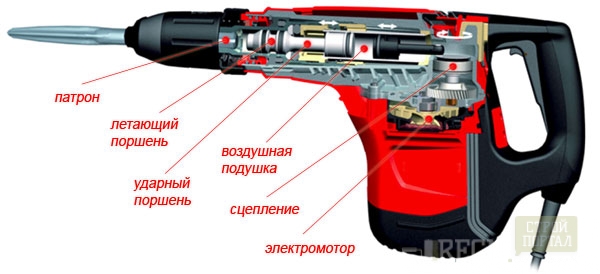

The main difference between the hammer drill and the hammer drill is the design of the hammer mechanism. It can be electromechanical and electro-pneumatic. The latter is found in most of the models on the modern market.

The principle of operation is as follows: the electric motor drives the gear of the reducer in rotation, on the output shaft of which a swinging or, as it is also called, drunk bearing is fixed (1). It drives the piston along the cylinder. As a result, the piston interacts with the ram (2), which hits the striker (3), transferring energy to the rig installed in the SDS cartridge (4). In this way, greater energy and depth of impact is achieved.

Interesting: at the same power, the impact energy of a hammer drill is 2 or more times higher than the impact energy of an impact drill, which is more suitable for concrete.

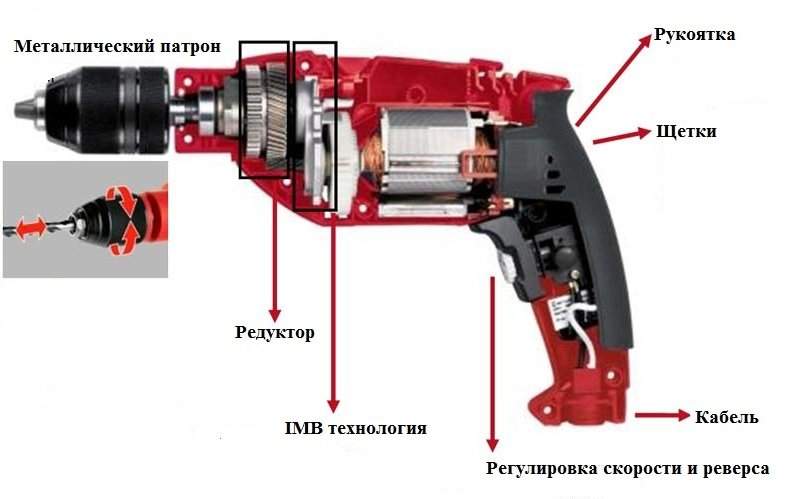

The second difference between a hammer drill and a drill with a percussion mechanism is the way the drills are fastened in the chuck. Whereas in the previous version, jaw chucks were used, SDS chucks are used here. It is impossible to install a conventional drill in them - only special drills with a corresponding shank. It should have 4 slots that have different diameters in pairs, they are needed to hold the rig.

To install conventional drills in the SDS chuck, you can mount an adapter on the chuck, but in this case it will not be possible to achieve high quality drilling due to beating.

It is also worth noting that there are two types of shanks and cartridges:

- 4 slots - SDS-plus, holds tooling up to 26 mm in diameter.

- Under 5 slots - SDS-max, drills with a diameter greater than 20 mm.

Choosing the right drill

Some drills will even drill through the rebar. If you need to drill a hole in a reinforced concrete surface, do not stint and buy a special drill designed for drilling concrete even through a metal mesh and reinforcement rods.

For about $ 50 you can buy an impact drill that can drill shallow holes in most types of masonry, but by spending a little more on a hammer drill, you will get two benefits in return: the ability to drill deep holes and, just as important, a higher drilling speed, which is especially important when you have to drill many holes at once. Drill impact power is measured by BPM (beats per minute)

But this is far from the only important indicator of the performance of a hammer drill: the amperage of its motor and how comfortable this tool is in your hands are much more important.Solid metal chucks are more durable than plastic chucks. Quick-release chucks are undoubtedly more convenient for everyday work, but they are not suitable for drilling masonry, since they lack the strength to hold the drill. The chuck diameter often dictates the maximum recommended hole size that can be drilled with a given drill.

