DIY jack repair

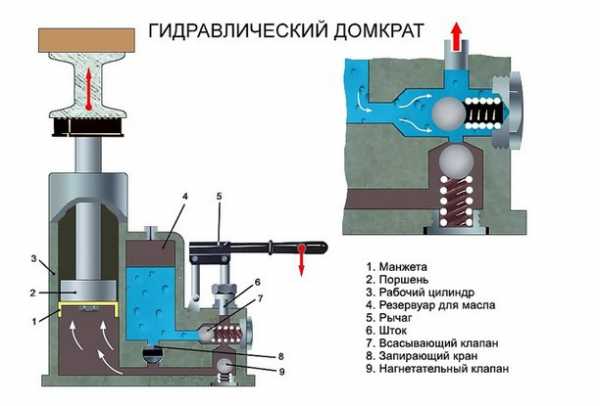

The plunger and working cylinder mirrors most often suffer from malfunctions. A defective component cannot hold pressure - in this case, the oil easily flows from the above-piston chamber to the working chamber. Such a device subsequently works poorly or is unable to withstand the load applied.

Important!

This breakdown occurs most often due to negligence. If the manufacturer does not indicate the possibility of storing the device in a horizontal position, it is not necessary to hold it like that: the working fluid leaks out, air enters the hydraulic system, which leads to corrosion .. Due to corrosion, seals and cuffs are exposed to wear.

The working oil becomes contaminated with debris, products of destruction of cuffs, particles of corrosion - the oil line and valves are clogged. It is important to change fluids and flush the hydraulic system in a timely manner.

Seals and lip seals are subject to wear due to corrosion. The working oil is contaminated with debris, products of destruction of cuffs, particles of corrosion - the oil line and valves are clogged

It is important to change fluids and flush the hydraulic system in a timely manner.

Repair of the hydraulic part

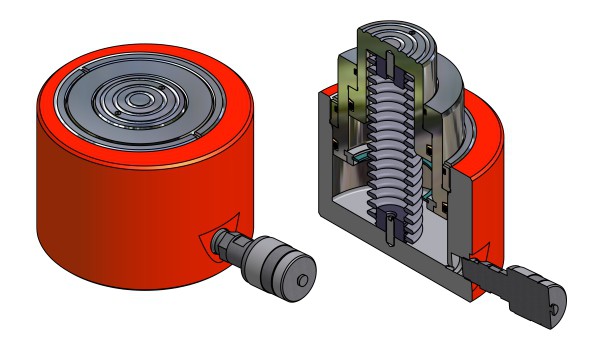

To do this, it is necessary to drain the old fluid, completely disassemble the jack, and then replace the seals and cuffs. If you have the right skills, you can do without the services of repair shops, because in fact all sizes of seals for hydraulic jacks are standard, and they can be bought at any automotive or tractor hydraulics store.

Repair of a hydraulic jack

Repair of a hydraulic jack

Repair of sliding hydraulic jack

Compared to bottle-type models, the rolling jack has a more complex mechanical part and hydraulics, which is profiled at work in a horizontal position. Mechanical problems can be related to wear on the linkage, main assemblies and joints, as well as in the adjustment of the lift.

After the jack is assembled, it is necessary to evacuate the air from the system and fill it with a new working fluid. Then the device needs to be pumped several times until the load is stable.

Repairing a hydraulic jack is pretty straightforward

Repairing a hydraulic jack is pretty straightforward

Low grip jack great for lifting loads that are at low heights

At the same time, it is important to take into account many of its features, as well as to know the conditions of its operation.

How to use?

The operation of any lifting equipment is inevitably associated with potential risks. This, of course, applies to situations where you need to raise and lower the car. But regardless of the work performed, it is strongly recommended to observe the following basic rules.

First of all, you must carefully study the instructions attached to the equipment.

In the process of performing any manipulations, people should not be near the lifted car or other load.

Carefully inspect the jack in order to identify damage in the form of chips and various deformations

We should also focus on the condition of the pins and rail.

The device, despite the simplicity of its design, must be regularly cleaned and serviced.

The equipment may only be operated with good quality lubricant (Teflon or silicone). This will maximize its service life.

Of course, in each specific case, the algorithm for working with a rack and pinion jack will have its own nuances.However, there is a certain instruction, according to which it is required to perform the following actions when raising and lowering the car:

- Place shoes under the wheels of the vehicle.

- Places the jack pad on a level and solid surface.

