Scope of application

Most electric drills in their technical specification are called universal. However, each model has its own design features. They define the field of application in which it is possible to most comfortably solve the tasks arising during the operation of the tool.

For example, a hand-held electric hammer drill is equipped with a reverse system, a rotation regulator, and an average power motor. It can be used as a screwdriver. But this will be inconvenient: you need to hold the drill with two hands, it is difficult to maintain the required speed, the engine goes to high speed and breaks the screw slot. The scope of application of the electric impact drill is drilling holes in hard surfaces.

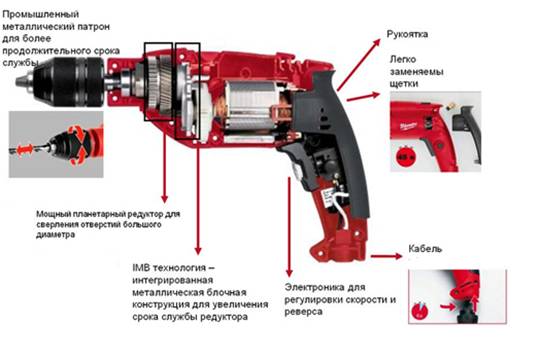

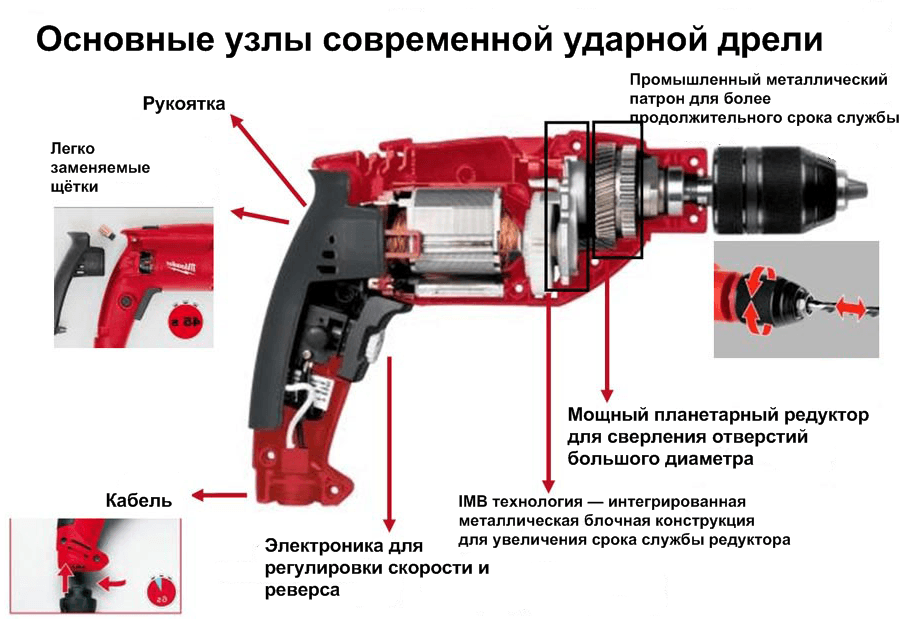

Hammer drill

The hammer drill has two drilling modes. Conventional, on which wood, tiles, glass, brick, drywall, etc. are drilled, and percussion, designed for drilling hard materials: concrete, some types of bricks, etc.

The principle of operation of the striking mechanism is as follows. Two ratchets have been added to the design. One is rigidly fixed inside the body, the second is on the main gear of the reducer. The ratchets are teeth facing each other. A drill shaft passes through their central holes. In the shockless mode, the ratchets do not touch each other, the drill does not perform oscillatory movements. After turning on the shock mode, the ratchets engage with each other with their teeth. When rotating, the teeth periodically break off the hook, pushing off each other, and re-engage. The ratchets reciprocate relative to each other. These movements are transmitted to the drill through the main gear of the gearbox and the drill shaft. The force of the drill on concrete depends on the force with which the drill is pressed when drilling.

ratchets

Disadvantages of the shock mode:

- insignificant impact force;

- hands get tired quickly;

- ratchet wear;

- it is impossible to drill concrete with a strength higher than M300.