Drill power is measured by BPM (beats per minute). But this is far from the only important indicator of the performance of a hammer drill: the amperage of its motor and how comfortable this tool is in your hands are much more important. Solid metal chucks are more durable than plastic chucks. Quick-release chucks are undoubtedly more convenient for everyday work, but they are not suitable for drilling masonry, since they lack the strength to hold the drill. The chuck diameter often dictates the maximum recommended hole size that can be drilled with a given drill.

The power of the hammer drill is measured in Joules

When choosing a hammer drill, remember that the more powerful the model, the better, but the power of its impact is even more important. Rotary hammers are classified according to the maximum hole size they can drill according to the manufacturer's recommendations, but this does not mean that this tool is not able to drill a hole and a larger size from time to time.

If you only need a drill to make centimeter-sized holes and nothing else, then buy a more powerful model so that it does not have to "puff" all the time at maximum power.

Difference in operating modes

The hammer drill has three modes of operation:

- chiselling,

- drilling,

- hammer drilling.

The first mode turns the hammer drill into a jackhammer, which allows you to hammer in walls, dismantle old tiles and plaster, chisel a gutter for wiring, and much more. Impact drilling allows you to punch huge holes, for example for air conditioner mountings. No hammer drill is capable of this.

The drill has only two modes:

- drilling,

- hammer drilling.

But can a hammer drill completely replace a drill if it has more modes? In theory it can, but in practice everything is much more complicated.

First, the drill and hammer drill have different chuck rotation speeds. If a drill, for example, Makita HP1640, has a drill rotation speed of 2800 rpm, then a hammer drill has 1000 rpm or even less. These low RPMs may simply not be enough to properly drill through sheet metal. But for drilling wood is quite enough.

Secondly, the punch chuck is not rigidly fixed on the axis of the device, therefore, there will be a slight backlash during drilling. And if you use an adapter, then the backlash will be even greater. Because of this, there is a possibility of damage to the material that we are drilling. That is why it is only necessary to use a hammer drill for drilling when the beat of the drill does not damage the workpiece material or the drill itself. For the same reason, we recommend using large drills with a hammer drill to drill small holes in metal, wood crowns and other large-sized bits.

However, drills thinner than 8 mm should be used with caution, as they can easily break due to play and runout. for wood and metal have round or hex shanks that simply will not be clamped in the hammer chuck. They require a jaw chuck or adapter (see

fig.), which is purchased separately. However, with an adapter, the drill runout increases slightly.

As you can see, the hammer drill and hammer drill are not interchangeable devices. Each is used for a specific purpose.In some cases, it is possible to compensate for the absence of one with the work of the other, for example, with a drill with a victorious drill, drill a couple of holes in concrete (do not buy a perforator for the sake of two holes). However, for constant work "along the profile" you need an appropriate tool.

Hammer drill

This tool is mainly intended for drilling various materials. But its design includes a special percussion mechanism that allows the drill to make striking movements during operation. It's like hitting a hammer. The function helps to work with durable building materials:

- brick;

- concrete;

- stone.

As a rule, this device has a switch that changes from simple drilling mode to hammer drilling. At the same time, it is necessary to understand that a conventional drill is not enough for crushing strong materials, therefore a nozzle with a victorious tip is used. In addition, this tool is not designed for strong impacts with a large amplitude of longitudinal movements of the drill. Beating movements are carried out within a few millimeters, so they can rather be described as vibration of the drill during the operation of the tool.

But the drilling capabilities of this tool do not end there. Attachments in the form of grinding wheels are perfect for the drill, on the sticky surface of which you can fix any sandpaper. This helps to sand the painted surface or putty on any material. Also, with the help of attachments, you can turn an ordinary drill into a brush for removing coloring compounds from metal. When using twisted wire, the processing will be rough, with corrugated wire - finishing.

Thanks to the fast rotating movements of this machine, you can mix cement or putty: just insert a mixer fork. The number of such attachments is varied, making the drill a fairly versatile unit.

Tool characteristics

When choosing a hammer drill, it is necessary to take into account the main indicators of impact energy. It is measured in joules. A professional device can have an impact force of up to 15 joules, while a home device can only have 1–2 joules. The higher this indicator, the more efficiently the perforator works, and the larger holes it punches. If such a tool has too little impact force, then it will drill more into the wall than drill, and the nozzle will quickly fail.