- Raise the switch.

- Turn the lever lock and pull it back slightly.

- Set the "beak" under load, and then raise this element to the maximum safe stop.

- Lower and raise the handle with both hands. In this case, the hook and heel of the jack must remain stationary.

- When lifting to the required height, lock the lever horizontally.

- Install an emphasis (most often special repair stands are used), lower the car on it and remove the load from the lifting equipment.

Lowering the vehicle or any other load is performed in the reverse order. This requires:

- position the jack correctly and slightly raise the object;

- remove the previously installed emphasis;

- raise the handle to a vertical position;

- lower the switch all the way;

- lower the load by moving the lever up and down;

- take the load off the equipment.

After completing the work, set the handle in a vertical position and fix it using a special mount.

It is important to remember that the operation of any device and equipment can be associated with danger to health, and often life.

Therefore, special attention should be paid to the observance of safety regulations. Naturally, rack and pinion jacking and lifting heavy loads are no exception.

It is important to remember that jacks of this type, despite all their performance characteristics, are not recommended for long-term holding of the vehicle in a raised position. A frivolous attitude towards recommendations and overconfidence in the reliability of the device can lead to serious consequences.

There are a number of rules, the observance of which will help to secure the process of performing the necessary work as much as possible. We are talking about the following important points.

- The machine should be as level as possible. Naturally, when conquering off-road, the fulfillment of this condition is almost impossible.

- Before lifting a car, all its moving parts must be blocked.

- You should also make sure that forward or reverse gear is engaged. It will not be superfluous to put the car on the handbrake. In other words, it is required to exclude the possibility of movement.

- Lifting should be done smoothly, without jerking.

- If necessary, place a solid material under the device support area. The use of bricks and similar items is not permitted.

After lifting the vehicle and installing the support, it is strongly recommended to ensure that it is stable. To this end, you can shake the object from side to side. Only after this is it allowed to carry out the intended work.

The operating instructions for the rack and pinion jack are presented in the video below.

How to choose?

Before you go shopping for a rolling jack, you need to immediately decide on what tasks you are facing. Will it be a professional service, which may contain machines of different heights and weights, or is it a small workshop, or you are purchasing it exclusively for home use. The choice of the appropriate equipment depends on this.

The second important condition will be the dimensions of the jack itself and its handle. If the total length of the jack and the handle is greater than the distance from the side of the car to the wall, then it will be extremely difficult to use it. You can understand the permissible length of the product in working order by driving the car into the garage and measuring the distance from the side to the wall with a tape measure. The result obtained will be the maximum allowable length of the assembled mechanism.

Based on the above, we can assume that if the long jack does not fit between the wall and the machine perpendicularly, then it can be placed diagonally, and then it will fit perfectly. You can put it, but remember that it is unsafe, because in this case, during the lifting of the car, the entire load will fall on 1 wheel, which is farthest under the car, and the direction of force will also be on the diagonal of the wheel, but it is not designed for such a load. This installation method can lead not only to breakdown of the jack itself, but also to the fall of the car or at least damage to it.

Now you need to select the lifting capacity. Everything is simple here. For a car service, you need to have a solid reserve of carrying capacity, and for your garage a jack is suitable, which can lift a weight equal to 1.5 of the mass of your car. This small margin is needed so that the product does not work to its limit and will serve you as long as possible.

Lift height is very important because there is very little sense from the jack, which is not enough to completely lift the wheel off the ground. It is best if your product can lift the weight to a height of 40 cm, and for services - by 60 cm.

Pickup height - this parameter should also not be forgotten when choosing. You need to take into account the minimum ground clearance of the car you plan to service. The smaller this value is, the lower the car you will be able to pick up with this device.

It is best to purchase such a product in a specialized store with a long-term positive reputation.

Ask the staff for a quality certificate for the purchased products, this will save you as much as possible from buying a low-quality product. If you cannot be provided with it for any reason, then it is best to refuse to purchase in such an institution.

Be sure to take a check and a warranty card for the purchased product - this will allow you to exchange it for a new one in case of problems or return the money spent.

After purchasing, be sure to inspect your purchase very carefully, especially for oil leaks. The pump and oil cylinder must be dry and free from visible damage. If you find cracks on the sealing lip, scratches on the working surface of the stem, then be sure to ask to replace this product. With such damage, it will not work for long.

An overview of the NORDBERG N32032 trolley jack for 3 tons is presented in the following video.