The impact mode cannot be used constantly - this leads to a quick breakdown of the electric drill. If you need to drill many holes in hard materials, it is better to do this with a hammer drill.

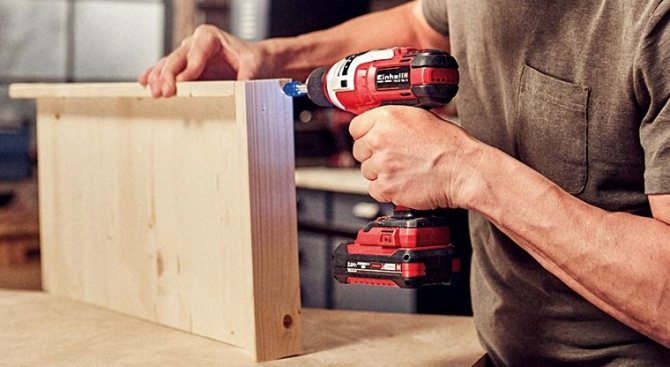

Drill for screwing in hardware

Drills for installing fasteners have features that make this work comfortable and productive. Such electric drills are lighter and more compact than standard ones. They are T-shaped and battery powered. It is convenient to use them with one hand.

Specifications:

- the presence of a reverse. When working with fasteners, it is often used. Therefore, brushless systems are preferred in which there is no power loss during reverse rotation and the motor is not subjected to additional stress;

- maximum rotation speed - 2000 rpm. This is enough to screw in and out the hardware. At such speeds, the tool has a large torque, which is necessary for screwing in large screws;

- the presence of a speed controller;

- pulse mode, in which the drill shaft rotates intermittently, with periodic jerks. The strength of these jerks depends on the resistance of the fastener. In this mode, it is convenient to unscrew old screws without the risk of ripping off the slot. Good

- adjustment of the twisting force.

Drill for screwing in hardware

Drill types by purpose

By appointment, the choice is made between the following groups:

- ordinary;

- with a percussion mechanism;

- screwdrivers;

- mixers;

- corner.

They differ in their design, application and cost. In order not to make a bad choice, you need to navigate in their features.

Regular

It has the simplest design, has the only function - to rotate the drill. Suitable for occasional repairs in a wooden house, on a plot.

Most often it is powered from the mains, but there are also more expensive battery models. If you are looking for an inexpensive home drill with no frills, this is a good choice.

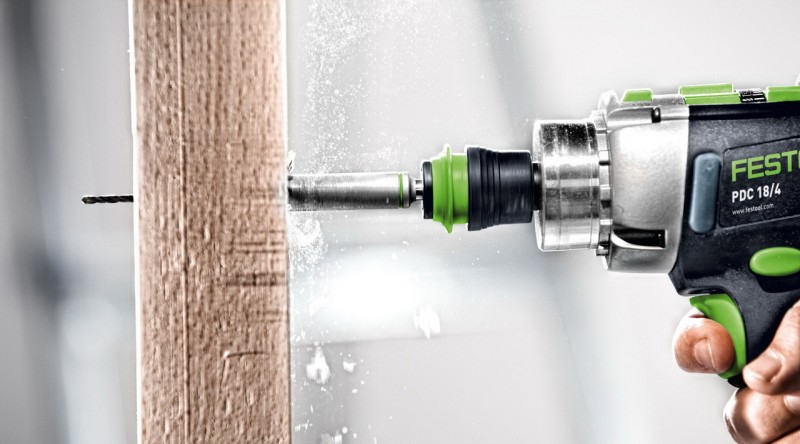

With impact mechanism

Such devices are more versatile. With their help, using special drills with a tip made of hard alloys, you can drill concrete, brick, and other solids. On most models, the striking mechanism can be turned off - then it turns into a regular one.

The percussion mechanism in such devices is primitive in comparison with the complex reducer of a perforator, therefore they are designed for small volumes of use. With prolonged use, the drummer, and with it the entire device, quickly depletes its resource.

Impact drill

For confident drilling of thick materials, the power of the device must be at least 800 watts.

A device with a percussion mechanism costs more than usual, but noticeably less than a perforator. If you need a versatile tool, a hammer drill is worth choosing.