The second important indicator is the frequency of the striking movements. The more beats per minute the apparatus makes, the faster it will punch a hole. But more speed means more wear on parts in less time. That is why it is worth choosing only high-quality and well-known brands that have already proven themselves. The parts of such tools are made of higher quality materials. They are designed for increased loads.

The frequency of rotation of the shaft is also not fundamental, unlike a drill. It's all about the purpose of this function in the hammer drill. Rotation of the nozzle during chiselling is performed to remove the destroyed material, and not to create a depression.

In addition, the drill bits have a large diameter, and it is difficult for a low-power engine to rotate them at high speed. A large engine significantly increases the weight of the unit, which complicates its operation. That is why the standard shaft speed in the hammer drill fluctuates at an average level (from 600 up to 1500 rpm).

And another important criterion for evaluating the tool is the type of chuck for installing drills and drills.

The punch has three of them:

- SDS plus (the tool weighs 4 kg and punches holes up to 3 cm in diameter);

- SDS max (weight - up to 11 kg, diameter - up to 5.2 cm);

- SDS-top (average weight with a hole diameter of 1.6-2.5 cm).

The latter type of chuck is practically universal, it is installed mainly on Bosch rotary hammers and is optimal for home repairs.

As for the characteristics of the drill, here the beat frequency does not play a key role, since the maximum efficiency in the hammer mode is achieved by pressing the tool firmly. This is the main difference between rock drill and hammer drill specifications.

To successfully perform its main functions in a drill, power and shaft speed are important. The average power of the drill is 500–900 watts. If it is supposed to be used as a mixer, then this indicator should be significant. Then the tool will not overheat during use. However, the higher the power, the greater the weight of the apparatus. Therefore, for homework, it is better to choose average characteristics.

As for the shaft speed, it must be large. At its high value, the holes are drilled evenly. In a home drill, a high RPM helps to compensate for low power. Drill chuck type - cam or key. In the jaw drill, it can be clamped quickly and without the use of additional force. This simplifies and speeds up the process of changing the nozzle. The key cartridge is distinguished by the presence of an additional device in the form of a small key. It takes time to replace the nozzle, but as practice shows, such models break less often.

How does a puncher work

The main unit of this apparatus is the percussion mechanism. Depending on the nature of the action, electromagnetic and electro-pneumatic types are distinguished. The magnetic type is rarely used in construction practice, as it quickly breaks down under the influence of dust. By structure, there are types equipped with a connecting rod (used for heavier work, have a large impact amplitude) and mechanisms of the "drunken bearing" type. Another difference with a drill is the presence of a clutch that dampens the rotation process when the nozzle is jammed.

The perforator is used to break tiled coverings, chipping bricks, chipping walls

The principle of operation of the punch

Like a drill, this device has a conversion of electricity by a motor and a gearbox. The difference is that the impulse is directed to the bearing (or to the mechanism with the connecting rod), which moves the piston hermetically sealed into the tube, and this, in turn, transfers the movement to the ram. This latter directs the impact energy to the block, then the impact of the working nozzle occurs.

The purpose of the punch

The functions of the device include:

- Breaking ceramic coatings;

- Slitting of concrete walls;

- Chipping off pieces of brickwork;

- Removing old plaster from the surface;

- Making holes in thick walls.

The tool has a much higher efficiency than a drill and is used mainly by professional builders.

Rotary hammer bits

The most commonly used attachments include

- A drill for creating holes in concrete;

- Chisel used for demolition work;

- Lance for slitting;

- Crown drill for large holes.

The hammer drill is equipped with a set of nozzles for performing different types of construction and repair work

SDS Plus device

This is one of two types of tail rigs used in rock drills. Includes two pairs of gutters, one of which is closed. When the mechanism is placed in the cartridge, the latter moves along open grooves, in closed ones, locking balls are used for fixation.

SDS Max device

It includes 5 grooves, of which only two are closed. With this design, the drill is fixed more steadily. It is she who is used in apparatuses for professional builders.