Screwdriver

The screwdriver is designed for screwing and unscrewing self-tapping screws and other screw fasteners. The device has a function of stepped torque limiting so as not to damage thin or brittle material.

Advanced models have a two-speed gearbox. At first speed, the revs are limited, but a lot of torque develops. This is the screwdriver mode. At the second speed, the torque is small, but the rpm is maximum. This mode is used for drilling.

On the site, among wooden buildings, this versatile tool will be the best choice. But you should not choose it for drilling concrete - screwdrivers are not equipped with an impact mechanism.

Mixer

A specialized tool for mixing mortars. The set includes a set of nozzles for mixing solutions of various consistencies. Typically has a double handle for a more comfortable grip.

Drill mixer

It is theoretically possible to drill with such a device, but in practice it is a bad choice. It makes sense to choose it if you plan to plaster and level the walls, floors and ceilings in a large apartment or private house.

Angle drill

In this highly specialized device, the gearbox is designed in such a way that the chuck is rotated 90⁰ in relation to the motor axis. Allows you to transfer power to the drill without loading the motor shaft. It is used for a large number of holes when assembling the formwork, for use in confined and hard-to-reach places, in which a conventional tool simply cannot fit in a working position. Choosing such a device for a regular workshop is not a good idea.

Impact drill or hammer drill?

If you suddenly need to drill a hole with a diameter of more than 1.5 cm, or you are working with a material that is much harder than concrete, then the power of the above device may not be enough. In such cases, a puncher will help you.

While the hammer drill works by rotating the ribbed engaging plates, the hammer drill works on the principle of a real hammer piston. Therefore, the rock drill is easier to hold in the hand while still providing more power output. However, this tool is not without its drawbacks - it is much more cumbersome than the first and, at the same time, can only be used for stone materials.

The rotary hammer drills are equipped with a special SDS chuck, into which only special SDS drills and other accessories can be inserted. However, they also have switches that allow you to turn off the rotation mode for crushing stone material and other similar tasks.

The purpose of the drill is the difference from a hammer drill and a screwdriver

The drill is designed primarily for drilling holes in various materials. The chuck in which the drill is fixed rotates at a higher or lower speed. Wood, metal and plastic workpieces are easily handled with a conventional drill.For drilling concrete or stone walls, you will need to add a reciprocating action to the rotary movement of the drill, which has a crushing effect on the material that is compacted during drilling. An impact device can replace a hammer drill if the number (and size) of holes is small.

The hammer drill is a professional power tool of high power, its main action is hammering, and the rotation function is optional. The puncher is designed for deep holes of large diameter, grooving channels in walls and ceilings, dismantling structures and coatings.

Another tool that looks like a drill in appearance, but also structurally different from it, is a screwdriver. It runs at much lower rpms, has more torque. The screwdriver gearbox has a torque limiter in order not to damage thin and fragile parts when screwing self-tapping screws into them. If the limiter is turned off, the screwdriver turns into a low-speed drill.

Screwdriver

All modern models of simple and impact drills, rotary hammers and screwdrivers have the function of reverse, or rotation in the opposite direction.

Rating

Metabo SBE900 Impuls is considered one of the best powerful impact drills.

Every year Metabo's electric tool becomes the leader of the marketing charts, overtaking such giants as Bosch and Makita. The cost of such a power tool is quite high. The price, for example, for one of the best SBE900 drills, with all the desire to budget, can not be called by any means.

The tool weighs only about three kilograms, has well-thought-out functionality, and is easy to use. The vibrations transmitted to the hand are relatively small. The oscillation frequency can reach several tens of thousands per minute.

The drill has a convenient mechanism that can adjust the rotation speed, its advantage is that it makes it possible to select the optimal torque mode. In order to set the desired mode, there is a tuning wheel located on the front of the case.

The drill body is made of aluminum, it contains a gearbox that activates a switch.

The functionality is largely copied from the models of the best rotary hammers. A clutch is “hidden” inside the body, which reliably protects the mechanism in case the drill unexpectedly jams. Metabo is not cheap, but it is trouble-free and has good power.

If we talk about the shortcomings of this impact drill, then it should be said about the cartridge. He does not cope well with drills of large diameter, they slip. A quick-release mechanism is not needed in this design. The best option would be to use a traditional chuck, which is adjustable with a key.

Metabo prices vary as follows:

- Metabo SBE900 Impuls about 20,000 rubles;

- Metabo SBE 701 SP - 15,000 rubles;

- Metabo SBE 760 about 7,000 rubles.

The Makita HP1640K costs three times less than the Metabo SBE 900, so it makes sense to look closely at this good tool. Ergonomics and functionality are thought out to the smallest detail, drilling with a drill is easy and pleasant. For homework, a similar tool is quite suitable. The power is 685W, and the speed can be effectively controlled. The unit weighs two kilograms, which allows you to work with one hand. Among the shortcomings, it should be mentioned: the impact mechanism is weak, but it is possible to work on concrete.

Consider the drill "Bison ZDU-850 ERMM2"

The gearbox housing is made of metal, which in itself can draw close attention. The machine is quite powerful and can function for a long time, 860 W is enough to work within a private household

Without exaggeration, one can say: "Bison ZDU-850" is not inferior to world analogues from Makita or Bosch. The Zubr can work quite tensely, it has a good margin of safety.

Of the design flaws, it should be said about the trigger on the handle - this is not the best idea to control the revs.Reason: it is difficult to smoothly accelerate the drill, at low speeds it is almost impossible to do this.

Another important drawback of "Zubr" is the lack of strength factor for the ratchet of the impact mechanism.

The main advantages of the device:

- good powerful engine;

- minimal vibration;

- duration and reliability in work.

How to choose an impact drill for stone work

Most drills have a three-jaw chuck that can be used with standard drills for metal, plastics, woodworking (conventional, non-hammer drilling). Working with a stone requires special tools.

The stone drill features recessed indentations, a hardened tip and hard inserts connected to the cutting ends. Such drills are usually 15 cm in length, however, there are specimens and shorter - 8 and 10 cm.The presence of a flat, pointed tip makes it possible to clearly identify this type of drill at a glance.

Advantages and disadvantages

According to users, the tools of this brand are very popular. And this is not surprising, since they have a number of advantages that distinguish Zubr drills from similar devices. First of all, one cannot fail to note a wide range of models. This allows you to choose a tool based on your personal needs and preferences. The devices are quite compact, which is very convenient to work with them, while they have high power, due to which a minimum amount of time is spent on drilling holes.

The button for turning on the tool and changing the speeds is often the same or located in the immediate vicinity. All models are equipped with a reverse function. They are able to work even in fairly severe frost, at temperatures down to -25 degrees. The presence of an additional handle makes the device more convenient to use. As for the shortcomings, one of them is the difficulty in selecting spare parts for outdated models. Also, during operation, it is necessary to take into account the moment that the metal gearbox cools faster. Therefore, in the case of a non-metallic element, you will have to withstand a longer period of time in order for it to cool completely.

Engine power

Engine power determines the performance of the device, its speed limit and torque. The market offers devices with a power of 300 to 2000 watts.

It must be understood that the higher the power, the higher the dimensions and weight. A large power reserve will lead to rapid fatigue and excessive consumption of electricity. A household device needs 400-600 watts, if you plan to drill a brick, you will have to choose a more powerful tool - from 800 watts.

For continuous drilling of compacted concrete or for a construction mixer, it is better to choose a drill with a power of 1000-1500 watts.

Popular models

Among the many models, there are the best impact drills that have proven themselves over the years.

Bosch. A powerful drill with an impact function, it has a number of advantages: keyless chucks, reverse, light weight and accuracy. Convenient speed control wheel and handle. Power consumption 1010 watts.

Makita. The Japanese hammer drill is a convenient and reliable tool. A notable feature - the speed switch is equipped with a lock button. The side handle can be locked in various directions. The kit includes a depth gauge.

Interskol. A quality drill of Russian production at an affordable price. Power up to 1000 W. The gearbox is equipped with ball bearings. The drill rotates without runout for precise drilling.

DeWALT. Polymer housing that will last for more than one year, rubberized pads, two-speed gearbox and light weight. An excellent option that will last for many years.

Hitachi. Japanese drill. It has high performance, comfortable design and durable body. Also, the model is equipped with electronic speed control and reverse.Has a higher price category, but justifies itself in the work.